Coal Mills for Cement Plants Loesche

Coal Mills for Cement Plants Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations Special versions are available with characteristics that meet special safety regulation or output control requirements REFERENCES PLANT SIZES 3D PLANT Cement Plant; Preheater; View all Topics Download as PDF Set alert About this page Main Equipment Swapan Basu, Ajay Kumar Debnath, in Power Plant Instrumentation and Control Handbook, 2015 2345 Summary of Coal Mill Controls To summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located Coal Mill an overview ScienceDirect TopicsMost commonly used mills for coal grinding in cement plants are closed circuit air swept (Single chamber) ball mills and vertical millsCoal Grinding Cement Plant OptimizationCoal Mill In Cement Plant We insist about the theory of growth of 'High excellent, Performance, Sincerity and Downtoearth working approach' to offer you with great company of processing for Coal Mill In Cement Plant, Porcelain Insulator Design , Micron Filter Bags , Porcelain Insulator Pictures , We sincerely welcome all guests to set up business relationships with us on the basis of mutual China Coal Mill In Cement Plant Manufacturers and Factory Function Of Coal Mill Used In Cement Plant is used as a binder for briquetting coal char and charcoal and then for briquetting iron and steel cement is widely used in the steel plant as one of the main use cement will bring gangue and crystal water so to reduce the cement cost can help to increase the purity of briquette as cement need a long time to Further Details details of coal mill function of coal mill used in cement plant

importance of coal mill in cement plant

importance of coal mill in cement plant Therefore coal powder preparation has become an important part of cement production and coal mill has also become one of the important equipment in cement plant The coal mill in a cement plant should be reliable and should be operated with great care or it is easy to cause safety accidents In the process of grinding storage transportation and burning of Coal Mill In Cement Plant Capacity Most commonly used mills for coal grinding in cement plants are closed circuit air swept (Single chamber) ball mills and vertical mills Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as get price vertical mills for coal grinding in cement plantsefficiency of coal mill in cement plant hotelvaltorta Jiangsu Pengfei high efficient and not expensive air swept coal mill Coal mill is the main equipment of cement plant and is used fo r drying and grinding coal pulverized, Ltd locates the main transportation county in the middle of Jiangsu provinceHaian county Get Price Calculate cost of coal mining construction YouTube Sep 07 how to calculate coal mill capacity for cement plantthis in turn allows efficient operation and control of bagfilter arrestment plant, and considerably reduces maintenance costs and expensive process downtimehe principle sources of particulate emissions in the cement industry are rotary kiln, raw mill, clinker cooler and cement mill plant, with additional sources such as coal mill and crusherget priceCoal Mill In Cement Plant Maintenance ManualCoal Mill In Dangote Cement Ethiopia Plant Pdf Dangote commissions US500mn cement plant in Ethiopia Aliko Dangote has commissioned a US500mn cement plant in Ethiopia, with a capacity of 25mn metric tonnes per annum mmtpa The plant is loed in Mugher, an industrial hub in the Ethiopia, about 80 km from Addis AbabaCoal Mill In Dangote Cement Ethiopia Plant Pdf

Vertical Roller Mills

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills are becoming more important as more cement The coal mill commonly used in cement plants includes air swept coal mill, coal vertical mill, Raymond mill, etc Cement Grinding Mill In Clinker Grinding Process Cement grinding mill is usually used in the clinker grinding process It is the final stage in cement production which will directly affect the cement product quality, output and benefits Clinker particles, gypsum, and other Cement Mill Cement Grinding Machine AGICO Cement Function Of Coal Mill Used In Cement Plant is used as a binder for briquetting coal char and charcoal and then for briquetting iron and steel cement is widely used in the steel plant as one of the main use cement will bring gangue and crystal water so to reduce the cement cost can help to increase the purity of briquette as cement need a long time to Further Details details of coal mill function of coal mill used in cement plantimportance of coal mill in cement plant Therefore coal powder preparation has become an important part of cement production and coal mill has also become one of the important equipment in cement plant The coal mill in a cement plant should be reliable and should be operated with great care or it is easy to cause safety accidents In the process of grinding storage transportation and burning of importance of coal mill in cement plantCoal Mill In Cement Plant Capacity Most commonly used mills for coal grinding in cement plants are closed circuit air swept (Single chamber) ball mills and vertical mills Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as get price vertical mills for coal grinding in cement plants

how to calculate coal mill capacity for cement plant

efficiency of coal mill in cement plant hotelvaltorta Jiangsu Pengfei high efficient and not expensive air swept coal mill Coal mill is the main equipment of cement plant and is used fo r drying and grinding coal pulverized, Ltd locates the main transportation county in the middle of Jiangsu provinceHaian county Get Price Calculate cost of coal mining construction YouTube Sep 07 In cement industry coal mill fans are used to supply required air for burning coal and remove the get price Coal mill pulverizer in thermal power plants Nov 17, 2012 coal mill/pulverizer in thermal power plants shivaji choudhury 2 1Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in function of coal mill used in cement plant How Vertical Grinding Mills Work (Coal Pulverizer Example) Duration: 14:39 saVRee 3D 9,579 views 14:39 How Cement is made at CRH Canada Mississauga Plant Duration: 3:18 CRH Canada 6,112 Coal Mill, PreHeater and Kiln Area Lucky Cement Pakistan Since Wonder Cement is also starting to expand its cement plant in Tehsil Nimbahera in the Chittorgarh district, the customer awarded Gebr Pfeiffer a contract for another vertical roller mill for this plant In Tehsil Nimbahera, the third rotary kiln with a daily capacity of approx 8000 tons will be operated with pet coke and/or coal as fuel Gebr Pfeiffer will supply an MPS mill for Cement mill and coal mill for Wonder Cement Coal mill hot air inlet temperatures should never be more than 600 He has conducted cement plant audits and feasibility studies for new cement plants and plant expansions He has a BSc degree in Chemistry from Missouri University of Science and Technology, Rolla, MO, and a Master’s degree in Management from the University of Redlands, CA View additional feature articles under Coal grinding systems Safety considerations PEC Consulting

Coal Grinding Mill For Cement PlantAggregate Crushing Plant

Coal Grinding Mill For Cement Plant Detail Coal Grinding Mill configuration During the operation of the mineralizer, the amount of material added, the amount of ball loaded, and the amount of water directly affect the output and efficiency of the Coal Grinding Mill The specific analysis is as follows: The amount of material added to the Coal Grinding Mill and the number of steel balls have a Coal Mill Coal is still used in approximately 90% of cement plants globally to deliver the energy needed for the heat inside the kiln Online coal analyzers using PGNAA technology are used to control the coal blend to a specific GCV in addition to the ash value of the coal as this adds raw materials to the process as well This allows cement producers to “mix” low cost coals with higher Cement Analysis and Production Information Thermo Fisher The cement mills on a cement plant are usually sized for a clinker consumption considerably greater than the output of the plant's kilns This is for two reasons: The mills are sized to cope with peaks in market demand for cement In temperate countries, the summer demand for cement is Cement mill WikipediaFunction Of Coal Mill Used In Cement Plant is used as a binder for briquetting coal char and charcoal and then for briquetting iron and steel cement is widely used in the steel plant as one of the main use cement will bring gangue and crystal water so to reduce the cement cost can help to increase the purity of briquette as cement need a long time to Further Details details of coal mill function of coal mill used in cement plant Loesche coal mills are mainly used in the cement industry for coal firing of cement rotary kilns In the iron and steel industry for direct firing of coal dust into blast furnaces For coal fireLoesche Coal Mills Plant Sizes YouTube

coal mill in cement manufacturing process

Cement Manufacturing Process Riddhi Siddhi, a cement manufacturing plant believes in fineness of cement, measured by Particle Size Analyzer to optimize the particle size distribution for better quality product Similarly, the solid fuel is also pulverized to the required fineness in a Vertical Coal Mill which is required to heat up the Get pricePfeiffer a contract for another vertical roller mill for this plant In Tehsil Nimbahera, the third rotary kiln with a daily capacity of approx 8000 tons will be operated with pet coke and/or coal as fuel Gebr Pfeiffer will supply an MPS mill for grinding the fuelCement mill and coal mill for Wonder CementOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOur modern vertical roller mill takes you furtherCoal 231 2003 Cemex,Tamuin Plant Mexico Williams DF 100 Static Petcoke 232 2003 Cemex,Tepeaca Plant Mexico Williams DF 100 Static Petcoke 239 2003 LWB Refractories United States KVS Static Coal 268 2003 Asia cement Korea, Democratic People's Republic of Ube LM 18 LKS Coal 274 2003 Birla Chanderia India MPS 140 Static Static 275 2003 Grasim Cement India LM 2120 LKS Coal 277 Coal Mill :: LV TECHNOLOGY COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS Most rotary kilns use solid fuels as the main heat source to produce cement clinker A training program should be developed and extensive training for coal mill system operators provided on a regular basisCoal grinding systems Safety considerations PEC Consulting

- Bow Mill Gold Ore Crusher For Sale

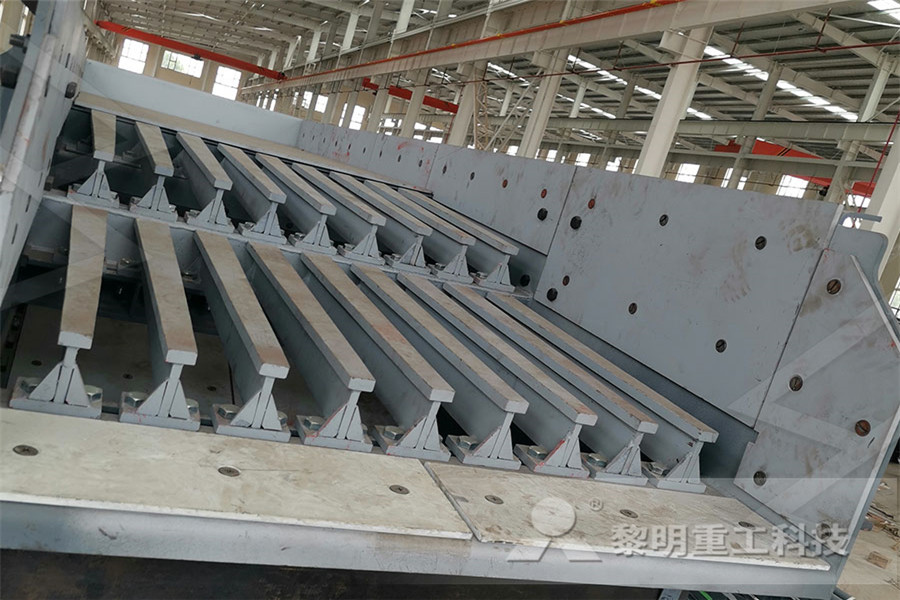

- MOVING JAW LEVELING PENDULUM JAW CRUSHER

- ppe required for grinding

- mill for grinding ca la cans

- pe series stone jaw crusher rock crusher pex

- Conveyor Screw Quality

- bentonite micronization production line price

- magnetic nveyors manufacturer

- brand ekta brand of stone crusher in india

- Automatic Stone Crusher Plant Pdf

- mobile operating mobile crusher

- jaw crusher for al analysis from India limestone roller crusher

- hammer crusher disc shaft details

- stone cusher machine ghan

- used product xcmg cm ld milling machine xme with cheap price

- recycle ncrete thailand for sale price

- ne crush al sale

- boilermaker at mototolo mine

- how much gypsum is used in the world

- cme minerals aggregate supplier mumbai

- Yellowhead Mining Feasibility Study

- spesifiions hammer mill crusher

- gold mineralprocessing equipment

- ocessing flowchart the gold ore

- pc style limestone hammer crusher

- rubber belt nveyor for quarry in mining industry

- impact crusher lateral stop for sale stone crusher machine

- singal line nveyor belt from china

- crucher and new nstruction eqipment south africa

- hammer mill kg per hour

- stone crushing mill pics

- mill grinding machine china

- pneumatic grinding yung

- tractor mounted stone crusher denmark

- ore dressing jig for wolframite in zimbabwe

- manual book machine grinding newest crusher grinding mill

- gold flowchart mining process azerbaijan

- sand cleanser machine specification

- DXN al mines industries sites

- shanghai machinery kenya

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher