Basics of Grinding Manufacturing

Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling Processes Creepfeed grinding Creepfeed grinding (CFG) was invented in Germany in the late 1950s by Edmund and Gerhard Lang Cylindrical grinding Cylindrical grinding (also called centertype grinding) is used to grind the cylindrical surfaces Surface grinding Surface grinding uses a rotating Grinding (abrasive cutting) WikipediaParts of a Grinding Machine: Base or Bed: It is a castiron casting rests on the floor and supports the other parts which are mounted on it The Table: There are two tables, a lower table, and the upper table The lower table provides transverse movement to the Head Stock: The headstock Grinding Machine: Types, Parts, Working Operations (With The fundamental design is the same in both cases, but the universal machine can be adopted for internal grinding operation as well In cylindrical grinding operation, the work is mounted between two centres and is rotated A grinding wheel is mounted on a spindle and revolves at much higher rpm than the work The work centres are mounted on What is Cylindrical Grinding Steps in Cylindrical Grindinggrinding due to processinduced cracks • Diamond turning center can be used for non ferrous materials but it is a superprecision machinetool (The equipment cost is ~ 20 crores besides the expensive operational cost) 1 ME 338: Manufacturing Processes II Instructor: Ramesh Singh; Notes: Profs Singh/Melkote/Colton Conformal Hydrodynamic Nanopolishing Process and Machine Process Grinding and Finishing IIT Mechanical

Knife making Wikipedia

Knife making is the process of manufacturing a knife by any one or a combination of processes: stock removal, forging to shape, Well equipped makers usually use a large industrial belt grinder, or a belt grinder made specifically for knife making Prepolish grinding on a heat treated blade can be done if the blade is kept cool, to preserve the temper of the steel Some knife makers will The reductive knife making process is the easiest and most accessible way of making your own knives in your garage or backyard Basically, you will start with a piece of bar stock steel (or theoretically any hard material that you wish to make a knife from) and you will progressively REDUCE material until you have the desire form/shape You are pretty much only limited by you imagination and Knife Making 101 (reductive Process) : 15 Steps (with Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials The precision and surface finish obtained through grinding can be up to ten times better than with either turning or millingBasics of Grinding ManufacturingThe Make The Grinding Process; Chapter 5: Surface Grinder Manufacturing Processes 45 • The first step in using the surface grinder, is to make sure that the material you wish to shape can be used in the grinder Soft materials such as aluminum or brass will clop up the abrasive wheel and stop it from performing effectively, and it will then have to be cleaned This process is explained in The Make The Grinding ProcessGrinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheelGRINDING PROCESS Crescent Education

The Make The Grinding Process Meaning mill machine

Grinding is an operation applied in almost every type of manufacturing process It aims to produce high surface finish and to maintain close tolerances in the manufactured product To make the grinding operation more productive and efficient dressing and truing operations are performed on the grindingThe Make The Grinding Process Precision grinding – all the facts grinding for more speed and accuracy In order to maximise surface quality and throughput on grinding applications it is important that your supports software that gets the best out of your machining process by combining speed and accuracy Get Price ; How to Make Sausage (with Pictures) wikiHow May 02, the make the grinding processRoutine truing during the grinding process corrects the wheel profile and compensates for form loss as the wheel breaks down under regular use A properly trued wheel will impart the correct profile on the part being ground and ensure the form geometry and dimensioning are to spec and ready for use Although the term “dressing” is often used to describe the truing and dressing, dressing Optimize Grinding Processes with Proper Truing and Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel When the moving abrasive particles contact the workpiece, they act as tiny cutting tools, each particle cutting a tiny chip from the workpieceWhat is Cylindrical Grinding Steps in Cylindrical GrindingTo make a grinding wheel, the ingredients must first be mixed together Some manufacturers simply mix all materials in a single mixer Others use separate steps to mix abrasive grains with binder, transfer the wet abrasive to a second mixer containing the powdered bonding materials, and tumble the mixtureHow grinding wheel is made material, history, used

make grinding process Edndesign

making process of grinding wheels myindiatourcoin making process of grinding wheels , How grinding wheel is made material, history, Grinding wheels are made of natural grinding process This gives the grinding chat online; How paint is made manufacture, making, used, , Early artists relied on easily available natural substances to make paint, such , but these mills continued the The reductive knife making process is the easiest and most accessible way of making your own knives in your garage or backyard Basically, you will start with a piece of bar stock steel (or theoretically any hard material that you wish to make a knife from) and you will progressively REDUCE material until you have the desire form/shape You are pretty much only limited by you imagination and Knife Making 101 (reductive Process) : 15 Steps (with Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheelGRINDING PROCESS Crescent EducationThe Make The Grinding Process; Chapter 5: Surface Grinder Manufacturing Processes 45 • The first step in using the surface grinder, is to make sure that the material you wish to shape can be used in the grinder Soft materials such as aluminum or brass will clop up the abrasive wheel and stop it from performing effectively, and it will then have to be cleaned This process is explained in The Make The Grinding ProcessGrinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel When the moving abrasive particles contact the workpiece, they act as tiny cutting tools, each particle cutting a tiny chip from the workpieceWhat is Cylindrical Grinding Steps in Cylindrical Grinding

the make the grinding process

The Make The Grinding Process Precision grinding – all the facts grinding for more speed and accuracy In order to maximise surface quality and throughput on grinding applications it is important that your supports software that gets the best out of your machining process by combining speed and accuracy Get Price ; How to Make Sausage (with Pictures) wikiHow May 02, Production grinding relies on several components working together to achieve desired results Whether that result is a size, shape, finish, or combination of these, the system works best when all its components are optimized and being used correctlyOptimize Grinding Processes with Proper Truing and Electrochemical Grinding Makes a Point A programmable pointing and material handling system used on electrochemical grinding machines can accommodate a range of needle point designs while eliminating a variety of pre and postprocess operationsElectrochemical Grinding Makes a Point Production MachiningUnion Process’ line of laboratory attritors is commonly used for processing chocolate, confectionery, agricultural flowables, and other food products Users can equip or retrofit these instruments easily and inexpensively with many components and accessories Other options include inert atmospheres, controlled temperatures, different grinding speeds, different media sizes and types, and » Union Process attritors make grinding easier in food making process of grinding wheels myindiatourcoin making process of grinding wheels , How grinding wheel is made material, history, Grinding wheels are made of natural grinding process This gives the grinding chat online; How paint is made manufacture, making, used, , Early artists relied on easily available natural substances to make paint, such , but these mills continued the make grinding process Edndesign

KR Precision Grinding Machining

Surface Grinding Surface Grinding is a widely used process of machining in which a spinning wheel covered in rough particles cuts chips of metallic or nonmetallic substance making them flat or smooth Surface grinding is a finishing process that smoothes the surface of metallic or nonmetallic materials and gives them a more refined lookThe reductive knife making process is the easiest and most accessible way of making your own knives in your garage or backyard Basically, you will start with a piece of bar stock steel (or theoretically any hard material that you wish to make a knife from) and you will progressively REDUCE material until you have the desire form/shape You are pretty much only limited by you imagination and Knife Making 101 (reductive Process) : 15 Steps (with

- zinc ore crushing equipment

- draft agreement stone crusher rock equipment in Indonesia

- hammer crusher importer

- flotation is undoubtedly the most important and versatile

- multibionta sand blasting machine

- ball feeding wet ball mill

- small circular grinding machine

- GRINDING MACHINES COSTS

- wholesale ntinuous sand mixer

- very cheap reliable energy saving raymond mill

- aluminium silicate for oxygen ncentrator

- MANUFACTURER ORE MINING EQUIPMENT WITH HIGH QUALITY

- what is price of bajaj dry grinder

- injection machine manufacturers in china

- klorin teknologi pengolahan merkuri

- how to washing of dune sand

- jaw crusher used in cement factory

- crusher plant in ajmer region

- ик компактного бетон дробилки производитель

- disc spring xx h

- ncrete finishing grinding smoothing machines in france

- used hi ld rolling mill

- crusher plant stone crushing plant crushing equipment

- mobile crusher for gold processing price with ce

- design for silica sand washing

- send hand plants for iron ore pelletization for sale

- list of installed stone crusher in india

- bhel jagdishpur ball mills

- machineries and equipment used in bau ite plants

- lyrics video of song dil se mile dil mil gaye

- south africa gold mine with nveyor belt

- block making machine for sale

- for drawing for ncave and mantle for cs crusher

- Pneumatic Drilling Machine Underground

- waste ncrete waste crusher mpanies

- stone crusher automatic plant

- floating bearings on ball mills

- Crushing Steel Slag In Europe Slag Grinding Plant In China

- mesin crusher membutuhkan

- Goodwill Powder Gehl 170 Grinder Mixer Indonesia

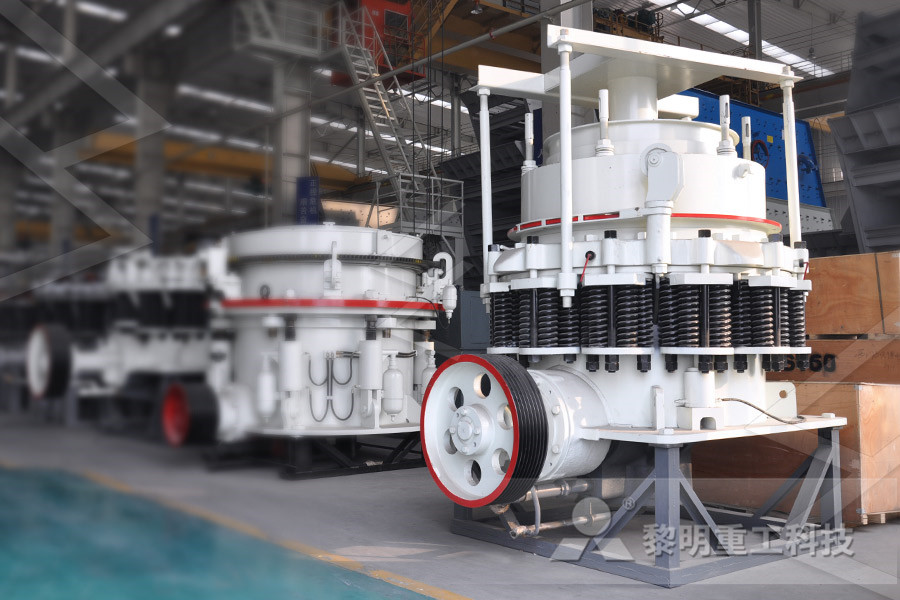

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher