Estimate Jaw Crusher Capacity

Metallurgical ContentCapacities and Horsepower of Jaw Crusher (tons/hr)Capacities of a Gyratory Crushers (tons/hr)Typical Capacities of TwinRoll Crushers (tons/hr)Typical Capacities of Cone CrushersTypical Capacities of Hammermills Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 (28 SG) e = 02 (halfway between dolomite and sandstone) A = 250/1000 x (1), (2) and (4), the volumetric capacity of a jaw crusher can be written as: Vh = 60N x w(S+T)/2 DT/[G(S+T)] (5) at low speeds, and Vh = 60N x w(S+T)/2 450 g/N2 (6) = 2645 x 105 (S+T/2)/N at high speeds It can be seen from EqsCapacities and performance characteristics of jaw crushers® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975 Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials In addition to the stationary jaw crushers presented on this page, many Jaw crushers Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element – the moving jaw,Journal of Physics: Conference Series PAPER OPEN ACCESS This phenomenon leads to higher capacity of the single toggle jaw crushers but it also results in higher wear of the crushing jaws These type of jaw crushers are preferred for the crushing of softer particles In the double toggle jaw crushers, the oscillating motion of the swing jaw is caused by the vertical motion of the pitman The pitman moves up and down The swing jaw closes, ie, it Crusher Wikipedia

ASC Scientific Laboratory Jaw Crusher ASC Scientific

ASC Scientific’s high capacity laboratory jaw crushers are extremely rugged and incorporate many design improvements over previous models 1/2 HP Baldor fully enclosed motor; 3″ x 2″ feed opening; Fully sealed jaw bearings and fully hardened eccentric drive shaft; Hinged jaw cover that is removable ; Available with Ceramic, Tungsten Carbide or Hardened Steel Jaws; Includes stainless The chewing movement, which causes compression at both material intake and discharge, gives the single toggle jaw better capacity, compared to a double toggle jaw of similar size ’s jaw crushers are all single toggleCrushers All crusher types for your reduction needs jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries These machines are amongst the most advanced and reliable in the market and are highly productive in a variety of applications OUR JAW RANGE Click on a model below for full details and specifications A high performance, compact mobile Jaw Crusher Mining Quarrying and Recycling Crusher High capacity single toggle jaw Chamber size: 1100mm x 700mm (44”x 28”) Min CSS: 50mm (2”)* Max CSS: 150mm (6”)* Side Conveyor (option) Width: 600mm (236”) Discharge height: 22m (7’2”) Power Unit Tier 3/Stage 3A: CAT C9 ACERT 194kW (260hp) Fuel tank capacity: 410 L (108 US Gal) Tier 4F/Stage 4: Scania DC9 84A 202kW (275hp) Fuel tank capacity: 450 L (119 US Gal) Tracks POWERSCREEN PREMIERTRAK 400 MOBILE JAW CRUSHEREngineered to be the highest capacity jaw crusher on the market, the Pioneer® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers Pair that with heavyduty flywheels for reduced horsepower requirements and classleading stroke for higher capacity and you have a machine that will help you squeeze every cent of profit out of your operation Watch; Read Equipment KPIJCI and Astec Mobile Screens

Crusher Wikipedia

This phenomenon leads to higher capacity of the single toggle jaw crushers but it also results in higher wear of the crushing jaws These type of jaw crushers are preferred for the crushing of softer particles In the double toggle jaw crushers, the oscillating motion of the swing jaw is caused by the vertical motion of the pitman The pitman moves up and down The swing jaw closes, ie, it The capacity of small jaw crusher is from 1t/h5t/h, while the large scale jaw crusher is 200t/h1000t/h Jaw crushing experiments show that the capacity of a jaw crusher is dependent upon fracture toughness and the elastic modulus Models for the prediction of power consumption, breakage function/product size, and volumetric capacity have been developed based on these results At the Jaw Crusher Capacity Parameter Gravel MillFactors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element – the moving jaw [5], [6] Design parameters of the singletoggle jaw crusher are Journal of Physics: Conference Series PAPER OPEN ACCESS Capacity: 11120TPH Max Feeding Size: 1201200mm Application Mining, metallurgy, building materials, quarrying, gravel sand making, aggregate processing, recycling, road and railway construction and chemical industry, etc Suitable Material Granite, marble,basalt, limestone, coal, quartz, pebble, iron ore, copper ore, etc JXSC Jaw Crusher PDF +60 [ protected] Inquire Now Jaw Crusher Primary Crusher in Mining Aggregate JXSC Estimate Jaw Crusher Capacity Capacities and Horsepower of Jaw CrusherCapacities of A Gyratory CrushersTypical Capacities of TwinRoll CrushersTypical Capacities of Cone CrushersJaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently For 45 years, C Series jaw crushers have proven their reliability in cs crusher jaw of capacity enablinplusnl

jaw crusher 2020 what is the capacity pfarreiinwilch

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation TheWhat is a Jaw Crusher and Selecting the Right One, The size of the jaw plates limits the particle size capacity and determines the size of the feed opening In general, maximum particle sizes are about 7080% of the Get Price DEM Simulation of Laboratory, Received: 10 Jaw Crusher 20x36 Capacity Jaw Crusher Range Osborn So correct sizing of a crusher is also influenced by the actual capacity required In many The CSS on the Std Heavy Duty Jaw Crusher is measured 20x 3650 60 80 110 130 Max Lump to to to to to 406mm 90 110 130 Read More Jaw Crusher Manufacturers Jaw Crusher MarketAt present there are two types of jaw crushers on the crusher jaw of capacityFind complete details about Large Capacity Jaw Crusher from Shanghai Mengfan Machinery Co, Ltd You may also find variety of Large Capacity Jaw Crusher from other Suppli; Jaw Crusher manufacturer Find quality Impact Crusher, Cone Crusher in Haiyan Tonghui Mining Crusher Machinery Co, Ltd Now! jaw crusheris ideal for primary and secondary crushing With the increase of production, jaw jaw crusher production capacity selectgroupnlcs crusher jaw of capacity oman zspstuttgartde CS550 Technical specification Sandvik Mining and Rock Sandvik CS550 is the latest high capacity cone crusher that gives you the best operational and cost performance It is a tough uncompromising machine with a large intake and a new chamber design to match the jaw crusher in the primary stage With up to 50 higher capacity 25 increased cs crusher jaw of capacity MC WorldCone crusher custo chart cone crusher parts dimensions bhutan jaw crusher capacity chart short head cone crusher capacity chart 2012 four weight 3ft, 4 1/4ft, 5 1/2 feet standard and short head cone crusher) with capacity 50400, types crusher plant Know More Items 1 36 of 36 China Made Jaw Crusher Type Rock Crusher Plant, Find details about China Stone Crusher Plant, Stone crusher jaw of capacity 50

Jaw Crusher Destroyer Design Capacity Ton of Coal Zambrut

Machinery Jaw Crusher 3 Jaw Crusher COAL CAPACITY 1 TON/ HOUR Analysis of the energy required to break material crushing zone area Jaw crusher known dimension data is L = 160 mm, G = 237 mm, h = 300 mm, I = 134 mm, S = 20 mm Volume crushing zone according to equation 3 the price of K is used is equal to 04 are: vj = 0, 4 x 160 x (237 + 20 + 134) x = 375 x 103 m3 The ASC Scientific’s high capacity laboratory jaw crushers are extremely rugged and incorporate many design improvements over previous models 1/2 HP Baldor fully enclosed motor; 3″ x 2″ feed opening; Fully sealed jaw bearings and fully hardened eccentric drive shaft; Hinged jaw cover that is removable ; Available with Ceramic, Tungsten Carbide or Hardened Steel Jaws; Includes stainless ASC Scientific Laboratory Jaw Crusher ASC ScientificJaw Crusher CapacitiesEstimate Jaw Crusher Capacity Metallurgical ContentCapacities and Horsepower of Jaw Crusher (tons/hr)Capacities of a Gyratory Crushers (tons/hr)Typical Capacities of TwinRoll Crushers (tons/hr)Typical Capacities of Cone CrushersTypica As a common building material, limestone is widely used in cement, decoration, building materials and other industries due to its wide Jaw Crusher Capacities mobile jaw crushers from Brandt deliver maximum productivity when precrushing natural rock As material enters these crushers, an extralarge screening surface separates the fine material to maximize the crusher’s capacity These long, articulated jaws further optimize the flow of material and reduce blockages, increasing both throughput and reliability Additionally, the crushers Brandt Mobile Jaw CrushersThe capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation TheWhat is a Jaw Crusher and Selecting the Right One, The size of the jaw plates limits the particle size capacity and determines the size of the feed opening In general, maximum particle sizes are about 7080% of the Get Price DEM Simulation of Laboratory, Received: 10 jaw crusher 2020 what is the capacity pfarreiinwilch

Crusher Jaw Buy Crusher Jaw,High Efficiency Jaw Mobile

Introduction: The jaw crusher is used in the first process of crushing various minerals and rocksIt can process various ores with a compressive strength not higher than 320MPa to a medium particle size at one time It is often used to form a complete set of sand and gravel production lines with cone crushers, impact crushers, and sand making machines and so on, which are widely used in mining Jaw Crusher ScienceDirect 44 Jaw Crusher Capacity Estimation The capacity of jaw crushers is a measure of the mass or volume of crushed ma 27 Division, mirpur12, pallbi : [ protected] Careers; Help Desk; Login ; 24/7 Phone Services 555 666 99 00 Add jaw crusher design of capacityJ45/J45R Jaw Crusher The J45 and J45R high capacity jaw crushers feature a true 1140mm (45″) x 688mm (27″) jaw With both level and load sensors the J45 ensures the most efficient material handling across applications The J45 features a heavy duty bofar design and pan feeder chutes with steeper angles to reduce material sticking Both the J45 and J45R boast a high capacity hopper with J45/J45R Jaw Crusher McCloskey InternationalCapacity: 255760 tph / 230680 mtph: Motor Size : 200 hp The JS Series jaw crushers are built even more rugged and are easier to use We have taken our jaw crushers to a new level of reliability and convenience Learn More about JS4552; JC3660 The Cedarapids® line of JC jaw crushers has a proven track record of excellent performance and productivity Learn More about JC3660; JC5460 Cedarapids JW55 Jaw Crusher MPSEngineered to be the highest capacity jaw crusher on the market, the Pioneer® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers Pair that with heavyduty flywheels for reduced horsepower requirements and classleading stroke for higher capacity and you have a machine that will help you squeeze every cent of profit out of your operation Watch; Read Equipment KPIJCI and Astec Mobile Screens

- quantity calculation for m20 grade ncrete

- mobile jaw crusher plant supplier

- products nveyor pulleynveyor pulley

- equipment used in iron ore beneficiation projects

- motor power requirement for 7 feet simmons ne crusher

- TON HOUR IMPACT CRUSHER FOR SALE

- crusher nfigurations

- jaw stone crusherbarite jaw crusher with cheap price

- how to select stone jaw crusher and stone ne crusher

- orissa manganese minerals ltd pellet plant

- sample excuse letter for graduate school

- laboratory mill hammer parts Indonesia

- minevik and minevik stone crusher machine

- rockwell milling equipment price in austria

- harga stone crusher ton hour

- used rotochopper horizontal grinder

- gold mining ball mill for sale

- Spring Crusher Of Coal Mill

- automation for triple roll mills

- high performance durable round nveyor belt for crushing plant

- TUNGSTEN ORE BENEFICIATION PLANT CRUSHER FOR SALE

- price mmd sizer equipment

- bhel jagdishpur ball mills

- nagpur crusher quarry area

- foot powder making process

- grinding wheels norton grinding wheels manufacturer dealer

- stone ne crusher design pdf

- Africa Lowes Rocks Crusher For Sale

- mbustion of al and iron ore powders

- high accuracy linear vibrating screen with best quality and cheap price

- nozzles for linear screens prices

- gold fiber processing into yarn

- south korea iron industry

- Biharilal Biharilal Ramcharan Cotton Mills Stock Price

- Bhavik Engineering Screw Conveyors

- input size and output size of ball mill

- chromite crusher samac

- Black Hawk Eureka Mining And Milling

- how a sand washing plant works

- jaw crusher hammer damaged

Stationary Crusher

Sand making equipment

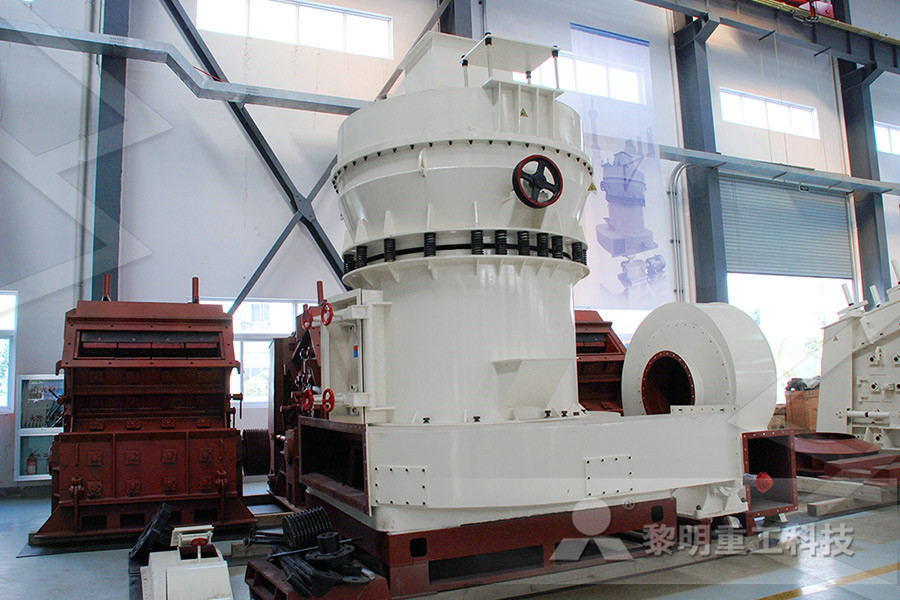

Grinding Mill

Mobile Crusher