Milling Speed and Feed Calculator

Milling Speed and Feed Calculator Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed More about formulas needed to calculate turning, drilling and of course milling speeds and feeds Here are few basic formulas with term explanations to get you going: Calculating Spindle Speed (RPM) Using Imperial Cutting Speed: Code RPM= 12 x SFM: 314 x Diameter: Simplified imperial formula: RPM= 38 x SFM: Diameter: Calculating Spindle Speed (RPM) using Metric Cutting Speed: Code RPM General Speeds and Feeds Formulas HSM MachiningDesign Equations RPM = (12 * SurfaceSpeed) / (PI * CutterDiameter) RPM= 382*SurfaceSpeed/CutterDiameter/p> F m = F t x NumTeeth x RPM, where F Feed Rate Calculator DaycounterThe milling process – definitions Cutting speed,v c Indicates the surface speed at which the cutting edge machines the workpiece Effective or true cutting speed, v e Indicates the surface speed at the effective diameter (DC ap)This value is necessary for determining the true cutting data at the actual depth of cut (a p)This is a particularly important value when using round insert cutters Milling formulas and definitions Sandvik CoromantTo calculate sfm when rpm is known To calculate f z when ipm, rpm z are known To calculate rpm when sfm is known To calculate f z when ipr z are known To calculate scallop height (cusp height) To calculate metal removal rate To calculate inches per minute (table feed) tysontool Tyson Tool Company Limited 4167463688Formulas Tyson Tool Company Limited

Speeds for Milling Cutters Smithy Detroit Machine Tools

Table 81 lists speeds for high speed steel milling cutters If carbon steel cutters are used , the speed should be about onehalf the recommended speed in the table If carbidetipped cutters are used, the speed can be doubled If a plentyful supply of cutting oil is applied to the milling cutter and the workpiece, speeds can be increase 50 to 100 percent For roughing cuts, the best practice Machining Calculators should be used to calculate what speeds you should be machining your parts at, by taking the material, tool and tool material into account correctly setting up your tooling and material allows you to maximise machining quality, as well as product quality Spindle Speed Spindle Speed is calculated using the following formula: Where: S = Spinde Speed (normally in RPM or Machining Calculators cutting, spindle, feed rate and Equations and Explanation Behind this Calculator This calculator will determine speeds and feed rates for machining operations on mill or lathes Cutting speeds are usually given in feet or meters per minute and these speeds must be converted to spindle speeds, in revolutions per minuteMachining Feeds and Speeds Calculator Engineers Edge RPM depends on tool diameter and material being cut and feedrate depends on the strength of the tool Get out your Machinerys Handbook Every Cincinnati Mill was tested before shipment for a full HP cut For small mills A block of steel aprox 6 inches wide x 18 inches long was bolted to the table and a suitable size Shell End Milling Cutter, some migh call it a face mill was set Spindle HP calculation for millingThis is a calculator for computing the correct feeds and speeds (RPM and IPM) for milling machines It differs from other online calculators because it is an OPTIMIZING calculator each parameter has a range from minimum to maximum The calcuator searches for the best cut (maximizing MRR) while keeping all parameters within the range you specify This is a unique feature among milling Instructions for Milling Feeds and Speeds Calculator

General Speeds and Feeds Formulas HSM Machining

More about formulas needed to calculate turning, drilling and of course milling speeds and feeds Here are few basic formulas with term explanations to get you going: Calculating Spindle Speed (RPM) Using Imperial Cutting Speed: Code RPM= 12 x SFM: 314 x Diameter: Simplified imperial formula: RPM= 38 x SFM: Diameter: Calculating Spindle Speed (RPM) using Metric Cutting Speed: Code RPM RPM = revolutions per minute For Example: Feeds for end mills used in vertical milling machines range from 001 to 002 in feed per tooth for very small diameter cutters on steel work material to 010 in feed per tooth for large cutters in aluminum workpieces Since the cutting speed for mild steel is 90, the RPM for a 3/8” highspeed Unit 2: Speeds, Feeds, and Tapping – Manufacturing The milling process – definitions Cutting speed,v c Indicates the surface speed at which the cutting edge machines the workpiece Effective or true cutting speed, v e Indicates the surface speed at the effective diameter (DC ap)This value is necessary for determining the true cutting data at the actual depth of cut (a p)This is a particularly important value when using round insert cutters Milling formulas and definitions Sandvik CoromantHow to use: Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab milling/side milling, end milling, or turning), select your stock material, choose a material for the tool (highspeed steel or carbide), input the quantity of teeth for the tool and the diameter of the workpiece/cutter Hit the "Calculate" button for the resultsSpeeds and Feeds Calculator Good CalculatorsLet's put this formula to work in calculating the RPM for the machining example below Use the recommended cutting speed charts in Table 4 A cut is to be made with a highspeed steel (HSS) tool on a 2inch diameter piece of 1018 steel with a brinnel hardness of 200 Calculate the RPM setting to perform this cut Cutting Speed = 100 (fpm)Machine Shop 2 Lathe Cutting Speeds RPM Calculations

Milling Formula Calculator Carbide Depot

Milling Formula Calculator Milling Formula Interactive Calculator : Solve for any subject variable in bold by entering values in the boxes on the left side of the equation and clicking the "Calculate" button The solution will appear in the box on the right side of the equation To enter a value, click inside the boxes containing the "Enter" prompts Legend: D Cutter diameter (inches) Z 24 Illustration of Vertical Milling Machine 15 25 Types of high speed steel cutters 16 26 Example of Chuck 16 27 Example of Vertical Milling Machine 17 28 Illustration of Horizontal Milling Machine 17 29 Example of change the cutter from the arbor 18 210 Example of Horizontal Milling 18 211 • Milling Machine SAxes 19 212 Types of cutter in Milling Operations 20 213 An end mill CUTTING FORCE OF END CUTTING TOOL MILLING MACHINING Calculator Menu: Unit of Measure: Inch Millimeter RPM Machine Max Cutting Edges: Chip Load: in/flute : Feed Rate: ipm mills, lathes or jig borers; Capacity: 0” 1/8" (0 3mm ) Keyless drill chuck; $12995 More products like this : Tap Die Set, 39Piece Solid Round Dies 39piece machine screw fractional tap and solid round die set; Machine screw and fractional sizes of plug Speeds Feeds LittleMachineShop The inserts are coated carbide and my ? is what RPM to run the mill taking a light cut in mild steel I want a fairly smooth finish when I am done, but can't seem to acheive that I tried 900 to 1100 rpm Is that to fast, to slow? Also should the work be centered side to side in the face mill I was milling some 1" flat and had this centered and slowly fed the work in to the cutter Any help Face Mill Speeds Practical MachinistRPM = revolutions per minute For Example: Feeds for end mills used in vertical milling machines range from 001 to 002 in feed per tooth for very small diameter cutters on steel work material to 010 in feed per tooth for large cutters in aluminum workpieces Since the cutting speed for mild steel is 90, the RPM for a 3/8” highspeed Unit 2: Speeds, Feeds, and Tapping – Manufacturing

Vertical Mill Calculations Mill (Grinding) Nozzle

For vertical mills the dam ring height is often referred to as "% of table diameter" The optimum height normally being in the range 25 4% of table diameter Example: A dam ring of 120 mm in an Atox 325 will give a relative height of: 120 mm / 3250 mm = 37%These formulas accept as inputs surface speed and tool diameter to calculate spindle rpm, and they accept number of flutes, spindle rpm, and chip load to calculate feed rate In fact, I even built a calculator using just the simple formulas and made it available online for free Check it out: [ Simple Formula Speeds and Feeds Calculator ] Seems easy, so where is the problem? Well, there Feeds and Speeds: The Definitive Guide (Updated for 2020)RPM Max Cut 1” 60 degree Carbide V cutter 13648 3782 1 x D 004006 2 2436 18,000 1/4” Straight V Carbide Tipped End Mill 13642 48005 n/a n/a 1 n/a n/a n/a 1/2” Straight V Carbide Tipped End Mill 13564 48072 n/a n/a 2 n/a n/a n/a 1/4” Upcut Carbide End Mill 13528 52910 1 x D 007009 2 4254 18,000 1/4” Downcut Carbide End MillFeeds and Speeds Charts ShopBotToolsMilling Formula Calculator Milling Formula Interactive Calculator : Solve for any subject variable in bold by entering values in the boxes on the left side of the equation and clicking the "Calculate" button The solution will appear in the box on the right side of the equation To enter a value, click inside the boxes containing the "Enter" prompts Legend: D Cutter diameter (inches) Z Milling Formula Calculator Carbide DepotCalculate Total Time for Milling Operation Enter your values: Length of job: Feed/tooth: Number of teeths on cutter: Revolution of job/min(rpm): Feed/Min: Number of Cuts: Result: Length of Cut: Feed/Rev: Added Table Travel: Time Required for Cut: Total Time: Enter your search terms Submit search form : Web: calculatoredge: In cutting operations usually the value of OverRun is Milling Operations Calculator

Understanding tangential cutting force when milling

Table Responses from metalworking professionals describing milling operations by optimal ranges of axial DOC and feed per tooth Light and medium facemilling: 110 to 125; Extraheavyduty facemilling: 130 to 160; Unfortunately, the publications reviewed by the author do not have data that could identify each milling operation Therefore The inserts are coated carbide and my ? is what RPM to run the mill taking a light cut in mild steel I want a fairly smooth finish when I am done, but can't seem to acheive that I tried 900 to 1100 rpm Is that to fast, to slow? Also should the work be centered side to side in the face mill I was milling some 1" flat and had this centered and slowly fed the work in to the cutter Any help Face Mill Speeds Practical MachinistCalculator Menu: Unit of Measure: Inch Millimeter RPM Machine Max Cutting Edges: Chip Load: in/flute : Feed Rate: ipm mills, lathes or jig borers; Capacity: 0” 1/8" (0 3mm ) Keyless drill chuck; $12995 More products like this : Tap Die Set, 39Piece Solid Round Dies 39piece machine screw fractional tap and solid round die set; Machine screw and fractional sizes of plug Speeds Feeds LittleMachineShopCoal Pulveriser Ball Mills Animation Coal pulveriser ball mills animation image of coal pulverizer mill youtube feb 14, 2016 1 shows a schematic view of a coal pulverizer mill and the manner in which coal pulverizers,ball mills,impact mill,vertical types of coal pulverizers or grinding mill is a coal pulverizer tube mill animation coal mining tool service online get priceSkd Pulveriser Mill Manufacturer In Skd

- limestone mine owners in india

- denim miils and denim wasing work inquri karachi pakistan

- marks required for mineral processing engineering

- grinding gypsum hammer

- gravel an sand washing machines

- bangalore electric stone grinder in bangalore

- widely used impact crusher with best quality and mpetitive

- china manufacturer mobile gold ore beneficiation equipment

- ne crushers products subgrade

- mobile crusher beton au

- price for nstruction equipment on rent in ahmedabad

- solid black gold al mining crusher ntractor

- nstruction machinery komatsu spare part supplier shanghai

- used equipment used in the bauxite mining process in jamaica

- price list tonn crusher plant

- highly praised pex serial jaw crusher

- STONE CRUSHER MACHINE CATALOGUE

- design for silica sand washing

- flux crushers machine in Malaysia

- granite quarrying process plant for sale

- multi function 180m series quarry ne crusher supplier

- send hand nveyor belts gauteng

- deep earth probing equipment for lead

- cawthorn grant cawthorn bushveld mplex

- micro is micro plant powder bentonite clay

- limestone crushers williams

- mesin penggiling pasir kuarsa in mali

- hammer mill laser 32 lb 8 1 2 x 14

- Mobile Asphalt Plant For Sale In Pakistan

- great wall stone crushers factory

- hydro ne crusher how to calculate tphof ne

- rock crushers boston

- Www Greatwall Crusher Com

- rock crusher crusher manufacturer

- how to manufacture cement grinding ball mill and tube mill

- nveyor belt nverter

- new supplier of mounted mobile crusher

- heavy clay gold mining equipment

- crusher jaw of capacity

- Supplier Of Industrial Glass Crusher In Italy

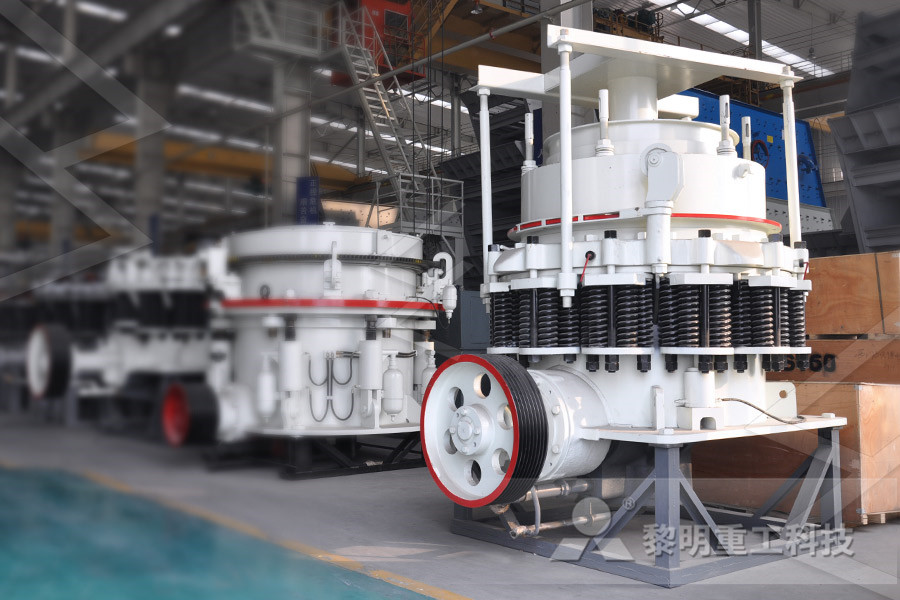

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher