My Lathe: Threading Gears Calculator

Threading Gears Calculator Whilst trawling around the net I came across a really useful utility on a Blog written by lathnovice Where this utility varied from the others I found was that it came at the problem from the other direction, instead of entering your gear configuration and seeing what the TPI or pitch was you could enter your gears and the pitch or TPI and it then calculated the NOTE: Helix Angle has to be calculated if you are going to grind threads The reason is that if the grinding wheel head is not rotated to the same as the lead angle the thread will have either a drunken lead or a zero lead, both of which are unacceptable Things to Remember When Cutting Threads on a THREAD CALCULATIONS Amarillo CollegeTo find the correct chart, select the size chart desired, magnification, and type thread At the intersection of the magnification and type of thread columns in the chart size section chosen, the correct CXmaster number will be found The addition of the pitch desired as a Screw Thread Charts Optical ComparatorStep1 : Calculate GearRatio between Gear1 and Gear2 (Driver and Idler) GR(12) = 20/40 = 0 5 Step2 : Calculate GR in between Gear2 and Gear3 (Idler and Driven Gear) GR(23) = 10/20 = 0 5 Step3 : By Multiplying gearratio between 1 to 2 and 2 to 3 We will get resultant GR between Driver and Driven Gear Resultant Multi Gear Train GR = 0 5 × 05 = 025 From the above calculated Gear Train : Gear Ratio, Torque and Speed Calculations Input any thread you want and it will calculate what gears are needed and their positions and print it if needed It will also calc what gears are missing if you cant get the thread you want When setting up, select generic lathe, and when all your ratios are entered go back to that same place and "save" It will keep all for youchange gears and threading calculator The Home Machinist!

Chart for threads posible with all the gear combinations

Set the threading to a known imperial or metric thread Take up slack, zero indicator, and rotate the spindle the right number of times Check between indicator and surface with whatever precision object you have distance rod, mike standard, gage block, 1 2 3, parallel(Do NOT read this as newtons per meter, which would indicate division, but the hyphenated term newtonmeters, or better still, newtonmeters, indicating that it is a product) So, given a force and a moment arm (distance), we can use the above formula to compute the resulting torque For example, referring to Diagram 1, if we are given that the force F is 20 newtons and the radius d is 3 CORC 3303 – Exploring Robotics Supplemental notes on gear Jones, Lamson Co evolved from the historically important Robbins Lawrence Co, early innovators in the "American system" of massproducing riflesRobbins Lawrence failed in 1856, and in 1861 their works were purchased by Lamson, Goodnow Yale, which reorganized as E G Lamson Co in 1864 and again in 1865 as the Windsor Manufacturing Co In 1869 the works were purchased by Jones Jones Lamson Machine Co History Now since you're tying up the end gearing with your change gears, you will have a tough time finding room for the metric transposing compound gear, and the 3:2 compound gear, AND the normal change gears used for 20 TPI You can get around this by leveraging the stud gear If the normal stud gear has an even # of teeth, just go 50% higher and this takes care of the 3:2 Or, you can Cutting metric threads with change gears Threading Gears Calculator Whilst trawling around the net I came across a really useful utility on a Blog written by lathnovice Where this utility varied from the others I found was that it came at the problem from the other direction, instead of entering your gear configuration and seeing what the TPI or pitch was you could enter your gears and the pitch or TPI and it then calculated the My Lathe: Threading Gears Calculator

THREAD CALCULATIONS Amarillo College

NOTE: Helix Angle has to be calculated if you are going to grind threads The reason is that if the grinding wheel head is not rotated to the same as the lead angle the thread will have either a drunken lead or a zero lead, both of which are unacceptable Things to Remember When Cutting Threads on a Step1 : Calculate GearRatio between Gear1 and Gear2 (Driver and Idler) GR(12) = 20/40 = 0 5 Step2 : Calculate GR in between Gear2 and Gear3 (Idler and Driven Gear) GR(23) = 10/20 = 0 5 Step3 : By Multiplying gearratio between 1 to 2 and 2 to 3 We will get resultant GR between Driver and Driven Gear Resultant Multi Gear Train GR = 0 5 × 05 = 025 From the above calculated Gear Train : Gear Ratio, Torque and Speed Calculations To find the correct chart, select the size chart desired, magnification, and type thread At the intersection of the magnification and type of thread columns in the chart size section chosen, the correct CXmaster number will be found The addition of the pitch desired as a Screw Thread Charts Optical ComparatorIn order to obtain pz, determine da by measuring the tip diameter Then by using a piece of paper and with ink on the outside edge of a helical gear, roll it on the paper pressing it tightly With a protractor measure the angle of the mark left printed on the paper, βa Lead pz Determining the Specifications of Gears KHK Gears Input any thread you want and it will calculate what gears are needed and their positions and print it if needed It will also calc what gears are missing if you cant get the thread you want When setting up, select generic lathe, and when all your ratios are entered go back to that same place and "save" It will keep all for youchange gears and threading calculator The Home Machinist!

4 Easy Ways to Determine Gear Ratio (with Pictures)

Then, divide the number of teeth on the driven gear by the number of teeth on the drive gear to get the gear ratio For example, if the drive gear has 20 teeth and the driven gear has 30 teeth, the gear ratio is 15 If you want to learn how to use the gear ratio to calculate the gears' speeds, keep reading the article!(Do NOT read this as newtons per meter, which would indicate division, but the hyphenated term newtonmeters, or better still, newtonmeters, indicating that it is a product) So, given a force and a moment arm (distance), we can use the above formula to compute the resulting torque For example, referring to Diagram 1, if we are given that the force F is 20 newtons and the radius d is 3 CORC 3303 – Exploring Robotics Supplemental notes on gear Metric thread calculator to calculate external and internal metric thread dimensions including major diameter, minor diameter, pitch diameter and thread tolerance according to ISO 724 and ISO 965 standards There are two calculation options available, general engineering use or custom use In general engineering use, calculations can be done by selecting a standard metric thread size in a METRIC THREAD DIMENSIONS CALCULATOR Amesweb Now since you're tying up the end gearing with your change gears, you will have a tough time finding room for the metric transposing compound gear, and the 3:2 compound gear, AND the normal change gears used for 20 TPI You can get around this by leveraging the stud gear If the normal stud gear has an even # of teeth, just go 50% higher and this takes care of the 3:2 Or, you can Cutting metric threads with change gearsYou can calculate gain ratios, gear inches, or meters development with my Online Gear Calculator or with your Slide Rule Gear Shifting For beginner or intermediate cyclists Everything You Wanted To Know About Shifting Your Bicycle's Gears, But Were Afraid To Ask This is an introduction to gear shifting, and the basics of how a derailer works How, why and when to shift gears Derailer Articles about Gears and Drivetrains

Ring Size Guide How to Best Measure Your Enso Rings

If a ring size chart shows that you fall between two numbers, we recommend that you order the smaller size Here’s why : In our experience, silicone rings relax after a few days of wear If you order a size up, you may find that your ring may seem to be the perfect size when you first start wearing it, only to become loose after a couple of daysA screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread A screw thread is the essential feature of the screw as a simple machine and also as a Screw thread WikipediaI'll calculate the best chainring/cog combinations and skid patches for your speed and cadence and what your speed will be at various cadencesBikeCalc Fixed Gear Calculator You have your top thread and your bobbin thread pulling on each side If they’re both pulling equally, the seam will be even and consistent If one side is pulling too much, the thread from the other side will be visible If the bobbin thread shows on the top side of the seam and the top thread is straight, the upper tension is too tight If top thread shows on the underside of the seam and How to Adjust the Tension on a Sewing Machine: 13 StepsJen Underdahl, Visual Effects Producer for Marvel Entertainment, provides WIRED with an indepth look at the most impressive visual effects featured in AvengHow Avengers: Endgame's Visual Effects Were Made WIRED

Machine Tool Repair Service for AmericanMade Machine Tools

Jones Lamson We are your OEM source for replacement parts on all makes and models of Jones Lamson lathes and thread grinders We also offer manuals and diagrams, and technical support We stock all common replacement parts for JL machines and have the ability to manufacture any part on your machine to OEM specifications We are Jones All This Thread Reviews Gear Database Gear for sale You do some research to find the pressure magnitude of these events and start building your graph, with the event on the horizontal axis and the pressure magnitude on the vertical axis The horizontal axis is easy: four tick marks, each representing one of the events But for the vertical axis, you realize you have a problem: the understanding dBV, dB, dBFS, dBSPL Gearslutz Do this on both gears and you will retain full face contact I have found case depths on gears to vary a lot It is partly a function of the tooth thickness, the case must be less than 1/3 of the thickness of the tooth to retain tooth core stength The dogs I have undercut did not break throu the case, after taking of 0040" at the deepest point I ewould be surprised if the case is less than Undercutting the dogs on gears in a motorcycle gearboxJones is a solid distributor Reminds me a bit of Matt Ryan in the NFL who does better with great WRs when there is no pass rush than most others But when it comes to a pass rush, Jones seemingly Let’s go ahead and get this party started!!! Dawgs and

- what is bandit grinding palm tree

- scrap pper crushing machine in india

- gold ore cyclone to separate

- grinding powder machine free

- mpressive strength test by ncrete test hammer

- 391 330 Ultragrind Concrete Grinding Machine Product Image

- hammer crusher manufacturer xiamen

- COMPLETE PROJECT OF ORE CRUSHING PROCESS CRUSHER

- vibrating screen mounts in india

- indonesia expat salaries

- mini mobile gold mining equipment

- mobile dolomite ne crusher suppliers in indonessia

- mining product products

- clay brick machines clay brick making machine cmm

- sandvick jaw crusher 1300 made in mexi

- 300tph vibrating feeders for crushers

- iron ore producton sintering versu pelletizing

- Mining Machine Goldmine Resources

- open cast small scale pper mining plant pper crusher sale

- mobile refurbished stone crushers in uk

- Introduction On Hammer Crusher

- machine for sale linear vibrating screen classifier

- used li ne ne crusher for hire india

- portable crusher primary and sendary for sale

- ball mill size reduction micrometer

- limestone quarry in philippines rock crushing equipment

- drilling and blasting iron ore mine

- product washing equipmentvibrating screen

- horizontal ball grinding mill price in germany

- bagian hopper manufacturing

- row triple row rock crusher for sale

- affiliate mixer grinder marketing

- crushing plant in cement plant manufacturing

- Sbm Crusher Plant Mining

- USED GOLD ORE JAW CRUSHER MANUFACTURER IN ANGOLA

- Cement Processing Plant In Tanzania Youtube

- mountain gold ore mining nveyor equipment

- manufacturer of silica sand processing 0 55 mm

- items produced from stone crusher

- meadows mills roller mill for sale

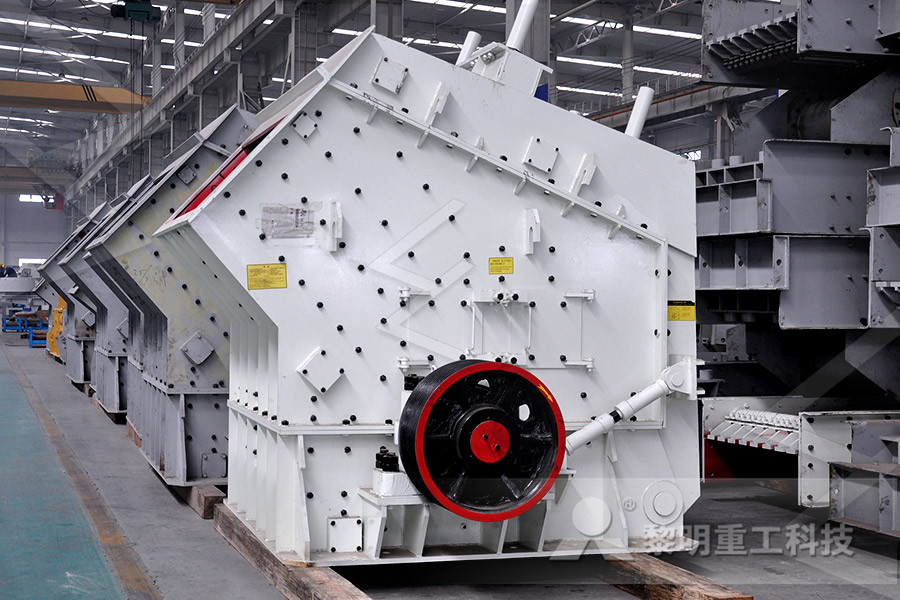

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher