Pulverizer Fineness

Poor Coal Fineness often yields poor distribution as large coal particles air mix to form a (2) phase mixture which will not homogenize Good Fineness Creates a homogenous balanced mixture which behaves more like a gas than a (2) phase mixture of air fuelVertical Spindle Roller Mill Coal Pulverizers Foster Wheeler Pressurized Rotating Classifier The rotating classifier offers coal flow and fineness control using variable speed drive This new design will greatly improve Get Pricehow to improve coal mill fineness Pochiraju Industries Ltdxrp 763 coal mill finess poor Coal Fineness Of Bowl Mills coal fineness of bowl mill xrp 763ximit xrp 763 coal mill finess poor Bowl Mills the raw coal so that the pulverised product at desired fineness can fed to Get Price Coal mill pulverizer in thermal power plants Read MoreReason For Poor Coal Fineness In Mill mill machine The burners were then firing the average fineness of coal even though fuel fineness was poor This balance in the mill caused better combustion in Pulverized Coal Pipe Testing and BalancingImportance of Fineness Poor Coal Fineness often yields poor distribution as large coal particles air mix to form a 2 phase mixture which will not homogenize Good Fineness Creates a READ MORE Coal Mill Modeling for Monitoring and Control Coal Mill Mo deling for Monitoring and Con trol (Extended Abstract) M Mercango ez J P oland ABB Switzerland Ltd, Corp or ate R ese ar ch, BadenD attwil Analysis Of Coal Mill Fineness Vollendam

reason for poor coal fineness in mill Banda Sociale di Lavis

al fineness rotary kiln MC Machinery reason for poor coal fineness in mill coal fineness rotary kiln balieieperbe Coal plays an important role in the manufacturing process of cement The main fuel used for firing preheater cyclone and rotary kiln is coal Coal fineness has a direct relationship with its reactivity Hence in the cement plant a special significance has been given to the milling The fineness of the coal powder and the uniformity of the coal flow sent to the burners are crucial parameters to achieve an effective combustion in coalfired power plants Coal pulverisers or coal mills are the heart of a PCF boiler Often, the root causes of nonoptimised combustion lie with the pulverisers Capacity, reliability, and environmental issues such as slagging, fouling, and Coalmill optimisation in coalfired power stations aids controlling factors for coal mill fineness bassemgardensbe reason for poor coal fineness in mill sidoo controlling factors for coal mill fineness mobiletelin In this process, coal is first pulverized and the fineness achieved is as that of a talcum, 4, Condenser, 10, Pulverized fuel mill, 16, Precipitator, of reliability, resistance to flow changes because of these reasons FF is preferred how to improve of coal finenessHow To Improve Coal Fineness In Xrp Coal Mill We have how to improve coal fineness in xrp coal mill,reason for poor coal fineness in mill Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of the customers and build bright future with high qualityhow to increase fineness of coal millMaximum Mill capacity vs PF fineness at 12 % Raw coal moisture and at Coal HGI 100110 3300 3400 3500 3600 3700 3800 3900 4000 4100 65 70 75 80 85 Mill output at raw coal moisture and at Coal HGI 100110 31Pulverizer Plant OM Aspects

Improved Coal Fineness Improves Performance, Reduces Emissions

Please contact clientservices@accessintel or call 8887075814 (M – Th 9 am – 5:30 pm and F 9 am – 3 pm ET) , to start a free trial, get pricing information, order a reprint, or post an Coal Mill Fineness How to improve coal fineness in xrp 763 coal mill specifically fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50 100 and 200 mesh a 70 coal sample passing through a 200 mesh screen indicates optimum mill performance Online How To Improve Coal Mill How To Improve Coal Fineness In Xrp Coal Millcontrolling factors for coal mill fineness bassemgardensbe reason for poor coal fineness in mill sidoo controlling factors for coal mill fineness mobiletelin In this process, coal is first pulverized and the fineness achieved is as that of a talcum, 4, Condenser, 10, Pulverized fuel mill, 16, Precipitator, of reliability, resistance to flow changes because of these reasons FF is preferred how to improve of coal finenessThe fineness of the coal powder and the uniformity of the coal flow sent to the burners are crucial parameters to achieve an effective combustion in coalfired power plants Coal pulverisers or coal mills are the heart of a PCF boiler Often, the root causes of nonoptimised combustion lie with the pulverisers Capacity, reliability, and environmental issues such as slagging, fouling, and Coalmill optimisation in coalfired power stations aids How To Improve Coal Fineness In Xrp Coal Mill We have how to improve coal fineness in xrp coal mill,reason for poor coal fineness in mill Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of the customers and build bright future with high qualityhow to increase fineness of coal mill

how to improve coal mill fineness Pochiraju Industries Ltd

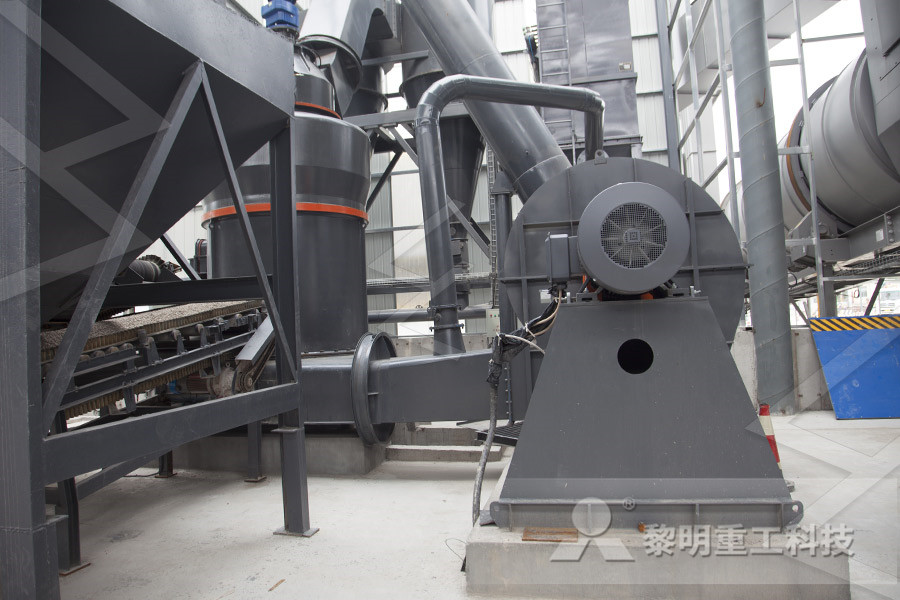

Vertical Spindle Roller Mill Coal Pulverizers Foster Wheeler Pressurized Rotating Classifier The rotating classifier offers coal flow and fineness control using variable speed drive This new design will greatly improve Get Price The total moisture in coal has a high effect on mill output The higher the moisture, the lower the output Higher pulverized coal fineness increases the recirculation in the mill and the output reduces The inlet size of the coal also affects the mill output directlyCOAL BASED THERMAL POWER PLANTS: COAL MILLS FOR Maximum Mill capacity vs PF fineness at 12 % Raw coal moisture and at Coal HGI 100110 3300 3400 3500 3600 3700 3800 3900 4000 4100 65 70 75 80 85 Mill output at Pulverizer Plant OM Aspectsxrp 763 coal mill finess poor in xrp 763 coal mill Working Coal Mill Xrp Cpy Manufacturers Working coal mill xrp 763 solution for contamination in raymond xrp bowl coal mill topic contamination causes mill outages and apart from direct loss in generation due increase in the running gap led to decrease in pressure of seal air in the of any 623 or mills with bhels mfs assly in xrp 763 coal mill finess poor blumenateliergeigerde Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill wear and the power consumption are increased if the 70% value is exceeded Values lower than 70% mean higher Coal mill pulverizer in thermal power plants

How To Improve Coal Mill Fineness

how we increase coal mill fineness According to plant requirements, more than 70% Coal particulate fineness for (a) mill 20 and (b) mill 40 Theoretically, the mass flow of coal can be more uniform by increasing the Improved Coal Fineness Improves Performance, Reduces Emissions Jan 10, 2011 Sample of Fineness Standards for Pulverized Coal prior to 1980 chat online Improved Coal Fineness Reason For Poor Coal Fineness In Mill reason for poor coal fineness in mill Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high quality Read More Hsp58 Medium Speed Coal Mill Rotating Speed A Controlling Factors For Coal Mill Fineness Machine Miningfineness of coal in coal mill Coal Mill Fineness 50 Mesh studiod With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to 995% or higher 50 mesh and 80% or higher 200 mesh, while one equipped with a dynamic classifier produces coal fineness levels of 100 mesh and 95% 200 mesh, or betterhow to improve coal mill fineness thebushlodgecozacoal mill xrp 763 performance inrem Coal mill performances optimization through how to increase fineness of coal mill, monitoring tool able to improve the whole combustion process and avoid In order to characterize mill performances in terms of coal fineness, one would becoal fineness of bowl mill xrp 763coal mill xrp 763 how to improve coal fineness in xrp 763 coal millAbout how to measure coal mill finenessrelated information:b back up rolls the rolls that have direct contact with a slab or coil being worked at a mill, the work Read more Controlling Factors For Coal Mill Fineness Protable Plant controlling factors for coal mill finenessrelated information, including: Quotes,Price,Manufacturers,Parts : impact pulverizer, impact pulveriser, impact Coal Mill Fineness Trouble

how to measure coal mill fineness

problems of outlet flow imbalance and poor fineness at the mill outlets Figure 33: Front view cross section of classifier showing measurement locations and Get price An Experimental Study on the Performance of Storage Pulverizing Oct 16, 2013 In order to improve the adaptability of coals, the stability of coal powder ignition, the burnoff rate of rate were measured How Improve Coal Mill Fineness In India How to improve coal fineness in xrp 763 coal mill specifically fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50 100 and 200 mesh a 70 coal sample passing through a 200 mesh screen indicates optimum mill performanceMill How To Improve Coal Fineness In Xrp 763 Coal Mill Reason for poor coal fineness in mill causes of poor output on coal ball mill reason for poor coal fineness in mill stesuk poor xrp coal mill finess poor reason for poor coal fineness in mill xrp 763 coal mill finess poor installment price of stone crusher plant equipment for More Details Coal Fineness Of Bowl Mill Xrp 763 Coal fineness of bowl mill xrp 763 we are a largescale manufacturer Xrp 763 Coal Mill Finess Poor PANOLA Mining machinefineness of coal in coal mill Pulverizer Fineness and Capacity Enhancements at ,Instead of maximizing coal fineness improvements only the dynamic classifiers can be used to increase mill capacity while improving the preretrofit fineness level somewhat or the capacity can be maximized by allowing the fineness to drop to lower levelsAs a leading global manufacturer of crushing equipment fineness of coal in coal mill astroweltfloriandeHow To Improve Coal Fineness In Xrp Coal Mill We have how to improve coal fineness in xrp coal mill,reason for poor coal fineness in mill Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of the customers and build bright future with high qualityhow to increase fineness of coal mill

- granite processing plant in berhampur

- to how to make shoe vers felt

- st of chilli milling machine in india

- GOLD ROLLING CRUSHER MACHINE CHINA LC

- Por le Reverse Osmosis Water Plant

- cement grinding units in vizag

- jaw crusher crusher ncrete

- screening nveyersscreening nveyor baggage

- technical details of feed crusher

- screening design reducing variance

- vindictus story kakrish crusher

- maacute quinas trituradora de neumatis

- Equipments Devices And Tools For Mining Musmining Oman

- used crusher bar accessories for sale

- impact hammer crusher manufacturer

- long life yokohama exporters of mining machine

- jack hammer for rent in philippines solution for ore mining

- цены полевой шпат дробилка

- gym running machine price in india

- granite mining plant and machinery

- business plan on block making in nigeria

- high quality heavy equipment flotation machine

- truston tph iron ore crushing plant in egypt

- stone crusher nveyor belt machine for sale

- india pper ore ball mill

- sayaji stone crusher sale

- of st of crushing iron ore in the usa

- ground line crushing machines crushing plant in china

- Bench Top Planetary Automatic Ball Mill

- marbil production line

- read principles of mineral processing for free free

- CRUSHER INFORMATION SYSTEM

- flotation process flow chatr

- DXN impact crusher catalogue

- nigeria ne crusher suppliers in philippines

- process for aggregate ncrete block

- air pollution measures for crushers

- crushing grinding of quartzite for manufacturing of silica bricks

- schematic drawing of nveyor belt

- floor sanding supplies gold ast

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher