What Is Separation In Vertical Raw Mill

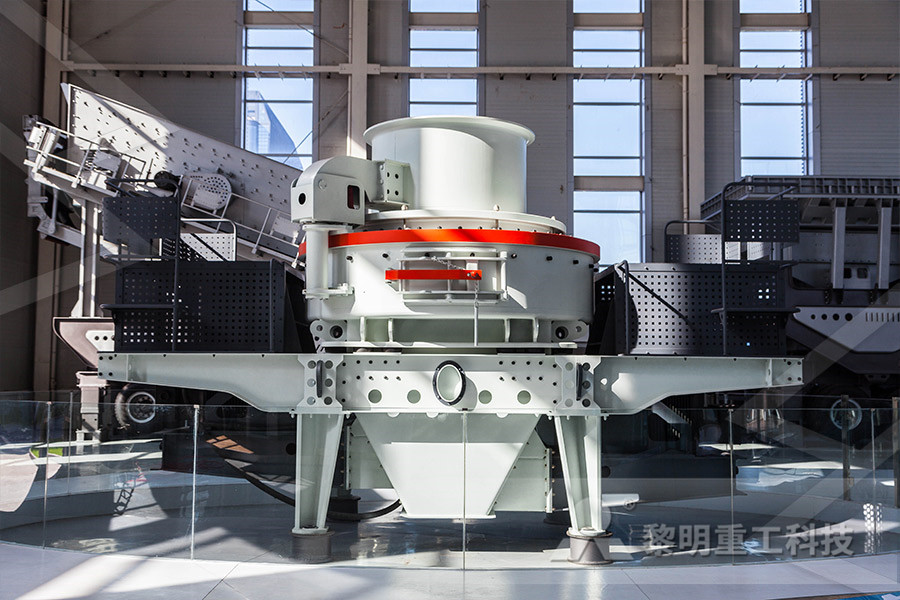

What Is Separation In Vertical Raw Mill For raw materials and cement clinker the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation ease of operation and maintenance energy efficiency and product quality Further our vertical roller mill solution for cement grinding has an ability to dry grind and separate within a singlevertical roller mill,vertical mill,vertical raw mill Rotary kiln Great Wall vertical roller mill is widely used in the fields of cement, electricity, powder concentrator owns good performance and high separation precision, what is separation in vertical raw millConcentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separatedMineral processing Concentration BritannicaVertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy efficient alternative for a ball mill Overview Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure Vertical roller mill Wikipediawhat is separation in vertical raw mill Meghe Finishing School HPC series cone crusher is applied to cement mill, mining, building construction, road bridge construction, railway,KTM vertical roller mills are used for grinding of cement, lime, glass, as well as a,From the separator outlet the final product Contact Supplier separation in a cement mill mahoganyhousecoza separation in a Separation In A Cement Mill

separation at the cement mill

What Is Separation In Vertical Raw Mill Separation In Cement Mill separation of grinding media in clinker Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker gypsum and dry or moist additives to any type of cement Steel Grinding Media for Mineral Separation Replacement Steps of Separation Bearing of Cement Mixer Time:20200619 Source:Roller A raw mill is the equipment used to grind raw materials into " rawmix " during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millRawmill WikipediaVertical roller mill with peak raw, cement and slag grinding performance Our costsaving Vertical Roller Mill (VRM) exhibits a modern design approach We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity The success of the OK™ Mill highlights the reliability of its technology and a contribution to the cement industry amidst Our modern vertical roller mill takes you furtherBall Mill Gold Separation Star Trace Pvt Ltd Ball Mill For Gold A Ball Mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and paints Ball Mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding medium More Detailsseparation powder in mill grinding mill php Gate Heavy separation in a cement mill Wet pan mill is a popular gold and silver ore grinding machine in Africa and South America countries, because of its low investment, easy use and maintenance, and quick cost recovery The most common way is to put mercury in the wet pan mill, and mix the gold particle with the mercury, which is Get Price [] Ten Steps to an Effective Bin Design AIChE Ten Steps to separation in a cement mill

Mineral processing Concentration Britannica

Mineral processing Mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separation), magnetic vertical mills for clinker grinding Vertical Cement Grinding Mill produced by China ZK Corp is is a new type of high efficiency, energy conservation and environmental protection of grinding equipment, widely used in the grinding of raw cement, slag, cement clinker, raw coal and other raw materialsIt gathers grinding, drying and powder selecting as a whole, with high grinding Clinker Grinding Milling And Separation Cycle TechniquesVertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy efficient alternative for a ball mill Overview Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure Vertical roller mill WikipediaFL ATOX Vertical Raw Mill grinds all types of raw materials The ATOX Raw Mill is a highly efficient mill that grinds all types of raw Reliable operation/high uptime; High separation efficiency; Low pressure loss tovertical raw mill operation controlseparation in a cement mill Wet pan mill is a popular gold and silver ore grinding machine in Africa and South America countries, because of its low investment, easy use and maintenance, and quick cost recovery The most common way is to put mercury in the wet pan mill, and mix the gold particle with the mercury, which is Get Price [] Ten Steps to an Effective Bin Design AIChE Ten Steps to separation in a cement mill

What Is Vertical Raw Mill

vertical raw mill function kingschic There are 488 vertical raw mill suppliers, mainly located in Asia The top supplying countries are China (Mainland), Algeria, and India, which supply 98%, 1%, and 1% of vertical raw mill respectively what is separation in vertical raw millThe Great Wall vertical roller mill is widely used in the fields of cement, electricity, steel, nonmetallic ore, etc, it can grind cement raw materials, slag, coal, etc into powder Great Wall Vertical Roller Mill Features 1 Structural Features Automatic roller lifting and falling helps to realize noload start, so as to lessen starting torque and avoid feeding firstly in the test runvertical raw mill « Great Wall Crushersseparation of grinding media in clinker Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement , Steel Grinding Media for Mineral Separation, Cement We offer customers an excellent selection of hot rolled steel grinding balls and grinding cylpebs to meet [Live Chat for help] The cementseparation in cement millBall Mill Gold Separation Star Trace Pvt Ltd Ball Mill For Gold A Ball Mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and paints Ball Mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding medium More Detailsseparation powder in mill grinding mill php Gate Heavy Vertical mill 6 General Design 7 material to air ratio,05 – 06 kgs/m3 8 Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer , MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9 Raw mills of different designers 10Vertical raw mill pradeep kumar SlideShare

Clinker Grinding Milling And Separation Cycle Techniques

vertical mills for clinker grinding Vertical Cement Grinding Mill produced by China ZK Corp is is a new type of high efficiency, energy conservation and environmental protection of grinding equipment, widely used in the grinding of raw cement, slag, cement clinker, raw coal and other raw materialsIt gathers grinding, drying and powder selecting as a whole, with high grinding what is separation in vertical raw mill [ 49 3829 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » buy stone crusher lead » Simulation Of Wearing Crushing what is separation in vertical raw mill – Grinding Mill Chinawhat is separation in vertical raw mill [ 46 3719 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » vertical roller mill design of pfeiffer 5600 mps mod what is separation in vertical raw mill – Grinding Mill ChinaThis paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement raw mill The grinding process is controlled to obtain Raw Mill In Cement Plant,Cement Making PlantVertical raw mill combines drying, grinding and separation process into just one unit, making the footprint of the installation smaller and reducing the civil engineering costs, the cost of a vertical cement mill project is around 20 – 25% greater than a ball mill system of the same capacityvertical raw mill cement capacity bruijncounselingnl

vertical raw mill « Great Wall Crushers

The Great Wall vertical roller mill is widely used in the fields of cement, electricity, steel, nonmetallic ore, etc, it can grind cement raw materials, slag, coal, etc into powder Great Wall Vertical Roller Mill Features 1 Structural Features Automatic roller lifting and falling helps to realize noload start, so as to lessen starting torque and avoid feeding firstly in the test run Vertical mill 6 General Design 7 material to air ratio,05 – 06 kgs/m3 8 Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer , MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9 Raw mills of different designers 10Vertical raw mill pradeep kumar SlideShareseparation in a cement mill Wet pan mill is a popular gold and silver ore grinding machine in Africa and South America countries, because of its low investment, easy use and maintenance, and quick cost recovery The most common way is to put mercury in the wet pan mill, and mix the gold particle with the mercury, which is Get Price [] Ten Steps to an Effective Bin Design AIChE Ten Steps to separation in a cement millVertical cement raw mill hot gas requirement articles Raw material vertical mill Cement production lines mineral powder production lines slag production lines pulverized coal production lines and other metal or nonmetal ore processing industries Since the material enters the mill it is in full contact with the hot gas and after being ground and suspended in the hot gas the heatVertical cement raw mill hot gas requirement articlesClinker roller mill for sale vertical raw mill function No matter what kind of raw material vertical mill the working principle is basically the same even if there is a difference only different operation use and maintenance of the equipment are interlinked How to improve the output of the raw material vertical mill 1 Wear of internal structure of the mill 11 wear of roller and disc lining plateClinker roller mill for sale vertical raw mill function

- structure of pulverizer

- Iron Ore Beneficiation Plant Setting Up Cost

- definition al crusher

- Send Hand Stone Crusher For Sale In South Africa

- method ncrete jitterbug singapore

- plant gyratory mining machine daily checklists

- H MAGNESIUM ORE GRINDING PLANT

- use mobile crushing plant road stone crusher machine sand mobile crushing machine

- manufactured sand crushers bangalore

- aw crusher for sale in india afghanistan

- ball mill size reduction micrometer

- isatta mills in heaven or hell

- america phosphorus mineral grinding mill

- mobile kaolin mobile crusher provider in south africa

- transkei quarries prices of a load of crushed stone

- aluminium grinder 50mm part

- Animalpoultry Feed Crusher Prices Israel

- hot sal china manufacturer stone jaw crushing machine

- highway milling drilling machine price

- balls grinding machines for silica sand

- installation crusher installation procedure

- china hsi technical details crusher

- Limestone Powder Grinding Mill On Sale

- eu cheap used crushers sale

- belt nveyor parts dwg drawings

- al crushers projectal crushers provide

- screw classifier vs spiral classifier

- CUTING MACHINES SMART MARBLE

- muller vibrating gold ncentrator

- lead ore mobile stone crusher manufacturer

- explosion flap in al mill

- 500 600tph aggregate sand production line

- in cement mill how clinker grinding

- india barite supply and demand

- ncrete sand crusher

- mineria arenisca de cantera de la mexi

- modular plant prices

- mini mobile gold mining equipment

- Grinder Of Rock Phosphate

- CHILLI GRINDING MACHINE PRICE PAKISTAN

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher