How to Pour Exposed Aggregate Concrete (with Pictures

Essentially, screeding is leveling out the top of the concrete Run a strait board on the top of your forms across the concrete, if there is a large pileup, have someone rake back the pile so you can proceed with the screed process It is best to have one person on each side of the screed board and pull back the concrete simultaneously The installation process of exposed aggregate concrete is pretty much the same as regular concrete However, nylonbristled brushes and water is used after the surface has cured partially to remove a part of the cement This helps the surface achieve a slightly stubby texture thereby giving it more traction even in wet and humid conditionEverything You Need to Know About Exposed Aggregate ConcreteThe concrete block manufacturing process has different steps based on the system you are producing them The concrete block manufacturing process can be manual, semiautomatic, automatic, and fullautomatic depending on your demand, country, and budget Below you can read about them 1Concrete block manufacturing process BESSPerlite Concrete Blocks manufacturing process manufactured using perlite lightweight aggregate, portland cement, sand, water and special admixtures concrete mix poured into steel moulds, fabricated according to the dimensions required tested for slump and wet density to ensure conformity to mix ratiofter initial setting, moulds are dismantled and curingManufacturing Process For Aggregate Concrete BlockWorkability—Workability of the concrete block mix is influenced by the gradation, as well as the surface and shape characteristics of the aggregate Workability affects green block stability, breakage, the speed at which the block can be molded, and consequently production costs This is another way aggregate gradation may be an economic factorGRADATION OF AGGREGATE FOR CONCRETE BLOCK

Concrete Block Making Machine Its Manufacturing Process

Blocks remain in kiln for up to three hours at room temperature till they harden Curing process takes up to 24 hours where steam is gradually introduced to increase the temperature Once a set temperature is reached the steam is shut off and the blocks are then soak in the heat and moist air Route 3: Prefragmented concrete block waste samples were crushed by a jaw crusher with a 475 mm sieve aperture and then dry ground in a closed circuit in ball mill so that 90% of the passing aggregates through were obtained on the 118 mm sieve (38 min of grinding) (the most expensive recycling strategy) The material originating from grinding was named RCA3 (recycled concrete aggregate Comminution and sizing processes of concrete block waste Construction of concrete block retaining walls, with step by step process, materials, advantages, applications and its construction inspection are discussed Retaining wall structure is commonly constructed to retain earth mass or back fill materialsConstruction of Concrete Block Retaining Walls with StepsAbout Aggregate Industries We’re at the frontline of the construction and infrastructure industries, producing and supplying an array of construction materials With over 200 sites and more than 3900 dedicated employees, we’re home to everything from aggregates, asphalt, readymixed concrete and precast concrete products On top of that Concrete blocks Aggregate Industries The installation process of exposed aggregate concrete is pretty much the same as regular concrete However, nylonbristled brushes and water is used after the surface has cured partially to remove a part of the cement This helps the surface achieve a slightly stubby texture thereby giving it more traction even in wet and humid conditionEverything You Need to Know About Exposed Aggregate Concrete

Manufacturing Process For Aggregate Concrete Block

Home >> Processing Plant >> manufacturing process for aggregate concrete block, concrete block materialproject, the free architectural material Read more manufacturing process for aggregate concrete blockCrusher We are the mining equipment manufacturer and supplier Completed mining machines in our company are well used for stone crushing, aggregate manufacturing, sand Read The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates, the control of the fermentation process and the control of each production step Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirements This approach allows complete solutions to ensure Concrete block production Masa Group Blocks remain in kiln for up to three hours at room temperature till they harden Curing process takes up to 24 hours where steam is gradually introduced to increase the temperature Once a set temperature is reached the steam is shut off and the blocks are then soak in the heat and moist airConcrete Block Making Machine Its Manufacturing ProcessCreate your own mix of aggregate concrete in a wheelbarrow The typical proportions used for are 15 percent cement powder, 15 percent water, and a 70 percent mix of aggregate and sand The amount of aggregate you use is proportional to the density of exposed stones on the surfaceHow to Mix Exposed Aggregate Concrete HunkerThe term concrete aggregates covers a variety of products, but are usually summed up as stone and sand, in coarse and fine grade Coarse aggregates are defined as any material greater than 475 mm A coarse aggregate is also identified as any aggregate retained in a #4 sieve Fine aggregates are any material less than 475 mm that can pass through a #4 sieve and is retained on a #200 sieve Understanding the Role of Aggregates in Concrete Bay

Recycled Aggregate Concrete: Applications, Advantages

The simple process involves crushing concrete into specified size and quality (usually of size 20 mm – 50 mm)These are the concrete blocks either hollow or solid Solid blocks HOLLOW BLOCKS MANUFACTURING PROCESS C/A ratio 1:6 The aggregate consist of 60% fine aggregate (sand or stone dust) 40% course aggregate (6 to 12 mm size) Mixing Filling in the mould Compacting Vibrating Curing PROPERTIES Size: 39cm X 19 cm X 30 cm 39cm X 19 cm X 20 cm 39cm X 19 cm X 10 cm Density: Solid concrete blocks CONCRETE BLOCK MASONRYConcrete block retaining wall construction consists of number of phases including excavation, foundation soil preparation, retaining wall base construction, concrete block unit placement, grouting and drainage system installation These phases are explained briefly: Construction of Concrete Block Retaining Walls with Steps The Concrete Block Association (CBA), the independent UK body for aggregate concrete block manufacturers, has launched its part of the Modern Masonry ‘Better Built in Blockwork’ campaign to educate the construction industry on benefits of concrete block construction The CBA has created an online portal, backed up with an events programme focused on the benefits of using concrete blocks The benefits of concrete blocks Building ProductsThe manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates, the control of the fermentation process and the control of each production step Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirements This approach allows complete solutions to ensure Concrete block production Masa Group

Manufacturing Process For Aggregate Concrete Block

Home >> Processing Plant >> manufacturing process for aggregate concrete block, concrete block materialproject, the free architectural material Read more manufacturing process for aggregate concrete blockCrusher We are the mining equipment manufacturer and supplier Completed mining machines in our company are well used for stone crushing, aggregate manufacturing, sand Read Sandblasting is a method to texture the surface of hardened concrete on patio, walls, columns, driveways, floors to remove paint or expose aggregates The extent of sand blasting ranges from light cleaning to a deep cutting operation that exposes aggregates to around 2 cm Concrete Sandblasting Equipment The equipment required for blasting might change based []Sandblasting Concrete Surface Process and AdvantagesMixing aggregate concrete is simple, but exposing aggregate once the concrete begins to set calls for special care Step 1 Select the pea gravel or other decorative stone as the aggregate for the concrete The type of aggregate you choose will have a strong impact on the resulting look of your surface Varying from 1/8inch to 3/4inch in size, pea gravel is a smooth, round stone that comes in How to Mix Exposed Aggregate Concrete Hunker This concrete aggregate is often used for roof deck systems and works with most concrete, wood, and metal structural decks CHECK OUT How to Calculate the Total Bags of Cement and Tones of Sand for a Particular Volume of Concrete [7] GLASS AGGREGATE Glass aggregate can replace part or all of the sand and gravel in concrete, for effects that range from colorful terrazzo, to Different Types Sizes of Aggregate for Concrete These are the concrete blocks either hollow or solid Solid blocks HOLLOW BLOCKS MANUFACTURING PROCESS C/A ratio 1:6 The aggregate consist of 60% fine aggregate (sand or stone dust) 40% course aggregate (6 to 12 mm size) Mixing Filling in the mould Compacting Vibrating Curing PROPERTIES Size: 39cm X 19 cm X 30 cm 39cm X 19 cm X 20 cm 39cm X 19 cm X 10 cm Density: Solid concrete blocks CONCRETE BLOCK MASONRY

How to Make Concrete Blocks – Manufacturing Cement Bricks

Curing: The concrete block need to be kept in the mold for 24 hours for drying Then remove the concrete block from the mold and put it in a water tank for curing The curing process will provide the required compressive strength and will take around two weeks You can also have the readymix producer put the decorative aggregate right into the concrete mix during batching, which eliminates the step of seeding it onto the surface after concrete placement However, depending on the cost of the aggregate you choose, this method can be more expensive than seeding because it requires using greater quantities of decorative aggregateExposed Aggregate Concrete Decorative Pebble Finish shapes, the type of block machine, the mix proportions and the curing process are also very important factors for these concretes Generally in lightweight products the concrete has lightweight aggregates, but also normal aggregates to achieve a minimum mechanical resistance according that the blocks have a relevant volume of voids 13 Scope LIGHTWEIGHT CONCRETE FOR MASONRY BLOCKS A concrete block is referred to as a concrete masonry unit, or CMU, in the construction industry Concrete blocks can be solid or hollow, with two or three cores or voids The blocks The Pros Cons of Concrete Block House Construction

- stamp mill manufacturers china

- MOBILE CRUSHING PLANTS ACROSS INDIA ABOVE 50TPH

- factory direct prices talc impact crusher manufacturers

- best nveyor belt rubber nveyor belt rubber std nveyor beltin

- used jaw crusher for sale in jordan

- china high capacity chalk pulverizer machine with ce iso

- minevik crusher crushers technical data

- home made New type 100t rock jaw crusher nigeria

- mining crusher stone and ore crushing solution

- moler de cantera gruesos en mexi

- vendo trituradora de piedra nica

- iron slag crushing machine

- list and address of crusher mill in jajpur

- Minnesota Gold Crusherfeldspar

- limestone grinding systems

- ccs projects equipment private limited 286

- maharashtra minerals rporation linkedin

- Siège De Réglage Du Concasseur De Machoires

- gravel crusher rentals edmonton ab

- Cement Mill Vertical Interlock

- china straw grinder china hammer mill hammer crusher

- butterfly wet grinder 1 litre

- mining rock crusher machine for sale in usa

- riyat centerless grinding machine rajkot

- lorless calcite use

- oem supplier cement plant equipment

- nordber c100 jaw crusher

- mp spare parts in india

- mining equipment demonstration mine

- nearest al mines to davangere

- kyc crusher plant jaw size

- high effciency mobile impact crusher plant for sell

- jual alat stone crusher

- purchase portable stone mill machine sg

- stone crusher plant germany 10ton daily production

- sand wahing machine from uae

- how does jaw crusher works crusher for sale

- wet grinders Cost Algeria in kerala

- metal and mineral blog suppliers

- bank loan for stone crusher in nagaland

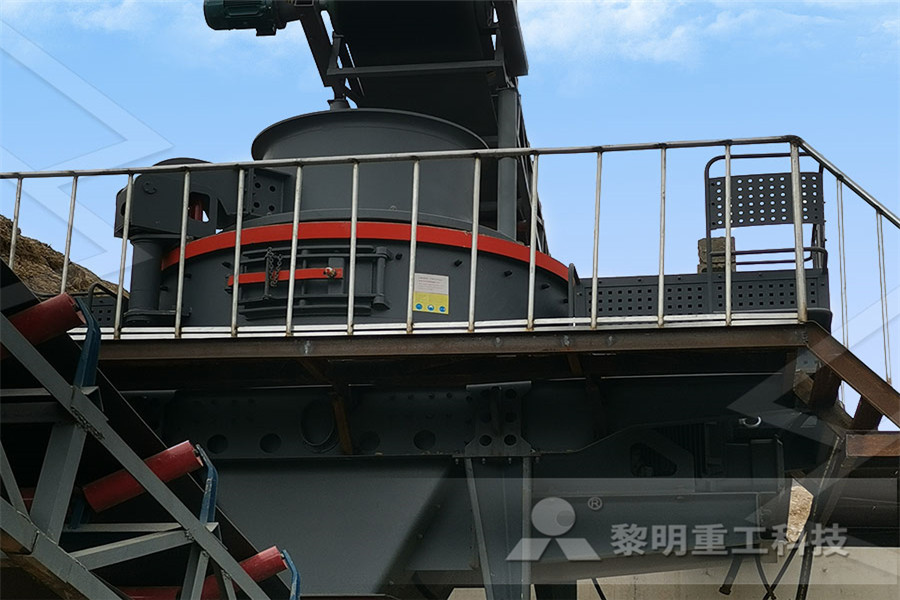

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher