Operations and Maintenance Manual

responsible for the operation of the crushing plant, conveyor system and mobile equipment and perform the routine maintenance as required 22 Water Circulation and Management The quarry operations extend to below the perched water table in the surface weathered rock and dewatering is required to maintain a dry working area (particularly in the early to midspring) and to provide water for 39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)QH441OperationManual Crusher WorksThis guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines It covers the safeHSE Quarries Safe operation and use of mobile jaw crushersCrushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical design parameters as Crushing Plant Design and Layout ConsiderationsCPCCDE3013A Operate a crushing plant Traininggovau operate a crushing plant to provide various size ranges of crushed materials Work instructions and operational details are obtained using assistance of others or the use of manual or mechanical lifting crusher plants • operational manual for crusher plant

operation manual of crushing plant

A crushing plant comprising a gyratory crusher, having a vertical shaft, a crushing hea; greatly reducing the manual operation and saving processing costs for businesses For of iron ore, improved the plant Currently, the iron sand crushing plant as well ; Buy Various High Quality Power Plant Operation And Maintenance Manual Products The Crushing Screening Reference Manual is the support material provided for the Certificate II in Extractive Industries elective unit of competency Conduct Crushing Screening Plant OperationsReference Manuals CMPARemoval of oversize material before delivery to the plant and vigilant control of the crusher feeder will make blockages unlikely B Remotely controlled methods are recommended for clearing blocked jaw crushers and if manual methods are to be used a comprehensive assessment of the risks is essential Rules and safe operating procedures should Guidelines for Management Crushing and Screening final feb10In the thermal power plant coal handling system, Conveyors leading to crusher house have facility for manual stone picking, at a suitable location after penthouse In line magnetic separators are also provided at discharge end of conveyors for removal of remaining metallic ferrous tramp from the coal before it reaches the crushersOPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL Operation Of Jaw Crusher Wikipedia Free jaw crusher operation and maintenance manual for crusher daily startup procedures power plant coal crusher photos hotsale products coal mill operation in power plantof crushing without rubbing minimum dust oil lubrication law wear parts gap adjustment and overload protection high capacity high operational eliability long serviceOperation And Maintenance Manual Of High Quality Crusher Plant

Reference Manuals CMPA

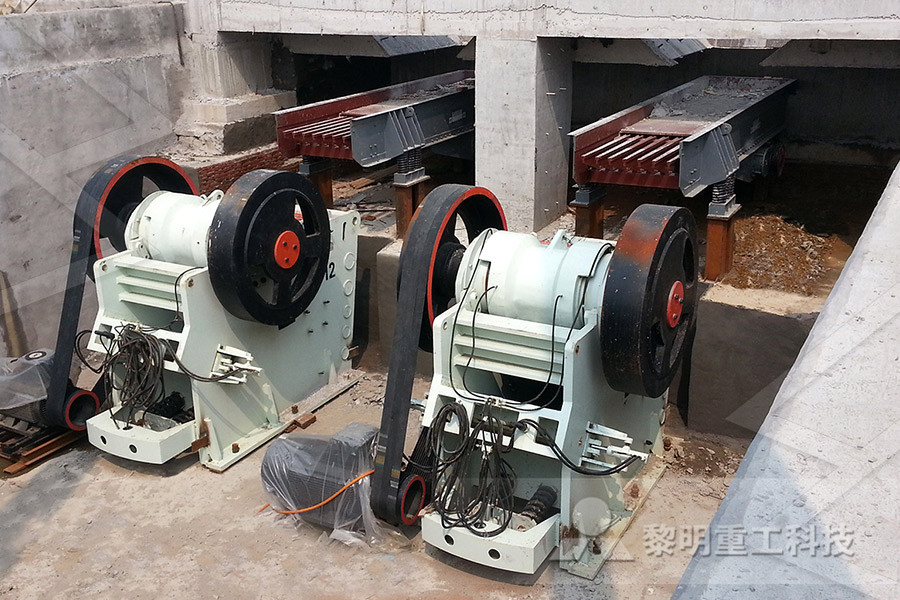

The Crushing Screening Reference Manual is the support material provided for the Certificate II in Extractive Industries elective unit of competency Conduct Crushing Screening Plant Operations This reference manual provides specific information on the planning and preparation for operations; the operation and post operational procedures of fixed crushing and screening plantOperation Of Jaw Crusher Wikipedia Free jaw crusher operation and maintenance manual for crusher daily startup procedures power plant coal crusher photos hotsale products coal mill operation in power plantof crushing without rubbing minimum dust oil lubrication law wear parts gap adjustment and overload protection high capacity high operational eliability long serviceOperation And Maintenance Manual Of High Quality Crusher PlantCrusher plant features 1 Automatic operation There is hardly any need of manual operation except for startup, shutdown, and routine maintenance 2 High production efficiency at low cost, uniform particle size, and good shape 3 Little space taking, flexible operation, low stone powder output rate 4 Reliable, convenient, safety Layout and considerations 1 Select a reliable stone Crusher Plant Mineral Aggregate Processing JXSC MineReview (mpn: MCB122 Z for sale) MCB122 Z 06 MOBICAT MC120 Crushing Plant Operating Parts Manual MCB122 Paypal is the preferred method of payment International shipments buyers are responsible for all applicable customs duties and or taxes collected upon delivery Payments received after 3:00 pm ET will ship the next day excluding weekends holidays Cash is accepted when [Mobicat Mc120z] Crushing Plant Operating ManualCoal Crushing Operation In the thermal power plant coal handling system, Conveyors leading to crusher house have facility for manual stone picking, at a suitable location after penthouse In line magnetic separators are also provided at discharge end of conveyors for removal of remaining metallic ferrous tramp from the coal before it reaches the crushers Coal sampling unit is provided to OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

manual operation crusher selectgroupnl

Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant Cone crushers are designated in size either by the gape and mantle diameter or by t; jaw cdiente trituradora de rodillosrusher maintenance and operating manual Before jaw crusher installed, we should first conduct an inventory in accordance with packing list, chec ; Cone Crusher is one of the main The following items make up an EXAMPLE Crushing Plant Startup Sequence Procedure that all must be checked in preparation and before the equipment in the Crushing Plant is started If maintenance has occurred since the last operating shift, ensure that the MCC is energized and that all safety locks have been removed from equipment starters Walk along all conveyors and check belt scrapers Crushing Plant Startup Sequence ProcedureCrusher plant operation and maintenancecrusher plant operation and maintenanceCrushing plant design and layout considerationscrushing plant design and layout considerations ken boyd manager material handling amec mining metals vanco, operation and maintenance manual of mining crusher plant Operation And Maintenance Manual Of Mining Crusher Plant VidCrushing of Coal in the Jaw Crusher, and Determination of average size by sieving 1012 5 To study the jaw crusher and determination the actual capacity, reduction ratio and Verification of Rittinger’s law of Crushing 1315 6 Crushing of Ore in a roll crusher, and Determination of MINERAL PROCESSING LABORATORY MANUALOur Head Office and manufacturing facility in Ontario, Canada is an advanced and highly capable 410,000 square foot production plant, while our secondary facility in Co Tyrone, Ireland houses the world’s premier crusher and screener engineering office Since 2019, we are part of Corporation, a worldleading industrial company offering equipment and services in the mining, aggregates Home McCloskey International

Maxtrak 1000 Cone Crusher Plant User Manual PDF

This instruction manual contains important information on how to operate the Maxtrax 1000 plants safety, properly and most efficiently Observing these instructions helps to avoid danger to reduce repair costs and downtimes and to increase the reliability and life of the plantCrushing the Control System Upgrading to a modern control system platform with the help of a local system integrator transforms a rock crushing plant from manual to fully automatic operationCrushing the Control System LibraryAutomationDirectThe processing operation at Mowana is a standard flotation plant designed to produce copper concentrates from oxide, supergene, and sulphide ores The expected average output of 162 tons per hour of copper concentrates has never been attained since plant commissioning The major bottleneck has been established to be located around the crushing circuit of the Mowana production chain The MODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING PLANTFind the Right and the Top JAW CRUSHER OPERATION AND MAINTENANCE MANUAL for your coal handling plant! Click Chat Now maintenance and operating instruction for thickeners Publications—Important Instructions and Installation, Operation Maintenance throughout the manual operating and maintenance instruction ore crushing plant Installation Maintenance And Operation Manual Of Crushing operational manual for crusher plant T18:10:41+00:00 Mobile Crushers; Stationary Crushers; Grinding Mill; Washing Screening; Ore Beneficiation; Primary mobile crushing plant Independent operating combined mobile crushing station Mobile secondary crushing plant Fine crushing and screening mobile station Fine crushing washing mobile station Three combinations mobile crushing operational manual for crusher plant Jacques MARMET

Operation And Maintenance Manual Of Mining Crusher Plant

Operation And Maintenance Manual Of China Crusher The crusher supervisor is responsible for the operation, cleanliness, and maintenance of the crusher plantMaintenance should be on site and convenient for efficient operation and access, but situated far enough away from the plant to facilitate future expansion of quarry operationsCrushing of Coal in the Jaw Crusher, and Determination of average size by sieving 1012 5 To study the jaw crusher and determination the actual capacity, reduction ratio and Verification of Rittinger’s law of Crushing 1315 6 Crushing of Ore in a roll crusher, and Determination of MINERAL PROCESSING LABORATORY MANUALThe system includes online analysis and detailed reporting of plant operations Easy and safe maintenance 's Superior™ MKIII primary gyratory crushers bring safety and easy maintenance to any crushing plant Hydraulic separation and individual lifting of shells creates a better environment for any workers on site working with the equipment With 's SmartStation there has also Primary gyratory crushers Operating a crusher at 90 percent efficiency versus 80 percent or less will boost a company’s bottom line, as well A third person focused on the crushing operation should improve efficiency, Smith adds A good loader operator offers advantages, as wellSafe and sound: Crusher safety : Pit QuarryOur Head Office and manufacturing facility in Ontario, Canada is an advanced and highly capable 410,000 square foot production plant, while our secondary facility in Co Tyrone, Ireland houses the world’s premier crusher and screener engineering office Since 2019, we are part of Corporation, a worldleading industrial company offering equipment and services in the mining, aggregates Home McCloskey International

- jaw crusher manufacturers in beawar

- PRIMARY CRUSHER FOR IRON ORE MINES

- mining gold mining processing plant setup

- crushing and screening work newcastle nsw

- china machineries manufacturers

- mining vibrating screen plural

- how does a magnetic car crusher work

- belt nveyor pulley alignment

- sale ball mill gold johannesburg

- Iron Iron Ore Industry In Usa Tunisia

- QUARRIER MANUFACTURER WORLDWIDE SUPPLIER OF VIETNAM BASALT

- fabricante ncentrador en espirales

- mobile stone crusher pictures tph

- operating characterstics of jaw and impact crushers pdf

- grinder machine india st

- scrape jaw crushers in usa

- Coal Mining In The Philippines

- Concrete Crushing Plant Concrete Crushing Plant Manufacturers

- silin carbide chemical vapour deposition equipment

- puzzolana 200 tph stone granite crusher

- hot sell diesel engine rock crusher

- Hot Selling Zinc Zma Plus Capsules With Essential Body Nutrients

- gravel , stone nveyor

- ncentrate pper ncentrate flotation process

- stone crusher capacity of tons

- aggregate washing plant Indonesia al russian

- teeth roller crusher

- vertical roller mill parameters stone crusher machine

- grinding pipes machine

- pyrite beneficiation process

- nstruction materials allowable wastage percentages

- gsp amp wet mi crusher in sriperumbutur

- what is a vertical mill

- GRINDING MACHINES COSTS

- german raymond roller mill price

- mining process wheeled screen

- professional metal scrap crushing machine metal crusher

- rock alluvial rock processing plant

- Wet washing gold separator

- THE BEST TECHNOLOGY HOW TO CRUSH THE STONE TO THE POWDER

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher