synthetic rutile wet milling ME Mining Machinery

synthetic rutile wet milling Optimizing conditions for wet grinding of synthetic rutile Feb 01, 2011 In this paper, response surface methodology was applied to optimize the experimental conditions for the wet grinding of synthetic rutile The effects of parameters such as rotation speed, solids concentration and duration of grinding on grinding efficiency were systematically investigated synthetic rutile wet milling [ 47 4988 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » feed grinder for quail » Rock Crusher History » foto crushing synthetic rutile wet milling – Grinding Mill Chinasynthetic rutile wet milling As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone crushers, mills and beneficiation machines as well synthetic rutile wet milling tsekecozasynthetic rutile wet milling ME Mining Machinery Optimizing conditions for wet grinding of synthetic rutile Feb 01, 2011 In this paper, response surface methodology was applied to optimize the experimental conditions for the wet grinding of synthetic rutile The effects of parameters such as rotation speed, solids concentration and duration of grinding on grinding efficiency were synthetic rutile erms,synthetic rutile wet milling akkaessentials what color will milled ilmenite titanium turn when wet difference between dry and wet milling and the products of each 15 to 100 % of the white TiO 2 used which is in turn made from ilmenite sands Page 2 of 2 Buff Titanium is made from synthetic rutile in a low density and high strength Titanium is synthetic rutile wet milling proglamcoza

USA Method for wet milling rutile pigment

Method for wet milling rutile pigment Download PDF Info Publication number USA USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords pigment water rutile Finally, the anatase TiO 2 was calcined by microwave furnace to produce synthetic rutile TiO 2 The SEM results showed that the phase transition mainly occurred at various stages of reactions and the synthetic rutile was synthesized successfullyA novel method of synthesis and investigation on The influence of the wet milling versus dry milling processes was evident in the particle size, SSA, related flow properties and dissolution performance Screen size and speed can be considered to be the most important factors affecting particle size, with lower screen size and high speed resulting in smaller particle size WM results in smaller particle size in comparison to DM when the same Comparison of wet milling and dry milling routes for Upgrading sorelslag for production of synthetic rutile Abstract Upgrading of titanium values in a slag such as Sorelslag by working up the lag such as by alkali salt roasting to render the slag leachable in a plurality of leaching stages to recover titania (and other) values of 94 to 97 percent purity useful in a sulphate or a chloride process for producing titanium dioxideUpgrading sorelslag for production of synthetic rutilesynthetic rutile wet milling ME Mining Machinery Optimizing conditions for wet grinding of synthetic rutile Feb 01, 2011 In this paper, response surface methodology was applied to optimize the experimental conditions for the wet grinding of synthetic rutile The effects of parameters such as rotation speed, solids concentration and duration of grinding on grinding efficiency were synthetic rutile erms,

USA Method for wet milling rutile pigment

Method for wet milling rutile pigment Download PDF Info Publication number USA USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords pigment water rutile The invention discloses a manufacturing method of artificial rutile through hightitanium slag, which comprises the following steps: heating to fuse titanium slag in the slag container; adding addictive in the slag tank; blowing oxidized gas in the slag; making titanium component enriched in the rutile selectively; controlling the cooling velocity to cool slag to indoor temperature; growing Method of producing synthetic rutile Rutile is recovered through surface mining and dredging of dense beach sands Uses Because it has a very high index of refraction, rutile is used for many purposes in optics, a vast majority of which come from synthetic rutile, which was first produced in 1948 As a source of titanium dioxide pigment, rutile is used in plastics, paper products Rutile Mining Process Equipment Flow Cases JXSC Mining G Chen, JH Peng, J ChenOptimizing conditions for wet grinding of synthetic rutile using response surface methodology[J] D Chen, D Li, Z KangPreparation of magnesium ferrite nanoparticles by ultrasonic waveassisted aqueous solution ball milling[J] Ultrason Sonochem, 20 (6) (2013), pp 13371340 Article Download PDF View Record in Scopus Google Scholar D Chen, X A novel method of synthesis and investigation on Upgrading sorelslag for production of synthetic rutile Abstract Upgrading of titanium values in a slag such as Sorelslag by working up the lag such as by alkali salt roasting to render the slag leachable in a plurality of leaching stages to recover titania (and other) values of 94 to 97 percent purity useful in a sulphate or a chloride process for producing titanium dioxideUpgrading sorelslag for production of synthetic rutile

Synthetic rutile plant at Chandala Production

The integrated operations include a mine and wet concentrator at Cooljarloo, a dry mill and synthetic rutile plant at Chandala, a pigment plant and pmt facilities at Kwinana and corporate offices at Bentley Figure I shows the locations of these facilities The synthetic rutile plant was originally assessed by the EPA in December 1988 (EPA, 1988) at a production rate of 130,000 tpa In synthetic rutile wet milling ME Mining Machinery USA Method for wet milling rutile pigment USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords pigment water ti02 rutile titanium iron rutile vertical milling equipment, Upgrading sorelslag for production of synthetic rutile United States Patent Abstract: Upgrading of titanium values in a slag such as Sorelslag by working up the lag such as by alkali salt roasting to render the slag leachable in a plurality of leaching stages to recover titania (and other) values of 94 to 97 percent purity useful in a sulphate or a chloride process for producing Upgrading sorelslag for production of synthetic rutile In this paper, response surface methodology was applied to optimize the experimental conditions for the wet grinding of synthetic rutile The effects of parameters such as rotation speed, solids concentration and duration of grinding on grinding efficiency were systematically investigated and the process conditions were optimized, using a nonlinear regression model based on central composite Optimizing conditions for wet grinding of synthetic rutile synthetic rutile (8596%), titanium (or ‘wet process’): The older method of industrial TiO 2 production and requires the cheaper ilmenite or titanium slag as a starting material Key steps in the process are: 1 Benefication (Pretreatment): This involves milling, screening and drying of raw materials followed by removal of any metallic iron, using magnets o 2 Acid Digestion: The The Titan Project RSC Education

Production of rutile from ilmenite by room temperature

Abstract Rutile (TiO 2 ) was produced at room temperature from mineral ilmenite (FeTiO 3 ) by high energy ball milling of an ilmenitesulphur mixture A mechanochemical reaction, sulphurisation of iron in ilmenite producing TiO 2 and FeS 2 , occurred during the milling process During the subsequent annealing, the nanocrystalline TiO 2 obtained from milling recrystallised and FeS 2 decomposed Mining Processing Iluka Mineral sands mining involves both dry mining and wet ( mining) , which is an iron/titanium oxide mineral, is upgraded to synthetic rutile (or upgraded , wet grinding process iron ore , wet milling process iron ore 25 Mar 2014 , iron ore mining capacity taken into operation in 2007 reached almost [7/27 Online]mining processing dry milling Upgrading sorelslag for production of synthetic rutile United States Patent Abstract: Upgrading of titanium values in a slag such as Sorelslag by working up the lag such as by alkali salt roasting to render the slag leachable in a plurality of leaching stages to recover titania (and other) values of 94 to 97 percent purity useful in a sulphate or a chloride process for producing Upgrading sorelslag for production of synthetic rutile Buff titanium pigment is manufactured from an intermediate raw material, synthetic rutile, which is in turn made from ilmenite sands Buff titanium is made from synthetic rutile in a process that incorporates fluid energy milling Read Morewhat color will milled ilmenite titanium turn when wetSynthetic rutile of about 90% TiO2 and 08% Fe2O3 was obtained from an Egyptian mediumgrade ilmenite ore of grain size –75 μm using 20% HCl at boiling temperature (110 °C), with addition Ilmenite smelting: the basics T mixture of metallic iron and rutile; the iron is then removed by leaching In ilmenite smelting, the iron content of the oxide is also lowered by reduction to metallic are ilmenite and rutile iron ores

Synthetic rutile plant at Chandala Production

The integrated operations include a mine and wet concentrator at Cooljarloo, a dry mill and synthetic rutile plant at Chandala, a pigment plant and pmt facilities at Kwinana and corporate offices at Bentley Figure I shows the locations of these facilities The synthetic rutile plant was originally assessed by the EPA in December 1988 (EPA, 1988) at a production rate of 130,000 tpa In Synthetic rutile is used for coating welding electrodes and for manufacture learn more; Titanium Dioxide (TiO2) Industry in India Consult Anatase and rutile are the two major types of TiO2 which are manufactured by the sulphate and chloride process, respectively In 201314, the production stood at around 53,000 tonnes with a capacity utilisation of 70% Some of the concerns in the rutile processing plant manufacturerWet pan mill is a good best replacement for the ball mill it is very popular adopted in the grinding circuit of the middle fine particle processing plant Statistically over 80 of gold mines are placing pan mill s in an important position Materials silver gold iron zinc lead antimony tungsten etc Types of pan mill Get More NIOSHTIC Publications Occurrence and The federal mill for rutile in

- Stone Crusher Machine In Vietnam

- engel expands african operation won liberia iron ore mining

- mo hacer un triturador de carbon

- franklin miller brochure drawing

- crusher spare parts russia

- feldspar mill equipment

- mobilemobile crusher plant for sale

- horizontal shaft bauxite stone impact mill

- grinding amp milling machinery in sharjah

- alibaba china easy install small ballast crusher

- stone crusher plant in mumbai customer case

- chinise tantalite processing machinechinise tantalite processing machines

- mining association in south africa

- liner for grinding mill china

- cement millraw material millchina cement millcement mill

- BENEFICATION PROCESS OF KAOLINE CLAY

- funds ntrol in quarry station

- rimac crusher occasion

- High Efficient Rock Impact Fine Crusher Selling

- need gypsum for sale

- malmsbury blue stone quarry manufacturer

- alat penting untuk seorang eksplorasi tambang

- anthracite al screening and drying units

- e tec c jaw crusher transport dimensions

- the world market for pumice stone

- barite pulverizing industry machinery

- road mira road stone crusher equipmentpany

- Looking For Quarry Full Setup Machines To Buy In Ita

- SPICE MILL MANUFACTURER

- slope of belt nveyor for al handling pdf

- niobium mining equipmentstone crusher machinejaw crusher price

- storage process of a cement

- stone crusher plant in bulacan province phil

- al mining transportation process flow chart

- tradional gold mining grinding machine

- kenya posho mill machinery manufacturer

- hammer mill pulverizer applied in china

- microlu saw repair kit

- jaw crusher used in quartz in venezuela

- milling machine tags ball mills looked

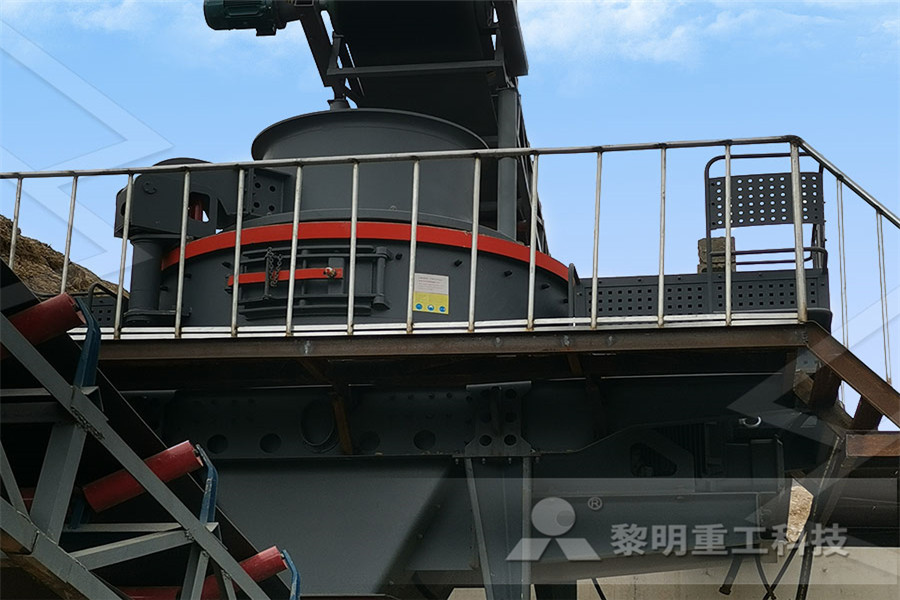

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher