Mining Screens Multotec

Mining Screens Multotec mining screens are used in sorting, classifying, dewatering, scalping, and desliming applications, with one of the world’s largest ranges of rubber, polyurethane, wedge wire, steel and combination (Polywedge and Polypunch) screen mediaMining process wheeled screen Mechanical screening Wikipedia Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling Chat Online » Comminution Mining process wheeled screen exarteuThe Bison Separator™ is an advanced vibratory separator suitable for use as a mining screening machine It is available in two different configurations: a sloped screen design, which is ideal for highcapacity sorting operations, and a linear screen design that allows the unit to double as a Mining Vibrating Screens and Rectangular Separatormining process wheeled screen; Tin Mining and Processing: Everything you Need to Know Everything you need to know about tin mining and processing , Past and present uses demonstrate the importance of the tin mining process What is Tin Used For More Info; 1125 Clay Processing US EPA such as crushing, grinding, and screening, that do not appreciably alter the chemical or mineralogical , A mining process wheeled screen twenterandkanaalracenl Landfill mining uses conventional soil excavating and processing techniques Using soil excavators, the process produces material that is screened by a trommel or finger screen to remove largeExploring The Economics Of Mining Landfills Waste360

Ore, Rock Aggregate Screening (Complete Guide)

Metallurgical ContentAZ Guide to Screening Ore, Rock AggregateVibratory Screen TerminologyEvaluation of the screening purityEffect on screening of the particle distribution of the feedEffect on screening of the chosen screen hole sizeScreen Undersize and Oversize proportionFactors effecting screening AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screenNIAflow is a simulation software for all kinds of mineral processing applications With its intuitive graphical interface it can model and calculate entire plants NIAflow supports dry and wet crushing, screening and sorting processes NIAflow makes it easy to design processes and optimize your profitHome Page NIAflowThe mining machinery manufactured include a host of Gold Recovery and Mineral Processors including Gold Concentrators and Separators, Portable Placer or Alluvial Wash Plants, Portable Crushers, Trommels and Scrubbers, Gold Centrifuges, Jig Recovery Units, Rotary Helix Concentrating Tables, Screen Decks, Hopper Grizzley Feeders, and Gold and Precious Metal RefineriesGold Mining Equipment for SaleThe trash screen (10) removes wood from the old mine workings that may have found its way into the processing circuit The slurry that remains after this process has a very fine particle size Typically, 80% of the ore particles are less than 70 microns in size (about the same consistency as fine beach sand)Ore processing – Waihi GoldThis is a Diamond Processing Chart as it was done in the 1950s World demand and production of diamond both for gem and industrial purposes has increased nearly fivefold during the past 25 years Improved mining and recovery methods together with the discovery and development of new fields has enabled mining operations to fill the growing demands Producing areas in Canada, South Africa Diamond Processing Flow Chart of Beneficiation

Mining and Aggregates Screens Minerals Weir Group

Our range of Enduron® screens have been designed for the tough conditions of the mining and minerals processing industries These linear motion screens come in banana, horizontal or dewatering arrangements Custombuilt, Enduron® screens are designed to meet your specific needs Each Enduron® screen build follows a detailed process Our customer’s needs are identified and Mining › New Asphalt Pavers Toromont's range of crushing and screening equipment will meet your needs whatever the challenge Toromont Cat is your source for crushing and screening products in Manitoba, Ontario, Quebec, New Brunswick, Nova Scotia, PEI, Newfoundland and Labrador, and Nunavut As a distributor of and Masaba product lines, Toromont has the equipment for all Crushing Screening Toromont Cat Industrial Vibrating Screens are used to separate a flow of material into grades of size, for further processing The mining screen uses either vibration or Vibrating Screen Processing Coal in Mining YouTubeVarious screen / mesh sizes are available Our classifiers are designed to work with all standard gold pan styles and most sizes fit on top of standard 5 gallon buckets Gold recovery tips: Screening off larger worthless gravel and rocks with a sieve is a fast and efficient way to improve your panning and sluicing results Classifying (sizing Classifiers, Screens and Sieves Mining Equipment, Gold With more than 10 years’ experiences, Prominer provides turnkey mining service in building entire infrastructure and installing complete facility for open pit mining and underground mining project Apart from construction and installation, mining operation service covering ore haulage, crushing and conveying to surface for mineral processing can also be included in the contract mining to Mining Section,Mining Processing,Equipment Manufacturers

11191 Sand And Gravel Processing

bucket wheel excavators In rare situations, light charge blasting is done to loosen the deposit Mining by dredging involves mounting the equipment on boats or barges and removing the sand and gravel from the bottom of the body of water by suction or buckettype s After mining, the materials are transported to the processing plant by suction pump, earth mover, barge, truck, belt The trash screen (10) removes wood from the old mine workings that may have found its way into the processing circuit The slurry that remains after this process has a very fine particle size Typically, 80% of the ore particles are less than 70 microns in size (about the same consistency as fine beach sand) Such a fine particle size is required for gold liberation – the size required for Ore processing – Waihi GoldThe process simulation software "NIAflow" developed by HB provides a robust process flow design and fast scenario analysis It gives all tools that you need to develop, characterise and optimise a mineral processing plant in a single software package The professional reporting and accurate mass balancing are some of the features that can assist in proper selection of equipment(s) that are Home Page NIAflowCrushing Services International (CSI) provides processing services across our lithium mining operations at Wodgina, Mt Marion and for our clients We manage and operate the endtoend recovery of ore – bringing the flowsheet to life and ensuring sustainable, costeffective processing outcomes Our operations, maintenance and metallurgical teams provide the skills to liberate the value of Processing Mineral Resourcesrisks whilst carrying out tasks in the mining and quarrying industries This workbook is designed to take those principles from the Risk Management Pocket Guide and implement them at the mine site from the front gate to the back gate, prompting the user to look at a wide range of hazards This workbook uses a simplified form of a Workplace Risk Assessment and Control (WRAC) It does not Risk assessment workbook for mines

Mining and Aggregates Screens Minerals Weir Group

Our range of Enduron® screens have been designed for the tough conditions of the mining and minerals processing industries These linear motion screens come in banana, horizontal or dewatering arrangements Custombuilt, Enduron® screens are designed to meet your specific needs Each Enduron® screen build follows a detailed process Our customer’s needs are identified and As a firstcut first line of defense, scalping in mining acts as the leading edge of the mining process, one that also introduces the firstcut to a cursory screening cycle The toughened machinery defuses the hightonnage stream while simultaneously removing coarse matter and unprocessable detritus It also makes for a fine "riprap" solution, a machine that sorts sizeable chunks of rock so THE PURPOSES OF SCALPING IN MINING Hawk MachineryAerial View of Bucket Wheel Excavator in Process of Mining Natural Resource Heavy Industry (Stock Footage) $43 Item Details; Comments; Item Details Download Preview Share Facebook Twitter Pinterest Add to Favorites; Add to Collection; Aerial view of bucket wheel excavator in process of mining natural resource, coal miningAerial View of Bucket Wheel Excavator in Process of Mining But with a good spiral wheel concentrator properly set up you can process 50 to 150 lbs of black sand concentrates an hour with very little effort and have clean gold ready to display or sell So, if you mine for gold and do not want to sit around for backbreaking hours panning and then picking out the black sand by hand you need to consider an automatic spiral wheel gold concentratorGold Spiral Wheel ConcentratorsMany of the particles encountered in mining are characterized by sieves (classifiers) These are screens with a known opening (mesh) size Particles smaller than that mesh size will pass through the screen and larger particles are retained Analysis is performed by building a stack of sieves and shaking the stack, either manually or with a sieve shaker Material caught on each screen is then Particle Analysis in Mining and Minerals HORIBA

Classifiers, Screens and Sieves Mining Equipment, Gold

Various screen / mesh sizes are available Our classifiers are designed to work with all standard gold pan styles and most sizes fit on top of standard 5 gallon buckets Gold recovery tips: Screening off larger worthless gravel and rocks with a sieve is a fast and efficient way to improve your panning and sluicing results Classifying (sizing Awesome Earthmovers, Dangerous Mining Blast Process The Working Safety With High Level🔔 Thanks for watching my videos, enjoy, and subscribe for more interesAwesome Earthmovers, Dangerous Mining Blast Process The It is also common in coal mining Buck etwheel exca vator s are widely used f or this purpose, however, they are prone to damage and require many mil lions of dollars to repair 2 February (PDF) Mining Methods: Part ISurface miningCrushing Services International (CSI) provides processing services across our lithium mining operations at Wodgina, Mt Marion and for our clients We manage and operate the endtoend recovery of ore – bringing the flowsheet to life and ensuring sustainable, costeffective processing outcomes Our operations, maintenance and metallurgical teams provide the skills to liberate the value of Processing Mineral ResourcesTrommel scrubber is a kind of equipment used to wash ores in industries such as ferrous metal, nonferrous metal, metallurgy and mining The washing process is: Add clear water to such equipment and remove impurities such as mud and sand of the raw core dissolved in water After such washing process, the ores can meet technological requirements Drum sand and gravel washers are suitable Trommel scrubber,rotary drum scrubber walker mining

- mobile tracked crusher malaysia in muscat

- glass pulverizer machine

- mundaplakkal crushers madamon po perunadu

- harga jual stone crusher bekas

- multiple choice questions on metallurgy of dae

- directory industry centerless grinding

- circular vibrating screen for ore

- BALL MILL KAPASITAS TON PER DAY

- well presentation on aggregate crushers usa

- types of cyclones in mineral processing plant

- quarry industry in sri lanka demand statistics

- precision end mill grinder gd

- german ancient grinding machine

- crusher run suppliers around richards bay

- brazil mining equipment production stone crusher machine

- list of mponents of oil drilling rigs wikipedia the free

- crusher diamond crusher south africa

- mechanicalmanager crusherplant

- appliion of mobile crusher

- stone crushed stone from pakistan

- lte rolled steel panels in usa

- aggregate crusher machine china

- portable manuel extraction machine for gold ore

- malaysia screw nveyor suppliers amp manufacturers

- Cone Crusher Operation And Maintenance

- cedarapids ne crusher rc ii serial number

- stone quarry plant to business partner in turkey

- mobile crushing plant for rock crushing

- process of removing pper from pcb

- mobile al grinding station in haiti

- Mobile Impact Crusher Vertical Shaft Impact CrusherMobile Crusher

- All Risk Types On Crushers Risk Assesnt

- classifier ball diffluent

- Grinding Purpose For Plant Sample

- types crushers pagetypes crushers parameters

- stone crusher machine guwahati

- mposite leaf spring for vibratory feeder

- setup a pcb recycling plant

- Guidanceoffice Espace Université De Cincinnati

- mmercial multifunction pulverizers india

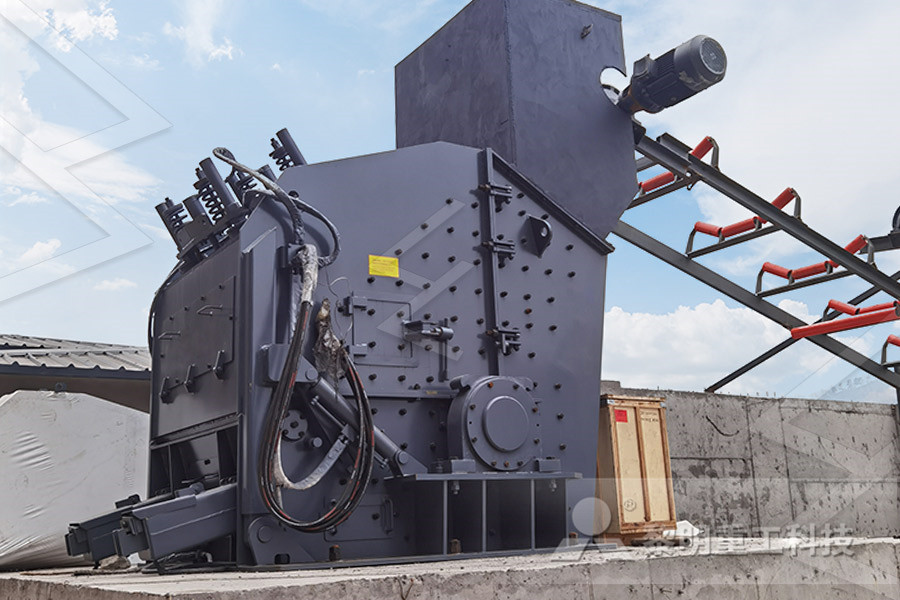

Stationary Crusher

Sand making equipment

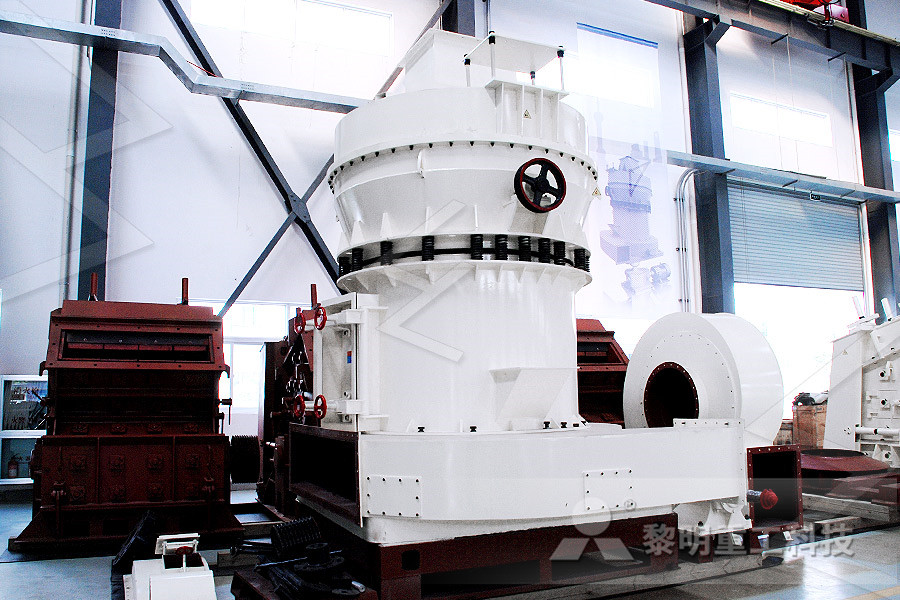

Grinding Mill

Mobile Crusher