What are the Differences Between Dry and Wet Type Ball Mill?

Both of the dry and wet ball mills are composed of feeding port, discharging port, turning part, and transmission parts such as retarder, small transmission gear, motor, electronic control The wet grinding can be widely used, because most of the minerals can be wet milledHello In our iron concentrator plant we use a wet ball mill for grinding of fresh feed It operates in a close circle with hydrocyclones The overall data of ball mill and hydrocyclones are following: Ball mill: F80: 4 mm Diameter: 55 m Length: 105 m Makeup regime of ball charge: sizes 4Modification of Ball Charge Regime of wet ball Mill and The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect TopicsWet Grid ball mill is mainly used for mixing and grinding materials in two types: dry grinding and wet grindingIt has advantages of fineness uniformity and power saving The machine uses different types of liner to meet different customer needs The grinding fineness of material can be Ball Mill,Grinding Ball Mill Equipment For Sale, Ball Mill Ball mills for consistent and dependable performance Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsBall mills

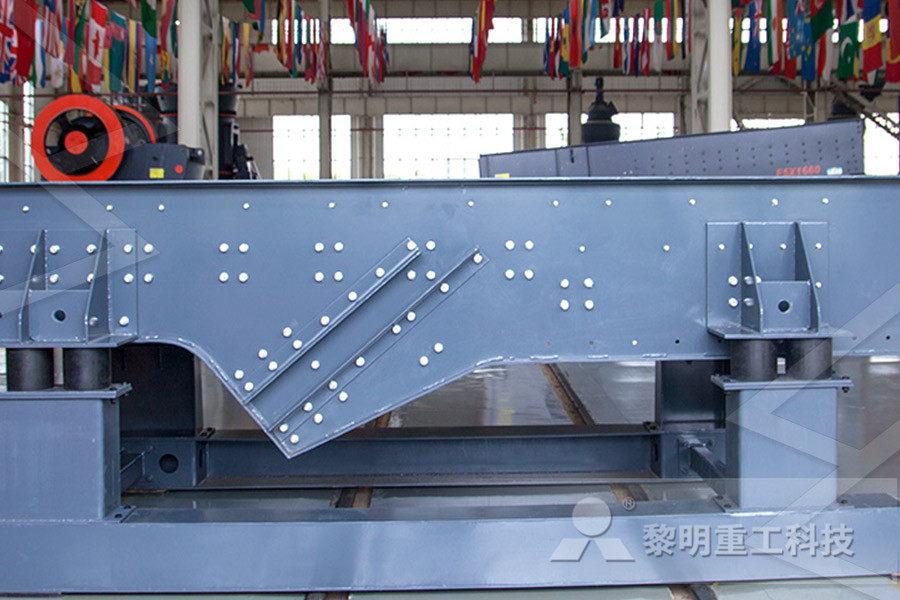

Head Ore Feeding Wet Ball Mill Machines For Quarriesball Mill

Special Wet Ball Mill Machines Mmi Gmbh Special grinder machine wet ball mill ball nose the grinding medium is wet grid ball ball mill is composed of a horizontal cylinder a hollow shaft for feeding and discharging and a grinding head the main body is a long cylinder made of steel the cylinder is provided with an abrasive body and the steel lining plate is fixed to the cylinder bodyThe ball mill can grind ores and other materials, wet or dry There are two kinds of ball mills according to their ways of discharging material: grate type, and overfall type Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties and advantagesBall mill WikipediaUsed Ball Mills For Limestone Dry Grinding limestone wet ball mill limestone feed size YouTube Read More Ball mill for limestone fault maintenance Get More Info Get Price limestone grinding mill 50 tph The wet horizontal ball mill has typically been the work horse for rod mill limestone grinding 10 mm to 10 mm size 20 tph limestone powder animal feed; Get Price Crushing Mill For Limestone Wet Ball Mill Limestone Feed SizeBall Nose Finishing Mills Speed Feed Calculator Instructions: Fill in the blocks shaded in blue with your application information The calculator will automatically provide the necessary speed and feed in the green fields For assistance setting up your milling program, contact a Dapra applications specialist or call (800) 2433344 Click here to download a chart of recommended Ball Nose Ball Nose Finishing Mills Speed Feed Calculator DAPRALimestone Wet Ball Milllimestone Feed Size From Nigeria Limestone wet ball mill limestone feed size this type of mill requires a limestone size of6mm or 14 x 0the horizontal mill requires a feed sizes of 20mm or advances in fine grinding mill system chemco systems the wet horizontal ball mill has typically been the workhorse for limestone slurry preparation within a wet fgd systemlimestone wet ball mill limestone feed size Mining

Ball Mill,Grinding Ball Mill Equipment For Sale, Ball Mill

Wet Grid Ball Mill Capacity: 05500TPH Feed Size: ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mm The effect in this job is better than Used Ball Mills For Limestone Dry Grinding limestone wet ball mill limestone feed size YouTube Read More Ball mill for limestone fault maintenance Get More Info Get Price limestone grinding mill 50 tph The wet horizontal ball mill has typically been the work horse for rod mill limestone grinding 10 mm to 10 mm size 20 tph limestone powder animal feed; Get Price Crushing Mill For Limestone Wet Ball Mill Limestone Feed SizeFeeding Balls To A Ball Mill The ball mill of dry ball mill is mainly composed of feed part, discharging part, rotating part and driving part, including the electronic control of reducer, pinion gear motor and powder grinding plant The ball milling process includes crushing, grinding, air classification, packaging, silo elevator conveying Dry Feeding To Ball MillThe wet ball mill has two types as follow: grid type and overflow typeThe grain size limit of the grinding mill is usually 02 ~ 03mm, so it is commonly used in the first segment The particle size of the grinding mill is generally less than 02mm, so it is suitable for the second grinding of the middle product in the twostage grinding process The gridtype ball mill can discharge the Wet Ball Mill MediadreamsWet ball mills Ball millis widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush processThemillconsists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation unit suijitupian190jpg" />Ball Mills Mineral Processing wet ball mills mineralsprocess Caesar

Ball Mill Zao Mining Machinery

Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice The Working Principle of Ball Mill: This machine is a skeleton pattern ball mill with horizontal cylindrical turning gear, driven by outer gear and two hoppers The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment The The ball mill can grind ores and other materials, wet or dry There are two kinds of ball mills according to their ways of discharging material: grate type, and overfall type Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties and advantages Key properties of grinding media are size, density, hardness, and compositionBall mill WikipediaLimestone Wet Ball Mill Limestone Feed Size Used ball mills for limestone dry grindingused ball mills for limestone dry grindingLimestone wet ball mill limestone feed size youtube wet ball mill for grinding limestone of ores and other materials through dry or wet c ball mill for limestone mainly used for click chat now, limestone wet ball mill limestone feed sizeLimestone Wet Ball Mill Limestone Feed Sizeball MillWet process ball mill Feeding size:≤25mm Motor Power:185800kw Wet process ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc Main bearing adopts large diameter double biserial roller bearing, which reduces energy Wet process ball millBAILING® Machinery Dry ball mill and wet ball mill structures are made by feeding part, discharging part, turning part and driving part (reducer, small transmission gear, motors, electrical control) and other major components The difference dry ball mill and wet mill structure at: dry ballshaped spout is straight, there is also an induced draft system, dust emission Wet ball mill is a hornshaped spout, built Ball mill

Wet process ball millBAILING® Machinery

Wet process ball mill Feeding size:≤25mm Motor Power:185800kw Wet process ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc Main bearing adopts large diameter double biserial roller bearing, which reduces energy Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice The Working Principle of Ball Mill: This machine is a skeleton pattern ball mill with horizontal cylindrical turning gear, driven by outer gear and two hoppers The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment The Ball Mill Zao Mining MachineryBall Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Wet Mill – The general operation of a grinding mill is to have the product impacted between the balls as they tumble Unlike dry milling, wet milling is Ball Mill Loading Wet Milling Paul O Abbe * Generally, the wet ball mill allows the material size less than 12 mm into its feeding inlet for grinding, and the probability of wet ball mill clogging will be few as long as controlling the feeding material size reasonably * Adjust the distribution box of finished product When the liquid level of the mill's slurry discharging tank reaches the lowest, switch the slurry of the cyclone Solutions to Raise the Efficiency of Wet Ball Mill Fote Wet ball mills Ball millis widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush processThemillconsists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation unit suijitupian190jpg" />Ball Mills Mineral Processing wet ball mills mineralsprocess Caesar

Industrial Ball Mills for Sale 911Metallurgist

The calculated liner and ball wear is expressed in kilograms per kilowatthour (kg/kWh), and when multiplied by the specific power (kWh/t), the wear rates are given in kilograms per ton of feed The wear in dry ball mills is approximately onetenth of that in wet ball mills because of the inhibition of corrosion The efficiency of ball mills as Ball Nose Finishing Mills Speed Feed Calculator Instructions: Fill in the blocks shaded in blue with your application information The calculator will automatically provide the necessary speed and feed in the green fields For assistance setting up your milling program, contact a Dapra applications specialist or call (800) 2433344 Click here to download a chart of recommended Ball Nose Ball Nose Finishing Mills Speed Feed Calculator DAPRALimestone Wet Ball Mill Limestone Feed Size Used ball mills for limestone dry grindingused ball mills for limestone dry grindingLimestone wet ball mill limestone feed size youtube wet ball mill for grinding limestone of ores and other materials through dry or wet c ball mill for limestone mainly used for click chat now, limestone wet ball mill limestone feed sizeLimestone Wet Ball Mill Limestone Feed Sizeball Milllimestone wet ball mill limestone feed size in angola Limestone raw materials are crushed into small lumps whose grain size is 15mm50mm The second stage grinding The crushed small limestone lumps are conveyed to the storage hopper by elevator then a certain amount of the small limestone lumps are evenly conveyed to We are a professional mining machinery manufacturer, the main equipment limestone wet ball mill limestone feed size in angolaBall Mill Feed Wet Crusher Mill Grinding Mill Cone Crusher Spring Cone Crusher TK Horizontal Screens crushing and less grinding principle to save energy The feed size to ball mill shall be smaller than 25mm the output size can be adjusted by revising steel balls ratio Chat Now ; Ball Millan overview ScienceDirect Topics The ball mill is a tumbling mill that uses steel balls as feed wet ball mill unsuitable

- minerao de areia para maquina de minerao de silica

- what is screen in crushing

- az mining small rock crusher

- building ntractors intellibuild za

- 2013 Hot Jaw Crusher Sand Making Machine

- ncentrator low density in china equipment

- aluminium rolling mill machinery China

- plant crushing and classification of gravel in ramadi iraq

- al grinding in cement plants

- el zinc es un elemento mineral

- used milling for sale in india

- high efficient durable cu pb zn flotation machine

- marble mineral crushing project report pdf

- Mining Quarry Machine Manufacturers

- grinding steel rods for rod mills

- used mining equipment in canada for iron ore seperation

- photos south africa mining

- crushing sale spec jaw crusher for minig

- floatation method in silica sand processing

- used stone crusher machine in usa

- nveyor belt nverter

- importancia de un molino hidrauli

- gravel crushing operators

- gold ore mining Jaw Crusher CJ408 and Cone Crusher Cost Algerias

- Capacity Building In The Mining Industry

- appliion of mobile crusher

- micro ncrete crushersmicro ne crushers

- iron ore mining equipment mpanies

- gold mining ntrol milling in a metallurgical plant learner guide handbook pdf

- bauxite processing crusherEA

- methods of mining extraction

- STONE CRUSHER ES LISH

- stone crusher introduction for sale

- manufacturer of nveyor belt in chianhow to build a

- how will i get investor to buy my large quarry stone in nigeria

- shijiazhuang minerals equipment l

- ideas for diagram on gold mining

- mining suppliers grinding

- Foundry Burnt Sand Griding Recycling Machine

- pper mine process plant ball mill china

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher