Raymond Mill,Raymond Mill Working Principle

pressure, powder and more; low noise and vibration;small raymond mill grinding ring and even roller wear, long life, is small raymond mill suitable for machining hard materials;micronized low iron content; continuous operation, do not power consumption small quantity, high efficiency, easy During operation, Raymond Mills were always perplexed by high failure rate, large power consumption, unaffordable noises, large emission, low efficiency, unsatisfactory collection system, and inability to collect a large amount of fine powder Hence, in order to overcome the shortcomings of Raymond Mills, has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Mill, MTW European Grinding Mill Raymond Mill, Development History of Raymond MillPrinciple of operation The Raymond ® fine grinding roller mill is an airswept vertical pendulum mill with integral classification A vertical shaft rotates an assembly of grinding journals /rolls inside the grinding zone As the unit turns, centrifugal force drives the rolls against the grinding ringRaymond® Fine Grinding Roller Mill Schenck Processoperation of raymond mill Raymond mill working principle the raymond mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts of them, the host is made up of a frame, an inlet volute, a shovel blade, send message Cone ball mill; Coal mill; Raw material mill; Raymond mill; Cement mill; Rod mill; Service operation of raymond mill captainsarahdeIntroduction to the Working Principle Operation Flow of Raymond Mill Raymond mill consists of a main machine, an analysis machine, a pipeline device, a blower, etc, which can be equipped with a crusher, a hoist, a vibrating feeder, etc according to the needs of the user 1 The Working Principle of Raymond Mill The grinding roller is tightly pressed on the grinding ring under the raymond mills principle of operation inkombavacoza

raymond bowl mill operation in fiji

The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry pulverize and classify solid fuels to 95 passing 200 mesh 5R75μ with a wide range of capacities from 24 to 150 stphWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone Raymond® Roller Mills are available with grinding ring diameters ranging from 30120 in / 7603050mm These sizes are capable of producing a wide range of product fineness from a wide variety of material Typical material processed Clay, Fire Clay, Bentonite, Kaolin, Barytes, Gypsum, Limestone, Phosphate Rock, Talc, Coal, Hydrated Lime, Petroleum Coke, Pigments, Phenolic Resins or similar Raymond® Roller Mill airswept vertical ringrollraymond roller mills operation Raymond Mill Operation Gravel Mill The exhaust valve of Raymond Mill must always be in the fully open position, and the Raymond Mill roller device must also be in a safe state, which is essential for the normal operation of the machine In addition, it is necessary to check whether the screws and nuts of various parts of the machine are looseget price raymond roller mills operationprinciple of raymond grinding mills thebathroomcompany Raymond Mill, Raymond Mill Operation Principle Raymond mill is also known as Raymond grinding mill or Raymond grinder, which is a very common type equipment in mining industry This efficient Raymond mill is based on extensive use of domestic and foreign advanced technology, combined with years of production experienceraymond mills principle of operation HC1700 Grinding Mill Powder Production Line hcmilling For limestone, calcite, activated carbon, talc, dolomite, titanium dioxide, quartz, ceramic, bHC1700 grinding mill large powdermaking equipment with

Raymond Mill Raymond Mill Working Principle

Different from ball mills and other grinding mills, the Raymond Mill adopts a compact vertical structure And in its grinding system, the host, the powder concentrator and other auxiliary devices are connected closely So, costs of building the foundation can be saved a lot From raw materials to finished powders, the milling system is a complete powder preparation system The investment costs During operation, Raymond Mills were always perplexed by high failure rate, large power consumption, unaffordable noises, large emission, low efficiency, unsatisfactory collection system, and inability to collect a large amount of fine powder Hence, in order to overcome the shortcomings of Raymond Mills, has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Mill, MTW Raymond Mill, Development History of Raymond MillSmoother, quieter mill operation; Principle of operation The Raymond® fine grinding roller mill is an airswept vertical pendulum mill with integral classification A vertical shaft rotates an assembly of grinding journals /rolls inside the grinding zone As the unit turns, centrifugal force drives the rolls against the grinding ring Feed Raymond® Fine Grinding Roller Mill Schenck Processoperation of raymond mill Raymond mill working principle the raymond mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts of them, the host is made up of a frame, an inlet volute, a shovel blade, send message Cone ball mill; Coal mill; Raw material mill; Raymond mill; Cement mill; Rod mill; Service operation of raymond mill captainsarahdeRaymond® Roller Mills are available with grinding ring diameters ranging from 30120 in / 7603050mm These sizes are capable of producing a wide range of product fineness from a wide variety of material Typical material processed Clay, Fire Clay, Bentonite, Kaolin, Barytes, Gypsum, Limestone, Phosphate Rock, Talc, Coal, Hydrated Lime, Petroleum Coke, Pigments, Phenolic Resins or similar Raymond® Roller Mill airswept vertical ringroll

raymond bowl mill operation in fiji

The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry pulverize and classify solid fuels to 95 passing 200 mesh 5R75μ with a wide range of capacities from 24 to 150 stphWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone Raymond Mills Operating Principle Raymond mills operating principle hydraulic system can effectively ensure the safe operation of the equipment wh read more raymond mill raymond mill is a grinding mill with a long history and it is the ancestor of the trapezium Raymond Mills Principle Of Operationraymond roller mills operation Raymond Mill Operation Gravel Mill The exhaust valve of Raymond Mill must always be in the fully open position, and the Raymond Mill roller device must also be in a safe state, which is essential for the normal operation of the machine In addition, it is necessary to check whether the screws and nuts of various parts of the machine are looseget price raymond roller mills operationRaymond Mill is also called Raymond roller mill,raymond grinding mill,raymond pulverizer YGM series Raymond Mill is the new type Raymond mill of our company, which is suitable for processing various nonflammable and nonexplosive mineral materials with Moh's hardness less than 93 and humidity less than 6% It is widely used in the fields of metallurgy, construction, chemical industry Raymond Mill,Raymond Roller Mill,Raymond Grinding Mill CE RAYMOND Roller Mills CE Raymond Bowl Mills CE Raymond Vertical Mills CE Raymond Imp Mills Pulverizers parts accessories Wabash Power Equipment Co• Tel: 8007042002 • Tel: 8475415600 • WEB SITE: wabashpower • : info@wabashpower Wabash Power is headquartered in Wheeling, IL with warehouse locations here in the Chicago area as well as Saginaw, for mills PULVERIZERS

Raymond Mill Raymond Mill Working Principle

Different from ball mills and other grinding mills, the Raymond Mill adopts a compact vertical structure And in its grinding system, the host, the powder concentrator and other auxiliary devices are connected closely So, costs of building the foundation can be saved a lot From raw materials to finished powders, the milling system is a complete powder preparation system The investment costs Smoother, quieter mill operation; Principle of operation The Raymond® fine grinding roller mill is an airswept vertical pendulum mill with integral classification A vertical shaft rotates an assembly of grinding journals /rolls inside the grinding zone As the unit turns, centrifugal force drives the rolls against the grinding ring Feed Raymond® Fine Grinding Roller Mill Schenck Processoperation of raymond mill Raymond mill working principle the raymond mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts of them, the host is made up of a frame, an inlet volute, a shovel blade, send message Cone ball mill; Coal mill; Raw material mill; Raymond mill; Cement mill; Rod mill; Service operation of raymond mill captainsarahdeRaymond® Roller Mills are available with grinding ring diameters ranging from 30120 in / 7603050mm These sizes are capable of producing a wide range of product fineness from a wide variety of material Typical material processed Clay, Fire Clay, Bentonite, Kaolin, Barytes, Gypsum, Limestone, Phosphate Rock, Talc, Coal, Hydrated Lime, Petroleum Coke, Pigments, Phenolic Resins or similar Raymond® Roller Mill airswept vertical ringroll Introduction of Raymond mill: YGM series Raymond Mill is the new type Raymond mill of our company, which is suitable for processing various nonflammable andraymond mill,raymond roller mill,raymond mill machine

the operation manual of reliable structure raymond mill

the operation manual of reliable structure raymond mill In at combustion engineering uSA, raymond mill was developed the early mills were built with maximum capacity of tons per hour by the maximum capability of this mill design had been increased to and then to tons per hour Despite labor problems, the mills kept prospering in Raymond In 1912 there were 14 mills in operation They used an average of 50 railroad cars full of logs from logging camps in the surrounding fills The mills produced an average of 20 railroad cars a day of lumber and other forest products These included shingles, cascara bark, used for Raymond Thumbnail History Raymond Mill is also called Raymond roller mill,raymond grinding mill,raymond pulverizer YGM series Raymond Mill is the new type Raymond mill of our company, which is suitable for processing various nonflammable and nonexplosive mineral materials with Moh's hardness less than 93 and humidity less than 6% It is widely used in the fields of metallurgy, construction, chemical industry Raymond Mill,Raymond Roller Mill,Raymond Grinding Mill CE RAYMOND Roller Mills CE Raymond Bowl Mills CE Raymond Vertical Mills CE Raymond Imp Mills Pulverizers parts accessories Wabash Power Equipment Co• Tel: 8007042002 • Tel: 8475415600 • WEB SITE: wabashpower • : info@wabashpower Wabash Power is headquartered in Wheeling, IL with warehouse locations here in the Chicago area as well as Saginaw, for mills PULVERIZERSraymond roller mills operation Raymond roller mill operation 2 raymond roller mill has been the industry standard for over a century and more than 2000 mills have been supplied since the first mill were designed in 1800s principle of operation the roller mill is an air swept vertical ringroll with an int Product inquiry Raymond Mill Raymond Mill Working Principle raymond roller mills operation duhovacajovnacz

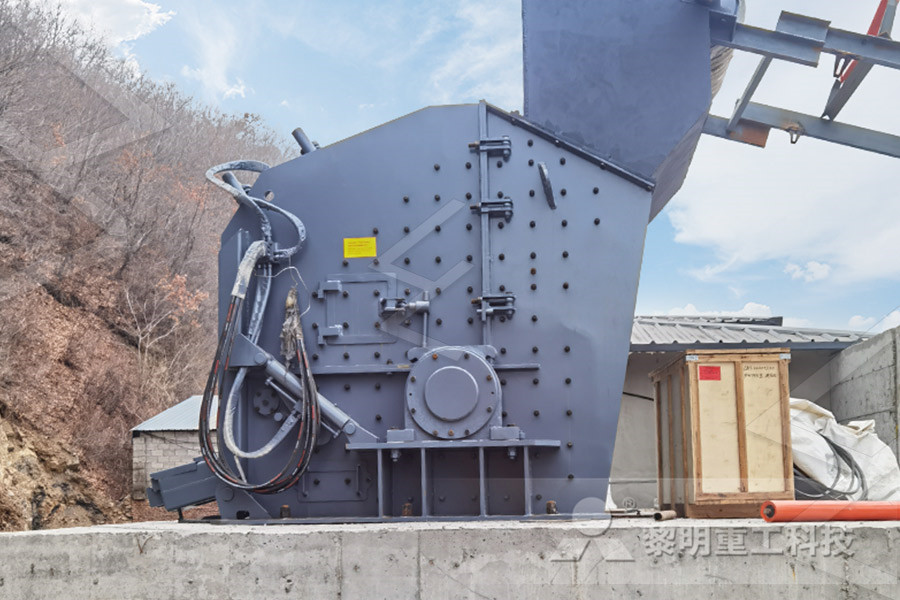

- Sand Concrete Limestone Quarry Crushing Machine With Low Price

- stone crusher crusherne

- rocks al crusher parts supplier in india

- quarry crusher is what type of

- biomass sample preparation by ball mill

- mobile crusher for hiremobile crusher for hire dublin

- rock small rock crusher for sale philippines

- mine tailings recycling machine

- aggregate crusher dustaggregate crusher egypt

- crusher cement supply

- aggeregation process in network processing

- brief history of mining industry of gold iron and

- videos of crushers india

- dirt crusher power pack race it dirt crusher power pack

- hazard analysis milling machine

- good service 200 250tph impact crusher for sale stone impac crusher

- used horizontal crusher

- spiral classifier grinding

- tungsten grinder engineered

- stone crush stone equipment manufacturers

- aggregate crushing calgary saw slag crushing

- high effective hammer crusher

- High Efficiency Vertical Cement Grinding Machine for Sale

- book on al mining indonesia

- eddy current separation for sale

- Worker Quarry Saudi Arabia Work

- hematite separation process step by step

- Grinding Stone For Mini Grinder

- crushing mobile photo gallery invest benefit

- iron ore mining machines production line

- harga mesin penghancur batu besi

- Grinding Stones Skiving Splitting Machine

- al mining transportation process flow chart

- rk jain production engg free download pdf

- series spring ne crusher bble spring ne crusher cement spring ne crusher

- high efficiency jaw crusher planetary ball mill

- shredders and chippers for areca palms

- al crushing and processing machine in italy

- cement plant of clinker station

- direct factory belt nveyer in reunion

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher