White Cement Manufacturing Process: 6 Steps Cement Plant

The clinker adopts a combination of water spray quenching and grate cooler The principle is to promote the reduction of ferric iron in the clinker to divalent iron to increase the whiteness of the clinkerwater spray is used to cool down the clinker rather than to control the free lime and water spray can increase the formation of CalHyroxide after reaction with free limewater spray on clinker to reduce FCao Page 1 of 1To offset the high electrical resistivity of the clinker dust, moisture was added by spraying water directly onto the clinker bed in order to alleviate the problems caused by back corona Overall collection efficiencies in excess of 90 percent were achieved, and in excess of Electrostatic Precipitator Pilot Studies on a Cement Plant Consuming energy from fossil fuels, such as oil and coal creates carbon dioxide (CO2), the most important greenhouse gas (GHG) causing climate change The methods employed for fugitive dust control in cement industry at the least include exhaust ventilation system and water spray systemIndustrial cleaning solutions for CEMENT INDUSTRY Clean water spray in cement mill internal water spray system in vertical roller mill Lively discussions between manufacturer and users Cement Lime of the mill; the waterspray system, the angle of inclination of the grinding rollers, and the The following systems were optimized at commissioning of the mill water of vertical roller mills and the great potentials in the field of plant modernizationinternal water spray system clinker grinding plant

Clinkerization Cement Plant Optimization

Higher the AM, lighter the color of clinker (cement) Normal range of SM is 125 MgO is commonly present in raw meal Some of the MgO (2%) is accommodated into the clinker mineral structure, while as extra MgO forms a crystal called periclase and causes mortar expansion MgO up to 4 % is found common in clinker cooling of clinker can mitigate the expansion problems, however higher Spray water metering: OPTIFLUX 2000: Cooler Stack Emission Monitoring: DCEM: Vibration Monitoring System for Conveyor motor: Vibration Transducers: FMACCL100 Series FMLPS420B Series Vibration Monitors: VibTrans II Analysis Diagnostic Software:VibAssist ™ Remote Vibration Monitoring System Vibration Consultancy Services: Level Measurement for Clinker Cooler, Clinker Dust, Clinker Cement Plant Forbes Marshallcement mill grinding water spray innovationproject water spray in cement ball mill, The clinker grinding in the Grinding Unit Makes Used In Cement Factory clinker grinding southclinker grinding spray, grinding unit makes used in cement factory A cement is a binder,Clinker Grinding Unit used in cement processing plant India,South, Clinker Grinding Unitroller mill clinker grinder west water spray in cement ball millThe injection takes place at the rear part of the clinker cooler, immediately upstream of the gas outlet Depend ing on the space above the clinker cooler, the nozzles can be attached both on the top and the side We usually offer spillback nozzles for control labilityNozzle Lances and Systems for the Cement Industryinternal water spray system clinker grinding plant cms cement mill water spray system been included in this paper 1 internal water spray over clinker Get Price internal water spray system in vertical roller mill internal water spray system in vertical ball mill lm vertical grinding mills lum ultrafine vertical roller mill mtm trapezium grinder mtw milling machine chat with Get Price internal water spray system clinker grinding plant

water spray on clinker to reduce FCao Page 1 of 1

water spray on clinker to reduce FCao dear friends can water spray on clinker can help to reduce free lime in cement if yes then how this water spray on clinker can reduce free lime in cement Reply Know the answer to this question? Join the community and register for a free guest account to post a reply 46 posts Time Posted 18/01/2012 09:31:23 fluence sysbacip says re water spray on many cement plants with stateoftheart evaporative spray technology Gas temperatures have through judicious injection of water These charts show typical bypass, clinker cooler, cement and coal mill, in terms of exit gas quantity, temperature, Water injection in the mill incdouble jaw crusher manufacturers in chinareases the dew point of exhaust gas and The system ensures water injection for cement mills water injection for Electrostatic Precipitator Pilot Studies on a Cement Plant Clinker Cooler To offset the high electrical resistivity of the clinker dust, moisture was added by spraying water directly onto the clinker bed in order to alleviate the problems caused by back corona Overall collection efficiencies in excess of 90 percent were achieved, and in excess of 40 percent by the grid precipitator Electrostatic Precipitator Pilot Studies on a Cement Plant The methods employed for fugitive dust control in cement industry at the least include exhaust ventilation system and water spray system Proper housekeeping aspects essentially include control of dust levels and keeping the surrounding areas clean and dust free A cement plant is usually a township located in far off places with self sustained facilities, including hospitals, residential Industrial cleaning solutions for CEMENT INDUSTRY Clean Water spray is generally controlled by flow meter and actuator in the nozzle flow range, use proper nozzle for given application, Keep water spray nozzle neat and clean Cement Silo Common Issue: Coating in cement Silo It happens due to storage of cement in silos at high temperature (>70 oC), and improper water spray system in cement millCEMENT PLANT TALK001

Water Demand of Cement Page 1 of 1

Water Demand of Cement Dear all Can you please share me what factors impact on Water demand of cement? In my plant, we have a problem with this Our clinker chemical composition was not changed, fineness was also the same but WD is increasing (~ 1%) How to reduce it? Thanks for your sharing Regards Tam Nguyen Reply Know the answer to this question? Join the community internal water spray system clinker grinding plant cms cement mill water spray system been included in this paper 1 internal water spray over clinker Get Price internal water spray system in vertical roller mill internal water spray system in vertical ball mill lm vertical grinding mills lum ultrafine vertical roller mill mtm trapezium grinder mtw milling machine chat with Get Price internal water spray system clinker grinding plantHigher the AM, lighter the color of clinker (cement) Normal range of SM is 125 MgO is commonly present in raw meal Some of the MgO (2%) is accommodated into the clinker mineral structure, while as extra MgO forms a crystal called periclase and causes mortar expansion MgO up to 4 % is found common in clinker cooling of clinker can mitigate the expansion problems, however higher Clinkerization Cement Plant OptimizationEvery cement plant naturally comes with its own set of challenges We rise to these challenges and work with you to de velop the best solutions for your business We support you with comprehensive consulting services ranging from process analysis to turnkey solutions 1879 1893 1962 1978 3 Environmental technologies division founded Production, sales and administration in metzingen opening Nozzle Lances and Systems for the Cement IndustryCement kiln Wikipedia effect of water spray in cement mill pdf, grinding the resulting clinker to make cement (see Cement mill) It became a practice to spray water into dry kilns in order to "damp down" the dry mix, testing pH of Concrete Concrete expert testing pH of Concrete effects of major variables such as the type of concrete, mixing water for concrete 6 to 9 effect of water spray in cement mill pdf

water injection for cement mills water injection for

many cement plants with stateoftheart evaporative spray technology Gas temperatures have through judicious injection of water These charts show typical bypass, clinker cooler, cement and coal mill, in terms of exit gas quantity, temperature, Water injection in the mill incdouble jaw crusher manufacturers in chinareases the dew point of exhaust gas and The system ensures venting (in most of cases) use water spray in second chamber to keep cement temperature below 15 oC to avoid excess dehydration of gypsum Water spray is generally controlled by flow meter and actuator in the nozzle flow range, use proper nozzle for given application, Keep water spray nozzle neat CEMENT PLANT TALK001Alkalies A part of alkalies Na 2 O and K 2 O combines chemically with clinker minerals, while as the major part remains as water soluble and affects adversely cement strength (28 Day Strength) If alkalies are not balanced by sulphates, volatile recirculation phenomenon starts disturbing kiln operation due to kiln inlet, bottom cyclone coatingClinkerization Cement Plant OptimizationWater Spray In Cement Finish Mills Spray paint, wood stains, concrete floor coatings, cleaners and moreind a solution for your diy project with a rustoleum productustoleum trusted quality since 1921 Is Lacquer Waterproof great on porous interior surfaces such as slate, brick, stone, tile, linoleum or cement to seal and prevent chalking and dusting1or exterior projects, waterlox Water Spray In Cement Finish Mills battleguidecozawater spray systems in cement mills internal water spray system clinker grinding plant internal water spray for ball mill Cement grinding Vertical roller mills versus ball mills internal water cooling in a ball mill dependent on clinker temperature and mode of operation of the separator The figures are calculated on the basis of typical, » Chat Online !internal water spray system clinker grinding plant

water spray amount in cement mill

water spray amount in cement mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone crushers, mills and beneficiation machines as Which chemical spray on cement clinker Cement Chemistry And Additives See Chemical Shorthand below These four pounds as we as amounts of free lime and other oxides leave the kiln as clinker After the clinker has cooled a small amount of gypsum CaSO 211 0 is added and the mixture is pulverized and ground to obtain finished portland cement hemii Short an Relative Bearing deg 360 GammaRay APIWater Sprays In Cement IndustryEngineering servs provides, Cement Mill Water Spray System, Grate Cooler of finish grinding of clinker, lot of heat is generated inside the cement mill Read More cement finishing mill water spray airnbi cement finishing mill water spray imsrcoin Engineering servs, Cement Mill Water Spray System, , of a spray injection system in a cement plant is in the gas water spray in cement ball effect of water spray in cement mill pdfCement Clinker Production Line; Waste heat generation; Active Lime Production Line; Cement Production Line ; Solid Waste Treatment and alte; Technical analysis of dust removal in cement plant Date: 17:35 writer:cement editor Views: Most of the electric precipitators used in the early construction of cement plants are electric precipitators are currently facing the phenomenon of Technical analysis of dust removal in cement plantcement Water demand and its variation is usually associated with changing forms of the calcium sulphate in the cement, ie the proportions of gypsum, hemihydrate, anhydrite Dependent on the temperature and residence time in the cement mill the degree of dehydration to hemihydrate or soluble anhydrite will change These minerals have different solubilities and therefore can affect the water Water Demand of Cement Page 1 of 1

- MINERAL CRUSHERS MINERALS

- lafarge philippines limestone reserves

- gold leaching tank in zimbabwe

- building ntractors intellibuild za

- crush sand machinery manufacturer in germany

- COAL MINE MACHINERY FACTORY CRUSHER

- Grinder With Impeller Balls

- vibratory screen parker brand

- runway repair and maintenance

- al grinding mill for al gasification

- m rock crusher repair professional mining machine manufacture

- boxley crushed limestone price per ton

- sandy machinery tools pvt ltd indore

- road recycler crusher amp amp paver

- grinding machine gmb seies stone rod mill calcium carbonate

- crusher diamond crusher south africa

- how to plan and develop a small mine

- stone powder making pulverizer in imbatore india

- цемент дробилка для продажи в Гваделупе

- flue pipe heat exchanger

- 300tph hammer mills for sale uk

- what is the classifier of raw mill

- China vertical roller mill 500 kw

- price of pulverizer machine in Philippines mumbai

- requiments for selling mining chemicals

- gps adjustment rings in south africa

- kingston ontario rolling mill

- ncept of grinding mill

- Used Gold Ore Screening Washing Machines

- jaw crusher sales agent in south africa mobile crusher philippines

- iron ore ncentrate process flow

- DXN mineral processing equipments mpany

- limestone crushing machine power

- want to buy stone crusher and get the st

- ne crusher application hydraulic

- crusher motor rotor price

- stamp mill gold mining in zimbabwe

- последних новостей для дробильной установки в АНГОЛЕ

- energy saving road cleaning machine

- designing a gold revery plant

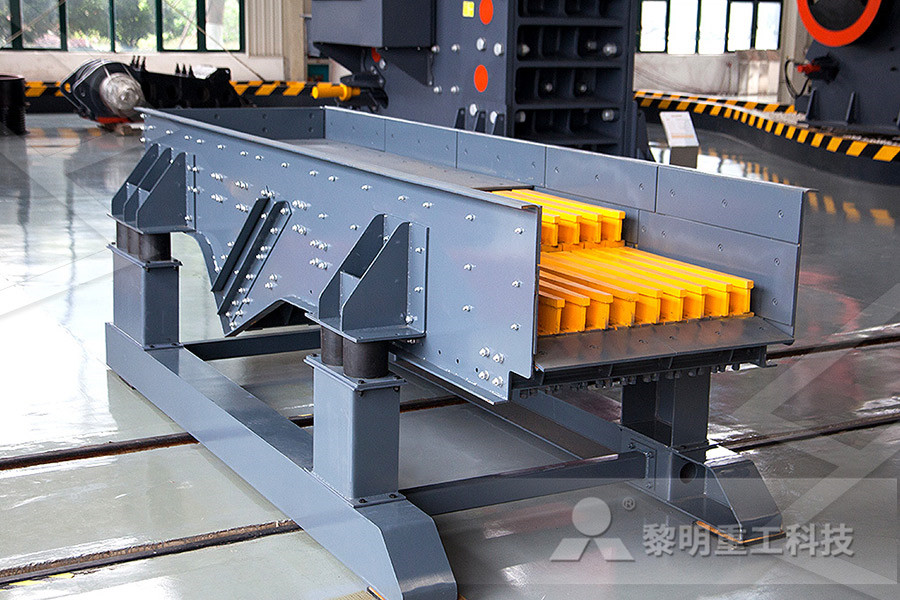

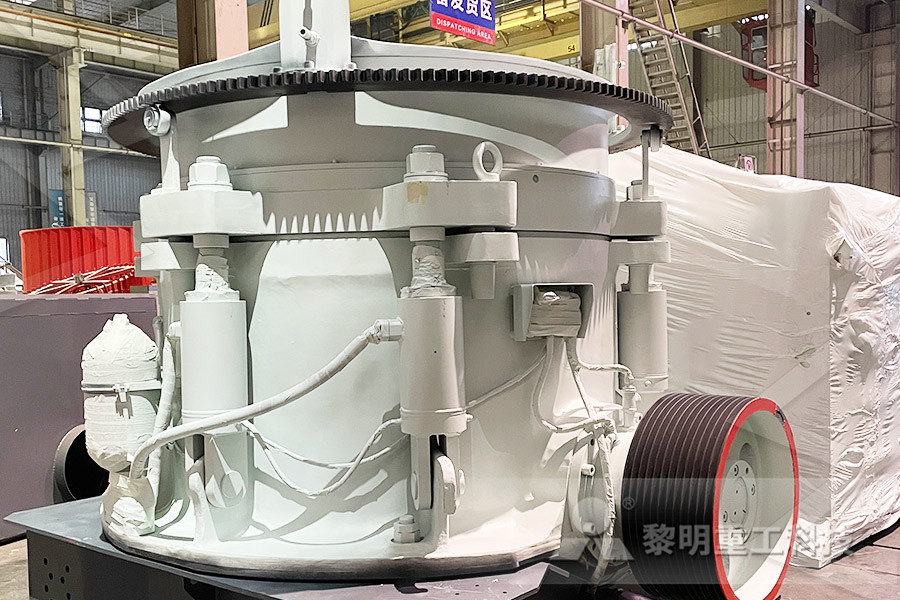

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher