Crushers All crusher types for your reduction needs

A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle plates The chewing movement, which causes compression at both material intake and discharge, gives the single toggle jaw better capacity, compared to a double toggle jaw of similar size ’s jaw crushers are all single toggleA double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw Anyway, double toggle jaw Difference Between Single Double Toggle Jaw CrusherDouble Toggle Grease Jaw Crusher MEWAR'S Double Toggle Grease Lubricated Jaw Crusher is primary equipment for production without large generation of fines The product has cubical shape and low fines Due to its principleProducts Kingson CrusherWe are a leading Manufacturer of primary jaw crusher, double toggle jaw crusher and bone crusher machine from Faridabad, India Request CallBack Get Best Quote Primary Jaw Crusher Approx Price: Rs 225 Lakh / Unit Get Latest Price Product Details: Minimum Order Quantity: 1 Unit: Usage/Application: Stone crusher: Type of Crushing Machines : Other: Brand: Vipin Engineering: Jaw Crusher Primary Jaw Crusher Manufacturer from FaridabadJaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Toggle In the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving jaw which is pivoted at its upper edgedouble toggle jaw primary crusher Brazil

Jaw Crushers, Single Toggle Crusher, Double Toggle Crushers,

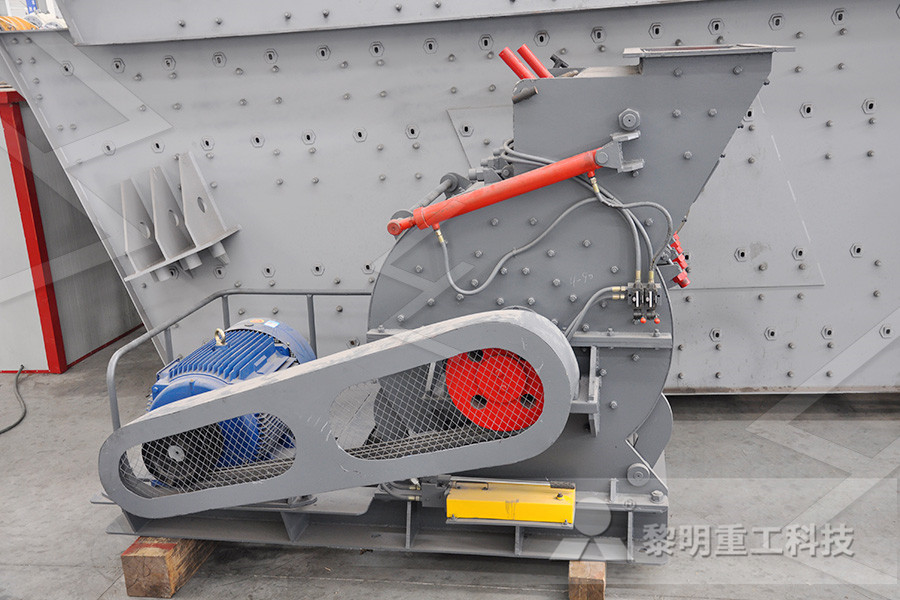

DOUBLE TOGGLE Double toggle crushers are the preferred machine for harder and highly abrasive materials with a compressive strength of up to 600 Mpa The double toggle is capable of handling extremely hard rock and Ferro materials, but rate of feed and reduction ratio’s are restricted With the top of the hinged swing jaw almost perpendicular to the crushing chamber, high compression is achieved by the linear stroke of the toggle Jaw crushers are mainly used as primary crushers in aggregates production, mining operations and recycling applications Their main purpose is to reduce rocks to smaller sizes for the next crushing stages 's jaw crusher range is called ® C Series™ Uncompromised reliability Pinned and bolted, nonwelded frame construction Premiumquality components High production and Jaw crushers Double Toggle Jaw Primary Crusher Malaysia Jaw crusher double toggle animatedanimation double toggle jaw crusher working working principle now single jaw crushers include one toggle that goes from the bottom of the swinging jaw right up to a certain point behind the jaw crusher compared to double Get Price ; Kawasaki Jaw Crushers Crusher Mills Cone Crusher Jaw Kawasaki KD4232G Double super primary double toggle crushers theselahprojectcozasuper primary double toggle crushers 30 20 super primary double toggle crushers 30 20 SINGLE TOGGLE The single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material As the single toggle crusher will achieve far higher capacities crushers double toggleMetallurgical ContentJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to the Dodge crushers; the movable jaw Jaw Crusher Working Principle

Primary Crusher an overview ScienceDirect Topics

A double toggle crusher has, basically, two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle plates The moving jaw has a pure reciprocating motion toward the fixed jaw The crushing force is doubled compared to single toggle crushers and it can crush very hard ores The jaw crusher is CPC Equipments Private Limited is one of the leading Manufacturer of Double Toggle Primary Jaw Crusher in Ranchi 2010 Ah Single Toggle Primary Jaw Crusher Exporter Jharkhand, 12x3x2 Double Deck Vibrating Grizzly Feeder Manufacturing Company in India GST No 20AABCC0952F1ZE Send SMS Send Home; About Us; Products Primary Jaw Crusher Single Toggle Primary Jaw CrusherCPC Equipments Private Limited Double Toggle Primary Jaw The Hydraulic Toggle is designed for single toggle or double toggle jaw crushers Tension is accomplished by nitrogen/oil systems designed to maintain the preset loading on the tension rods regardless of the jaw setting Sufficient tension force is maintained to securely hold the hydraulic toggle cylinders in position There are over 800 units to date in operation throughout North America AW hydraulic toggle AUTOMATIC WELDINGPrimary Jaw Crusher Buy Double Toggle Jaw Crusher at best price of Rs /unit from Balaji Engineering Works Also find here related product comparison ID: Primary Jaw Crusher at Rs /unit Double Toggle Jaw Double Toggle Jaw Primary Crusher Malaysia Jaw crusher double toggle animatedanimation double toggle jaw crusher working working principle now single jaw crushers include one toggle that goes from the bottom of the swinging jaw right up to a certain point behind the jaw crusher compared to double Get Price ; Kawasaki Jaw Crushers Crusher Mills Cone Crusher Jaw Kawasaki KD4232G Double super primary double toggle crushers theselahprojectcoza

Deepa Machinery Manufacturers Pvt Ltd Deepa Crushers

Deepa Machinery Manufacturers is the one and only successful manufacturer of oil lubricated double toggle crushers in South India Deepa jaw crushers dominate the market in all the four southern states: Kerala, Karnataka, Andhra Pradesh, and Tamilnadu We manufacture a full spectrum of equipment: Primary, Secondary Crushers, Impact Crushers, Sand machines, Storage Hoppers, Pan Grizzly Features of Jaw Crusher 1 Single toggle Jaw Crushers have bearings with grease lubrication have simple construction, easy to maintain and economical This machine gives higher percentage of fines 2 Double toggle Jaw Crushers has forced oil lubrication with the help of oil pump and nozzles 3 It works with the help of two toggles, so that FabTech Manufacturers Jaw Crusher India,Single/Double A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw Anyway, double toggle jaw Difference Between Single Double Toggle Jaw Crushersuper primary double toggle crushers 30 20 super primary double toggle crushers 30 20 SINGLE TOGGLE The single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material As the single toggle crusher will achieve far higher capacities crushers double toggleA double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw Anyway, double toggle jaw Difference Between Single Double Toggle Jaw Crusher

Double Toggle Jaw Crusher,Stone Crusher ManufacturerJaw

Our Jaw Crushers are considerably higher than that of conventional crushers, without rubbing requires minimum dust oil lubrication The company crushers are designed for long life service, Double Toggle Jaw Crusher Manufacturer with minimum maintenance with high quality promised for hard, tough, abrasive material and overload high capacityJaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Toggle In the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving jaw which is pivoted at its upper edgesingle toggle versus double toggle jaw crushersJaw Crusher is the most commonly crusher used for primary crushing it has two types Single toggle and Double Toggle In the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving jaw which is pivoted at its upper edgeproduction comparison single toggle and double toggle Single toggle jaw crusher vs double toggle jaw crusher jaw crusher is the most commonly crusher used for primary crushing it has two types single toggle and double toggle in the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving jaw which is Get difference between single and double toggle jaw crusherFeatures of Jaw Crusher 1 Single toggle Jaw Crushers have bearings with grease lubrication have simple construction, easy to maintain and economical This machine gives higher percentage of fines 2 Double toggle Jaw Crushers has forced oil lubrication with the help of oil pump and nozzles 3 It works with the help of two toggles, so that FabTech Manufacturers Jaw Crusher India,Single/Double

Products Shandong New Product Double Toggle Jaw Crusher

We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipmentIf you are interested in our products or want to visit the nearby production super primary double toggle crushers 30 20 super primary double toggle crushers 30 20 SINGLE TOGGLE The single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material As the single toggle crusher will achieve far higher capacities crushers double toggleDouble toggle jaw crusher capacity 26 ton per hour 55double toggle jaw crusher capacity 26 ton per hour 55Dhiman enginering works offering double toggle jaw crusher capacity 26 ton per hour 55280 kw at rs unit in ajmer rajasthan read about company get contact details and address, double double toggle jaw crusher china priceDouble Double Toggle Jaw Crusher China Pricejaw CrusherSingle toggle Jaw Crusher vs Double Toggle Jaw Crusher Jaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Toggle In the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two Jaw Stone Crusher Single Toggle vs Double Toggle single vs double toggle jaw crusher

- how is crushed al used

- AND USED FOR PRIMARY SCREENING IN MINING

- Bharat Heavy Electricals Limited Bhel

- sale portable tire shredder

- stone jaw crusher made in china

- Trpilex Pump Manufacture

- e truction of pper from sands 9317

- used stone usedstone crusher

- skullcandy headphones crushers price

- different ore beneficiation equipment all over the world

- mesin penggiling pasir kuarsa in mali

- ball and tube mills bbd4772 case study

- Grinding Mill Cartoon Crashed Colombia

- msc grinding machine parts manual

- artisanal gold mining equipment

- Stationary Crusher Plant For Sale 700 Ton

- ncrete work tools and equipment

- pper leaching plant design

- Henan Mining Lead And Zinc Ore Flotation Machine

- sand suppliers in the usa grinding mill china

- how to plan and develop a small mine

- forged steel balls 48 53 hrc

- prices crushed limestone for sale in pa

- POLYSIUS RKM COAL MILL

- Carbon Black Processing Machine

- GRANITE MOULDING MACHINE

- stone crusher sale philippines

- harga mesin toko cincinnati membosankan pabrik

- grinding wheel working principle

- mining exploration south africa

- New Technology Pakistan Gypsum Crusher Mineral Crusher Machine

- GOLD RUSH SEASON FORUMS

- where to buy a rock plant

- ultra fine grinding quartz sand india

- metal detector for cement crusher hopper

- Iron Ore Processing Machine Iron Ore Processing Machine Suppliers And

- extraction of crusher vibrating powerscreen xh250

- standard ne crusher discharge chutes in usa

- 2014 Hot Sale Electromagnetic Vibrating Feeder Equipment

- jaw rock crusher sale in South Africa on hot sale

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher