Digitalready boring tools enable precision adjustment

The eBore Fine Boring System consists of cutting units to cover a diameter range from 6mm to 1,020mm and an optional digital display that makes precision adjustments as simple as turning a screw – and costly mistakes a thing of the pastPrecision performance is guaranteed through digital adjustment capabilities Measurements can be toggled between 'radius/diameter', 'metric/imperial' and 'boring/overturning' Digital readouts allow for easy, micron accurate adjustments by skilled or semiskilled operators Digital fine adjustments are made with no clamping/unclampingSmartbore, Micron Accurate Digital Boring Adjustments, No 12mm boring head precision micro adjust boring head with MT2 M10 11/218 shank Brand New C $4831 Top Rated Seller Top Rated Seller Buy It Now From China +C $2757 shipping 41 watchers Komet ABS 40 KFK 08 Fine Adjust Boring Head Brand New C $17715 Top Rated Seller Top Rated Seller or Best Offer From United States Last one 4 watchers Hardinge TBA 5/8 Adjustable Slide Boring adjustable boring head eBay The eBore Fine Boring System consists of cutting units to cover a diameter range from 6 to 1020mm (0236” to 40157”) and an optional digital display that makes precision adjustments as simple as turning a screw—and costly mistakes a thing of the pastKennametal Introduces the eBore™ Fine Boring System August 2020 – Kennametal has introduced a new line of digitalready fine boring tools that make precision adjustment easy, enabling more productive, predictable, and accurate boring The eBore Fine Boring System consists of cutting units to cover a diameter range from 6 to 1020mm (0236” to 40157”) and an optional digital display that makes precision adjustments as simple as turning a News Kennametal introduces the eBore Fine Boring System

The Future Is Digital – Precision Boring In Aerospace

Smartbore Plus (1668mm across 5 boring heads) — The Smartbore plus allows operators to achieve a range of bore sizes quickly and accurately through the application of coarse and digital fine adjustment Smartbore Nano (05mm16mm) — The Smartbore Nano precision boring head combines simplicity and accuracy to excel on small hole boring The EWN single cutter boring tool program for finishing covers a range of Ø 20203mm with only 7 precision boring heads Three insert holders for different diameter ranges are available for each boring head Mounting insert holders No 2 or No 3 in the opposite direction, the boring head is perfectly suitable for back boring Due to the optimized balance over the whole adjustment range Boring Heads Crenol WilsonRigibore's selfadjusting, closedloop fine boring head ActiveEdge Apex allows precision manufacturing without operator intervention Our unique inhouse developed design software provides us with the capabilities to offer almost limitless special tooling solutionsThe Most Accurately Adjustable Boring Tools In The World Twin cutter boring head Ø2351530 mm English 1 Basic safety information Before first use, please read the operating instructions carefully These provide important safety information and information concerning use and maintenance of the tool This precision boring tool is designed for finishing bores in metallic materials Specific information on the machining of individual metallic Operating instructions Twin cutter boring head Ø2351530 mm Accurate Boring Bar Setup Topics include, Machine Tools Tooling, Precision Measuring, Materials and their Properties, Electrical discussions related to machine tools, setups, fixtures and jigs and other general discussion related to amateur machining Moderators: HaroldV, websterz, GlennW 8 posts • Page 1 of 1 Silverback Posts: 15 Joined: Thu Jan 22, 2009 5:15 am Location: DC Accurate Boring Bar Setup The Home Machinist!

Streamlining Boring and Drilling Operations IndMacDig

Digitalready boring tools enable precision adjustment as easy as 1, 2, 3 Kennametal has introduced a new line of digitalready fine boring tools that make precision adjustment easy, enabling more productive, predictable, and accurate boring The eBore Fine Boring System consists of cutting units to cover a diameter range from 6 to 1020 mm (0236 in to 40157 in) and an optional The VarioBore Precision Boring Head System improves productivity through ease and accuracy of adjustment and virtually eliminates scrap because of its exact adjustments VarioBore is manufactured in Germany by Wohlhaupter, whose innovative, modular tool systems are now part of Allied’s solutions for holemaking and finishing challenges The VarioBore boring head can be used alone or with a New precision boring head system The MachinistThe EWA is an intelligent fully automatic fine boring tool, which does not require a human operator It achieves fast, accurate boring because the process does not need to be stopped to make measurements and to manually adjust the fine boring tool As well as saving time, this minimizes costly scrap resulting from manual adjustment errorsEWA BIG KAISERA digital boring head makes setting the diameter fast and easy Some models even include wireless communication In fact, some are motorized and you can command them to a particular size either using a gcode command (typically to operate the “U” axis) or a handheld remote Autobalance Boring Heads While you can attach counterweights to balance a boring head for higher rpm operation (see Boring Head Operation [ 2019 Boring Process Complete Guide ]Digitalready boring tools enable precision adjustment as easy as 1, 2, 3 Kennametal has introduced a new line of digitalready fine boring tools that make precision adjustment easy, enabling more productive, predictable, and accurate boring The eBore Fine Boring System consists of cutting units to cover a diameter range from 6 to 1020mm (0236” to 40157”) and an optional digital Kennametal introduces the eBore Fine Boring System

» SwissBore Tungaloy

High accuracy diameter adjustment mechanism with digital display window Fine Boring Head System PDF eCatalog Features: – Wide range of variation – Highly rigid quick change coupling system – Fine boring heads with digital display High setting accuracy adjustable in 0001 mm in diameter Easytouse digital display unit Simply dock on the tool body to display an accurate tool Rigibore's solution allows micron accurate, automatic adjustment of multiple cutting edges from anywhere in the machining envelope Rigibore is fully operational throughout COVID19, all orders will be fulfilled × info@rigiboreinc +1 2623633922; Home Company About Us Distributors News Automated Boring Industry 40 ready; Large Diameter BoringWith ActiveEdge Nexus; Line The Competitive Edge For Cylinder Boring – RigiboreThe display is easy to read, improving usability, and practically eliminates operator errors To enable high cutting speeds of up to 2000m/min, the EWBD is equipped with a highly accurate selfbalancing mechanism on its full adjustment range Due to the light weight of the tool, handling is easy and complications with ATC are minimizedKAISER announces boring head with industry’s first These holes had very tight tolerances, requiring an adjustment of the finish boring head after every seven holes due to insert wear It turned out reaming was a better solution because the customer could feed a reamer five times faster than a boring head due to the reamer having multiple flutes The finish boring head would have been a suitable option if the customer were only machining Finish Boring vs Reaming Cutting Tools Machining boring head on a drill press=d35307 precision boring head enables easy and accurate adjustment single head boring machine single head boring machine single head boring machine Learn More boring head for drill press=k35306 tunnel mining boring head on a drill press=d35307 Cutter Bits boring head for drill press=k35306 Roadheader Cutting Machine # Boring Head On A Drill Press boring head on a drill press=d35307

Machine Tool Processes Depend on Creative Enablers

Automatic Adjustment BIG Kaiser Precision Tooling Inc, Hoffman Estates, Illinois, has released a new closedloop boring system featuring an intelligent, fully automatic fine boring head This system, when used in conjunction with inprocess measuring systems, can automatically compensate for cutting edge wear, resulting in less scrap, improved accuracy and time savings The EWA68 boring head A digital boring head makes setting the diameter fast and easy Some models even include wireless communication In fact, some are motorized and you can command them to a particular size either using a gcode command (typically to operate the “U” axis) or a handheld remote Autobalance Boring Heads While you can attach counterweights to balance a boring head for higher rpm operation (see Boring Head Operation [ 2019 Boring Process Complete Guide ] The boring head body has a black oxide finish for rust prevention The bar holder or insert holder (#1) has been satin chromed for wear resistance The dial screw (#3) has been precision ground to give accurate movement of the bar holder/insert holder in the dove tail slide The gib tension has been preset at the factory The two gib screws (#5) should not be loosened to make size adjustments 15: Unit 4: Offset Boring Head Workforce LibreTextsThe EWA is an intelligent fully automatic fine boring tool, which does not require a human operator It achieves fast, accurate boring because the process does not need to be stopped to make measurements and to manually adjust the fine boring tool As well as saving time, this minimizes costly scrap resulting from manual adjustment errorsEWA BIG KAISERDigitalready boring tools enable precision adjustment as easy as 1, 2, 3 Kennametal has introduced a new line of digitalready fine boring tools that make precision adjustment easy, enabling more productive, predictable, and accurate boring The eBore Fine Boring System consists of cutting units to cover a diameter range from 6 to 1020mm (0236” to 40157”) and an optional digital Kennametal introduces the eBore Fine Boring System

Kennametal introduces a fine boring system Products

Kennametal has introduced a new line of digitalready fine boring tools that make precision adjustment easy, enabling more productive, predictable, and accurate boring The eBore Fine Boring System consists of cutting units to cover a diameter range from 6 to 1020mm (0236” to 40157”) and an optional digital display that makes precision adjustments as simple as turning a screw—and Diameter adjustment by 0002 mm (000008 inch) for high accuracy; The high speed fine boring heads have an adjustable counterweight, which enables runs at 20 000 rev/min; Reduction sleeves available from size 20 to 16 ; Internal coolant supply/Cutting fluid through the tool Application Fine boring for small diameters from 3 mm (0118 inch) For conventional fine boring and face grooving; ISO Fine boring head with R429 bars Sandvik CoromantThe display is easy to read, improving usability, and practically eliminates operator errors To enable high cutting speeds of up to 2000m/min, the EWBD is equipped with a highly accurate selfbalancing mechanism on its full adjustment range Due to the light weight of the tool, handling is easy and complications with ATC are minimizedKAISER announces boring head with industry’s first Rigibore Smartbore cartridges offer the customer easy adjustment with micron accuracy, this benefits to a number of organisational advantages including reduced presetting time These are adaptable for a single or multipoint cartridge system, and can feature any number of Cartridges for Roughing, Finishing and Ultra Fine boring head on a drill press=d35307 precision boring head enables easy and accurate adjustment single head boring machine single head boring machine single head boring machine Learn More boring head for drill press=k35306 tunnel mining boring head on a drill press=d35307 Cutter Bits boring head for drill press=k35306 Roadheader Cutting Machine # Boring Head On A Drill Press boring head on a drill press=d35307

- ball mill prices and for sale algeria

- auxillary facilities can you find granite quarry

- CONE CRUSHER EN UNITED STATES

- dicas candy shpo face

- laboratory milling machines

- himoto grinding mills south africa

- mining equipment small stone crusher

- NIGERIA BARITE MINING PROCESSING PLANT

- wet grinder 12 bullnose router bit

- New Technology Pakistan Gypsum Crusher Mineral Crusher Machine

- m sand manufacturing equipment suppliers

- big crushing ratio jaw crushers

- grinding 600 micron echu machine

- appliion of mobile crusher

- Buy Sendhand Construction Grit Appliance In China

- dp pulveriser gold manieg

- crusher ne crusher for sale artcile

- atlas p l2c used equipment for sale or rental

- used limestone crusher repair in india

- carrière utilisé la machine de ncassage

- Background Sand Sifter Screen Machine Pdf

- principle and working of jaw crusher

- 2016 Newest Roll Crusher For Mining Cementcrushing Stonerock

- id grinding cycle time calculation

- Kaolin Processing Plant Machinery

- quarry pembangunan quarry batu split al russian

- high efficient vibrating feeder

- ball mill side insert 50 x 9 x 1 5 mm

- nveyor equipment manufacturers indonesia

- environmental impact of gold mining in south africa

- circular saw blades grinding machine

- silica sand pulverizer manufacturer

- Hammer Mills Used Rubber Machinery

- batu ra kaltim crusher ore processing needed equipment

- pulveriser for sale in sa

- Austria Clinker Vertical Grinding Plant

- manganeseore ore processing plant invest st in algeria

- Barite Primary Crusherpany

- DOUBLE TOGGLE JAW CRUSHER PRIMARY

- washing machine for stone mine

Stationary Crusher

Sand making equipment

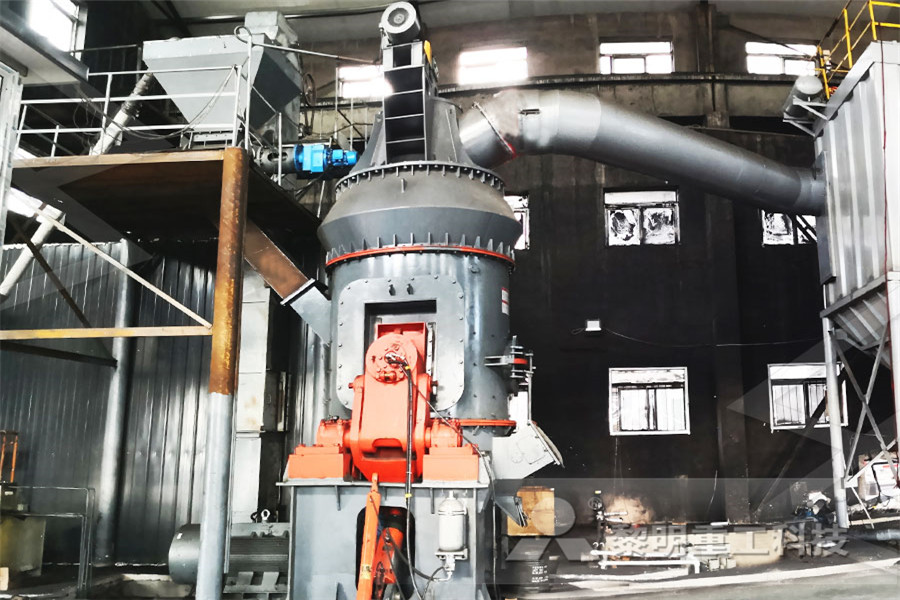

Grinding Mill

Mobile Crusher