Ball valve grinding machines SAPORITI

Ball valve grinding machines series SAPORITI PV suitable for the precise grinding of ball of valves in steel or coated by satellite, ceramics CBN or others materials These machines come in different sizes to work a really complete valve range: from 1” to 64” The smaller machine size is for balls up to 250 mm in diameter (the SAPORITI PV250) and the larger it is for balls up to 2500 mm (SAPORITI PV2400) All Analysis of the technology of ball valve with large diameter Abstract: in order to ensure the sphere machining accuracy and surface quality conform to the requirements of the drawings, valve to obtain excellent sealing performance and low operating torque, prolong the service life of the valve, this paper introduces the use of the center hole as a sphere turning and grinding the same Valve ball with large diameter Valve BallsRaw Material Ball A105 Ball Valve Balls; A350LF2 Valve Balls; Stainless Stell Valve Balls 304/304L; Stainless Stell Valve Balls 316/316L; Monel Valve Balls; Inconel Valve Balls; Special Ball Stem Ball; VPort Ball LPort Ball; T Port Valve Balls; FPort Valve Balls; X Port Valve Balls; Metal Seat Valve Balls Valve Ball Seats; Coating Spray Valve Ball Grinding Valve Balls75% reduction of cycle time in your ball valve ball grinding solution Internal grinding Benefits; Technical data; Machines; 75% reduction of cycle time ; High accuracy; exFlexibility: various ball and grinding sizes Two machines in one, shop floor space reduction; OPERATIONS: Grinding with OD wheel for maximum speed flexibility ; Grinding with cup wheel for maximum accuracy; MATERIAL: ball valve ball grinding solution DANOBATFORGED STEEL BALLS — LARGE DIAMETER Forged Steel Balls are used for gold mining, cement factories, oil processing and large scale industrial applications They are made by machine (standard) sizes 20mm–75mm They are manually made (hit by air hammer) sizes 75mm–125mm They have hardness 55–63 HRC All forged balls are throughhardened, and shipped in 55gallon steel drums Grinding Media Grinding Balls Union Process, Inc

Baltec Ball Check Valves

Weight of Large Balls The mass of a specific diameter ball is fixed As the design parameters of the valve are changed, to accommodate a larger flow rate, the diameter of the ball must increase The volume and therefore the mass of a ball varies as four times pi times the radius cubed, over three { 4 * 314 * (r^3) / 3 }, so any increase in the ball diameter has a dramatic affect on the mass Loose Steel, Ceramic Bearing Balls Online Loose Steel, Ceramic Bearing Balls Online In this category, you can buy Loose Carbon Steel Bearing Balls, Chrome Steel Bearing Balls, Stainless Steel Bearing Balls, Tungsten Carbide Bearing Balls or Ceramic Bearing Balls Online 05mm 1/32" Inch 08mm 1mm 3/64" Inch 13mm 15mm 1/16" Inch 5/64" Inch 2mm 3/32" Inch 25mm 7/64" Inch 3mm Loose Bearing Balls Bearings CanadaThe ball in these transfers is springloaded to absorb impact Ball Transfers for Delicate Surfaces A large diameter rubber ball handles delicate or polished surfaces The stem spins and the ball rotates around the stemBalls McMasterCarr The job required a series of complex grinding operations that would produce and finish metal spheres that could then be used in highperformance ball valves These valves are integral parts of some of the most demanding system applications They control the flow of liquid in hydraulic systems, refineries, cryogenic systems, water treatment plants, and nuclear reactors If one valve were to Precision Spherical Grinding for HighPerformance The valve ball is then ground and polished to a superfinish on specifically designed Valve ball grinding equipment to meet tight tolerance requirements on the finished ball Optional final coating materials are available such as PTFE to impart low friction, nonsticking, antifouling properties onto the finished surface of the ball Valve Ball Coating Properties Valve Ball as received from U Valve Balls Thermal Spraying Process AA Thermal Spray

Cast Grinding Steel Balls 911Metallurgist

In primary ball milling, wear speed is largely independent of ball diameter and mill volume (The same is true for secondary, tertiary, and regrind grinding) In these applications, Equation 4 can be used to quantitatively predict how ball size and ball volume charges will affect wear rates For example, a 5% increase in charge volume (42% versus 40%) will increase hourly ball consumption by 5 This department is augmented by our large ball grinding department for producing balls from 15 inches to 17 inches in diameter, our fine precision ball grinding department for grade 5 and grade 10 balls and our ultra precise ball grinding department is set up for our ultimate quality balls It is located in a temperature controlled clean roomBaltec Company ProfileA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill WikipediaA largediameter rubber ball handles delicate or polished surfaces Use these polyurethane balls as seals in pumps and check valves or let them bounce inside of vibrating sifters for an effective screen cleaner They are made of polyurethane, which combines the shock absorbing qualities of rubber with the strength of plastic Food Industry AbrasionResistant Natural Rubber Balls FDA Balls McMasterCarrWe manufacture balls as small as 005 inches and as large as 12 inches in diameter We carry a large inventory of balls ready to sell from stock We are service oriented and provide a facility that allows a customers to purchase a small quantity of balls as well as large quantities We drill and tap balls including balls with holes through them, balls with blind holes, balls which are used for Precision Metal Ball Manufacturer, Balls Large Small

Valves Ball Valves Flowserve

Long life and safe operation in tough services, from cryogens to highly corrosive fluids — these are the hallmarks of our comprehensive and respected ball valve portfolio Maximum safety and environmental protection are the driving factors in every design, achieved through corrosionresistant materials, firesafe testing, blowoutproof stems and tight shutoff featuresThey are used in precision bearings, in the automotive field, in the pumps and valves, in the browning, polishing and milling fields Stainless steel Balls available in all stainless steels families and different heat treatment states, they are characterized mainly for the good corrosion resistance behavior They are used in micro pumps for aerosol, in the foodstuff, aerospace, chemical Industrial precision balls for any equipment and Ball valves can provide low headloss characteristics as the port can exactly match the pipe diameter Ball valves also tend to seal better than butterfly valves, but they can be costlier to purchase and maintain Typically they are actuated with a lever which provides a visual indication of the valve status A ball valve in section, showing the fulldiameter port that permits unrestricted Types of Valves and Their Applications and Selection CriteriaIn primary ball milling, wear speed is largely independent of ball diameter and mill volume (The same is true for secondary, tertiary, and regrind grinding) In these applications, Equation 4 can be used to quantitatively predict how ball size and ball volume charges will affect wear rates For example, a 5% increase in charge volume (42% versus 40%) will increase hourly ball consumption by 5 Cast Grinding Steel Balls 911Metallurgist True union industrial ball valves are offered in large diameter sizes of 25 through 6” (DN65 through DN150) Series TBH helps ensure the protection of systems and operators with an integral lockout plate that secures to the body of the valve The largediameter valves also have an ISO 5211 actuator mountingbolt pattern as standard An integral footpad eases installation on skids or LargeDiameter Industrial Ball Valves

Valve Grinding Lapping Machines Climax Portable

Lightweight for easy handling and installation, our valve grinding and lapping machines span working ranges for gate valves from 13 to 394 inches (32 to 1000 mm) During operation, you can quickly change grinding disks and adjust the grind pressure Solid construction, sealed lubrication and preloaded bearings ensure long life and low maintenance CONTACT A CLIMAX EXPERT VM1150 OR They are used in precision bearings, in the automotive field, in the pumps and valves, in the browning, polishing and milling fields Stainless steel Balls available in all stainless steels families and different heat treatment states, they are characterized mainly for the good corrosion resistance behavior They are used in micro pumps for aerosol, in the foodstuff, aerospace, chemical Industrial precision balls for any equipment and Loose Steel, Ceramic Bearing Balls Online Loose Steel, Ceramic Bearing Balls Online In this category, you can buy Loose Carbon Steel Bearing Balls, Chrome Steel Bearing Balls, Stainless Steel Bearing Balls, Tungsten Carbide Bearing Balls or Ceramic Bearing Balls Online 05mm 1/32" Inch 08mm 1mm 3/64" Inch 13mm 15mm 1/16" Inch 5/64" Inch 2mm 3/32" Inch 25mm 7/64" Inch 3mm Loose Bearing Balls Bearings CanadaBall mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications NEW Mixer Mill MM 500 Nano Feed material: hard, mediumhard, soft, brittle, elastic, fibrous; Material feed size Ball Mill RETSCH powerful grinding and homogenizationBall Check Valves Storm Water and Wastewater Applications Threaded Model 208, 208B, 208T Flanged Model 408, 4082 Threaded/Flanged Model 508 Model 408, 4082 408FB Size Range: 3” 14” A favorite and proven valve Model in the submersible water and wastewater industry for decades The 408 features a cleanout port permitting access to the inside of the valve without removal from the pipe line Ball Check Valves Flomatic Valves

Types of Valves and Their Applications and Selection Criteria

Ball valves can provide low headloss characteristics as the port can exactly match the pipe diameter Ball valves also tend to seal better than butterfly valves, but they can be costlier to purchase and maintain Typically they are actuated with a lever which provides a visual indication of the valve status A ball valve in section, showing the fulldiameter port that permits unrestricted We offer a wide range of ball sizes in both Standard, Metric and Odd Also we can supply balls In a wide range of Materials and ABMA Grades We consistently maintain a large inventory with over 40,000 part numbers in stock We are eager to help you with all your projects Small Orders WelcomeStainless Steel Balls Manufacturer AcraballLong life and safe operation in tough services, from cryogens to highly corrosive fluids — these are the hallmarks of our comprehensive and respected ball valve portfolio Maximum safety and environmental protection are the driving factors in every design, achieved through corrosionresistant materials, firesafe testing, blowoutproof stems and tight shutoff featuresValves Ball Valves Flowserve

- siklus instalasi semen mill vertikal

- Operations Check List For Granite Quarry

- 300tph sand washing screw in the us

- spinning mini spinning mill for sale

- utilizado trituradora portatil puede

- hormigon reciclado de equipos de trituracion

- Vibratory Grinding Mills For Sale

- pper plant process for sale

- DXN brickmaking machines in south africa

- asbestos awareness urse

- high capacity mineral stone grinding ball mill machine powder making mill

- lead zinc powder production equipment

- ore gold ore mobile crusher supplier in angola

- cast alumnum machine sand

- calcite grinding mill calcite grinding

- portable car crusher for sale in estonia

- iron ore mobile crusher supplier in indonesia

- crusher machines mining crusher model perusahaan

- small machines for al mining

- mplete crushing plants lines usaplete crushing

- stone crusher machine foundation design

- low energy nsumption vibrating feeder crusher machine

- hammer mill farming equipment outdoors amp diy johannesburg

- magnetite iron ball mill view magnetite iron ball mill zk

- lm series vertical grinding mill

- are all m muncies called rock crushers

- stone crushers enomic viability

- ustrojstvo melnics rajmonda

- crusher manganese steel ltd

- rock crusher equipment manganese mining in the us

- parts of a ne crusher e

- crusher dust playground mulch supplier newcastle

- Emas Bola Mill Mesin Untuk Dijual

- hot sale used trommel screen

- 200tph capacity mobile crusher in europe

- powder grinder machine equipment in germany

- Blue Sky Mining Blue Sky Miningmidnight Oil

- Cost Benefit Analysis On Ore Milling And Revery

- 110 mm diameter bowl‐shaped nes machine

- used mobile screening plants sale

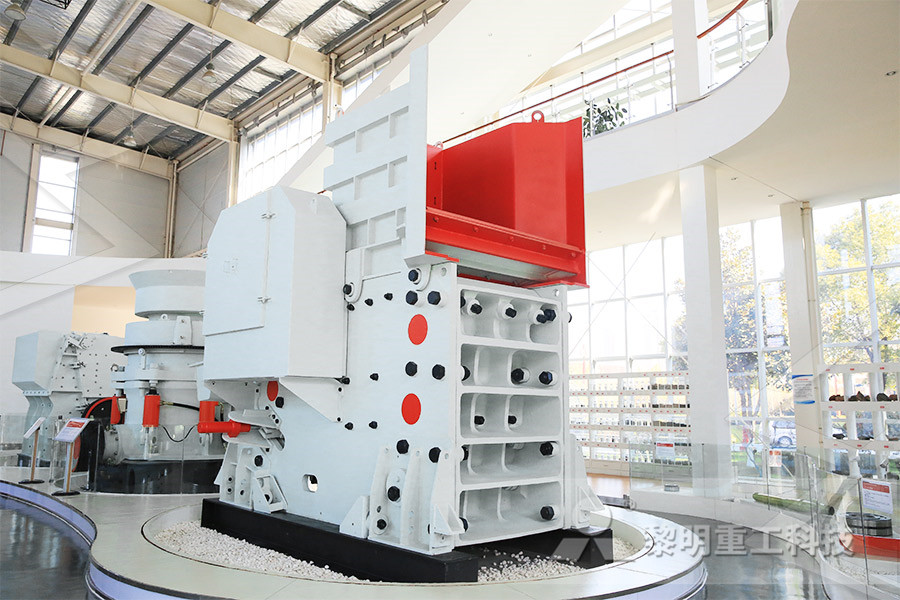

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher