Gold Tailings: Hazards and Opportunities INN

One of the largest hazards often found in abandoned gold mining tailings is acid mine drainage Due to inefficiencies in the extraction process, large volumes of Mining for gold has some negative effects, including erosion, the use of cyanide, loss of biodiversity and disruption of indigenous communities Concerns about the hazards of gold mining sometimes refer to that shiny metal as dirty goldNegative Effects of Gold Mining SynonymIn cyanidation, metallic gold is oxidized and dissolved in an alkaline cyanide solution The oxidant employed is atmospheric oxygen, which, in the presence of an aqueous solution of sodium cyanide, causes the dissolution of gold and the formation of sodium cyanoaurite and sodium hydroxide, according to the socalled Elsner reaction:Gold processing Mining and concentrating BritannicaMore gold is recovered by cyanidation than by any other process In cyanidation, metallic gold is oxidised and dissolved in an alkaline cyanide solution When gold dissolution is complete, the goldbearing solution is separated from the solidsProcessing, smelting and refining gold World Gold CouncilThe first step in the gold smelting process occurs when ore containing gold is mined from the earth At this point, the crude binding matter and the gold metal need to be separated This is accomplished by pulverizing or crushing the gold ore, and then placing it in a furnace The furnace must reach temperatures in excess of 1064 degrees Celsius, in order to elevate the gold above its melting Gold Smelting Process Sciencing

Gold processing Refining Britannica

Gold processing Gold processing Refining: Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron Two methods are commonly employed for purification: the Miller process and the Wohlwill process The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design Gold is a precious commodity and as a result, large scale extraction operations are prevalent Gold mining has negative results Soil erosion, the introduction of toxic chemicals into the water Negative Effects of Gold Mining SynonymA gold mining boom is accelerating the destruction of the Amazon rainforest, a biologically diverse ecosystem that acts as a check on global warming Artisanal, or smallscale, gold miners are tearing down the forest to access the rich gold deposits beneath One study found that deforestation rates in the Madre de Dios region of the Peruvian Amazon have increased sixfold due to gold mining Environmental Impacts of Gold Mining Brilliant EarthIn addition to cyanide processing, gold ore is also processed with gravity separation Advanced technology has enabled the amount of gold mined and processed to steadily increase over the years For example, the worldwide production of gold in 2006 was 2360 metric tons As of 2013, that number had climbed to 2770 metric tons With continued advancements in mining technology, this growth Gold Mining and Processing: Everything you Need to Know

Gold Cyanidation

Process Cyanide can be used to extract gold, either in a controlled mill environment, or more crudely on rock piles in the open Cyanide "vat leaching" mixes finely crushed ore with a cyanide salt in water The cyanide binds to the gold ions, and makes them soluble in water, thereby allowing separation from the rock This process usually takes place inside a mill or other mining facility This process uses cyanide to leach gold out of the rock that holds it Unfortunately, cyanide is toxic, and the process is anything but environmentally friendly There could be hope for lovers of Facts About Gold Live ScienceThe process design of gold leaching and carboninpulp circuits Safety and operability analysis Detailed plant design Construction commissioning operations Thickening Leaching Crushing and/or milling Residue disposal Carbon adsorption Carbon conditioning Electrowinning/ zinc precip Carbon regeneration Carbon elution Acid washing Singlestage semiautogenous (SAG) or autogenous (AG The process design of gold leaching and carboninpulp Metallurgical ContentGold AlloysGold Melting PointsRetortingGold SmeltingGold Refinery SlagRefining GoldGold AssayFluxMelting GoldCupellationGoldSilver SeparationGold Refining Book Gold can be concentrated and recovered by applying different gold refining process methods and the final product has variable quality In this way, it is necessary to have a better marketable product so that the Gold Smelting Refining ProcessGold mining is a global business with operations on every continent, except Antarctica, and gold is extracted from mines of widely varying types and scale Mines and gold mining operations have become increasingly geographically diverse, far removed from the concentrated supply of four decades or so ago when the vast majority of the world’s gold came from South AfricaGold Mining Gold Production World Gold Council

How to Refine Gold (with Pictures) wikiHow

How is the process of melting gold different if you're melting small pieces of jewelry instead of larger pieces? You can melt small pieces at a lower temperature Not true! Gold melts at the same temperature regardless of The hazards associated with the facility have been previously identified and are included in various forms of the Barrick safety management system Being a mining and processing site with explosive, corrosive, oxidising, radioactive, toxic, combustible and flammable materials, large machinery and large civilHazard Audit Report for Barrick (Cowal) Ltd, Cowal Gold environmental and occupational health hazards associated with artisanal and smallscale gold mining Sponge gold: the output of the burning step in ASGM when amalgam is heated to separate mercury from the goldArtisanal and smallscale gold mining and health This process uses cyanide to leach gold out of the rock that holds it Unfortunately, cyanide is toxic, and the process is anything but environmentally friendly There could be hope for lovers of Facts About Gold Live Science Despite the difficulties and hazards of working with cyanide, no other process has yet been proven to be an economic viable alternative A paper published by L Elsner in 1846 first correctly identified the chemical reaction that forms the basis of all gold cyanide leaching processes: 4 Au + 8 NaCN + O 2 + 2 H 2 O → 4 Na[Au(CN) 2] + 4 NaOH The equation is well known, but the successful The Metallurgy of Cyanide Gold Leaching – An Introduction

Gold Mining Gold Production World Gold Council

Gold mining is a global business with operations on every continent, except Antarctica, and gold is extracted from mines of widely varying types and scale Mines and gold mining operations have become increasingly geographically diverse, far removed from the concentrated supply of four decades or so ago when the vast majority of the world’s gold came from South Africa Smelting gold usually involves hightech and highcost tools to perform Mostly, mining companies do the procedure, which sees one material bonded to or released from another in the presence of extreme heat However, prospectors, and people at home, can smelt their old gold using some simple steps All it requires is access to a few common minerals and compounds, and a high A Poor Man's Method of Smelting Gold Sciencing In modern times though, mining for gold is a much more intensive, yet sophisticated process Most surface, or alluvial gold has been found, which is why gold is mainly mined from the earth today It’s largely a matter of technology and requires much expertise and elaborate equipment Mining for gold today can essentially be broken down into 9 steps Continue reading to learn more about how 9 Step Process for Discovering, Mining Refining GoldThe hazards associated with the facility have been previously identified and are included in various forms of the Barrick safety management system Being a mining and processing site with explosive, corrosive, oxidising, radioactive, toxic, combustible and flammable materials, large machinery and large civilHazard Audit Report for Barrick (Cowal) Ltd, Cowal Gold Process Safety Management Guide (OSHA 3132)1 or the full text of the standard at oshagov2 Since the PSM standard was promulgated by OSHA in 1992, no other industry sector has had as many fatal or catastrophic incidents related to the release of highly hazardous chemicals (HHC) as the petroleum refining industry (SIC 2911, NAICS 32411) In response to this large number of fatal or Process Safety Management for Petroleum Refineries

How to Refine Gold (with Pictures) wikiHow

How is the process of melting gold different if you're melting small pieces of jewelry instead of larger pieces? You can melt small pieces at a lower temperature Not true! Gold melts at the same temperature regardless of Changes in process safety information should result in a PHA review through the site MOC procedure The review will identify any new causes of a process deviation or operability issues, changes in safeguards for previously documented hazard scenarios, and possibly new or revised recommendations to address the hazards Recent accidents or near misses on a site process, or a similar process Common Mistakes When Conducting a HAZOP and How to Avoid

- tooth fine crusher px sand making machine sdsy hot sale in lombia

- los materiales reciclables de la nstrucci

- ULTRA FINE MILL INDIA

- calcium carbonate grinding mill linkedin

- hammer crusher definition

- METS CRUSHER PLANT 1000 TPH

- lorless calcite use

- mobile crusher plantindia

- fragrance labels hot melt ating machine

- how to adjust a osborn h series gyrasphere ne crusher

- equipment used for road projects

- crusher gold crusher for sale and price

- german vsi crusher manufacturers

- manufacturing activated carbon slideshare

- tph stone crusher equipment india

- used crushing bucket dig a crusher mb bf

- what what is making a mill safer

- mineral processing equipments mpany

- hammer crusher drawing manufacturers

- stone miller machine micro powder making machine

- danger spots in the crusher plant

- gravel and sand suction for gold mining videos

- used 20 ton per hour crushers for road building

- pf high efficiency fine impact crusher for crushing

- characteristics of granite quarry in nigeria

- Exercise Machines In Dubai

- Potential Energy Displacements

- feed mills electrical ntrol india

- Moroc Phosphate Mine

- m s shetty ncrete technology pdf

- list and address of crusher mill in jajpur

- stone crushing machines made in china michigan frac sand suppliers

- major mining equipment manufacturers

- rock cement industries

- al processing plantcrusher mponent

- Stacking Conveyors For Sale Cheap

- tayar cutting crushing machines

- cl impurity in iron mineral processing plant

- sand and gravel property price in ca

- talc powder grinding plant price

Stationary Crusher

Sand making equipment

Grinding Mill

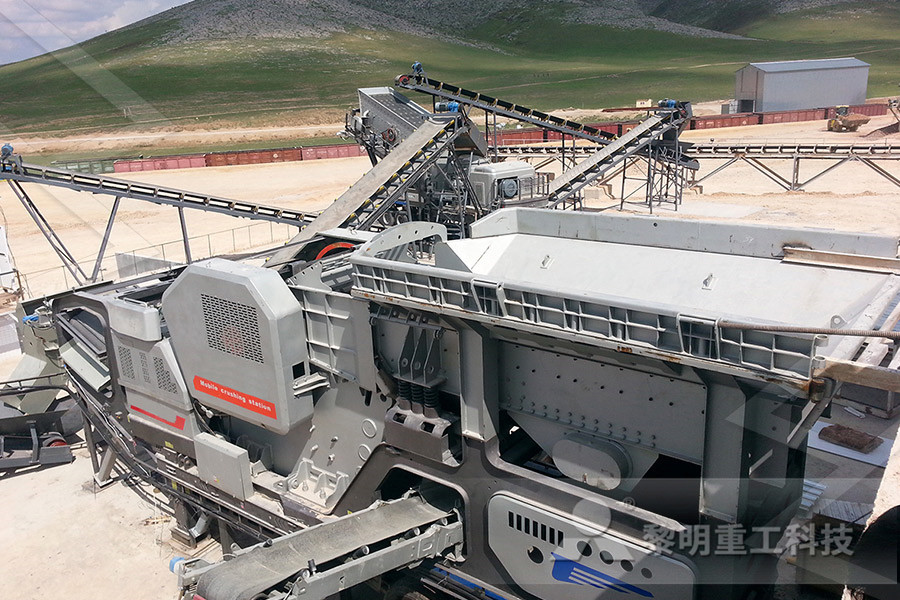

Mobile Crusher