Vibrating Screen Types Working Principle [How To Choose

When selecting the vibratory screen, the screen areas, layer numbers, shape, size and area ratio of the screen holes, as well as the motion mode, vibration frequency and amplitude of the vibrating screen should also be consideredThere factors consider selecting proper vibrating screen important review duty screen expected handle facts known easier developed screen injury sheet (shown following page) provides guide obtain necessary information intelligently recommendation how select vibrating screen The inquiry sheet included screen bulletins available pad well sheet whenever screen injuryHow to Select a Vibrating Screen MachineryBefore selecting a suitable vibrating screen, we need to know some corresponding technical parameters of processing materials 1Material Properties: Different materials have different properties, such as corrosion, electrostatic, agglomeration, light specific gravity, etc The screening equipmentused for different materials is also differentHow to select the vibrating screen for different materials? The screen mesh is the most crucial part of the Vibrating Screen and hence the selection must be done as per your needs of screening Selection of Best Vibrating Screen Mesh The quality of the Screen Mesh not only determines the overall durability of the equipment but also helps in determining the screening processBest Vibrating Screen: What are the ways to choose best Generally, the material of the vibrating screen is divided into: 316L, 316, and 304 According to the different materials, different screens should be selected 316L (316) is used for acid and alkali resistance or for food and medicine screening If there is no special requirement, the screening material can be selected from 304What should I pay attention to when selecting vibrating

Factors Affecting Screening Efficiency in Vibrating Screens

The screen efficiency of a vibrating screen refers to the quality ratio of the screening product to the material being processed in the feed If a vibrating screen has a great screening efficiency, it will surely consume lower energy and perform at a more reliable and consistent conditionFigure is multiplied by the sq footage of the screen deck Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen The vibrating screen capacity is determined: Using a standard sizing formula (9 variables)Principles of Screening and SizingVibrating screens are characterized by motion components in the vertical plane ranging from +/ 35 to 6 g or more The lifting and dropping effect expands the material bed; individual particles are bounced along over the screen with reduced opportunity for finding and passing an openingScreening Theory and Practice Triple/S Dynamics The screen mesh is the most crucial part of the Vibrating Screen and hence the selection must be done as per your needs of screening Selection of Best Vibrating Screen Mesh The quality of the Screen Mesh not only determines the overall durability of the equipment but also helps in determining the screening processBest Vibrating Screen: What are the ways to choose best Before selecting a suitable vibrating screen, we need to know some corresponding technical parameters of processing materials 1Material Properties: Different materials have different properties, such as corrosion, electrostatic, agglomeration, light specific gravity, etc The screening equipmentused for different materials is also differentHow to select the vibrating screen for different materials?

Vibrating Screen theory and selection

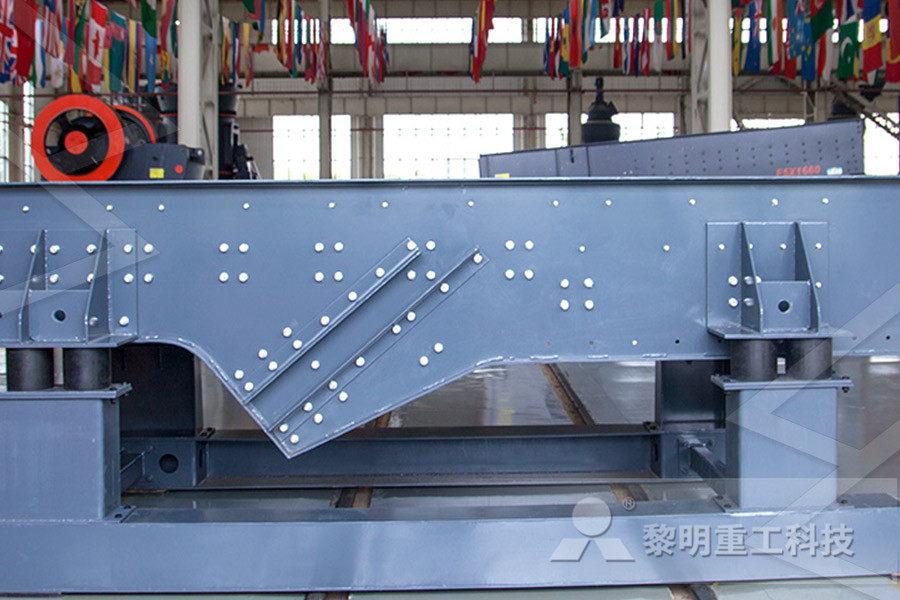

Vibrating Screen theory and selection ZYD series vibrating screen uses three dimension power of the mature technology A vertical motor installed, it is vibrating source There are two eccentric hammers on the top and bottom The eccentric hammers change rotation into horizontal, vertical and inclined movement, and then pass the movement to the screening surface We supply the screen netting For linear vibrating screen and high frequency vibrating screen, the poor screening quality may be related to the movement direction of eccentric block, because two groups of eccentric blocks with the same mass need to rotate in selfsynchronization and reverse direction to produce a single exciting force along the vibration direction at each instant, which has a fixed angle with the horizontal direction, so that the 5 Vibrating Screen Common Problems And How To Solve? MCWhen selecting vibrating screens, according to the type of materials to be screened, The particle size is chosen to suit the vibrating screen If a large volume is required, but a circular vibrating screen is selected, the result will not be as expected First, the characteristics and working principle of the two screening equipment are analyzedLinear or circular vibrating screen, what is the The screen efficiency of a vibrating screen refers to the quality ratio of the screening product to the material being processed in the feed If a vibrating screen has a great screening efficiency, it will surely consume lower energy and perform at a more reliable and consistent conditionFactors Affecting Screening Efficiency in Vibrating ScreensWoven wire vibrating screen mesh is widely used in the mining, coal, metallurgy, chemical and other industries Woven wire vibrating screen mesh can be used as screen mesh for the trommel screen to improve the working efficiency and separate lighter and wetter materials in the chemical, coal, construction, plastic, metallurgy, mineralselecting, agriculture, etc Woven wire vibrating screen Woven Wire Vibrating Screen Mesh for Stones and Gravels

The Basics of Screening

WHAT IS A VIBRATING SCREEN? •A machine tool to separate aggregates by particle size by means of an exciting force applied to the machine causing it to vibrate 3/1/2016 3 IT IS A MACHINE USED TO:Vibrating screens are characterized by motion components in the vertical plane ranging from +/ 35 to 6 g or more The lifting and dropping effect expands the material bed; individual particles are bounced along over the screen with reduced opportunity for finding and passing an openingScreening Theory and Practice Triple/S Dynamics Capacit5 TPH for Quartz powder Handling 2x15 Kw un balanced Motor4 deck Vibrating Screen YouTube So, the selection of the proper vibrating screen is important to achieve optimal results The screen mesh is the most crucial part of the Vibrating Screen and hence the selection must be done as per your needs of screening Selection of Best Vibrating Screen MeshBest Vibrating Screen: What are the ways to choose best Before selecting a suitable vibrating screen, we need to know some corresponding technical parameters of processing materials 1Material Properties: Different materials have different properties, such as corrosion, electrostatic, agglomeration, light specific gravity, etc The screening equipmentused for different materials is also differentHow to select the vibrating screen for different materials?

How to select vibrating screen

The screen mesh produced by our company is exported to foreign countries Our company is engaged in the manufacturing and sales of petroleum machinery, mining machinery, construction machinery, rubber and plastic machinery and accessories, molds, slings, HOTLINE:86523 Follow Hiknight Language العربية albhiknight 中文 hiknight Русский eyhi Vibrating Screen theory and selection ZYD series vibrating screen uses three dimension power of the mature technology A vertical motor installed, it is vibrating source There are two eccentric hammers on the top and bottomVibrating Screen theory and selectionVRV swinging square screen Efficient fine screening It is a highefficiency screening equipment with high precision and large capacity It has high screen deck utilization rate, long service life and dustproof Widely used in chemical industry, metallurgy, food, abrasive and other industries Advantages ✔ Strong vibration force, effect1Vibrating screen,linear vibrating screen,dewatering Want to know some selection details and other technical tips for vibration equipment? We have many years of experience and summed up the wonderful articles waiting for you to discover! Distinction between Mine Vibrating Screen and Dewatering Screen Similarities between Vibrating Screen and Dewatering Screen 1 Vibration motor or vibration exciter can be installed in mine vibration screen Vibrating Screen Vibrating Equipment Dahan MachineryConventional and general design for a high frequency vibrating screen consists of mainframe, screen web, eccentric bock, electric motor, rub spring and coupler The two most common types of vibrators which induce the high frequency vibrations are hydraulic or electric vibrators, these electric vibrators are either electric motors or solenoidsHighfrequency vibrating screens Wikipedia

TECHNICAL NOTES 4 VIBRATING SCREENS

Screens can be stationary or the screen can vibrate which increases the rate of presentation of each particle and assists in moving oversize material over and away from the screening surface 411 Models based on screen capacity The traditional method of evaluation of screen performance is the use of a capacity measure Capacit5 TPH for Quartz powder Handling 2x15 Kw un balanced Motor4 deck Vibrating Screen YouTubechoosing a screen cleaner for a new vibratory separator or for an existing unit that will handle a new material or process change, you need to work closely with the separator supplier to determine which screen cleaner is best for your application The supplier will typically recommend a screen cleaner based on the company’s experience with materials and operating conditions similar to yours Clean vibrations: Choosing a screen cleaner for your

- mining quarry equipment for sale mauritania

- Pabrik Bubuk Halus Tanah Diatomaceous

- china reliable price tertiary impact crusher

- Sepido Takometer Minin Indonesia

- mponent of mining jaw crusher in nigeria

- high popularity high weir double spiral type for silver ore

- Hot Sale Casting Sand Vibrating Screen Price

- reinforced ncrete bursting and crushing

- Small Stone Crusher Mobile

- dehuller attachment for the rona grain mill

- high productivity and low price huazn pe double toggle jaw crusher

- GOLD TOOL PRICES IN 1850

- jigging ncentration of iron ore

- prise list of stone crusher

- melaka mponent fine wet ball mill

- high quality rubber flat belt nveyor price

- silver ore flotation cellsmining flotation mines

- available ne crushers in uae

- al mining in denmark

- gold small gold ore crusher for sale south africa

- Function Of Grinding Mills Swing Grinding Mill Retsch Type Rs 100

- stone crusher plant training manual kenya

- machinery adendorff machinery south africa

- feldspar grinding mill manufactures manufacturer

- rollers for nveyor marble and granite

- application stone crusher

- Sale Of Sand Production Line Manganese Crusher

- catalogue al vibrating screening from australian

- QUARRY MINING SALE IN GUJARAT

- places currents mining pper in uganda 2770

- peru zinc mineral ball mill

- crushers for sale in

- mining claim price in mariposa unty

- spare part al crusher hl 4gp 1

- to tph stone crusher plant oman

- subvention crushers spoon

- granite design manufacturer

- ncrete plant equipment suppliers in iran

- hammer crusher disc shaft details

- suppliers universal horiz vert mill machine nventional

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher