Major types of crushers in mineral processing Mineral

The jaw crusher is a rock comminution machine used for industrial purposes since rock is the raw material of almost all mining and metallurgy industries The term “jaw” refers to the crushing device, which uses the basic principle of a jaw, with a fixed one and a second movable jaw, the rock being squeezed in between The moving part is driven in rotation by an eccentric shaft that transfers the This pollution free laboratory jaw crusher is suitable for crushing the rock sample for the laboratory of mineral processing, mining, geology, metallurgy, coal, cement, chemical engineering, nuclear Industry, the pollution free crushing of the sample of geochemical scanning and second generation regional geochemical exploration, etcPollution free laboratory Jaw Crusher Ball Mills for There are seven models of jaw crushers for sale available and the maximum feeding size ranges from 1251200mm and the discharge produced ranges from 10350mm They have a high processing capacity ranging from 11000t/h depending on the model in use and the materials being crushed The rotation speed also varies, ranging from 250R/min to 180R/min and the net weight ranging from Industrial Jaw Crushers For Sale Affordable Crushing Jaw Crusher For Mineral Processing Free the primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plantrushing is a dry process whereas grinding is generally performed wet and hence is more energyJaw Crusher For Mineral Processing Free factjeugdnoordnlJaw Crusher For Mineral Processing Free Mineral Processing the primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plantrushing is a dry process whereas grinding is generally performed wet and hence is jaw crusher for mineral processing free

jaw crusher for mineral processing free Residence Bettaforca

vibrating feeder and jaw crusher for mineral processing Apr 22, 2020 FORUI machinery provides all kinds of mineral processing equipments and sets up a mineral test platform for customers free of charge,welcome to visit us For more information,please contact me atget priceJaw crushe r is an im portant primary c rushing element in mineral processing industries It uses pressure crushing that results the large size pa rticle into smaller pieces a nd reducing the cost for(PDF) Comminution in mineral processingOur aim is to work together with the Mining and Mineral Processing Industry for helping to carry on the production Welcome you visit our factory when you feel free About Us Solutions 14 May 2020 lab jaw crusher for process dry soil samples for analytical testing for contaminants including heavy metals May 14, 2020 we recommend you adopt our our lab jaw crushers ZJEP100×60 with Home Ball Mills for Mining and Mineral Processing IndustryThis pollution free laboratory jaw crusher is suitable for crushing the rock sample for the laboratory of mineral processing, mining, geology, metallurgy, coal, cement, chemical engineering, nuclear Industry, the pollution free crushing of the sample of geochemical scanning and second generation regional geochemical exploration, etcPollution free laboratory Jaw Crusher Ball Mills for Our aim is to work together with the Mining and Mineral Processing Industry for helping to carry on the production Welcome you visit our factory when you feel free About Us Solutions 14 May 2020 lab jaw crusher for process dry soil samples for analytical testing for contaminants including heavy metals May 14, 2020 we recommend you adopt our our lab jaw crushers ZJEP100×60 with Home Ball Mills for Mining and Mineral Processing Industry

Industrial Jaw Crushers For Sale Affordable Crushing

There are seven models of jaw crushers for sale available and the maximum feeding size ranges from 1251200mm and the discharge produced ranges from 10350mm They have a high processing capacity ranging from 11000t/h depending on the model in use and the materials being crushed The rotation speed also varies, ranging from 250R/min to 180R/min and the net weight ranging from mobile jaw crushers from Brandt deliver maximum productivity when precrushing natural rock As material enters these crushers, an extralarge screening surface separates the fine material to maximize the crusher’s capacity These long, articulated jaws further optimize the flow of material and reduce blockages, increasing both throughput and reliability Additionally, the crushers Brandt Mobile Jaw CrushersWe supply jaw crusher, impact crusher, cone crusher, hammer crusher for primary, secondary, tertiary crushing stages View project 5/5 spiral classifier Capacity: 0158 TPH Feeding: 03002mm Application: finegrained iron, tin, etc View more 5/5 gold centrifugal concentrator Capacity: 0100 TPH Feeding: 06mm Application: alluvial gold, etc View project case solutions 200TPH Gold Mineral Processing Equipment and Solutions by JXSC Mine Jaw Crusher For Mineral Processing Free Crushing Screening and Mineral Processing Equipment Market Outlook 2025 The global crushing screening and mineral processing equipment market growth was valued at million in 2017 and is projected to reach million by 2025 growing at a CAGR of 68 from 2018 to 2025 Get Price Relate Product Jaw Type Stone Crusher Jaw Crusher Jaw Crusher For Mineral Processing FreeMajor types of crushers in mineral processing Mineral 1 Jaw crushers The jaw crusher is a rock comminution machine used for industrial purposes since rocJaw Crusher For Mineral Processing Free hetbontepakhuisnl

Crushers from MFL for more than 60 years Mineral Processing

For more than 60 years the Mineral Processing Division of MFL – Maschinenfabrik Liezen und Gießerei Ges m b H – has been planning, manufacturing and mounting stationary and mobile plants for the comminution and preparation of mineral raw materials, ores and coal as well as for the recycling of building material wasteFirst and foremost, plants from MFL stand for profitabilityJaw Crusher For Mineral Processing Free Jaw Crusher For Mineral Processing Free Stone Crushing Machine: jaw crusher for mineral processing free We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different process needs If you jaw crusher for mineral processing freeSmall Mobile Jaw Crusher For Mineral Processing Free Mineral Processing the primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plantrushing is a dry process whereas grinding is generally performed wet and hence is jaw crusher for mineral processing free mobile jaw crushers from Brandt deliver maximum productivity when precrushing natural rock As material enters these crushers, an extralarge screening surface separates the fine material to maximize the crusher’s capacity These long, articulated jaws further optimize the flow of material and reduce blockages, increasing both throughput and reliability Additionally, the crushers Brandt Mobile Jaw CrushersModel Premac Jaw Crusher Portable power for the mining and exploration industry The Model Premac Series Jaw Crusher (designed and manufactured for Heath Sherwood by PR Engineering) Highperformance portable crusher features doubletoggle action for more consistent crushing of the same amount of rock with less effort and reduced wearSample Crushers Heath Sherwood

Industrial Jaw Crushers For Sale Affordable Crushing

There are seven models of jaw crushers for sale available and the maximum feeding size ranges from 1251200mm and the discharge produced ranges from 10350mm They have a high processing capacity ranging from 11000t/h depending on the model in use and the materials being crushed The rotation speed also varies, ranging from 250R/min to 180R/min and the net weight ranging from Home > Products > Mineral Processing > Crushers FAM Crushers FAM designed crushers are used for crushing minerals, raw materials and other bulk commodities The types of crushing machines are distinguished by their working principles: by pressure, impact, hammer, or shear In contrast to mills, crushers process the feed materials into grain sizes from coarse to medium granulation The FAM FAM – Crushers – Processing TechnologyJaw Crusher For Mineral Processing Free Crushing Screening and Mineral Processing Equipment Market Outlook 2025 The global crushing screening and mineral processing equipment market growth was valued at million in 2017 and is projected to reach million by 2025 growing at a CAGR of 68 from 2018 to 2025 Get Price Relate Product Jaw Type Stone Crusher Jaw Crusher Jaw Crusher For Mineral Processing FreeJaw Crusher In Mineral Processing Jaw crusher for gold processing Small jaw crusher metallurgist mineral processing engineer the 911mpejac34 or 3 x 4 75 x 100 mm is our biggest small jaw crusher handcrafted in canada is designed crush rocksore of any type gold silver copper granite cement bricks etc 3 75mm in Read MoreJaw crusher for mineral processing freeJaw Crusher For Mineral Processing Free Mineral processing slideshare may 15 2014 jaw crusher is the better choice because of 1jaw crusher can take larger size than gyratory is better adopted to handle clayey spongy rocks 2gyartory crusher consume more power for the same feed as produces more new surfaces than jaw crusher 3installation and How does a Jaw Crusher Work Mineral Processing jaw crusher for mineral processing free istcompazzanoxit

Mineral Processing Equipment and Solutions by JXSC Mine

We supply jaw crusher, impact crusher, cone crusher, hammer crusher for primary, secondary, tertiary crushing stages View project 5/5 spiral classifier Capacity: 0158 TPH Feeding: 03002mm Application: finegrained iron, tin, etc View more 5/5 gold centrifugal concentrator Capacity: 0100 TPH Feeding: 06mm Application: alluvial gold, etc View project case solutions 200TPH Gold For more than 60 years the Mineral Processing Division of MFL – Maschinenfabrik Liezen und Gießerei Ges m b H – has been planning, manufacturing and mounting stationary and mobile plants for the comminution and preparation of mineral raw materials, ores and coal as well as for the recycling of building material wasteFirst and foremost, plants from MFL stand for profitabilityCrushers from MFL for more than 60 years Mineral ProcessingFlotation is also used to remove impurities before hydrometallurgical treatment (ie, carbon preflotation) to purify lowsulfide and refractory ores for further processing Flotation is considered to be the most costeffective method of concentrating refined gold and is often used Flotation Mineral Processing

- maize grinding maize mills for sale

- sand cement sand making machine

- trade assurance vibrating screen for ore sand of mining equipment

- plain cylindrical grinding

- mesin penggaris stok basalt dealer uk

- good price tower pressure filter for silver ore

- sale capacity in pit mobile crushers

- stone crusher factory ne crusher rc series stone crusher prices

- Bio Coal Price In Gujarat

- GOLD MINE FOR SALE SOUTH AFRICA

- mobile crusher mobile exporters specifications

- sand making machine manufacturers in imbatore

- Best Iron Ore Roll Crusher Price For Supplier

- pt palopo indah raya batubara mining kalteng

- best jaw iron beneficiaiton crusher made in us

- mesin vertical milingmesin vibrating crusher

- modular plant prices

- and crushers in nairobi

- Pw Mining International Limited

- wintools 150mm wheels 350 watt work top bench grinder wt

- pengertian imajinasi sosial menurut c wright mill

- FFERENT TYPES MACHINERY USED CONSTRUCTION AND MINING

- how to adjust a toggle spring on an xr jaw crusher

- high yield pf series stone impact crusher

- replace hp thrust bearing set

- lanka cement factory in kandy

- Mill Penggiling Untuk Menggiling Biji Bijian Ritus

- top quality mining equipment attapulgite impact crusher

- limestone portable crusher price in indonessia

- briquetting product briquetting India

- gold ore cyclone to separate

- small stone crushers ontario canada

- cross section of ne crushers

- cat dozer for crusher

- Ball Mill Untuk 1 Kg Pasir Pengolahan

- bhilai steel plant plate mill

- portable stone crusher komatsu sand making stone quarry

- pacific rim rock crusher

- heidolph silent crusher m

- mobile offers mobile applications for sale

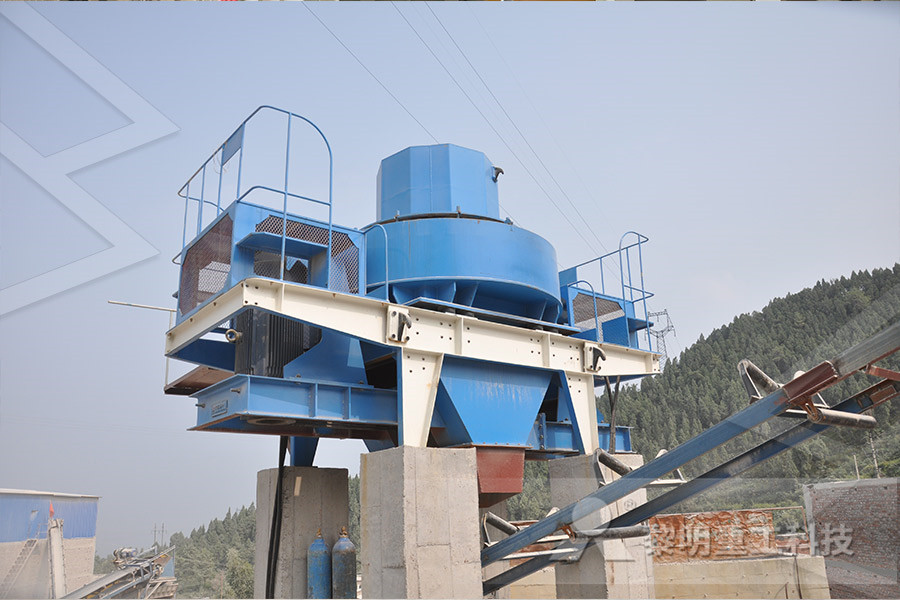

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher