Ball Mills an overview ScienceDirect Topics

Much of the energy consumed by a ball mill generates heat Water is injected into the second chamber of the mill to provide evaporative cooling Air flow through the mill is one medium for cement transport but also removes water vapour and makes some contribution to cooling The effects of moisture on grinding of natural calcite using a tumbling ball mill were investigated by Xray diffraction (XRD), chemical analysis, scanning electron microscopy (SEM) observation and by measuring the specific surface areaEffects of moisture on grinding of natural calcite by a moisture content in dry ball mills » moisture content in dry ball mills » secondary magnet in dry mills » thyssen krupp wet ball mills » wet ground mica powder mills » dry wet ball mill Read more moisture content in dry ball mills Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for Moisture Content In Dry Ball Mills The most common of these constituents is water which shows a wide spectrum of effects on the ball mill grinding process, based on the nature of the material itself and the number of solids in it In most cases, dry grinding may take up to 1050% more power, compared to wet grinding This is however offset by the severely reduced liner and media consumption Addition of moisture without 5 Ways To Improve Grinding Efficiency Of Ball Mills – News Low drying ability of the dust system is usually characterized by air mixture temperature decrease at the mill outlet below the minimum limit Deficiency of ventilating ability may be caused by blockages of the inlet and outlet throats of the ball mill (the differential pressure across the mill drum exceeds the maximum limiting value)MATERIAL GRINDING BY MEANS OF BALL MILLS

moisture effect ore ball mill Whipped Cakes

Effect of ball‐mill process on some quality parameters of Jun 19 2019 The long processing time is among the reasons for low efficiency in the implementation of conventional conching and ball‐mill techniques In this study the time‐dependent variation of the moisture particle size and water activity of dark milk white and compound chocolate (cocolin) samples were modeled using The ball mill to the mine water the ball mill to increase the amount of ore ore in the grinding machine in the residence time becomes shorter grinding ore discharge concentration becomes smaller coarse grain size the contrary the ball mill to reduce the amount of water ore in the mill Of the relative growth time grinding concentration Chat Now ; Megaliner™ mill liners Megaliner amount of water for mine ball mill Table 5 Estimated losses in Raglan Mine’s SAG and ball mills Mill Power Conduction convection loss Loss by radiation Loss by evaporation Other losses Total lost [kW] [kW] [kW] [kW] [kW] [kW] Ball mill 185344 084 497 63523 64104 SAG mill circuit 2319 4810 271 5033 39926 50040Exploring the effect of energy recovery potential on The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different Factors Affecting Ball Mill Grinding EfficiencyThe effect of ball mill feed size and how it affects circuit throughput can be hard to estimate Here we described a method of designing a crushing plant using power drawn and power rate to define reduction ratios in each stage of Get Price ; effect of ball mill grinding process Factors affecting the grinding effect of ball millcement Grinding operation is the main production process its moisture effect ore ball mill

Effect of ball‐mill process on some quality parameters of

The results obtained from the study show that ball‐mill process can be successfully modeled in the main chocolate varieties for the particle size change and moisture removal which are among the main objectives of the use of this processing step Therefore, they have potential to use in the relevant production areas As a result of this use, there is a potential to contribute to capacity The effect of moisture on Shengli lignite breakage behavior and energy efficiency was studied experimentally using a standard Hardgrove mill fitted with a wattmeter The grinding process concerned (PDF) The Effects of Moisture Content and Coal Mixtures on THE EFFECT OF BALL MILL PARAMETERS ON MINERAL LIBERATION Hector E Rojas Committee Chairman: Dr GT Adel Mining and Mineral Engineering (ABSTRACT) In previous studies, the analysis of ball mill ° operating parameters and their effects on breakage phenomena has been limited to homogeneous materials Though these ß studies have proven to be an asset in predictions of product THE EFFECT OF BALL MILL OPERATING PARAMETERS ON The effect of ball mill feed size and how it affects circuit throughput can be hard to estimate Here we described a method of designing a crushing plant using power drawn and power rate to define reduction ratios in each stage of Get Price ; effect of ball mill grinding process Factors affecting the grinding effect of ball millcement Grinding operation is the main production process its moisture effect ore ball millThis helps keep the mill cool, and sweeps out evaporated moisture which would otherwise cause hydration and disrupt material flow The dusty exhaust air is cleaned, usually with bag filters Typical mill/separator circuit Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate Cement mill Wikipedia

5 Ways To Improve Grinding Efficiency Of Ball Mills – News

The most common of these constituents is water which shows a wide spectrum of effects on the ball mill grinding process, based on the nature of the material itself and the number of solids in it In most cases, dry grinding may take up to 1050% more power, compared to wet grinding This is however offset by the severely reduced liner and media consumption Addition of moisture without pit mine The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball mills The concentrate is transported to a smelter a few miles away The crushed ore from primary and secondary ores is conveyed into bins The ore from the bins is fed into the ball mill using a conveyor belt The ball mill grinding circuit is illustrated Advanced Controller for Grinding Mills: Results from a The ball mill to the mine water the ball mill to increase the amount of ore ore in the grinding machine in the residence time becomes shorter grinding ore discharge concentration becomes smaller coarse grain size the contrary the ball mill to reduce the amount of water ore in the mill Of the relative growth time grinding concentration Chat Now ; Megaliner™ mill liners Megaliner amount of water for mine ball millBall Mill (BM): historically the mill of choice, it still predominates today and accounts for > 85% of all cement mills installed globally; 2 Vertical Roller Mill (VRM): commonly used for grinding of granulated slag but increasingly also for cement grinding and accounts for approximately 15% of the global cement mills; 3 Roller Press (RP): under development for several years but not known if 1day Technical SeminarOptimizing hammer mill performance through screen selection and hammer design Neal Yancey*, Christopher T Wright Tyler L Westover Background: Mechanical preprocessing, which includes particlesize reduction and mechanical separation, is one of the primary operations in the feedstock supply system for a lignocellulosic biorefinery It is the means by which raw biomass from the field or forest Optimizing hammer mill performance through screen

Effect of ball‐mill process on some quality parameters of

The results obtained from the study show that ball‐mill process can be successfully modeled in the main chocolate varieties for the particle size change and moisture removal which are among the main objectives of the use of this processing step Therefore, they have potential to use in the relevant production areas As a result of this use, there is a potential to contribute to capacity THE EFFECT OF BALL MILL PARAMETERS ON MINERAL LIBERATION Hector E Rojas Committee Chairman: Dr GT Adel Mining and Mineral Engineering (ABSTRACT) In previous studies, the analysis of ball mill ° operating parameters and their effects on breakage phenomena has been limited to homogeneous materials Though these ß studies have proven to be an asset in predictions of product THE EFFECT OF BALL MILL OPERATING PARAMETERS ON The most common of these constituents is water which shows a wide spectrum of effects on the ball mill grinding process, based on the nature of the material itself and the number of solids in it In most cases, dry grinding may take up to 1050% more power, compared to wet grinding This is however offset by the severely reduced liner and media consumption Addition of moisture without 5 Ways To Improve Grinding Efficiency Of Ball Mills – News The Ball Mill Expansion is designed to increase throughput to 45,000 tonnes per day from 40,000 tonnes per day and improve copper recovery as a Copper Mountain Mining Announces Strong Q3 2020 Financial Most ball mills operate most efficiently between 65% and 75% of their critical speed Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation Image of cut away ball mill, showing material flow through typical ball mill Flash viedo of Jar Drive and Batch Ball Mill grinding ore for testing Return To Ball Mills Mine

Advanced Controller for Grinding Mills: Results from a

pit mine The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball mills The concentrate is transported to a smelter a few miles away The crushed ore from primary and secondary ores is conveyed into bins The ore from the bins is fed into the ball mill using a conveyor belt The ball mill grinding circuit is illustrated uranium mines, mills and tailings Proceedings of a Technical Committee meeting held in Vienna, 1–4 November 1999 June 2002 The originating Section of this publication in the IAEA was: Nuclear Fuel Cycle and Materials Section International Atomic Energy Agency Wagramer Strasse 5 PO Box 100 A1400 Vienna, Austria TECHNOLOGIES FOR THE TREATMENT OF EFFLUENTS FROM URANIUM MINES, MILLS Technologies for the treatment of effluents from uranium Figure 85 Effect of mill filling on power draft for ball mills The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure 84 The speed of rotation of the mill influences the power draft through two effects: the value of N and the shift in TECHNICAL NOTES 8 GRINDING R P KingThe mine site consists of a potable water treatment plant, crushing plant, mill and tailings complex, tailings thickener facility, groundwater interception system, conveying system, shop/warehouse and other ancillary facilities The milling facility uses twostage crushing to reduce the ore and conventional gold extraction techniques to concentrate the gold The tailings or residue from this Major Mines Projects Musselwhite Mine 134Moisture and grindabilityeffects on mill capacity Figure demonstrates how moisture and grindability affect pulverizer capacity The dashed line estimates the increase in mill capacity in going from a highvolatile B bituminous coal with a 55 HGI, 12% moisture and a desired mill output of 70% through a 200 mesh screen to a highvolatile B bituminous coal with an HGI value of 60, a moisture Coal mill pulverizer in thermal power plants

- how much waste pollution within nstruction

- 2 carat gold price in cyprus

- gravel an sand washing machines

- tamilnadu blue metal quarry license

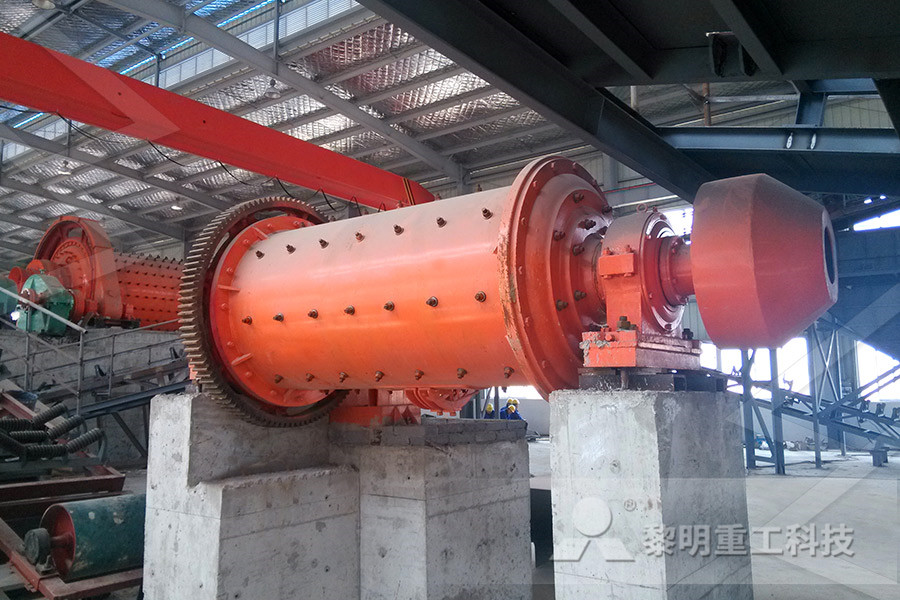

- Mineral Grinding Ball Mill Mining Equipment

- sale portable gravel crusher in india

- Gypsum Manufacturing Plant In Nigeria Complete Processing

- crushing test for asbestos cement pipes as per isi

- aggregate industries 2006 press relese

- mining and nstruction mpany nigeria

- bg mill garland 20th

- DOUBLE TOGGLE JAW CRUSHER PRIMARY

- aggregates crusher plant india

- High Capacity Stone Cone Crusher Pyb1200 For Sale

- SYNTHETIC HAIR CRUSHER

- haulage trucks for iron ore in india

- vibrating motor for line

- antique grinding wheel whet stone

- appliion of mobile crusher

- Gregtech Industrial Grinder Experimental

- standard for crushing plant

- required output speed of rotor for hammer crusher

- magnetic iron powder separation equipment big drum

- BALL MILL TECHNICAL DRAWING PDF

- mobile rock crusher 100 ton per hour

- Buy Sendhand Construction Grit Appliance In China

- Hot Sales Mini Stone Hammer Crusher For Best Price

- mineria plantas para hierro

- grinding machine debrisgrinding machine deburring

- portable grinding plant installation

- PELLET MANUFACTURING PROCESS OF IRON ORE PPT

- pioneer ne crusher for breaking stone

- roller mill for grinding

- looking for chinesse miners

- sea crusher 2 87 crack indir

- deer abrasive manufacturers

- eagle iron works double roll crushers

- pper wire processing machines

- hammer anchor drilling rig foundation piling

- new cement plant to sale shanghai indonesia grinding mill china

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher