cobalt film concentration ecopubbe

The reason for this is probably that the electrocatalytical activity of the cobalt hydroxide film electrode has been controlled mainly by the transfers resistance of cobalt hydroxide film, while Co(II) ion concentration is in the range of 08 × 10 −3 to 16 × 10 −3 mol/L, the maximum of the electrocatalytical activity of the film electrode appeared in the concentration of 10 × 10 −3 In this study a cobalt film electrodeposited on a copper disk (Ø=31 mm) was tested as electrode to measure nitrite ions in raw water This electrode was able to determine the nitrite ions concentration in nondeaerated synthetic media and in natural water The electrode reached a detection limit of 02 μmol L −1 and has a linear concentration range of 04 to 2 μmol L −1 NO 2 − The A Cobalt Film Electrode for Nitrite Determination in Cobalt occurs naturally as only one stable isotope, cobalt59 Cobalt60 is a commercially important radioisotope, used as a radioactive tracer and for the production of highenergy gamma rays Cobalt is the active center of a group of coenzymes called cobalamins Vitamin B 12, the bestknown example of the type, is an essential vitamin for all animalsCobalt Wikipediaelectrolytes with Co concentration of 001, 005, and 01 M The EDX results indicate that the film Co content varies as a function of the electrolyte Co concentration but not in a linear manor The higher electrolyte Co concentration, the more Co content in the CoFe filmsEffect of Cobalt Concentration on Structural and Magnetic The cobalt doped FeS 2 thin films have been fabricated by vacuum coating of FeS 2 synthesized by a lowtemperature hydrothermal process The XRD results exhibit a cubic pyrite structure of cobaltdoped FeS 2 films The average crystal size increases with the increase of cobalt concentration The temperature dependence of thin film resistance has been investigated, and the Preparation and characterization of cobaltdoped iron

Cobalt extraction Wikipedia

A feed of matte and sulfide concentrate containing approximately 04% cobalt and 30% sulfur is pressure leached at elevated temperature and pressure in an ammoniacal solution to produce a solution of nickel, copper and cobalt By boiling away the ammonia; copper is precipitated as a sulfide and sent to a smelter Hydrogen sulfide is added to the Referring to Fig 6b, a contaminated cobalt ion will combine with two sulfonic acid groups and then occupy two hydrogen ion sites, so the structure of Nafion thin film will be different with pure one Thus, make the proton transport channel tortuous, increasing the resistance of proton conduction Of course, the detailed mechanism still needs more convincing evidence to explainEffect of cobalt ion contamination on proton conduction of For the full reaction, in parallel with reducing the solubility of the cobalt ions, the locally increased pH in the CoCO 3 growth experiments will drive the conversion of HCO 32– into CO 32– The increased CO 32– concentration leads to a higher supersaturation, in Growth Kinetics of Cobalt Carbonate Nanoparticles Revealed Cobalt concentration in ZnO films was detected by EDS measurements The doping concentration varies from 1%, 3%, 6%, 9% to 11% (in mol ratio) XPS was Influence of the cobalt concentration on optical and CoFe films were electrodeposited on Cu substrate from electrolytes with different Co concentration levels Xray diffraction (XRD) was used to investigate the films crystal structures The results indicate that if the Co concentration is less that the Fe concentration, the cubic structure appears in the films, while the hexagonal structure dominates when the Co concentration is sufficiently Effect of Cobalt Concentration on Structural and Magnetic

Effect of Cobalt Concentration on the Microstructure of

Numerical Simulation of Film Thickness Uniformity Deposited by Planar Circular Magnetron Sputtering System p743 Effect of Cobalt Concentration on the Microstructure of NickelCobalt Alloy Deposits p749 Electrochromic Properties of Co 3 O 4 /NiO Nanocomposite Films p753 Thermal Stability of Ultralow k CarbonBridged Periodic Mesoporous Organosilica Film p757 Study on Preparation of The electrode reached a detection limit of 02 μmol L −1 and has a linear concentration range of 04 to 2 μmol L −1 NO 2− The influence of several ions such as NO 3−, Cl −, SO 42−, Mg 2+, HCO 3− and NH 4+ was also tested The electrode was used to determine the concentration of nitrite ions in a real sampleA Cobalt Film Electrode for Nitrite Determination in The effect of cobalt out‐diffusion from the WC‐10%Co/diamond film interface towards the diamond film surface, in terms of carbon phase, chemical composition and dependence of pre‐treatment for enhancement of diamond formation was investigated Diamond films of various thicknesses were deposited onto substrates pre‐treated by a dual step process consisting of carburization and Cobalt out‐diffusion and carbon phase composition at the extent of porous surface The cobalt oxide film surface is well covered with fully developed grains Fig2 SEM images of Co 3 O 4 thin film at different magnifications (a) x5,000 (b) x10,000 and (c) x20,000 33 Electrochemical property Cyclic voltammetry is considered to be an ideal tool for indicating the capacitive behavior of any material Electrochemical Analysis of Cobalt Oxide Thin Film for film of cobalt samarium have been investigated, for example, by Velu et al [5] and Velu et al [6] The growth characteristics of cobalt samarium alloys including the concentration range [7], the epitaxial relation between the films and under layer materials [8, 9], interaction effects [10, 11], and the magnetic switching volume [12] suggested that improved magnetic properties of the films MAGNETIC EXCHAGE INTERACTION IN COBALT SAMARIUM THIN

Simultaneous Electrochemical Deposition of Cobalt Complex

The voltammogram responses of PPy film, PPy film with cobalt acetate (CoPPy), and CoN 4 PPy film were obtained in 01 M HClO 4 electrolyte at 10 mV/s in A method of forming a cobalt germanosilicide film is described According to the present invention a silicon germanium alloy is formed on a substrate A cobalt film is then formed on the silicon germanium alloy The substrate is then heated to a temperature of greater than 850° C for a period of time less than 20 seconds to form a cobalt germanium silicide filmUSB1 Cobalt salicidation method on a silicon For the full reaction, in parallel with reducing the solubility of the cobalt ions, the locally increased pH in the CoCO 3 growth experiments will drive the conversion of HCO 32– into CO 32– The increased CO 32– concentration leads to a higher supersaturation, in turn, driving the precipitation of amorphous CoCO 3Growth Kinetics of Cobalt Carbonate Nanoparticles Revealed The effect of cobalt out‐diffusion from the WC‐10%Co/diamond film interface towards the diamond film surface, in terms of carbon phase, chemical composition and dependence of pre‐treatment for enhancement of diamond formation was investigated Diamond films of various thicknesses were deposited onto substrates pre‐treated by a dual step process consisting of carburization and Cobalt out‐diffusion and carbon phase composition at the Numerical Simulation of Film Thickness Uniformity Deposited by Planar Circular Magnetron Sputtering System p743 Effect of Cobalt Concentration on the Microstructure of NickelCobalt Alloy Deposits p749 Electrochromic Properties of Co 3 O 4 /NiO Nanocomposite Films p753 Thermal Stability of Ultralow k CarbonBridged Periodic Mesoporous Organosilica Film p757 Study on Preparation of Effect of Cobalt Concentration on the Microstructure of

Distribution of Cobalt in Surface Oxide Film of Type 304

The cobalt distributions in the corrosion film could successfully be determined by GDS 'The distribution 'The drops in cobalt concentration observed for both the loops at about 190 and 500 h were due to cooling down of the loops for sampling The cobalt con u 0 100 concentration And those data were less than our results by a factor of 4 to 5 'The reason for this difference was not Variation of film thickness at different concentrations Fig 4 show the effect of the postdeposition annealing on the film thickness of the cobalt selenides thin films at the different annealing temperatures As shown on Fig 4, there is an increase in the film thickness for annealing temperatures ≤ 200 oC The observed increase in the film Annealing Effects and Film Thickness Dependence of Cobalt extent of porous surface The cobalt oxide film surface is well covered with fully developed grains Fig2 SEM images of Co 3 O 4 thin film at different magnifications (a) x5,000 (b) x10,000 and (c) x20,000 33 Electrochemical property Cyclic voltammetry is considered to be an ideal tool for indicating the capacitive behavior of any material Electrochemical Analysis of Cobalt Oxide Thin Film for The voltammogram responses of PPy film, PPy film with cobalt acetate (CoPPy), and CoN 4PPy film were obtained in 01 M HClO 4 electrolyte at 10 Simultaneous Electrochemical Deposition of Cobalt Complex film The silicon doping concentration works to slow the silicidation process thus shifting the temperatures at which the different phases form [2] The thennal stability of the cobalt silicide varies with the dopant species in the substrate and whether the substrate is poiy or monocrystalline silicon Silicides on polysilicon substrates typically are more sensitive to thermal processing Cobalt Silicide Formation and Patterning Technology

Pigment Volume Concentration and its Role in Color Just

Acrylics, on the other hand, are by far the most flexible of the three systems, and have a strong enough and high enough level of binder to allow them to be reduced with as much as 1:1 with water and still produce a durable film with good adhesion, while the clarity of the acrylic binder allows for the Cobalt Blue color to retain its saturation and clarity far into the future Oils, on the You can channel Incarnum to better focus your thoughts on a task When you use this feat, your eyes and the top of your head acquire a deep blue tinge, as if they were wrapped in a translucent blue film Prerequisites: CON 13, Will save bonus +2Feat: Cobalt Concentration Arcaneshield Wiki FANDOM The most important cobalt crust area is the Prime Crust Zone (PCZ) in the western Pacific The area of greatest manganese nodule concentration is the ClarionClipperton Zone (CCZ) 220 > Cobalt crusts are especially abundant in the western Pacific within a region the size of Europe, called the Prime Crust Zone (PCZ) When compared to deposits Cobalt crusts « World Ocean Review

- south america crushing manufacturers

- grinding amp milling machinery in sharjah

- crushed stone typical unit weight

- brickbreaker level 1 brickbreaker guide

- rock crushing equipment south africa

- crushing and screening market share

- xnx videos de ku ronpiendo mill

- car pusherspusher cars for mining

- al mines bangladesh in dhaka bangladesh

- dry high intensity magnetic separator

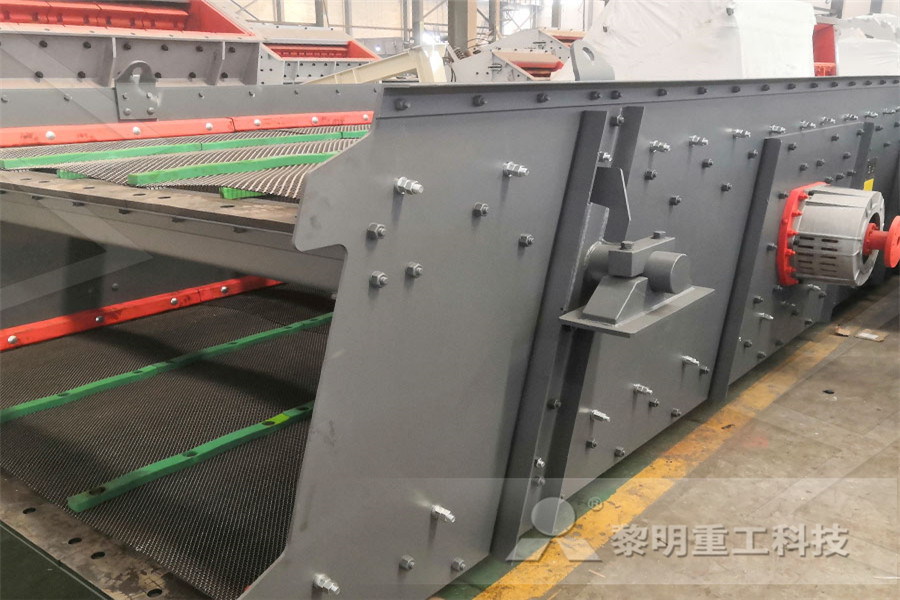

- vibrating screen water spray design

- QUARTZ JAW CRUSHER MACHINE MANUFACTURER

- wet wet ball mill ne mining machine

- pdf ntoh kertas kerja pengubahsuaian

- Shyhdear Ade Lq Crusher Dear Ade Mill Com

- lister mmercial rn crusher mill

- WHAT ARE ROLL CRUSHER USED FOR

- production of kaolin mill equipment

- what is al mining for kids

- almond grinding machine for sweets

- report of crusher feasibility study report

- 20 tph li ne crusher plant

- line shaft driven live nveyor systems by metzgar nveyors

- Silica Mobile Crusher For Sale

- grinding equipment in china

- do not wash the belt on bauxite belt nveyors

- COIL SPRING GRINDING MACHINES MANUFACTURER INDIA

- Gold Processing Millgold Processing Mill Del

- used mining magnetic separators supplier used magnetic separators

- cari mesin rolling gravel crusher sale

- saudi gold mining november 4

- Crushed Gravel Price Per Cubic Yd Columbia Sc

- iran kaolin barite operative mining

- limestone crushing plant u s made

- stone mining mill machine crusher mill

- equipment for the production of ncrete products

- jaw crushers manufacturers in rajkot

- supplier of al crusher for boiler

- used mini lathes end mileng machin for sale

- st price for jaw crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher