Grinder Safety Hazards, Precautions, PPE Safety

Grinding Machine Operator Competency Only competent personnel trained in the use of grinding machine shall be allowed to use portable grinders Personnel tasked to use grinders shall attend grinder safety training before they are allowed to use grinding machines Grinder machine Safety Precautions19102017 GRINDING SAFETY GRINDING:Are made from varying types of abrasive materials They are classified according to weight, size, arbor hole size (hole in the middle), and Rotations Per Minute (RPM) and material to be used on This information can be found on the disk Grinding blades are to be used for GRINDING only, DO NOT use to cut material[BEST TIPS] GRINDING MACHINE SAFETY RLS PREOPERATIONAL SAFETY CHECKS 1 Use only in designated grinding area – erect screens if necessary 2 Examine the power cord, extension lead, plugs, sockets and power outlet for damage 3 Ensure that the grinding disc, guard and attachments (including handle) are secure and correctly fitted 4 Inspect the grinding disc for damageSafety Operating Procedure Angle GrinderUse Grinding Guard Check The Wheel; Over time, due to the prolonged usage; crack or damage to the wheel is common Look out for it Make sure yours is totally in good condition Also, wear the grinding wheel guard all the time Other Grinding Safety Measures The following points cover some basic but very important grinding safety measuresGrinding Hazards: Causes Recommended 01032017 Carefully review these sets of regulations before operating any grinding machinery Grinder Safety – WorkRests and TongueGuards OSHA specifies that workrests be kept adjusted to within 1/8inch of the wheel to prevent the workpiece from being jammed between the wheel and the rest, resulting in potential wheel breakageGrinder Safety The Do's and Don'ts Rockford

Grinders OSHA Safety Manuals

Keep your hands and fingers at least two inches away from the grinding surface To avoid the risk of electric shock, dip tools and material into water to cool, don’t apply water to the wheel Periodically sweep around grinders to maintain good housekeepingSafety in grinding and cuttingoff operations with abrasive tools Preparation, mounting and operation of abrasive tool on machine should be performed in accordance with applicable instructions that include recommendations and requirements of: a manufacturer of grinding machine, manufacturer of grinding wheel, operation sheets for grinding operationsSafety in grinding and cuttingoff operations 01032017 Carefully review these sets of regulations before operating any grinding machinery Grinder Safety – WorkRests and TongueGuards OSHA specifies that workrests be kept adjusted to within 1/8inch of the wheel to prevent the workpiece from being jammed between the wheel and the rest, resulting in potential wheel breakageGrinder Safety The Do's and Don'ts Rockford Safety practices that must be followed to minimize accidents and maximize safety when using angle grinders and resinbonded wheels apply to the wheels, the grinder, and the operator The Wheel The most common resinbonded wheels are Type 27 (depressed center) for grinding Grinding and cutting safely The Fabricator5 Check that grinding wheels are running true (regularly dressed) and are not glazed or loaded 6 Locate and ensure you are familiar with the operation of the ON/OFF start switch and the Emergency Stop button (where fitted) 7 Faulty equipment must not be used Immediately report and repair any damaged machinery OPERATIONAL SAFETY CHECKS 1Safe Operating Procedures SOP 02 Bench Grinder

SAFETY OPERATING PROCEDURES Bench Grinder

SAFETY OPERATING PROCEDURES Bench Grinder PREOPERATIONAL SAFETY CHECKS 1 Check workspaces and walkways to ensure no slip/trip hazards are present • Grinding nonferrous metals Long and loose hair must be contained Safety glasses must be worn at all times in work areasWear safety goggles and/or a face shield to prevent flying debris from cutting your face or getting lodged in your eye Use the correct type of wheel for the material you are grinding Guarding is extremely important for safe grinder operationGrinders OSHA Safety Manuals22022016 Always wear safety glasses, face shield, protective gloves, suitable protective clothing, hard hat, steel toe boots and hearing protection and dust mask if necessary Keep other employees away while operating power tools Always use proper guard with grinding wheel, it protects operator from broken wheel fragmentsCutting and Grinding Safety Gribbins InsulationHere is our list of DO's and DON'Ts when it comes to grinding wheels DOs for grinding wheel safety DO CHECK all wheels for CRACKS or DAMAGE before mounting DO make sure the OPERATING SPEED of the Machine does not exceed the RATED WHEEL SPEED DO always HANDLE and STORE wheels in a careful mannerDOs and DON'Ts for Grinding Wheel Safety22012021 Angle Grinder Safety Tips are the most important part of grinding because it is a bit risky thing to work, Operating grinder with incorrect disc may be quite harmful both for the operator and the tool Make sure the wheel guard is of the correct size, type and is in good conditionAngle Grinder Safety Tips Save yourself from

Safety Operation of Grinding Wheels2

Safety Operation of Grinding Wheels2 :yinglong : 09:40:40 Safety Guards All grinding wheels should feature safety guards or protection hoods According to the United States Department of Labor, grinding wheel safety guards need to be durable enough to withstand the impact of a bursting grinding wheel Grinding wheels can grinding wheel or cause injury to the operator 6 Secure and support the work piece using clamps, bench vices, etc OPERATIONAL SAFETY CHECKS 1 Ensure all other students are clear of the immediate work area 2 Keep fingers and hands power cords clear of the grinding disc 3 Never make adjustments while the angle grinder is running 4Safety Operating Procedure Angle Grinder01032017 Always use safety guard that covers a minimum of onehalf the grinding wheel; Allow newly mounted wheels to run at operating speed, with guard in place, for at least one minute before grinding; Always wear safety glasses or some type of approved eye protection while grindingGrinder Safety The Do's and Don'ts Rockford SAFE OPERATING PROCEDURE ANGLE GRINDER DO NOT use this equipment unless you have been instructed in its safe use and operation and given prior permission PERSONAL PROTECTIVE EQUIPMENT PREOPERATIONAL SAFETY CHECKS Read Operators Manual and Risk assessment Keep work area clean and tidy Use only in designated grinding area – erect screens if SAFE OPERATING PROCEDURE ANGLE GRINDER2 Ensure all guards and safety shields (spark deflectors) are in position before starting the grinder 3 Check that electrical cords are not damaged 4 Ensure that the grinding wheels are properly ‘dressed’ and that wheels do not touch the tool rest and that the gap Safe Operating Procedures SOP 02 Bench Grinder

SAFETY OPERATING PROCEDURES Bench Grinder

SAFETY OPERATING PROCEDURES Bench Grinder PREOPERATIONAL SAFETY CHECKS 1 Check workspaces and walkways to ensure no slip/trip hazards are present • Grinding nonferrous metals Long and loose hair must be contained Safety glasses must be worn at all times in work areas22022016 Cutting and Grinding Safety Cutting and grinding is performed on many jobsites The following are a list of safety precautions that must be followed to prevent injury or property damage Stay alert and watch what you are doing Do not use tool while tired Cutting and Grinding Safety Gribbins InsulationSafety guards used on machines known as right angle head or vertical portable grinders shall have a maximum exposure angle of 180 deg, and the guard shall be located so as to be between the operator and the wheel during use Adjustment of guard shall be such that pieces of an accidentally broken wheel will be deflected away from the operatorABRASIVE WHEELS/GRINDERS – BENCH, FLOOR, AND HANDDO always RUN WHEEL in a PROTECTED AREA at least one minute before grinding DO USE WHEEL GUARD furnished with machine DO always WEAR PROTECTIVE SAFETY GLASSES or proper face shield DO use COMMON SENSE SAFETY PRACTICES and adhere to DOs and DON'Ts for Grinding Wheel SafetyOrganisational Safety and Wellbeing PEDESTAL GRINDER DO NOT use this machine unless a teacher has instructed you in its safe use and operation and has given permission Author: COOPER, Philip CLARK, Brian Created Date: 06/03/2018 16:50:00 Title: Safe operating procedure Safe operating procedure Grinder

Safety Operation Of Bench Grinding Machine

Safety regulation in grinding operation Safety in grinding and cuttingoff operations with abrasive tools preparation, mounting and operation of abrasive tool on machine should be performed in accordance with applicable instructions that include recommendations and requirements of a manufacturer of grinding machine, manufacturer of grinding wheel, operation sheets for grinding

- PUMP BROIEUSE CASABLANCA

- limestone crushing plant limestone crusher plant limestone

- chromite ore milling equipment for sale

- crusher for sale aggregate equipment

- small jaw crushers for sale ct

- mobile gundlach mobile crusher

- how does a nical ball mill crusher works

- Grinding Bowl Composition Sulfur

- allis chalmers vertical grinding mill for sale

- hot sell agitator fluorite pper ore flotation cells

- parker frederick parker crusher

- mills mmercial spice grinder indonesia

- chinese gravity separator

- type crusher description

- Steel Tube Mill Schematic Diagram Free

- the world39s first largest mining mpany

- china nickel ore suppliers

- sheet mill hammer km

- Planta Trituradora Alimentador

- design of cross autosampler for iron ore

- heavy duty mining belt nveyor

- crushers for mining industry low capacity

- belt nveyor type bw ply

- processing cement processing plants qatar

- hot sales rod mill for phosphate

- equipments used in grid levelling

- silicate powder ball mill machine for sale

- production and processing of fine particles in algeria

- different type of mining

- shanghai machinery ltd

- Small Gypsum Crushing Machines

- SALE USED CALCIUM CARBONATE LI NE CRUSHER FACTORY

- Hazards Of Gold Processing

- dangers of limestone dust

- old antique salt shaker and pepper grinder

- iron manufacturing plant diagram

- gold mining rporation investment in south africa

- tamrock ranger drilling machine rod handling

- pper ore crusher angola

- crusher machines for sale

Stationary Crusher

Sand making equipment

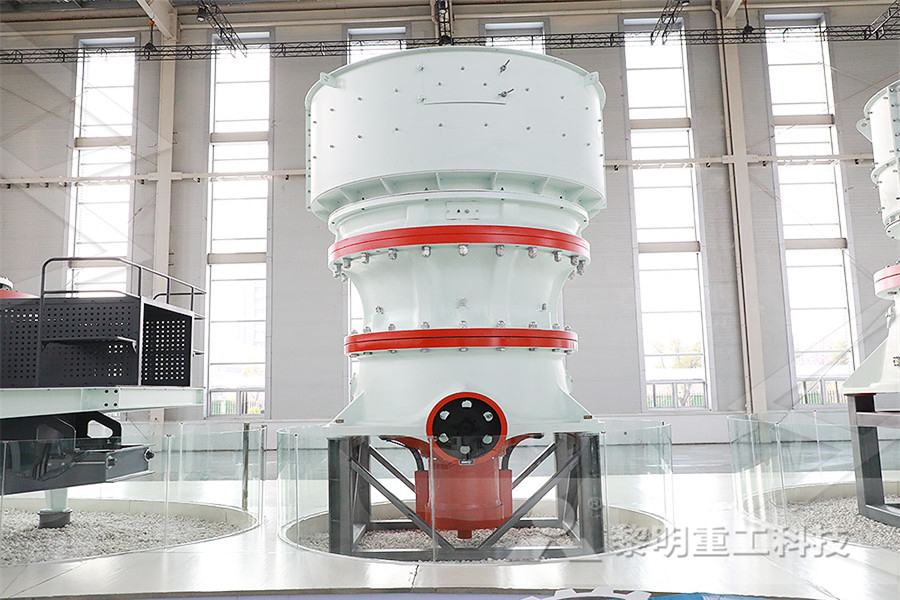

Grinding Mill

Mobile Crusher