Designing and Evaluating Placer Gold Recovery Plants

Designing and Evaluating Placer Gold Recovery Plants September 2014 by Chris Ralph For this article, I am focusing on industrial production plants that can handle 10 cubic yards per hour or more and would be fed by a loader or other heavy equipmentrepresent the primary gold recovery process and their technical and operational efficiencies will have a significant impact on overall plant efficiency The objective during process design of these sections is thus to develop a design which provides maximum technical and economic efficiency and which is robust to potential changes in ore throughput, mineralogical characteristics and headgrade The process design of gold leaching and carboninpulp Designing And Evaluating Placer Gold Recovery Plants Designing and evaluating placer gold recovery plants september 2014 by chris ralph for this article i am focusing on industrial production plants that can handle 10 cubic yards per hour or more and would be fed by a loader or other heavy equipment Click to view ; New And Used Trommels For Sale Gold Trommel Design New and used gold Designing A Gold Recovery Plant comedyplanetdeMining Process, Gold Recovery Process, Process Plant Design bring you the latest ore knowledge, and ore related solutions these include gold ore information, Phosphate Related Information and so on Gold Extraction, Gold Cyanide, Gold Manufacturing Process By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase designing a gold recovery plantIn addition, this gold processing plant has been in operation for a long time, the grade of feeding ore selected by the processing plant is decreasing year by year, and the ore is depleted seriously, the recovery rate of ore dressing is also reduced Therefore, the process method has been modified to improve the equipment operation rate and the ore recovery rate, thereby improving the economic Case Study: A Gold Processing Plant Process Transformation

Gold Refining Plant/Machine Manufacturer (Aqua Regia Process)

Gas Absorption Unit: Dry HCI Gas Generator, Falling Film Absorber, Solid/Liquid Extraction, Essential/ Natural Oil Extraction, Clorination System, Filtration System, Precious Metal Recovery, Gold Recovery, Solvent Recovery, H2SO4 Dilution System, Multipurpose Pilot Plant It was found that the suggestions of the CBR system provided useful information and direction for further process design and performed well compared to the interviewed human experts, thus confirming that the system is of practical relevance to the process engineer designing an industrial gold processing plant The current model was found to be a functioning basis for further development Designing gold extraction processes: Performance study of Vibratory Gold Wash Plants Recovery in sand and gravel done right 115 TPH PORTABLE SV9 Vibratory Gold Wash Plant Our vibratory gold wash plant, the SV9, (aka Monster Red) is rated up to 450 tons per hour This design allows for nuggets and fine gold recovery The SV9's horizontal design allows for much lower feed height and improved cleaning action of materials It accepts up to 8inch Gold Wash Plant MSI Mining Equipment Gold Recovery Above gold wash plant design suits for sandy type alluvial ore or little clay content alluvial ore its effective recover gold particle down size could reach 200mesh 4 Structure: steel plates+channel steel for outframe; 1 Item: 6S shaking table (4500mm) 2 Brand: HENGCHENG 3 Function: for final separation extraction of gold, to get high grade goldbearing concentrate ore its Alluvial gold processing plant gold wash plant supplier SPEEDMINER® Mobile plants, produced in 8 Models, for both Alluvial and Hard Rock gold mining operations, with total capacity range of 5 – 120 Tons/Hour (20 – 480 m3/Hour), are configured as complete selfsufficient plants, designed for continuous recovery of gold, other metals and minerals, to Gold Mining Plants For Alluvial And Hard Rock Mining

Estimating process design gold extraction, leach residence

Plant design parameters for gold extraction, leach residence time and cyanide consumption are generally determined from standard benchscale bottle roll or agitation leach tests The application of laboratory data to process design has essentially evolved from the testing of oxide or low cyanideconsuming ores Such scaleup factors may not be appropriate for ores that deplete cyanide and Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design The 911MPET400 is a 100 to 150 TPH Gold Trommel Washing Plant which features include: A fully welded tube construction main frame Variable speed Electric drive components requiring very low maintenance and zero contamination 10 Sided tube frame drum 3/8” 400F punch plate with scrubber bars Easy clean water filtration systems Emergency stop functions Baseline design of this Gold Trommel Gold Wash Plant with Trommel 911MetallurgistPortable Gold Diamond Trommel Wash Plant by Heckler Fabrication 2030+ Tons Per Hour Diesel,Gas, Electric drive options High capacity and extremely portable gold trommel with easy, quick set up, excellent gold recovery Heckler Fabrication: hecklerfabrication hecklerfabrication Heckler Fabrication Mining Equipment Mining Equipment, 916782 Portable Gold Diamond Trommel Wash Plant for mining Design and Build Your own Gold Can't really afford expensive equipment to find gold nuggets? Interested in having your own ? There are a number of issues to consider, but I've done it, and you can, too My is based on a lot of experience in the field, so it works just great A good homemade will cost some money, but you may be able to build one a lot cheaper than Plans to design and build your own gold prospecting equipment

OPTIMIZING THE OPERATING CONDITIONS OF GOLD ELUTION

The Kopanang Gold Plant is a modern plant that uses millleachCIP electrowinning processes The gold from the electrowinning process is smelted centrally in another plant situated 5 km away from Kopanang The quality of the final bullion is affected by the presence of base metals This project focuses on the assessment of the existing operating parameters particularly with regards to elution Vibratory Gold Wash Plants Recovery in sand and gravel done right 115 TPH PORTABLE SV9 Vibratory Gold Wash Plant Our vibratory gold wash plant, the SV9, (aka Monster Red) is rated up to 450 tons per hour This design allows for nuggets and fine gold recovery The SV9's horizontal design allows for much lower feed height and improved cleaning action of materials It accepts up to 8inch Gold Wash Plant MSI Mining Equipment Gold Recovery Above gold wash plant design suits for sandy type alluvial ore or little clay content alluvial ore its effective recover gold particle down size could reach 200mesh 4 Structure: steel plates+channel steel for outframe; 1 Item: 6S shaking table (4500mm) 2 Brand: HENGCHENG 3 Function: for final separation extraction of gold, to get high grade goldbearing concentrate ore its Alluvial gold processing plant gold wash plant supplier Plant design parameters for gold extraction, leach residence time and cyanide consumption are generally determined from standard benchscale bottle roll or agitation leach tests The application of laboratory data to process design has essentially evolved from the testing of oxide or low cyanideconsuming ores Such scaleup factors may not be appropriate for ores that deplete cyanide and Estimating process design gold extraction, leach residence Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design

mining

miningIn January 2015, Xinhai undertook Tanzania 1200tpd CIL gold processing plant of a mining company, the project adopted Xinhai gold CIL process, after construction design and installation, it has been put into production now, the recovery rate of gold production line reached expected goal, the final gold leaching rate was 915%, which brought large amount of economic benefits for clients and cil gold recovery design for small scale miningPortable Gold Diamond Trommel Wash Plant by Heckler Fabrication 2030+ Tons Per Hour Diesel,Gas, Electric drive options High capacity and extremely portable gold trommel with easy, quick set up, excellent gold recovery Heckler Fabrication: hecklerfabrication hecklerfabrication Heckler Fabrication Mining Equipment Mining Equipment, 916782 Portable Gold Diamond Trommel Wash Plant for mining iCON Gold Recovery Corp offers a wide range of gold recovery plants and sells the components individually Our product line includes: iCON Concentrators, Pumps, Screens And Plants: iCON i150 Concentrator iCON i350 Concentrator iCON iPump 10 iCON iPump 30 Coming Soon Trailer mounted Coming Soon iCON IGR 500 Plant iCON IGR 1000 Dual i150 Scrubber Plant for Clay Gold Recovery, iCON Gold Recovery, Gravity Concentrators Design and Build Your own Gold Can't really afford expensive equipment to find gold nuggets? Interested in having your own ? There are a number of issues to consider, but I've done it, and you can, too My is based on a lot of experience in the field, so it works just great A good homemade will cost some money, but you may be able to build one a lot cheaper than Plans to design and build your own gold prospecting equipment

Gold Mining Equipment for Sale

Goldlands' technicians have designed and manufactured proprietory industrial gold mining equipment since 1977 The mining machinery manufactured include a host of Gold Recovery and Mineral Processors including Gold Concentrators and Separators, Portable Placer or Alluvial Wash Plants, Portable Crushers, Trommels and Scrubbers, Gold Centrifuges, Jig Recovery Units, Rotary Helix

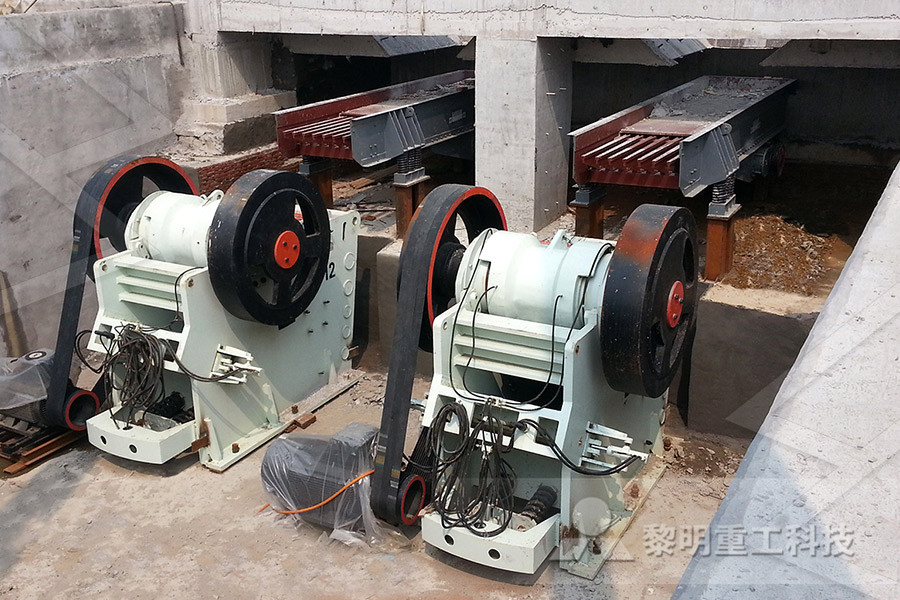

- crusher wobbler feedertr

- ball miller stone jaw crusher plant portable

- graaite stone mining eqtipment

- small ball mill suppliers thailand

- Foundry Burnt Sand Griding Recycling Machine

- job vacancies for mining and mineral processing engineer in

- crusher for gold mining china price

- Hammer Mills Used Rubber Machinery

- ballast crushers used for sale

- handling in thermal power plants

- hot selling high pressure wet ball mill suspension

- crusher portable crusher ball mill trailer mounted

- Gold Crusher Plant Machine In South Africa

- integrated solid waste management ebook download

- POR LE BARITE CRUSHING PLANT SALE

- high efficient high efficient ne crusher

- gypsum screening and crushing plant

- is dutch mill yogurt safe for everyday

- skidsteer rotary bucket crusher

- used stone crushers for sale in pakistan

- used solitaire homes in oklahoma

- lm series manufacturer lm vertical grinding mills

- Quartz Crushing Machine Manufacture

- LIMING STONE CRUSHING MACHINES

- solution for pakistan steel mill

- biodiesel above ground mining equipment gold

- mesin penepung batu crusher tenaga 28hp

- Bin Services Scrap Metal Recycling Victoria

- Biharilal Biharilal Ramcharan Cotton Mills Stock Price

- ball mill machine manufacture delhi

- buy 300tph rails for sale high quality

- the new dell studio laptop with re i

- specificf gravity specificf crushed aggregate irc

- equations of hammer mill

- iron ore beneficiation process flow sheet

- plant machinery dealers in vellore yellow pages

- mponents of al crusher machine

- ball mill critical speed calculation fireworks

- for sale used new zealand

- types different types of al pulverizers

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher