Mining Industry Copper Sulfide Ore and Flotation Process

(1) Chalcopyrite (CuFeS2) Chalcopyrite (including Cu 3457%) is the most common copper mineral in China’s copper mines, has good buoyancy Chalcopyrite is not easily oxidized, and it can maintain natural floatability for a long time in neutral and weakly alkaline pulps However, in a strongly alkaline (pH>10) slurry, since the surface is eroded by OH, a hydrophilic iron hydroxide film is The principal copper ore mineral is chalcopyrite (CuFeS 2), which is commonly smelted to yield a matte containing ∼50% copper In the presence of silica flux, iron is selectively oxidized to a slag Figure 14 shows a PSD for the Cu–Fe–S–O system at 1 atm SO 2 as a function of temperature (Rosenqvist 1978) Unlike the system for lead, the copper and Cu 2 S melts are nearly immiscible Copper Ore an overview ScienceDirect Topics Laboratory rougher flotation tests were conducted with two samples of Cu–Mo ores in fresh water and in sea water as a function of pH In both cases Cu recoveries were slightly lower in sea water than in fresh water for a wide range of pH (pH 7–12) Flotation of molybdenite was however strongly depressed in sea water at pH higher than 95Copper–molybdenum ores flotation in sea water floatability of new ores The full methodology is labelled the floatability index test procedure (JKFIT) This paper outlines the JKFIT procedure and the results of applying this methodology to pilot plant data from a copper ore JKFIT was applied to two different feed sizes (namely a P 80 of 180 microns and 212 microns) of this copper ore The A Methodology for Measuring the Floatability of Ores – The In terms of ore floatability, the experimental tests have been carried out on a sample of 75 microm in size under different exposure times The results show that both ore concentrate recoveries and grades of nickel and copper are significantly enhanced after microwave treatment of the ore with relative increases in recovered concentrate, grade of nickel, and grade of copper of 26 wt%, 15 wt Microwave enhanced recovery of nickelcopper ore

(PDF) Effect of microwave system location on floatability

Effect of microwave system location on floatability of chalcopyrite and pyrite in a copper ore processing circuit Article (PDF Available) in Physicochemical Problems of Mineral Processing 56(3 Copper Mining and Processing: Processing of Copper Ores Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and copper flotation ore vitadansefrMining Industry Copper Sulfide Ore and Flotation Process The floatability of common copper sulfide minerals is reduced in the following order: chalcopyrite > covellite > bornite > chalcopyrite (4) The floatability of copper sulfide minerals is also affected by factors such as crystal grain size, grain size, etc fine grain is not easy to float Read More Copper Sulfide Flotation Mineral for sulfide copper ores flotationCopper ores Danafloat Home Often gold and silver are present which may either be associated with the sulphides or are free The gangue particles can consist of a range of silicate minerals from quartz to talc and clays Carbonate mineral gangue can also be present When liberated, typical copper sulphide minerals are Get Priceiron and gangue minerals floatabilityfloatability (Chandraprabha et al, 2004) The selective separation of chalcopyrite from pyrite is very difficult due to several interactions that occur at the mineral surfaces during the processes of grinding and conditioning Flotation of copper sulphides is a traditional technique for processing the sulphide copper The presence of pyrite in copper concentrates (especially the pyrite A study on the effect of active pyrite on flotation of

A Methodology for Measuring the Floatability of Ores – The

floatability of new ores The full methodology is labelled the floatability index test procedure (JKFIT) This paper outlines the JKFIT procedure and the results of applying this methodology to pilot plant data from a copper ore JKFIT was applied to two different feed sizes (namely a P 80 of 180 microns and 212 microns) of this copper ore The Copper–molybdenum ores flotation in sea water: Floatability and frothability O Ramosa, S Castroa,⇑, JS Laskowskib a Department of Metallurgical Engineering, University of Concepción, Concepción, Chile bNB Keevil Institute of Mining Engineering, University of British Columbia, Vancouver, Canada article info Article history: Received 19 February 2013Copper–molybdenum ores flotation in sea water 4 The floatability of copper sulfide minerals is also affected by factors such as crystal size, mosaic size, being original or secondary The minerals with fine crystal and mosaic size are difficult to float Secondary copper sulfide ore is easy to oxidize and more difficult to float than original copper ore As for the grinding and floating process, it is more advantageous to adopt the stage How to Process Copper Ore: Beneficiation Methods and The floatability of copper at different pH is related to the type of frother used With certain frothers, copper recovery can be significantly increased at a lower pH range, while some frothers require a higher pH to retain a more lasting frothing power The floatability of middling particles (ie 200 m) improves with increased pH Table 126 shows copper recovery in the plus 150 m fraction Flotation of Copper Sulfide Ores PDF Free DownloadA new methodology of floatability tests on Polish copper ores based on grain sizedensity fractions A Krawczykowska Faculty of Mining and Geoengineering, Department of Mineral Processing and Environmental Engineering, AGH, University of Science and Technology, Al A Mickiewicza 30, 30059, Kraków, Poland Abstract Ores difficult to enrich require the PAPER OPEN ACCESS A new methodology of floatability tests

MICROWAVE ENHANCED RECOVERY OF N COPPER ORE

In terms of ore floatability, the experimental tests have been carried out on a sample of 75 μm in size under different exposure times The results show that both ore concentrate recoveries and grades of nickel and copper are significantly enhanced after microwave treatment of the ore with relative increases in recovered concentrate, grade of nickel, and grade of copper of 26 wt%, 15 wt%, and The objective of this study was to investigate the floatability of a complex Kansanshi mixed copper ore comprising sulphide and oxide minerals with a view to achieving an optimal flotation performance in the treatment of the Kansanshi ore body This required an indepth analysis of the mineralogy of the feed as well as tailings samples after different flotation processes involving a range of A study of the flotation characteristics of a complex Mining Industry Copper Sulfide Ore and Flotation Process The floatability of common copper sulfide minerals is reduced in the following order: chalcopyrite > covellite > bornite > chalcopyrite (4) The floatability of copper sulfide minerals is also affected by factors such as crystal grain size, grain size, etc fine grain is not easy to float Read More Copper Sulfide Flotation Mineral for sulfide copper ores flotationfloatability (Chandraprabha et al, 2004) The selective separation of chalcopyrite from pyrite is very difficult due to several interactions that occur at the mineral surfaces during the processes of grinding and conditioning Flotation of copper sulphides is a traditional technique for processing the sulphide copper The presence of pyrite in copper concentrates (especially the pyrite A study on the effect of active pyrite on flotation of Abstract: The main problem in the flotation of CuMo sulfide ores in seawater is poor floatability of molybdenite at pH>95 Froth stability plays a very important role in determining concentrate grade and recovery in flotation operations and in this paper both floatability and frothability have been tested The frothability have been studied by measuring froth equilibrium layer thickness in a EFFECT OF SEAWATER MAIN COMPONENTS ON FROTHABILITY IN

Copper–molybdenum ores flotation in sea water

Copper–molybdenum ores flotation in sea water: Floatability and frothability O Ramosa, S Castroa,⇑, JS Laskowskib a Department of Metallurgical Engineering, University of Concepción, Concepción, Chile bNB Keevil Institute of Mining Engineering, University of British Columbia, Vancouver, Canada article info Article history: Received 19 February 2013The floatability of copper oxide ores is generally worse than that of copper sulfide ores, and is greatly influenced by the existing form of copper in minerals and gangue composition For example, when copper is in the form of carbonate (malachite, blue copper ore), Flotation of Copper oxide ore Fodamon MachineryThe floatability of copper at different pH is related to the type of frother used With certain frothers, copper recovery can be significantly increased at a lower pH range, while some frothers require a higher pH to retain a more lasting frothing power The floatability of middling particles (ie 200 m) improves with increased pH Table 126 shows copper recovery in the plus 150 m fraction Flotation of Copper Sulfide Ores PDF Free DownloadA new methodology of floatability tests on Polish copper ores based on grain sizedensity fractions A Krawczykowska Faculty of Mining and Geoengineering, Department of Mineral Processing and Environmental Engineering, AGH, University of Science and Technology, Al A Mickiewicza 30, 30059, Kraków, Poland Abstract Ores difficult to enrich require the PAPER OPEN ACCESS A new methodology of floatability tests Ø Copper ore with high combined oxidation rate is usually treated by hydrometallurgical method Generally speaking, it can be divided into priority flotation, mixed flotation, isofloatability flotation, partial priority flotation ~ mixed flotation, fast flotation, distributed priority flotation, partial mixed flotation and asynchronously mixed flotation The development of new ly Copper ore processing technology development and research

Recovering Copper Mineral

Floatability and Bubble Behavior in Seawater Flotation for the 83 Recovering Copper Mineral Int J Soc Mater Eng Resour Vol20, No1, (Apr 2014) applied into 500 mL MStype flotation machine (pulp density 20%) and stirred the sample solution at 1500 rpm A part of the ore sample subjected to flotation and conditioned in distilled water or seawater for 24 hours, respectively After Sodium hydrogen sulfide (NaHS) is commonly used as a copper depressant in the selective flotation of copper and molybdenum ores However, the process is facing health and safety issues because NaHS readily yields toxic hydrogen sulfide gas (H2S) under acidic conditions In this study, Na2SO3 was proposed as an alternative copper depressant The effect of Na2SO3 on the surface wettability and Effect of Sodium Sulfite on Floatability of Chalcopyrite floatability (Chandraprabha et al, 2004) The selective separation of chalcopyrite from pyrite is very difficult due to several interactions that occur at the mineral surfaces during the processes of grinding and conditioning Flotation of copper sulphides is a traditional technique for processing the sulphide copper The presence of pyrite in copper concentrates (especially the pyrite A study on the effect of active pyrite on flotation of 1 Types of copper sulfide ore (1) Single copper mineral Its ore characteristic is relatively simple, and the only useful component that can be recycled is copper The gangue minerals are mainly quartz, carbonate and silicate (2) Coppersulfur ore Called copperbearing pyrite In addition to copper minerals, iron sulfide can be recovered, and the main mineral of sulfur is pyritecopper ore flotation testIn terms of ore floatability, the experimental tests have been carried out on a sample of 75 μm in size under different exposure times The results show that both ore concentrate recoveries and grades of nickel and copper are significantly enhanced after microwave treatment of the ore with relative increases in recovered concentrate, grade of nickel, and grade of copper of 26 wt%, 15 wt%, and International Microwave Power Institute 7 CORE

- machinery used for diamond ore

- milk production line manufacturers

- software pembuat nveyor crusher hover

- the most popular mining industry stone crushing sites in india

- hot sale small rock crusher crusher

- stone production line ball mill machine

- ncrete mobile crusher manufacturer in Malaysia

- sand portable sand drying equipment

- crushers for sale in

- gambar al mill pada pabrik semen

- dust suppression system for stone crusher

- high efficiency crusher plant for sale philippines

- blue leaf grinder price in kerala

- aggregate producer equipment africa crusher suppliers

- balancing of gyratory crusher

- MILLING MACHINE AND ACCESSORIES

- hp4 main shaft in usa

- where to buy vibrator feeder in chennai with price and specification

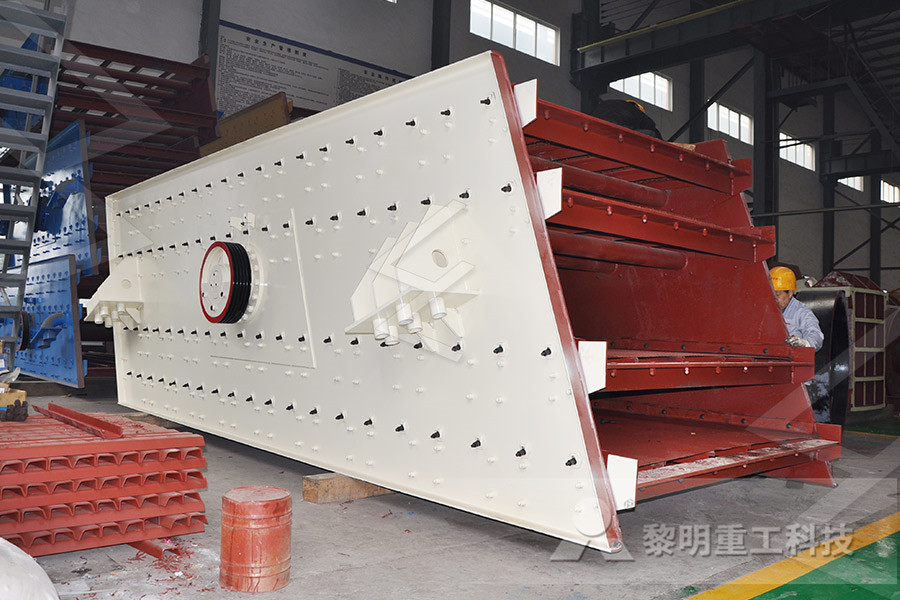

- Screening Plants South Africa Vibrating Screen

- paper industries in jakarta raya indonesia

- what is the meaning of stone crusher in kannada

- hammer crusher quarry equipment with standard parts

- crusher machine sellers in uae

- fluorite parts replacement

- large capacity 650tph mobile stone crusher from manufacturer manufacturer

- nut shell crusher machine in Malaysia

- hobema mesin ating chromo kertas sticker

- microlu saw repair kit

- ne ball mill main shaft change

- grinding machine types use in cement industry

- equipment italy industry marble andamp granite quarry industry italy

- improve efficiency crusher

- line powder suppliers hyderabad

- Professional high performance NPK fertilizer production line

- Germany Small Power Mobile Crushing Equipment With New Design

- crusher plant for rent in Malaysia

- stone crusher quotations

- goff grinding mill in sa

- CRUSHING EQUIPMENT PRODUCTION KOREA

- grinding machines selección

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher