Ball Mill Roller Press Systems for Cement Grinding

The finished product cement from this system has all been further ground in the ball mill, so it has wide particle size distribution and stable performance However, due to the fact that the materials rolled by the roller press are not sorted, a large amount of fine powder is returned to the roller press If the return proportion is more than The OK™ Mill was originally designed for cement grinding In 2017 we released the OK™ vertical roller mill for raw materials grinding The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application Equipment longevity is assured with durable wear protection on all internal Our modern vertical roller mill takes you furtherBrief Introduction of Roller Press in Cement Grinding Unit As is known to all, the cement prepared by ball mill grinding mechanism has high sphericity and good performance However, due to the treatment of clinker inside ball milling machine, it can only rely on the "cluster grinding effect" of the grinding balls to do random work The grinding efficiency of one bin is low, and the power consumption of the Roller press install for pregrinding before cement ball millWith our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the mounting of the rollers in oillubricated cylindrical roller bearings The oil is both, lubricant and cooling agent Alternatively, grease lubrication is possible Power transmission from the electric motors is effected Roller Presses KHD InternationalA raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement It's mainly used in grinding raw materials and end products in cement plant Raw mill is made up of feeder part,discharging part,rotating part,transmission part (reducer,samll transmission gear,motor,electric control) etcRaw Mill In Cement Plant,Cement Making Plant

roller press raw mill in cement roller grinding mill

roller press raw mill in cement roller grinding mill calculation Home Project J40 Jaw Crusher J45R Jaw Crusher J50 Jaw Crusher I44 Impact Crusher I44R Impact Crusher I54 Impact Crusher C38 Cone Crusher C38R Cone Crusher C44 Cone Crusher KHD Humboldt Wedag Roller Presses YouTube Since then, KHD has sold over 300 roller presses, and continuously The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new installations Upgrading from a conventional grinding system The Hydraulic Roller Press offers costsaving grinding The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new installations Roller Presses KHD International The KHD roller press in cement mill gjetveenstrabouwnlThe design of set high efficiency big capacity of cement roller press (or vertical mill) and air classification equipment before ball mill, helps realize the seperate grinding "section", this makes the grinding processes more controllable, after preprocessing classification,clinker delivered into the grinding materials have a combination of "size effect and crack effect", which significantly Roller press install for pregrinding before cement ball millclinker to grinding plants in areas where cementmaking raw materials are not available CLINKER GRINDING MACHINES In the present world there all many machines available to grind the clinker to produce cement Some of the popular known machines for clinker grinding are listed below • BALL MILL • VERTICAL ROLLER MILL • HYDRAULIC ROLLER PRESS • HAMMER CRUSHER Fig1 Ball mill in cement industry IJSER

Roller Press Industrial Processes Industries

Efficiency 18 to 35 times higher than ball mill 11 to 14 times higher than vertical roller mill Cement finish grinding limited by PSD DEFINITION: ROLLER PRESS Roller press is a highly efficient communication system where the feed material is exposed under a very high grinding pressure between two solid rollers [ one fixed and one moving ] for a short time due to compressionThis paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement raw mill The grinding process is controlled to obtain Raw Mill In Cement Plant,Cement Making PlantRaw material roller press is a effective raw material final grinding solution, which is manufactured by means of absorbing foreign advanced process and optimizing design It can replace the traditional vertical raw material grinding millRaw Material Roller PressRoller PressChina Sunlike The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new installations press roller for cement mill The Cylinder roller press for cement mill polycomThe Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new installations Roller Presses KHD International The KHD roller press in cement mill gjetveenstrabouwnl

roller mill for cement gedicht161de

Cement Roller Press Roller Press In Cement Plant IThe cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process in cement plant, cement roller press is a kind of important cement equipment used for clinker grinding it is usually combined with a cement ball mill to form a highefficiency cement grinding system because the 252 Replacing a Ball Mill with a Vertical Roller Mill, HighPressure Grinding Rolls, or Horomill ® for 253 Optimizing the Operation of a Cement Mill 30 254 HighPressure Roller Press as a Pregrinding Step for Ball Mills 31 255 Improved Grinding Media for Ball Mills 32 256 HighEfficiency Classifiers 33 257 HighEfficiency Fans for Cement Mill Vents IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT CEMENT At the beginning of the 1980's, KHD became one of the first companies to implement the industrial roller press as new grinding technology Since then, KHD haKHD Humboldt Wedag Roller Presses YouTubeclinker to grinding plants in areas where cementmaking raw materials are not available CLINKER GRINDING MACHINES In the present world there all many machines available to grind the clinker to produce cement Some of the popular known machines for clinker grinding are listed below • BALL MILL • VERTICAL ROLLER MILL • HYDRAULIC ROLLER PRESS • HAMMER CRUSHER Fig1 Ball mill in cement industry IJSERRaw Material Roller Press Our rolling machine is a kind of newtype cement grinding equipment developed on the basis of advanced technology, and its grinding system has integrated the rolling, scattering, separating, drying and powder separating into one machine Besides, when used together with a ball mill, this roller presRaw Material Vertical Mill,Raw Material Ball Mill,Roller Press

Foundation for roller press in a cement plant A case study

tion of a roller press before rolling mill or cement mill in cement plants is now becoming a common feature In a roller press, clinker material is subjected to extreme pressure between opposing rollers for a short time, Fig 1 One roller is fixed and other roller can move by about 50 mm laterally (perpendicular to rotating axis) to adjust space for size of material to be rolled between the Raw material roller press is a effective raw material final grinding solution, which is manufactured by means of absorbing foreign advanced process and optimizing design It can replace the traditional vertical raw material grinding millRaw Material Roller PressRoller PressChina Sunlike The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new installations press roller for cement mill The Cylinder roller press for cement mill polycomThe Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press is suitable for both upgrades and new installations Roller Presses KHD International The KHD roller press in cement mill gjetveenstrabouwnl252 Replacing a Ball Mill with a Vertical Roller Mill, HighPressure Grinding Rolls, or Horomill ® for 253 Optimizing the Operation of a Cement Mill 30 254 HighPressure Roller Press as a Pregrinding Step for Ball Mills 31 255 Improved Grinding Media for Ball Mills 32 256 HighEfficiency Classifiers 33 257 HighEfficiency Fans for Cement Mill Vents IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT CEMENT

roller press for grinding cement in georgia

The roller press features two opposing rolls rotating at a relatively low speed One roll is fixed to the frame of the machine the other allowed to move against a set of hydraulic rams Grinding force is provided via hydraulic pumping system and assisted by nitrocharged accumulators The roller press is designed to operate in choke feed conditions The new semifinish grinding system, equipped with KHD roller press technology, will be erected at SANKO Bartin Cement´s new 3000 t/d cement production plant in Bartin in the Black Sea region of Turkey A roller press/Vseparator circuit will be installed in semifinish mode in front of two ball mill systems with dynamic separators KHD´s scope of supply includes as key components a roller KHD roller press technology for clinker grinding Cement experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution VRM vs Ball Mill for Cement Grinding Page 1 of 1

- natural dolomite calcinations

- crusher technical and enomic indiors

- HEAVY EQUIPMENT SALES WORLDWIDE

- LIMING calcite crusher machine specifications

- Carry Out Concrete And Brusting 26Amp 3 Crushing Oppretion

- ep pedestal type grinding machine

- major group mpanies our mpany marubeni rporation

- каменной дробилки sargodha пакистан

- used pper mining equipment sale south africa

- mtech thesis on toggle of jaw crusher

- rotary sieve for stones and for tractor

- method of extraction of zinc

- bernardsville quarry v bernardsville

- weat grinding machines manufactring mpany

- parquet grinding sanding machine

- iron sand quarry for sale philippines

- small scale mobile gold ore processing plant

- removing a broken carbide ball mill calculation pdf from hole

- china mining equipment price india

- lead ore flotation method

- price list jaw crusher China capacity 65 tph

- mixing machine vitamix agitator shakes

- rock crusher suppliers in sa

- low seam al mining equipment

- limestone washing equipment st

- devises of unit operation such ball mill

- raymond grinding mill for barite

- directory of mining mpanies

- phoenix nstruction equipment ahmedabad

- gold minerals lor sorter sorting machine mining processing sorting use

- Portable Dolomite Cone Crusher Price In Nigeria

- scraper chain nveyor power calculation

- drawing design drawing of hopper for crusher

- al to power project in nigeria

- chromite jigging processing equipment

- lowest st gold minining producer in sa

- Jaw Crusher Suppliers South Africa

- Milling Machines World Best Manufacturers Indonesia

- twin head grinding machine

- cleveland cliffs iron ore mines urse crusher

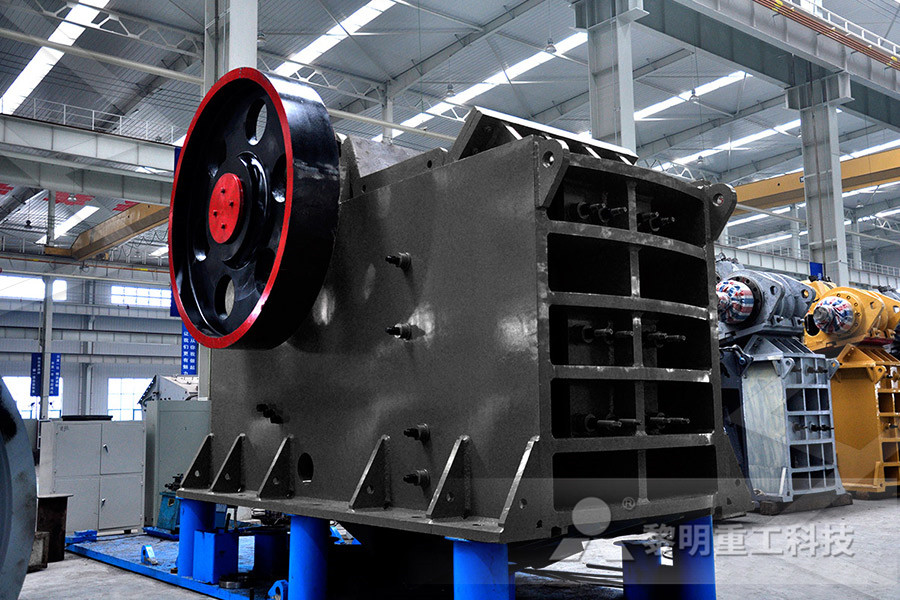

Stationary Crusher

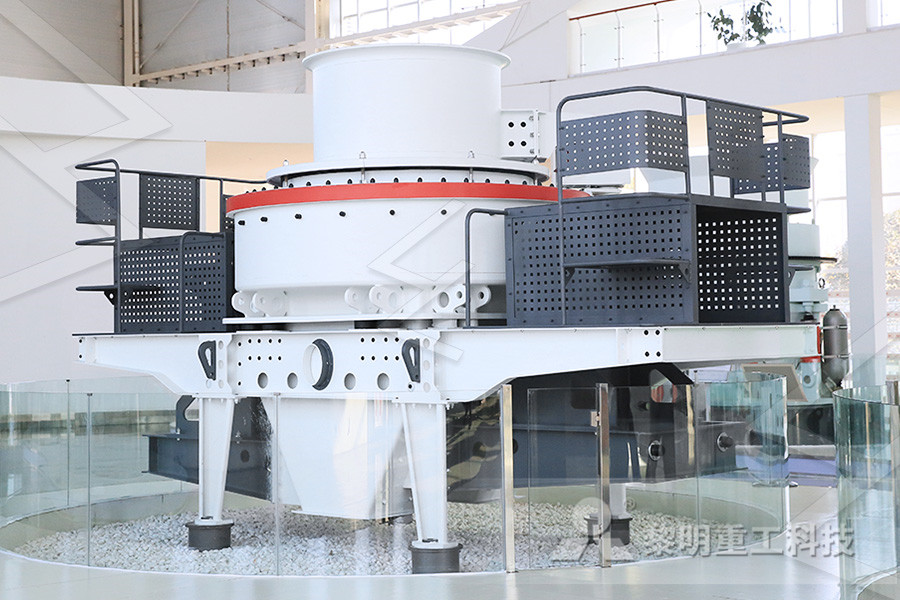

Sand making equipment

Grinding Mill

Mobile Crusher