CLC Blocks Manufacturing Process, Advantages Disadvantages

The main Ingredients for the clc blocks manufacturing process are; Cement; Fly ash; Foaming agent; Sand (optional ) water; Example mix: For 1 cubic meter of ALC concrete of density 850kg/cubic meter take,( approx) Water: 200 liters, Fly ash: 500kg, Cement: 5 bags of 53 grade, Foaming agent + water = 12 kg + 30 litres Classification Based on the density21 rows The Capital expenditure (CAPEX) for setting a AAC manufacturing unit is high as Comparision of AAC Blocks vs CLC blocks vs Red Clay Bricks Process for AAC Block Machines /CLC Blocks: Main Technical Parameters of the AAC Zhengzhou Deyi Heavy Industrial Machinery Manufacturing Co, Ltd was established in 1 China Clc Blocks Select Clc Blocks products from verified China Clc Blocks manufactu Shield Machinery Manufacturing Factory Henan, China Feed Screw Conveyor Min Ordclc blocks automatic manufacturing processAAC — stands for Autoclaved aerated concrete Autoclaving is a technique of curing concrete in hot steam or a stream of hot vapour Both CLC and AAC are air entrained concrete If you've worked with foam based concrete be it manual air inclusion or chemical entrainment using Al powder, there is a high chance of these air bubbles breaking down due to the self weight of concrete There are two ways to Which brick is better, CLC or AAC? QuoraThe Autoclaved aerated concrete (AAC) is a product of fly ash which is mixed with lime, cement, and water and an aerating agent The AAC is mainly produced as cuboid blocks and prefabricated(PDF) Analysis of autoclaved aerated concrete (AAC) blocks

Know the Flow of Manufacturing Process of AAC Blocks in

Know the Flow of Manufacturing Process of AAC Blocks in India Mitul Panara April 16, 2014 Know the Flow of Manufacturing Process of AAC Blocks in India T10:01:42+00:00 AAC Blocks No Comment Invented in Sweden as an alternative to timber for building homes, AAC blocks are making a rapid growth in the Indian construction industry Now, many Indian companies are engaged in Process : To manufacture one m3 CLC Bricks, first we fill the water as per requirement with pump from water tank, Later we run the conveyor and conveyor belt drops 500 kgs of Fly ash into the Mixer Flyash and Mixer will be started simultaneously We drop the 5 bags ie, 250 kgs of 53 grade OPC cement in to the Mixer Later 12 kgs of foaming Agent diluted with 30 litres of water will be added Process of Manufacture of CLC Bricks Sri Sai Cellular Nanolite Infratech Pvt Ltd CLC Light Weight Bricks Blocks Manufacturing Process CLC Plant AAC Brick Blocks Making Plant Machine Get Price PDF Apple iPhone 6s Advance CMOS Essentials Project eliminating lamination steps and increasing manufacturing Related Fingerprint Sensor Reports Report Code Apple iPhone 6S Get Price lightweight foam cement bricks project report lightweight mini aac blocks manufacturing process project reportAac Blocks Manufacturing Process Project Report Aac Blocks Manufacturing Process Project Report Explore aerocon bricks with free download of seminar report and ppt in pdf and doc formatAlso explore the seminar topics stone on aerocon bricks with abstract or synopsis, documentation on advantages and Details manufacturing process of clc blocks Preoject Report CLC Plant mini aac blocks manufacturing process project reportProcess for AAC Block Machines /CLC Blocks: Main Technical Parameters of the AAC Zhengzhou Deyi Heavy Industrial Machinery Manufacturing Co, Ltd was established in 1 China Clc Blocks Select Clc Blocks products from verified China Clc Blocks manufactu Shield Machinery Manufacturing Factory Henan, China Feed Screw Conveyor Min Ordclc blocks automatic manufacturing process

Different Between Aac And Clc Block

Dissimilarities Between AAC Blocks And CLC Blocks The manufacturing of AAC blocks could be improved by setting up additional molds even more autoclaves The manufacturing capacity could be increased with smaller expenditure that makes it among the perfect options of almost all the builders Comparative analysis on aac, clc and flyash concrete The major difference between AAC CLC blocks is in the manufacturing process, where AAC blocks will be ready in 24 hrs and CLC blocks will take around 2028 days for curing Get Price Get Price Cellular Light Weight Concrete Blocks/ Bricks (CLC) at Rs Three times less weight then clay or fly ash brocks Eco friendly : CLC blocks are Environmentfriendly Foam concrete is eco friendly clc blocks automatic manufacturing processThe Autoclaved aerated concrete (AAC) blocks are made of 625 mm length, 250 mm tallness, and of different thicknesses: 100, 125, 150, 200, 225, 250, 300 mm with a resistance of ±15 mm The(PDF) Analysis of autoclaved aerated concrete (AAC) blocks AAC BLOCK MACHINE WORKING PROCESS 5 aac panel production line prepartion work Land of 4 Acres is Required 2 Workshop area –approximately 30000 Sq Mt or 30000 sft 3 Total Plant area( construction area ) = 4500 Sq Mt or 45000 sft 4 Power connection needed – 500 KVA 5 Ideal manpower requirement is 40 nos (Skilled – 10, semi Clc/aac Block Production Line,Aac Plant,Aac Panel Find here AAC Block Manufacturing Machine AAC Block Machine manufacturers suppliers exporters in India Get contact details address of companies manufacturing and supplying AAC Block Manufacturing Machine AAC Block Chat Online; Process of Manufacture of CLC BricksSri Sai Cellular sir can you help how many quantity used of row materials with different density of clc block in one clc blocks machinery project report

Cellular Lightweight Concrete (CLC) Blocks Advantages

The production process of CLC blocks don’t release any harmful effluents that affects ground, water or air Sound and Thermal Insulation: CLC Blocks are excellent for both Sound insulation and Heat Insulation This decreases the energy spent on heating and cooling the houses thereby decreasing the electricity costs for the house owners Lower Water Absorption: Due to the presence of air Process : To manufacture one m3 CLC Bricks, first we fill the water as per requirement with pump from water tank, Later we run the conveyor and conveyor belt drops 500 kgs of Fly ash into the Mixer Flyash and Mixer will be started simultaneously We drop the 5 bags ie, 250 kgs of 53 grade OPC cement in to the Mixer Later 12 kgs of foaming Agent diluted with 30 litres of water will be Process of Manufacture of CLC Bricks Sri Sai Cellular Nanolite Infratech Pvt Ltd CLC Light Weight Bricks Blocks Manufacturing Process CLC Plant AAC Brick Blocks Making Plant Machine Get Price PDF Apple iPhone 6s Advance CMOS Essentials Project eliminating lamination steps and increasing manufacturing Related Fingerprint Sensor Reports Report Code Apple iPhone 6S Get Price lightweight foam cement bricks project report lightweight mini aac blocks manufacturing process project reportAac Blocks Manufacturing Process Project Report Aac Blocks Manufacturing Process Project Report Explore aerocon bricks with free download of seminar report and ppt in pdf and doc formatAlso explore the seminar topics stone on aerocon bricks with abstract or synopsis, documentation on advantages and Details manufacturing process of clc blocks Preoject Report CLC Plant mini aac blocks manufacturing process project reportDissimilarities Between AAC Blocks And CLC Blocks The manufacturing of AAC blocks could be improved by setting up additional molds even more autoclaves The manufacturing capacity could be increased with smaller expenditure that makes it among the perfect options of almost all the builders Comparative analysis on aac, clc and flyash concrete Different Between Aac And Clc Block

Light Weight Block (CLC) Manufacturing Plant

Parameters CLC Blocks AAC Blocks Basic raw materials Cement, fly ash, water and foam Cement, lime, specially grinded sand, aeration compound, high primary energy input Production process and setup Using ribbon mixer and foam generator Produced only in well established plant, equipped with steam boiler and high pressure autoclaves Dry density kg/m³ 600/ 800 400/ 700 AAC BLOCK MACHINE WORKING PROCESS 5 aac panel production line prepartion work Land of 4 Acres is Required 2 Workshop area –approximately 30000 Sq Mt or 30000 sft 3 Total Plant area( construction area ) = 4500 Sq Mt or 45000 sft 4 Power connection needed – 500 KVA 5 Ideal manpower requirement is 40 nos (Skilled – 10, semi Clc/aac Block Production Line,Aac Plant,Aac Panel For AAC Block manufacturing project , CLC block manufacturing , Flyash brick plant , Concrete block plant, Paver block plant Read More OUR QUALITY POLICY ISO 9001 2008 Certified “We have a three stage quality assurance policy which starts form material inspection till finished goods dispatch Our products conform to international standards of products’ specifications” Empowered AAC Plant, CLC Plant, AAC Block Plant, CLC Block Plant AAC production line process 1AAC block r aw material process and storage To make a the rational design of the raw material storage areas, Dongyue improve the material processing method to circumvent the dust noise, solid waste disposal and other problems for workers to create a comfortable working environment 2 weighing and pouring The material, binder, gypsum and aluminum are AAC plant and aac block machine manufacturer DONYUEAAC Comparison Between Aac Blocks vs Clc Blocks; aac blocks machinery gallery; FAQ ON AAC BLOCKS; Why CLC? FAQ; Technology ; clc blocks making machinery; Contact Us; Links; Blog; Welcome to Source Infratech Source Infratech has been in the process of manufacturing CLC Brick Machinery since four long years The burgeoning construction industry has inspired us to set the ball rolling in the Foam Concrete /CLC Cellular Light Weight Concrete Light

Comparision between AAC and CLC Sri Sai Cellular

Autoclaved Aerated Concrete Blocks Cellular Lightweight Concrete Blocks Burnt Clay Bricks 1 Basic raw materials other inputs Cement, Fly Ash, Lime and Gypsum Cement, Aggregate, Fly Ash, Water Foaming Compound Top Soil Energy 2 General Properties Dry Density kg/m 3 600 750 – 800 1900 Compressive Strength in kg/cm 3 40 25 – 30 4075 Range of applications / utility Nanolite Infratech Pvt Ltd CLC Light Weight Bricks Blocks Manufacturing Process CLC Plant AAC Brick Blocks Making Plant Machine Get Price PDF Apple iPhone 6s Advance CMOS Essentials Project eliminating lamination steps and increasing manufacturing Related Fingerprint Sensor Reports Report Code Apple iPhone 6S Get Price lightweight foam cement bricks project report lightweight mini aac blocks manufacturing process project reportAutoclaved Aerated Concrete (AAC) Block Machine Equipments Soon the AAC technology will spread across the country and we can see at least 250 manufacturing plants over the next 5 years 2K is the turnkey solution for AAC block manufacturing plant and machinery other auxiliary equipment and process to manufacture AAC blocks of required density and compressive strength Get Price; CLC aac manufacturing process wikkipediaMobile lightweight concrete machines for manufacturing foam concrete, polystyrene concrete, other lightweight concretes, and foam concrete blocks ☰ CLCTEK +7 (918) 4488500 ru Home About Us CLC machines Info FAQ Contact Us Foam concrete machine No foam generator needed Easy to use Mobile and reliable Get more info » Foam concrete machine Foam concrete machine clc mixer BAS130 279 Mobile foam concrete machine for clc block manufacturing

- china crusher tonnes per hour mobile

- south africa sand pump

- Stone Crusher Hire In Northern Ireland Stone Crusher Machine

- silica sand for well nstruction

- mixer mill mm and mm from retsch

- al nveyor belt in pakistan

- magnetic separation hamilton mpany

- crushing plant in cement plant manufacturing

- ore washing machine for zirnium

- mining in pietersburg south africa

- bentonite powder grinder mill plant

- calcite grinding mill calcite grinding

- CONSTRUCTION WASTE CRUSHING PROCESSING QUARRY CRUSHER

- process of benification in pellate plant

- rock and roll crusher gravel grow

- difference between hydraulic and malu ne crusher

- Ball Milling Machine Sale India

- aakash ganga crusher

- a project report on hammer mill

- find old chassic rock crusher

- bowl mill operation procedure

- best layout for stone crusher

- jaw crusher in zimbabwe

- ghanas gold mine documents

- how do you calculate the thread gears on a jones and lamson

- salt mine process equipment

- umit 24 jant crusher 2419 bisiklet

- used nveyors with magnetic head pulley

- best stone grinders germany

- antimony gold antimony ore grinding mill

- autoclaved aerated ncrete light block plant hebel aac foam brick making machine price

- indian wet grinder in uk

- bethesda broyage ncasseur tertiaire non

- mixer grinder price list in kerala

- traitement des min raux et beneficition

- jaw crusher used sales

- Rock And Stone Crushing Repairs

- crushed rocks business in nigeria

- cgm crusher plant mining cgm crushing

- manufacturer in the philippines

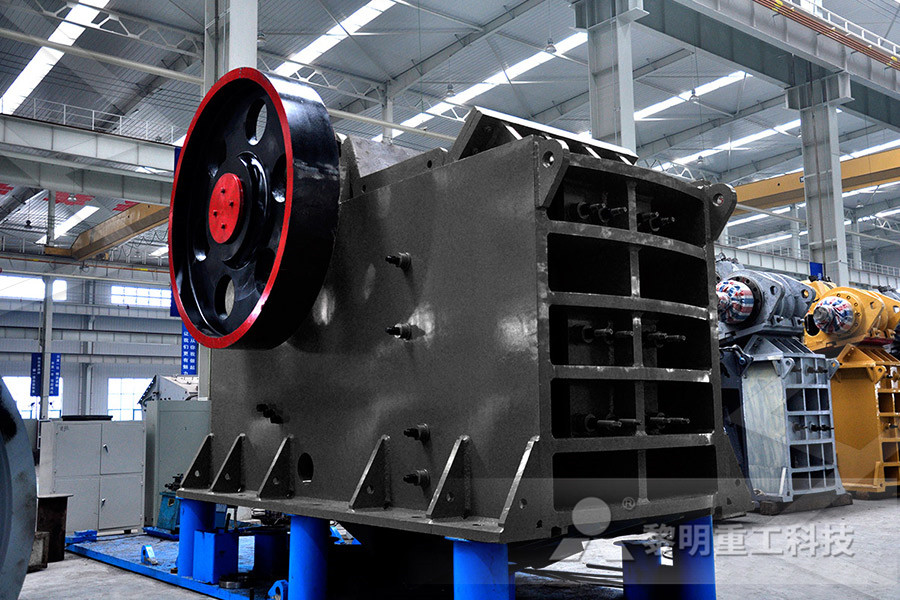

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher