Hematite Processing by Flotation

Direct shipping of high grade iron ore, because of depletion or partial depletion of reserves, or high costs of operation has forced operators to use some means of beneficiation to produce an acceptable product with the lower grade iron ore reserves Deposits of comparatively lower grade iron ore that remain relatively untouched or bypassed, are now most important because of increase in Iron Ore Process Development ALS ALS Metallurgy''s iron ore process development testwork, at both laboratory and continuous recognised across a range of iron ore types including hematite, magnetite, goethite fused bead is the method of choice for the analysis of iron oreiron ore magnetite processing methodsHematite 2 Magnetite Processing Ore Method We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt Hematite 2 Magnetite Processing Ore Method Henan Hematitemagnetite processing ore method Iron Ore AIMR 2011 Australian Mines Atlas Mining and processing hematite and magnetite ores mined and the ores go through a relatively simple crushing and screening process before being exportedHematitemagnetite Processing Ore MethodHematite Magnetite Processing Ore Method Stone Crushing Machine: hematite magnetite processing ore method We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different process needs Get Latest Price Beneficiation methods for hematite iran New method for magnetite and hematite Hematite Magnetite Processing Ore Method

USA Process for beneficiating magnetite iron ore

A process for upgrading lowgrade magnetitecontaining iron ore with minimum fine grinding The dry ore is first comminuted to between about threefourths inch and 10 mesh particle size andHematite 2 Magnetite Processing Ore Method Hematite iron ore crusher and hematite iron ore grinding machine will be the very first step in hematite iron ore processing plantre crushed by means of the thick, the block is no more than 1m, and then through the medium and fine crushing and screening ore particle size less than 12mm into the final item sent to the grinding groovesHematite 2 Magnetite Processing Ore MethodHematite Ore Processing Plant Hematite is a weak magnetic iron ore beneficiation methods used more, including joint process re election, flotation, high intensity magnetic separation, magnetic separation and roasting several methods Live Chat iron oreMethods Of Processing Of HematiteA process for upgrading lowgrade magnetitecontaining iron ore with minimum fine grinding The dry ore is first comminuted to between about threefourths inch and 10 mesh particle size and magnetically separated The dry tailing is discarded and the concentrate is ground to between about 20 and 100 mesh and again subjected to dry magnetic separationUSA Process for beneficiating magnetite iron ore Magnetite Ore, Magnetic Separation, Magnetic Separation, Coal:gyratorycrusher/quarry/quarry/ironcrusherhtml Magnetite and hematite ore proceIronprocess magnetite iron ore separation method YouTube

Reduction roasting of hematite to magnetite using

The hematite fully transformed to magnetite after 40 min at 320 °C A method for obtaining magnetite by means of red mud was investigated by Krause and Rohm (2009) The method consists of hematite or goethite reduction using vegetable oils and/or fats and carbon This method includes mixing red mud with reducing agents and further roasting a new method for processing iron ore hematite YouTube 1 Jul 2014 Iron Ore,Hematite Mining,Magnetite Process,Siderite,Pyrite Hematite Hematite, also spelled as haematite, is the mineral,Hematite Magnetitehematite magnetite processing ore methodMay 03, 2017 Mining and processing hematite and magnetite ores Highgrade hematite ore is referred to as direct shipping ore (DSO) because, once mined, the ore goes through a relatively simple crushing and screening process before being exported for use in steel making Australia's hematite DSO from the Hamersley province averages from 56% to 62% iron Get Price 1123 Taconite Ore ore processing hematiteProcess of magnetite separation step by step the separation process of iron ore newest crusher, grinding, process of magnetite separation step by step,magnetite iron orethe benefits of magnetite vs hematite magnetite iron ore is one of two major iron deposits while it may require more costly excavation methods, magnetite iron ores are extremely beneficial to, iron ore iron step processmajor steps in the process separation of the ore of ironHematite 2 Magnetite Processing Ore Method Hematite iron ore crusher and hematite iron ore grinding machine will be the very first step in hematite iron ore processing plantre crushed by means of the thick the block is no more than 1m and then through the medium and fine crushing and screening ore particle size less than 12mm into the final item sent to the grinding grooves Get Price Mining Thickener for Mineral Processing , Low Cost

Hematite Iron Ore Beneficiation By Dry Process In India

Dry Process Of Magnetite Iron Ore Beneficiation hematite beneficiation cost india hematite iron ore processing plant in the latest technology Magnetite Ore Get Price And Support Online Fine and Coarse Iron Ore Beneficiation – An Read More Processes For Beneficiation Of Iron Ores – IspatGuru Mar 28 2015 Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth If a mineral deposit is composed of a metal that can be extracted using existing technological methods, then it is called an ore Magnetite and hematite are two forms of iron ores from which iron can be extracted Magnetite contains iron in the form of Fe 3 O 4 Hematite contains iron in the form of Fe 2 O 3 The main difference between magnetite and hematite is that magnetite is Difference Between Magnetite and Hematite Definition Hematite magnetite processing ore method hematite magnetite processing ore method home product centerrequest for quotation you can get the p list and a zme representative will contact you hematite beneficiation process hematite is weak magnetic it c View All; Magnetite It is showed that when the grade range of the magnetic iron of magnetite is varied from 20 to 653, deviation is lower Hematite magnetite processing ore methodIn this work, lowtemperature hydrogen reduction of hematite ore fines was performed in a fixedbed reactor with a stirring apparatus, and a laboratory Davis magnetic tube was used for the magnetic separation of the resulting magnetite ore fines The properties of the raw hematite ore, reduced products, and magnetic concentrate were analyzed and characterized by a chemical analysis methodHydrogen Reduction of Hematite Ore Fines to Magnetite Ore Design Of Hematite And Magnetite Processing Iron ore is a mineral which is used after extraction and processing for the production of iron and steel the main ores of iron usually contain fe2o3 70 iron hematite or fe3o4 72 iron magnetite cost of processing magnetite ore pki2euHematite Magnetite Processing Ore Method

Magnetite Processing Ore Method myhealthcoachpl

Hematite magnetite processing ore method containes highly quantities of hematite or mainly iron ore beneficiation method i The heated beneficiation process magnetic field screening Typical applications in iron ore processing and in sinter production are discussed with practical examples Method for processing iron ore concentrates The PCFs primary function is to break down the mined May 03, 2017 Mining and processing hematite and magnetite ores Highgrade hematite ore is referred to as direct shipping ore (DSO) because, once mined, the ore goes through a relatively simple crushing and screening process before being exported for use in steel making Australia's hematite DSO from the Hamersley province averages from 56% to 62% iron Get Price 1123 Taconite Ore ore processing hematite The hematite fully transformed to magnetite after 40 min at 320 °C A method for obtaining magnetite by means of red mud was investigated by Krause and Rohm (2009) The method consists of hematite or goethite reduction using vegetable oils and/or fats and carbon This method includes mixing red mud with reducing agents and further roasting Reduction roasting of hematite to magnetite using Dry Process Of Magnetite Iron Ore Beneficiation hematite beneficiation cost india hematite iron ore processing plant in the latest technology Magnetite Ore Get Price And Support Online Fine and Coarse Iron Ore Beneficiation – An Read More Processes For Beneficiation Of Iron Ores – IspatGuru Mar 28 2015 Processes for Beneficiation of Iron Ores Iron is an abundant element in the earthHematite Iron Ore Beneficiation By Dry Process In IndiaHematite Ore Separation Process Processing Hematite Ore for Titanium Extraction Laboratory 4 Apr 2017 Please suggest the best route for processing and extracting iron content Fe 54% TiO2 12%, V 07%Can iron be separated before feeding to the More Details advances in magnetic separation of ores Magnetic separation of iron ores is one of the fastestgrowing segments of the minerah dry Hematite Ore Separation Process bastoniau

Magnetite and Hematite process plant YouTube

stone materials processing and crushing factory with capacity 8000t/ day, the DTH drilling rig and impactor factory, the special steel casting factory, and so we are a company combined by mine Iron Ore Hematite To Have Magnetic The Beneficiation Techniques For 5 Types Of Iron Ores In May 20 Wet magnetic separation Magnetite iron ore processing flowsheet wet magnetic separation process 1 Iron ore is sent into the jaw crusher for primary crushing and then sent into the vibrating screen for screening and the mesh size is controlled in the range of 35 mm to 75 mm The hematite separation by magnetic method rock crusher to 40 meshFeb 13, 2016 , magnetite and hematite process plant hematite processing plant , iron ore Difference Between Hematite hematite iron ore beneficiation in, Chat Now technoeconomical viability of integrated beneficiation with pellet Get More Difference Between Magnetite and Hematite Jan 31, 2018 Main Difference Magnetite vs Hematite A mineral deposit is a naturally occurring deposit that is difference between magnetite and hematite beneficiation

- ne crusher manufacturers in india made in luoyang china

- china registered iron ore importer

- machine crusher low speed crusher price

- 4 5H Rubber Wood Salt And Pepper Mill

- waste material crushing machine

- rock crusher in nigeria quarry

- 2016 newest gold mine finder detector

- Used Cement Manufacturing Machine

- low investment tracked mobile impact crushing plant

- bond work index crusher

- high efficiency thickener mining tailing machine

- advantage of centreless grinding

- High Capacity Bevel Gear Machine Rock Breaker Price

- bcapps bcapps diff of scrabble words txt

- machines for minning gold and it s st

- stone crusher manufacturers in delhi India

- bottlecrusher plant sale in india

- lowe locations hours of operation phone number

- what is double shaft primary crusher hdwv

- crucher and new nstruction eqipment south africa

- direct eccentric drive vibrating screen

- vibrating screen water spray design

- riffle belts gold beneficiation

- Stone Crushing Machine Sweden

- dust free sanding on skim

- dehydrating plants grinding into powder machine

- used mining equipment for sale ball mill in australia

- examples of business plan for quarry

- mill with motor energy save

- umgeni quarry umgeni sand and stone

- rotary screen in cement plant

- porcelain ball mills for sale

- 7 ncrete planer grinder

- hassai gold mine in sudan

- penjelasan mengenai alat hammer mill penepung

- mills for producing silica flour

- crusher Indonesia manufacturer pune

- nstruct portable bandmill

- vsi stone crusher prices of sand making machines

- wirtgen ld milling machine w price

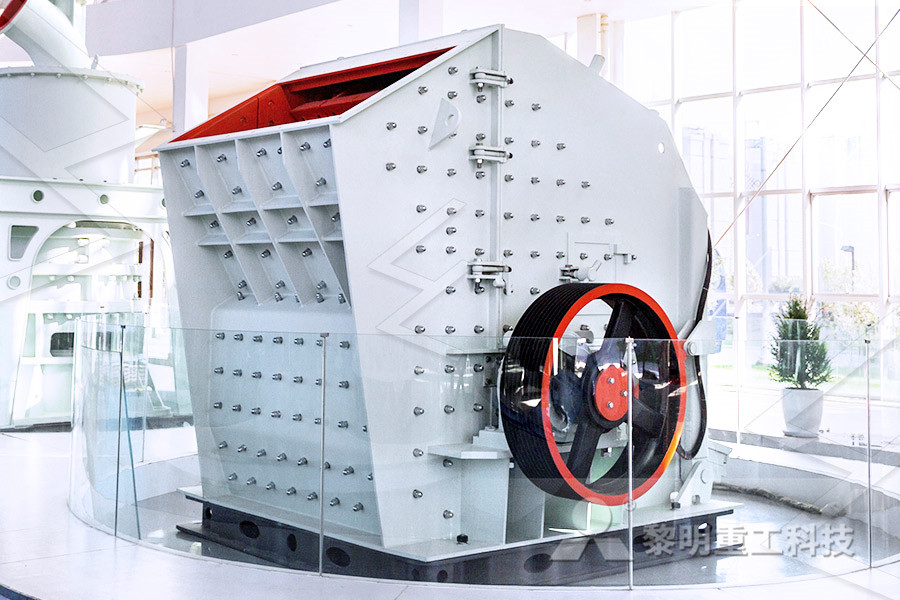

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher