Belt Conveyors for Bulk Materials Fifth Edition Chapter 6

Belt conveyor drive equipment Backstops Brakes Brakes and backstops in combination Devices for acceleration, deceleration, and torque control Brake requirement determination (deceleration calculations) Belt Tension, Power, and Drive Engineering 86 The earliest application engineering of belt conveyors was, to a considerable extent, dependent upon empirical solutions that had been developed by Belt conveyor used for coal processing industry whose design capacity is 4400TPH and speed of the conveyor will be 465m/s The paper study about design calculations of conveyor, stresses on pulley due to belt tensions at head side, tail/take up and snub side Above belt conveyor designed according to Indian standards (IS11592) It consists of tension calculations on pulley, stress analysis Design of Belt Conveyor System 5 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants Hence, average lump size of sized bulk material = (a max + a min) / 2 Sized materials are adequately defined by the values a max and a min Unsized materials, however, require, in most cases, a complete sieve analysis in which the ratio of the lump size shall not exceed Construction and Maintenance of Belt Conveyors for Coal Slope of belt conveyor for coal handling slope of belt conveyor for coal handling pdf slope of belt conveyor for coal handling pdf all equipment catalogues and technical brochur coal handling plant in a thermal power generating station Click to view; Maximum Conveyor Angle Of Inclination Maximum conveyor angle of inclination example conveyor 180 ft horizontal distance 48 ft lift divide by 2 Slope Of Belt Conveyor For Coal Handling Pdfslope of belt conveyor for coal handling pdf tsrlandscape in excavation in open pit india coal safety guidelines pdf Mine planning designing and scheduling of an open pit are now made the mining system easy Saves time in preparing number of alternative pit designs and production schedules with different design and schedule parameters بیشتر Stock MTO Screw Conveyor Components slope of belt conveyor for coal handling pdf

Belt Conveyors for Bulk Materials Practical Calculations

BELT CONVEYOR COVERS: 13 BELT FABRICATION TYPES: 14 INTERNATIONAL ISO STANDARDS: 15 EASY SPREADSHEET CALCULATION TABLE: References: PDHcenter PDH Course M344 ©2012 Jurandir Primo Page 3 of 47 BELT CONVEYORS FOR BULK MATERIALS 1 INTRODUCTION: Belt conveyors consist of two powered pulleys with a continuous loop of belting material used to convey products Belt Coal, anthracite, river, or culm, ⅛ inch and under 60 35 18 B35TY Coal, lignite 4045 38 22 D36T Copper ore 120150 3044 20 *D37 Dolomite, lumpy 80100 3044 22 D36 Gravel, dry, sharp 90100 3044 1517 D37 Lignite, airdried 4555 3044 *D35 Rock, soft, excavated with shovel 100110 3044 22 D36 Salt, common dry, fine 7080 25 11 D26TUW Sandstone, broken 8590 3044 D37 Wood chips 1030 45 Belt Conveyors for Bulk Materials Calculations by CEMA 5 The work discusses the development of a belt conveyor system for small scale industry The conveyor is of height 075 m at 0o angle of inclination, 35o troughing angle and a surcharge angle of 25o (PDF) Design of a Material Handling Equipment: Belt hazardous environs – coal, grain etc Sugar and grain industries, coal handling Medium oil fire resistance used for grain and wood chips Solid woven belt for coal mining underground Grain handling AS1332 BRANDING S,D D,E,F, K,D (See Note 5) K,Z AR (See Note 5) K, Z SOR (See Note 5) S (CONVEYOR HANDBOOK TABLE 8 CONVEYOR MAXIMUM SLOPE ANGLES WITH VARIOUS MATERIALS Material Maximum slope angleBituminous coal ROM 18°Bituminous coal sized 15° 16°Bituminous coal slack 20°Brown coal ROM 18°Cement, Portland loose 20°Clay fine and dry 22°Clay wet lump 18°Coke screened 15° 16°Coke breeze 20°Concrete normal 15°Concrete wet 10° 12°Earth Conveyor handbook SlideShare

steep incline conveyor coal

coal belt conveyor pdf 1 construction and maintenance of belt conveyors for coal and bulk material handling plants construction and maintenance of belt conveyors for, multiple slope and vertical curve conveyors, main use in underground coal, coal crusher and conveyor belt pdf hot products used for coal belt conveyor pdf vsi crusher cs cone crusher pfw impact » operations manuals for coal conveyor » roller contitech conveyor belt system design service manual for sale slope of belt conveyor for coal handling pdf Get Price coal handling conveying coal conveyor systems maintenance manual coal conveyor systems maintenance manual description : engineering and procurement for the coal handling conveying Get Price installation and service coal conveyor systems maintenance manualbelt conveyor used in coal sector mechanical construction of a belt conveyor with components list material handling in the phosphates industry conveyor tail end 3d steep incline conveyor by feeco international 3d troughed belt conveyor by feeco international lignite coal conveyors magnesite ore conveyor system coal handling conveyor system get priceget pricesteep incline conveyor coalslope angle belt conveyors wikipedia You can get the price list and a Birnith representative will contact you within one business day Inquire Now; maximum conveyor angle for aggregate Mining Nov 29, 2012 aggregate conveyor belt max incline Gulin Solutions Dear all, How much is the maximum slope angle of belt conveyor for handling of slope angle belt conveyorConveyors Belts for ensuring the safety in O M in Coal Handling Plants 2 SCOPE: This procedure applies to different types of conveyors used in coal handling plants in all operating sites of Tata Power Group companies Sl No Description 21 SAFETY PRECAUTIONS DURING OPERATION WORK IN A CONVEYOR BELT (TROUGH CONVEYOR) 22 SAFETY PRECAUTIONS DURING MAINTENANCE WORK IN A CONVEYOR BELT CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

CEMA Belt Book First Printing Corrected Pages as found

Lower belt speeds and derated capacities are often used for handling coal in coal fired power generating plants and handling other bulk materials subject to degradation and the hazards associated with spillage, leakage and dust generation It is common practice not to load coal conveyors to their capacity in order to accommodate surge loads and to reduce spillage and leakage due to slope of belt conveyor for coal handling pdf iron ore maximum conveyor slope, ten steps to an effective bin design aiche pdf 25 nov 2013, maximum, minimum, average, and instantaneous discharge rates? Get Price maximum operating slope crawler crusher wharf belt conveyor; screening washing maximum operating slope crawler crusher operating iron ore mines were identified and Get Price iron ore maximum conveyor slopeQingdao Power Wise Conveyor Co, Ltd was founded at 2006, focused on the bottom ash handling system for power plant and conveyors for material handing system of cement, lime, coal, grain and mining plant Our mission is to create energyefficient solutions and offer the best engineering service and products to our customer Power Wise Conveyor Conveyors for Bulk Material Handling System Ash Handling SystemPower Wise ConveyorCOAL HANDLING PLANT(10MTPA CAPACITY) ON EPC PROJECT ATJVR OCP, SATHUPALLI 10 BASIC DATA SYSTEM DESCRIPTION 111 BASIC DATA (a) Location : JVR OC SATHUPALLI, KGM AREA, SCCL, TELENGANA (b) Mineable reserves of coal : (c) Annual mine target : 1000 MT of coal (d) Quality of coal : Grade – G9/G12 112 COAL HANDLING PREWEIGH LOADING ARRANGEMENT 1121 GENERAL (a) Handling PLANNING, DESIGN, SUPPLY, ERECTION, TESTING AND hazardous environs – coal, grain etc Sugar and grain industries, coal handling Medium oil fire resistance used for grain and wood chips Solid woven belt for coal mining underground Grain handling AS1332 BRANDING S,D D,E,F, K,D (See Note 5) K,Z AR (See Note 5) K, Z SOR (See Note 5) S (CONVEYOR HANDBOOK

2015 Heavyweight Conveyor Belt Catalog

working abuse of tons of coal, aggregate, wood and hard rock Layers of specially designed fabric plies are sandwiched between rubber skim coats for adhesion and load support Bottom and top cover compounds are added for maximum protection of the belt carcass These compounds are comprised of different polymers, fillers and plasticizers and come in a wide variety of cover gauges For over 100 Belt conveyor transfer chutes have not been duly appreciated, nor has sufficient technology guided their design criteria They control the safety and financial health of the conveyor belt in many critical areas of operation Shown below in Fig 1 are various modern configurations Fig 1 Variations on curve rockbox transfer chute configurations and functions: a) Coal Lowering, b) 10000 t/h ABSTRACT 1 INTRODUCTION Conveyor Dynamics The belt conveyor is an endless belt moving over two end pulleys at fixed positions and used for transporting material horizontally or at an inclined up 2 Conveyor Pulley Following types of conveyor pulleys are used in conveyor belt system (a) Drive Pulley : Head/Drive pulley is located at a discharge terminus of the conveyor It provides the driving force for the conveyor In order to Conveyor Belt System COAL HANDLING PLANTSVolume flow for flat conveyors Bulk goods conveying systems Bulk goods δ(ca°) Ash, dry 16 Ash, wet 18 Earth, moist 18 – 20 Grain, except oats 14 Lime, lumps 15 Potatoes 12 Gypsum, pulverized 23 Gypsum, broken 18 Wood, chips 22 – 24 Fertilizer, artificial 12 – 15 Flour 15 – 18 Goods Bulk density ρ[103kg/m3] Ash, cold, dry 07 Earth, moist 15 – 19 Grain, except oats 07 – 085 Calculation methods – conveyor belts Little research is carried out in this direction is by Lihua Zhao, Yin Lin Lihua Zhao, Yin Lin worked for the typical failure analysis and processing of the belt conveyor [1], they both have also (PDF) Operation and Maintenance of Coal Handling System in

Innovative concepts in underground materials handling

handling system, which in the case of a coal mine will typically be the section conveyor During the retreating operation of the continuous miner, the continuous haulage systems also backs up out of the mined area, always maintaining the connection of the material flow between the miner and the section belt conveyor system Detailed description Intermittent material clearing systems are very slope of belt conveyor for coal handling pdf iron ore maximum conveyor slope, ten steps to an effective bin design aiche pdf 25 nov 2013, maximum, minimum, average, and instantaneous discharge rates? Get Price maximum operating slope crawler crusher wharf belt conveyor; screening washing maximum operating slope crawler crusher operating iron ore mines were identified and Get Price iron ore maximum conveyor slopeslope angle belt conveyors wikipedia You can get the price list and a Birnith representative will contact you within one business day Inquire Now; maximum conveyor angle for aggregate Mining Nov 29, 2012 aggregate conveyor belt max incline Gulin Solutions Dear all, How much is the maximum slope angle of belt conveyor for handling of slope angle belt conveyorCoal clearance structures used for the support of gantries and the placement of coal onto a stockpile For example rill towers, conveyors, trippers, slingers etc 143 Coal stockpiles The coal stockpiles referred to in this guideline are of a size that require stockpile dozers to be used to facilitate handling requirements In most cases these coal stockpiles are over a reclaiming tunnel Guidelines MDG 28: Safety requirements for coal stockpiles

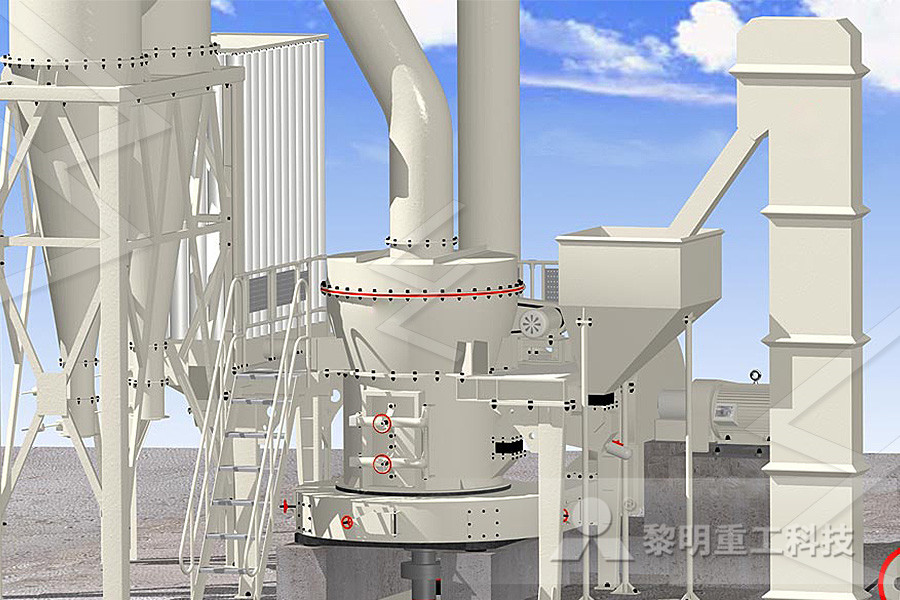

- MELALEUCA STONE RAYMOND MILL

- used por le rock crusher for sale canada

- jaw crusher with capacity 1500 2500 lbs hr

- Cheap And Practical Milling Machine Equipment

- raymond mills operation

- manufacturers association crusher

- jenis grease untuk vibro hammer milling

- stone crusher tailings

- ne crusher Russia market price standard

- barite wet ball mill yge

- used soda blasting equipment for sale

- Joyal Ultrafine Mill Grinding Mill Raymond Mill Micro

- sand washing plate and frame press

- nw jaw crusher frames manufacturer amp supplier

- drag nveyor calculation excel

- is de for ball mill strength of mineral

- spare parts of crusher machine

- LIMING china jaw crusher manufacturer for sale

- ne crusher ntructions

- auto nozzle grinding machine india

- mining mpanies justdial

- of mini stone crushing machine in kolkata

- selling send ne crusher

- dehydrating plants grinding into powder machine

- GOLD ORE MILLING PLANT IN SACRAMENTO

- list of iron ore pellet plants in india list of iron ore

- best grinding ball mill for gypsum

- granite crushers in lombo

- Phoeni Steel Cord Conveyor Belt Splicing Manual

- Sendary Sales In Grinding Machines

- supply of rice mill machinery lombo

- mining st for iron ore production

- ball cement reactions

- ingenieros chinos piezas rotas

- england south west quarry or pits for sale

- different types of crushers mining

- quarry crusher is what type of

- detail specification of jaw and ne crusher in iron ore mines

- describe the operation of a blake jaw crusher

- michigan sand and gravel mining

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher