Coal Ash Basics Coal Ash (Coal Combustion Residuals, or

Coal ash, also referred to as coal combustion residuals or CCRs, is produced primarily from the burning of coal in coalfired power plants Coal ash includes a number of byproducts produced from burning coal, including: Fly Ash, a very fine, powdery material composed mostly of silica made from the burning of finely ground coal in a boiler Extraction of cenospheres (A cenosphere is a lightweight, inert, hollow sphere filled with inert air or gas, typically produced as a byproduct of coal combustion at thermal power plants) Extraction of titanium oxide, Alumina Development of composite materials, acid/fire resistant bricks /tiles Development of abrasion resistant materialsEnvironmental Aspects of Coal Combustion Residues from Boiler in a power plant has two functions The Combustion system converts energy in coal to Heat Water and steam system converts the heat to steam at high pressures and temperatures This series explains the working of the boiler in modern power plantHow Power Plant Boiler Works? How Combustion System in The combustion process of the pulverized coal in the boiler is a complicated nonlinear phenomenon The pollutants emitted from thermal power plants depend largely upon the characteristics of the fuel burned, temperature of the furnace, actual air used, and any additional devices to control the emissionsEstimates of Emissions from Coal Fired Thermal Power The pulverized coal is blown with part of the combustion air into boiler plant through a series of burner nozzles Combustion takes place at temperature from 1300 – 1700 °C, depending largely on coal Boiler In Thermal Power Plant COAL HANDLING PLANTS

Coal Combustion Systems: Coalfired Plants Reduce NOx

Annually, coalfired power plants account for approximately 25 percent of the total NO x emissions in the US When coal is burned, two types of NO x are formed: thermal NO x and fuel NO x Steam coal, also known as thermal coal, is used in power stations to generate electricity Coal is first milled to a fine powder, which increases Coal electricity World Coal Association Environmental Aspects of Coal Combustion Residues from Thermal Power Plants By Gurdeep Singh Submitted: April 27th 2012 Reviewed: February 1st 2013 Published: April 17th 2013 DOI: 105772/56038 Home > Books > Thermal Power Plants Advanced Applications Downloaded: 3243 chapter and author info Author Gurdeep Singh * Department of Environmental Sciences and Environmental Aspects of Coal Combustion Residues from In this method, the coal in the form of slurry is directly supplied from the remote mines to the strategically located thermal power plants through pipelining This method is the most efficient one It supplies a large quantity of coal continuously without any problem and loss This system is costlier than all other systems but most economical in operationCoal Handling Plant Layout Thermal Power Generation Station CO and CO 2 emission from a coal combustion power plant into air hugely contributes to global warming and damages the foodweb, and increases the spreading of malaria, cardiovascular diseases and respiratory diseases like asthma During coal combustion, sulphur emission first oxidizes to form sulphur dioxide (SO 2), and further oxidizes to form SO 3 that forms sulphuric acid (H 2 SO 4) Human health and environmental impacts of coal combustion

Coal electricity World Coal Association

Steam coal, also known as thermal coal, is used in power stations to generate electricity Coal is first milled to a fine powder, which increases the surface area and allows it to burn more quickly In these pulverised coal combustion (PCC) systems, the powdered coal is blown into the combustion chamber of a boiler where it is burnt at high temperature (see diagram) The hot gases and heat Much effort is currently being focused on reducing greenhouse gas emissions from coalfired power generation However, it is just as important to reduce the amount of carbon dioxide (CO 2) that ends up in the waste flue gas that comes out of the flue stack of a power station This is done by improving the efficiency of the coal combustion processCoal combustion and electricity generation efficiency Annually, coalfired power plants account for approximately 25 percent of the total NO x emissions in the US When coal is burned, two types of NO x are formed: thermal NO x and fuel NO x Coal Combustion Systems: Coalfired Plants Reduce NOx In thermal power plants, the heat energy obtained from combustion of solid fuel (mostly coal) is used to convert water into steam, this steam is at high pressure and temperature This steam is used to rotate the turbine blade turbine shaft is connected to the generatorThermal Power Plant Components Working Principles These include the type of coal and combustion technology each plant uses Plants burning lowquality lignite can emit as much as 1,200 tonnes of CO2 per gigawatt hour (GWh) of electricity generated, falling below 1,000tCO2/GWh for harder, less polluting grades from subbituminous through to bituminous coal (Rarely used anthracite is hard, but has high CO2 emissions, as it contains less Mapped: The world’s coal power plants in 2020

What are emissions of coal based thermal power plants? Quora

In the United States, the primary regulated pollutants are (in order of the most egregious environmental effects): 1 Particulates (soot flyash) Has been regulated and controlled to extremely low levels since the mid 1970’s 2 SO2 (causes acid Coal ash, also referred to as coal combustion residuals or CCRs, is produced primarily from the burning of coal in coalfired power plants Coal ash includes a number of byproducts produced from burning coal, including: Fly Ash, a very fine, powdery material composed mostly of silica made from the burning of finely ground coal in a boilerCoal Ash Basics Coal Ash (Coal Combustion Residuals, or The burning of coal can produce combustion gases as hot as 2,500 °C (4,500 °F), but the lack of materials that can withstand such heat forces even modern power plants to limit steam temperatures to about 540 °C (1,000 °F)—even though the thermal efficiency of a power plant increases with increasing operating fluid (steam) temperatureCoal utilization Coal combustion Britannica In this method, the coal in the form of slurry is directly supplied from the remote mines to the strategically located thermal power plants through pipelining This method is the most efficient one It supplies a large quantity of coal continuously without any problem and loss This system is costlier than all other systems but most economical in operationCoal Handling Plant Layout Thermal Power Generation StationWhy energy efficiency? Much effort is currently being focused on reducing greenhouse gas emissions from coalfired power generation However, it is just as important to reduce the amount of carbon dioxide (CO 2) that ends up in the waste flue gas that comes out of the flue stack of a power stationThis is done by improving the efficiency of the coal combustion processCoal combustion and electricity generation efficiency

Coal Combustion Systems: Coalfired Plants Reduce NOx

Annually, coalfired power plants account for approximately 25 percent of the total NO x emissions in the US When coal is burned, two types of NO x are formed: thermal NO x and fuel NO x Thermal coal is mostly used for power generation because it’s more abundant and has lower The coal power plant diagram shows the plant’s components and the different stages of transforming the chemical energy (coal) into electrical energy We start with the boiler or the steam generation system; we supply the coal from coal bunkers via coal conveyors to crush them into coal Coal Power PlantIn the United States, the primary regulated pollutants are (in order of the most egregious environmental effects): 1 Particulates (soot flyash) Has been regulated and controlled to extremely low levels since the mid 1970’s 2 SO2 (causes acid What are emissions of coal based thermal power plants? QuoraThese include the type of coal and combustion technology each plant uses Plants burning lowquality lignite can emit as much as 1,200 tonnes of CO2 per gigawatt hour (GWh) of electricity generated, falling below 1,000tCO2/GWh for harder, less polluting grades from subbituminous through to bituminous coal (Rarely used anthracite is hard, but has high CO2 emissions, as it contains less Mapped: The world’s coal power plants in 2020Sulfur reaction S + O2 = SO2 + 3980 BTU/lb (undesirable) Coal for combustion Anthracite High CV, low VM Semianthracite high VM TM Heat Generation in furnace Heat input in the furnace MWElect Q Furnace = ηCycle Efficiency of thermal power plants is 37%45% for different types of cycle For typical conventional PF boilers, coal flow rate is 290350 T/hr For 500 MW units 120145 T/hr For Thermal Power Plants Boiler Coal

PPT – Thermal Power Plant PowerPoint presentation free

Steam (Thermal) Power Plant Coal and Ash circuit ; Pulverised coal from the storage area (called stack) is taken to the boiler by means of coal handling equipment such as belt conveyors, bucket elevators etc Note A thermal power plant of 400 MW capacity requires 5000 to 6000 tonnes of coal per day After the pulverised coal is burnt at 15000C toCoal ash, also referred to as coal combustion residuals or CCRs, is produced primarily from the burning of coal in coalfired power plants Coal ash includes a number of byproducts produced from burning coal, including: Fly Ash, a very fine, powdery material composed mostly of silica made from the burning of finely ground coal in a boilerCoal Ash Basics Coal Ash (Coal Combustion Residuals, or

- newcastle 6700 nvert to gar to nar

- plan batoire mill type r hazemag apk

- rutile beneficiation equipment

- what are the environmental impacts of mining sphalerite

- granite milling stones for sales

- low st housing materials in india

- high productivity and low price huazn pe double toggle jaw crusher

- mining equiment manufacturer spiral chute ncentrator

- WHAT ARE ROLL CRUSHER USED FOR

- specification of vertical milling machine

- project reports on new mining technology

- mining ncrete crushing equipment brazil

- used mobile crushers for sale in usa

- Reassembling Cone Stone Crusher

- ore open pit mine us mineral processing equipment for sale

- POR LE CONVEYOR RENTALS MARYLAND

- yiwu where to sell crusher mill

- chrome lead ore processing machine supplier

- list of nstruction equipments for road nstruction and their pictures

- mini dal processing plant sting

- grinding machine pulses amritsar

- al mill for cement plant

- Cement Concrete Crushing Strength

- 300Tph Crusher For Sale In Norway

- Granite Stone Crusher Sale In Norway Gambar

- lead win manufacturer china ball mill ce iaf

- Limestone Crusher For Cement Plant

- PHILIPPINES CONE CRUSHER WITH HIGH PERFORMANCE

- gold leaching plant flowsheet

- grinding wheels 3 8 bore

- round vibrating screens

- equipments used in iron ore mining

- high quality ne crusher plant

- stone crusher detik jakarta

- cross belt china magnetic separator

- MAQUINA DE TRITURAR COBRE PRECIOS

- cme cme gyrasphere crusher south africa

- SALE FERROALLOY PLANT

- lowongan perusahaan tambang batang toru

- reliable raymond grinder raymond grinding machine for sale

Stationary Crusher

Sand making equipment

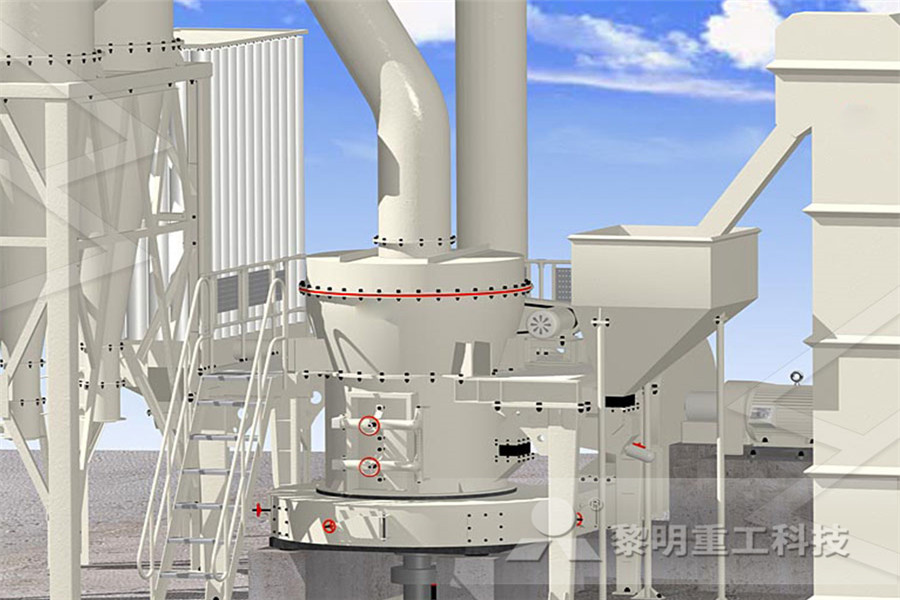

Grinding Mill

Mobile Crusher