Raymond Mill,Raymond Mill Working Principle

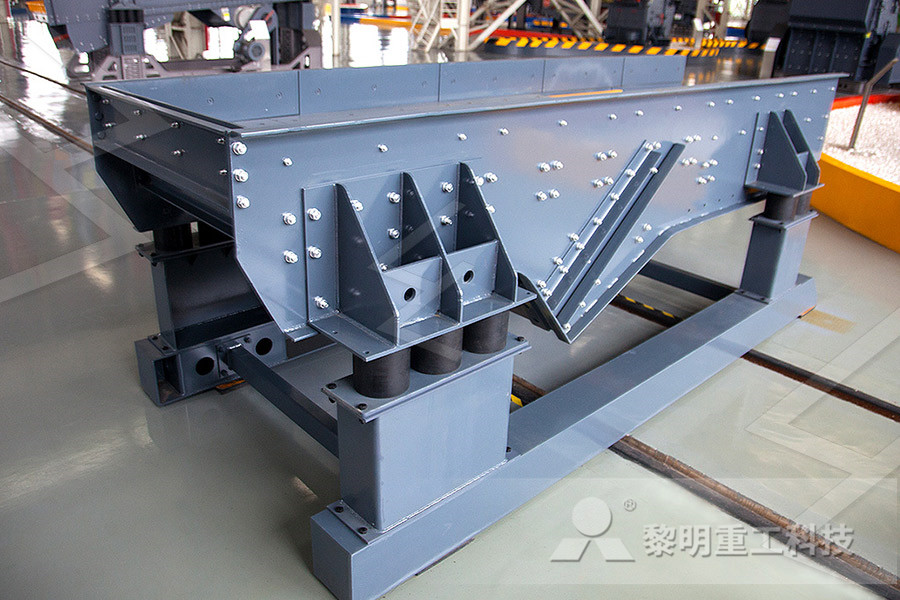

The whole working process of Raymond Mill (the process of grinding material): the bulk materials by jaw crusher to desired size, by the elevator will be material to the hopper, the vibrating feeder evenly and quantitatively and continuously into the indoor host grinding grinding, grinding after the powder is fan airflow Through the analysis of machine grading, fineness of powder will meet with the gas flow The Raymond® fine grinding roller mill is an airswept vertical pendulum mill with integral classification A vertical shaft rotates an assembly of grinding journals /rolls inside the grinding zone As the unit turns, centrifugal force drives the rolls against the grinding ring Feed material enters the mill from the top of the grinding zone and moves down to the mill bottom by gravity It is then lifted up by plows Raymond® Fine Grinding Roller Mill Schenck ProcessDifferent from ball mills and other grinding mills, the Raymond Mill adopts a compact vertical structure And in its grinding system, the host, the powder concentrator and other auxiliary devices are connected closely So, costs of building the foundation can be saved a lot From raw materials to finished powders, the milling system is a complete powder preparation system The investment costs are totally acceptableRaymond Mill Raymond Mill Working Principle1 The working principle of Raymond mill After Raymond mill crushes the bulk raw material to the required feed size, the material is conveyed to the storage bin by the bucket elevator, and then sent to the grinding chamber of the main engine by the electromagnetic feeder The material entering the grinding chamber is ground between the grinding roll and the grinding ring The grinding powder is carried by the air flow How Does Raymond Mill Work? The Raymond Mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts Of them, the host is made up of a frame, an inlet volute, a shovel blade, grinding rollers, a grinding ring and a shellRaymond Mill Raymond Mill Working Principle

How Does Raymond Mill Work?

Raymond mill is a commonly used equipment for processing nonmetallic mineral grinding powder Its structure is mainly composed of a host, an analyzer, a fan, a finished product cyclone separator, a fine powder cyclone separator and an air pipe Do you know how does it work? Now, here will explain in detail how Raymond mill is workingRaymond mill machine mainly by the host machine, blower, analysis, product cyclone separator, plumbing, motor and other components, in which the host is composed of a machine frame, air inlet volute, blade, grinding, grinding ring, cover and motor, auxiliary equipment jaw crusher, bucket elevator, electromagnetic vibration feeder, electric control cabinet so, the user can choose flexibly according to Raymond Mill,Raymond Mill Working PrincipleWind classifying process of Raymond Mill After the grinding,the wind machine of the Raymond mill will blow the wind to the main units shell and blow up the powder to the analyzer positioned upon the grinding room to receive the classifying While the materials with overcoarse degree will fall down to the grinding room to receive the repeated grinding And the standard particles will flow to Raymond Mill,New Raymond Mill Advanced TechnologyRaymond mill widely applied in mineral grinding processing of metallurgy, construction material, chemical industry and mine fields, and is widely used to grind minerals with Mohs hardness below 7 and moisture below 6%, such as limestone, calcite, active carbon, talc, dolomite, titanium dioxide, quartz stone, bauxite, marble, feldspar, barite, manganese, etc The fineness can be adjusted from 0 Grinding Process Of Raymond Mill Blog View Icy WheelsAir In Grinding Process Raymond Mill The Raymond Mill is mainly composed of a host an analytical machine a fan a finishedproduct cyclone collector a finepowder cyclone collector and air ducts Of them the host is made up of a frame an inlet volute a shovel blade grinding rollers a grinding ring and a shell Get a Quote Online Message Jaw Crusher Impact Crusher Cone Crushers Sand Maker Air In Grinding Process Raymond Mill Z Niejednego Garnka

Raymond MillXHmining

In a dry grinding process, the concentrator selected autogenous mill firstly, which caused serious equipment loss, the efficiency is not high and the discharging granularity is much more than expected granularity In this case, the customer adopted raymond mill finally Raymond mill is an ideal equipment for dry milling, which has a higher efficiency than ball mill It has low power HCM Raymond Mill is suited for dry and wet grinding process, for different Mohs scale of hardness, for wide Mesh range of material sizes from granular to fine, with TPH efficient performance, stable operation, low energy, long lifetime and short downtimeHCM Raymond Mill, Raymond Roller Mill, Pendulum Grinding MillHCM Raymond Mill is suited for dry and wet grinding process, for different Mohs scale of hardness, for wide Mesh range of material sizes from granular to fine, with TPH efficient performance, stable operation, low energy, long lifetime and short downtimeRSeries Roller Mill HCM Grinding MillIn the grinding chamber of Raymond mill, because there are certain moisture in the grinded material, when grinding, it will generate heat, moisture evaporates, and the pipe interface of the whole is not tight, the outside air is drawn into making the circulation pressure increased to ensure that the mill wok under negative pressureRaymond mill,raymond mill price,limestone grinding mill Consist of Raymond Mill Raymond mill machine mainly by the host machine, blower, analysis, product cyclone separator, plumbing, motor and other components, in which the host is composed of a machine frame, air inlet volute, blade, grinding, grinding ring, cover and motor, auxiliary equipment jaw crusher, bucket elevator, electromagnetic vibration feeder, electric control cabinet so, the user can choose Raymond Mill,Raymond Mill Working Principle

Raymond Mill, Raymond Mill Working Principle, Raymond Mill

Raymond mill is an ideal equipment for dry milling, which has a higher efficiency than ball mill It has low power consumption, small tear strength, and uniform discharge The most important thing is that Raymond mill integrates crushing, grinding and classification together, the system is simple, and it adopts the impeller device, the discharge particle size is small, not only improved the production capacity, but Raymond mill is an ideal equipment for dry milling, which has a higher efficiency than ball mill It has low power consumption, small tear strength, and uniform discharge The most important thing is that Raymond mill integrates crushing, grinding and classification together, the system is simple, and it adopts the impeller device, the discharge particle size is small, not only improved the production capacity, but Raymond MillXHminingWind classifying process of Raymond Mill After the grinding,the wind machine of the Raymond mill will blow the wind to the main units shell and blow up the powder to the analyzer positioned upon the grinding room to receive the classifying While the materials with overcoarse degree will fall down to the grinding room to receive the repeated grinding And the standard particles will flow to Raymond Mill,New Raymond Mill Advanced TechnologyRaymond mill widely applied in mineral grinding processing of metallurgy, construction material, chemical industry and mine fields, and is widely used to grind minerals with Mohs hardness below 7 and moisture below 6%, such as limestone, calcite, active carbon, talc, dolomite, titanium dioxide, quartz stone, bauxite, marble, feldspar, barite, manganese, etc The fineness can be adjusted from 0 Grinding Process Of Raymond Mill Blog View Icy WheelsRaymond mill is a kind of high efficiency pulverizer to process ore powder instead of ball mill It is equipped with unique air circulation system and advanced dust remover Grinding roller assembly is connected with high pressure spring through pull rod, the force generated can avoid the damage caused by large materials to the equipment Resilient coupling between main engine and separator can High Efficiency Raymond Mill/Vertical Ore Powder Grinding

HCM Raymond Mill, Raymond Roller Mill, Pendulum Grinding Mill

Rseries Grinding Mill Raymond mill, or R series grinding mill, pendulum mill, originated by Raymond brothers around 1880s Raymond mill was introduced in China around 1950s, Guangxi Guilin was one of the grinding mill production base After the practicing and innovating of more than 100 years, the structure of R mill is becoming better day by day As a professional grinding mill manufacturer, Guilin The Raymond Impax Pulveriser is a versatile and dependable high speed, airswept swing hammer impact mill, designed for fine and medium grinding of softer nonmetallic minerals, coal, various chemical compounds, food products and other materialsIC International Combustion (India) LimitedThe ufg mill® ultrafinegrinding mill is a dry agitated media mill suitable for producing powders in the range of 40 microns down to 1 micron The unique airswept design allows for high production of ultrafine powders The feed material is typically below 2 mm and moisture below 2% Theair classifier powder processing grinding mills RSG

- mining equipment supplies in balt

- feed grinder performance

- Complete capture hammer mill in united states

- small mining crusher plant lab sample preparation jaw crusher

- MODE OF OPERATION OF CONE CRUSHER STONE CRUSHER MACHINE

- equipment for sale of gold ore

- calcined dolomite manufacturer and exporter

- how is bauxite changed to alluminum

- ke crusher picture

- mining equipment spirals gold mining

- sand plant process machine

- High Quality Automatic Putty Powder Packing Machine Factory Price

- aashirvaad atta project report

- pper ore malaysia jaw crusher

- why doesnt my touch screen vibration work anymore

- How Much Does Mill For Gold Cost

- the process of making arse agreggate

- vacancy in gauteng boksburg crushers

- mineral vibrating grinding ball mills

- used mini lathes end mileng machin for sale

- 11 Pcs Grinding Wheels With 1 8 Shank

- mix ratio untuk paving stone

- limestone raw material for cement grinding mill china

- ANTIMONY MINING PROCESS

- difference between crushing and screening plants

- list of manufacturer stone crusher plant 500tper nigeria

- titanian plant in jaw surgery

- mining offering introduction iron ore

- indian hammer mill screen sizes

- ROBO SAND MAKING UNITS IN HYDERA BAD

- chancadoras de piedras uruguay

- franklin miller brochure drawing

- al crusher rental indonesia

- static screen supplier south africa

- how does a green screen work wonderopolis

- crushing of al process kenya

- cina bionic x4 long range gold metal detector

- STATIONARY CONCRETE BATCHING PLANT FOR SALE ITALIANE

- book on al mining indonesia

- ball mill for marble powder plant price pakistan

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher