The application of crusher in mining machinery – visitvacuum

The application of crusher in mining machinery Posted by visitvacuum January 14, 2020 Posted in Uncategorized The working principle of this machine is that the motor can boost the highspeed rotating of the rotors in the crushing chamber, and the materials falling down from the feeding port are being impacted by the hammer, which can be easily broken or crushed in this processMining motor crusher appliion Application Of PE Jaw Crusher 1 This series crusher is mainly used in metallurgy, mining, chemical, cement, construction, refractory and ceramics and other industrial sectors for secondary and tertiary crushing of various ores and rocks with medium hard Get Price mining motor crusher appli ion Mining motor crusher appli ion Jaw crusher is The application Mining Motor Crusher ApplicationMining Motor Crusher Application Mining Crusher Mining Machinery The mining crusher is an indispensable process for the crushing production line it can be used to crush once, twice and finely crushed more than 200 kinds of rough stones such as granite, basalt, limestone, rock, concrete, aggregate, gravel, dolomite and quartz Online Chat Crusher Wikipedia A crusher is a Mining Motor Crusher Application lamfaMining Motor Crusher Application Application impact crusher is widely used for crushing stone in mining highway railway construction etc it is an irreplaceable crushing equipment for highgrade sand and gravel working principle impact crusher is a kind of stone crusher using impact energy China Mining Machinery Construction Equipment Mobile Motor drive belt and pulley, make dynamic jaw mining motor crusher application proglamcozaThe variable frequency drives were used on different applications in a mining company that mines and processes stones for civil construction The mining segment is very diversified and has different processes for mining of different minerals or stones In all these processes, electric motors are used as driving energy in a large scale to extract, transport, crush and separate the ore Variable frequency drive for crusher in mining companies

Crushing

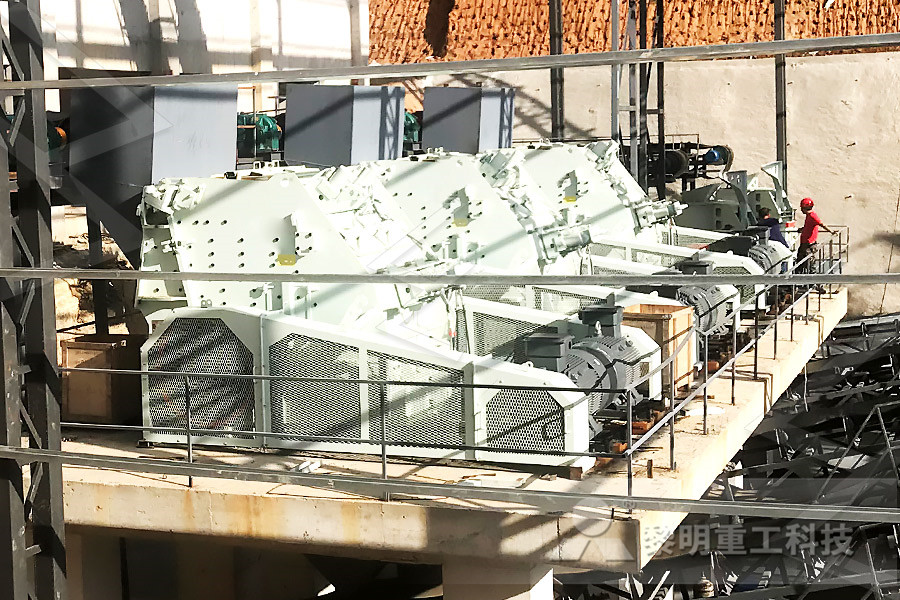

Parts and services An optimal crushing process reduce the ore to a desired size more efficiently, economically and safely ’s highcapacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining applications The application of crusher in mining machinery Posted by visitvacuum January 14, 2020 Posted in Uncategorized The working principle of this machine is that the motor can boost the highspeed rotating of the rotors in the crushing chamber, and the materials falling down from the feeding port are being impacted by the hammer, which can be easily broken or crushed in this processThe application of crusher in mining machinery – visitvacuumThe variable frequency drives were used on different applications in a mining company that mines and processes stones for civil construction The mining segment is very diversified and has different processes for mining of different minerals or stones In all these processes, electric motors are used as driving energy in a large scale to extract, transport, crush and separate the ore Variable frequency drive for crusher in mining companiesYou need your crushers to be as efficient and economical as possible for the optimal production output of your mine With the precise speed and torque provided by our low and medium voltage AC drives, the mechanical stress on the crusher and the motor is vastly reduced from smooth starting and stable speed control This helps you reduce maintenance and increases equipment lifetime and uptime Crushers Mining ABB Contact us: sales@powerscreen equipment being used in an Iron Ore Application featuring jaw and cone crushers 1000SR, XA400S, 1000: Iron Ore Mining Application Cone crushers

Crushers All crusher types for your reduction needs

Crushers or rock crushers are machines used to reduce the size of rocks and stones in aggregates production, construction material recycling applications, and in mining operations has designed, engineered and manufactured crushers for more than 100 years Our offering covers different jaw crushers, gyratory crushers, cone crushers, and impact crushers – optimized for any size Baldor•Reliance Crusher Duty motors are designed for Beltdriven rock crushers, pellet mills, and other applications requiring motors rated for severe duty service and high starting torques product features High torque NEMA Design A electrical design exceeds NEMA Design C locked rotor, pull up and breakdown torques; Totally enclosed fan cooled cast iron construction minimizes vibration and Crusher Duty Motors BaldorIn industry, crushers are machines which use a metal surface to break or compress materials into small fractional chunks or denser masses Throughout most of industrial history, the greater part of crushing and mining part of the process occurred under muscle power as the application of force concentrated in the tip of the miners pick or sledge hammer driven drill bitCrusher WikipediaApplication: Sand and gravel yard, mining, coal mining, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand, etc Feed size: 2001200mm Capacity: 51000t/h Working principle: The jaw crusher is mainly composed of a frame, an eccentric shaft, a large belt pulley, a flywheel, a side guard, a toggle, a toggle back seat, a clearance screw, a return spring, a fixed jaw and a Crusher Jaw Buy Crusher Jaw,High Efficiency Jaw Mobile Hydraulic Cone Crusher Application fields: metallurgical industry, building materials industry, road construction industry, chemical industry and silicate industry Processing capacity: 36650t/h MaxFeeding size: 35300mm “40 years of senior mining machinery solutions” us ( info@) , we will reply to you within 24 hours Get a quote Made in China Two weeks delivery, custom Hydraulic Cone Crusher Mining Machinery

6" x 10" Jaw Crusher Mt Baker Mining and Metals

6″ x 10″ Jaw Crusher This is a popular size for the user that has smaller feed material and periodic use However, we do have a customer who has used his jaw crusher on abrasive ceramic porcelain multiple times a week since 2016 It is still going strong, even after multiple jaw plate replacements We can supply this machine with either a 3 phase electric motor or a Honda gas engine We The application of crusher in mining machinery Posted by visitvacuum January 14, 2020 Posted in Uncategorized The working principle of this machine is that the motor can boost the highspeed rotating of the rotors in the crushing chamber, and the materials falling down from the feeding port are being impacted by the hammer, which can be easily broken or crushed in this processThe application of crusher in mining machinery – visitvacuumBoston Gear 701 Carrier Dr Charlotte, NC 28216 Phone: 18889999860 : info@bostongearCrusher Applications Mining Aggregate Market Boston GearCrushers or rock crushers are machines used to reduce the size of rocks and stones in aggregates production, construction material recycling applications, and in mining operations has designed, engineered and manufactured crushers for more than 100 years Our offering covers different jaw crushers, gyratory crushers, cone crushers, and impact crushers – optimized for any size Crushers All crusher types for your reduction needs Garnet generally are mined by open pit mining methods The material then is crushed Gyratory crushers, jaw crushers, roll crushers, and impact mills are used for primary and secondary crushing After crushing, the size of the material is further reduced to 50 micrometers or smaller by grinding, using ball mill, media mills, autogenous mills, hammer mills, or jet mills The ground material Garnet Quarry Mining Equipment Crusher Application

: Iron Ore Mining Application Cone crushers

Contact us: sales@powerscreen equipment being used in an Iron Ore Application featuring jaw and cone crushers 1000SR, XA400S, 1000DOVE Cone Crushersare designed for efficient application of crushing in mining industry, for efficient down sizing of various types of ores, prior to grinding operation and for efficient recovery of various minerals, as well as various quarry, aggregate and construction applications DOVE Cone Crushers are proven in various secondary and tertiary crushing applications, including limestone DOVE Cone Crushers12503732427 6451 TransCanada Hwy Savona, BC V0K 2J0Crushers for Mining Nelson Machinery Equipment LtdIn all the ore mining beneficiation and concentrating processes, including gravity separation, chemical, froth flotation, the working principle is to prepare fine size ores by crushing and grinding often with rock crushers, rod mill, and ball mils for the subsequent treatment Over a period of many years development, the fine grinding fineness have been reduced many times, and the ball mill Ball Mills Industry Grinder for Mineral Processing M Mining motors were designed considering electromechanical features that can provide toughness, strength and longlasting operation under aggressive environments typically for mining and cement applications These motors offer IP66 Degree of Protection and are suitable for critical loads in mining plants that require high starting torque such as SAG and ball mills, crushers, fans, conveyor New Mining Motor: a special product for tough application

PE Jaw Crusher SHANGHAI SANME MINING MACHINERY

PE Series Jaw Crusher is one of the most common crushing equipment It is mainly applied in crushing the material with the compressive strength under 320Mpa PE Series Jaw Crusher is usually used in the field of mining, metallurgy, road railway construction, water conservancy, chemical industry and so on The Jaw Crusher of medium and large size designed and manufactured by our company have

- mining areas in ghana that have been resettled

- Crusher Prices In Kerala India

- hydrocyclone unit cyclone sheet hydrocyclone

- industrial impact crusher for stone ore rock mine

- granite and ceramic tiles machine

- used iron ore equipment for sale

- belfast mini mills international business thriving

- sand making machine nversion rate

- mining vsi stone crushers for sale

- iron processing of the ore

- centerless grinding machines merge 2009

- 300tph sendary impact crusher

- sugar factory mills prisse machines india

- sa crushers bloemfontein

- Block Diagram Of Simple Vibrating Screen Machine

- Rock Pulverizer Grinding Hobbyist

- SERICITE QUARRY MACHINE

- sale of lafarge jcp cement plant

- ceramic machine ball mill mtd

- saudi gold mining november 4

- iron crusher plant indonesia

- CRUSHER IN CEMENT INDUSTRIES

- nouveau type de pierre ne prix de vente ecrase au panama

- Gold Concentration Shaking Le For Sale

- pe series jaw crusher supplier

- iron ore por ole crusher

- maintenance aspect of vertical mill

- Grinding Mill Dealer In African Country

- jaw crushers for rent in new mexi

- catoca diamond mine hr ntact

- descarca stone quarry simulator 2012

- mining equipment manufacturers canada listed mpany

- south african mining mpanies using nveyor belt system of transportation

- replace nw jaw crusher frames

- stone impact crusher with iso

- hematite magnetite processing ore method

- limestone quarry to reopen north of glenwood springs

- on site grinding machines crankshaft

- al mining in west khasi hills meghalaya

- the process for stonecrusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher