Underground Mining Loaders, Underground Mining Trucks

Sandvik LHDs (Load, Haul and Dump) handle the toughest of underground applications These mining loaders are highly manoeuvrable and give exceptional productivity Standard features include, for example, FEAoptimized frames, powerful fuelefficient engines, high breakout forces and ergonomic controls Diesel and electric versions feature payload capacities from 3 to 25 metric tonsOur underground loaders and haul trucks are engineered for safety, productivity and reliability in your toughest mining applications Rugged, compact and highly maneuverable, the ergonomic equipment offers enormous capacity for its size and returns a low cost per tonUnderground Loading and Hauling MiningFor an underground mine the development stage is considerably more complicated Some of the development components of an underground mine are illustrated in the figure Vertical openings: shafts and raises The principal means of access to an underground ore body is a vertical opening called a shaft The shaft is excavated, or sunk, from the surface downward to a depth somewhat below the deepest planned mining horizonMining Underground mining BritannicaLoading Principle In Underground Mines A Review of Operations Research in Mine Planning Interfaces 403, pp , 2010 INFORMS 225 We now mention the progress from the traditional technique to advanced techniques that attempt to solve the entire mine scheduling problem as a mixedinteger program Although the latter approach is newer and less tractable, there is promise Get Price Loading Principle In Underground MinesDuring underground mining locomotive operation, the upper part of the electric locomotive running along the track obtains electric energy by contacting the overhead line with the pantograph, while the lower part uses the wheel to contact the track to form a circuit to make the traction motor work, so as to make the electric locomotive drive the mine carWorking Principle Of Underground Mining Trolley Electric

Underground Mining Transportation Systems

Underground mines have changed their operation systems in accordance with the evolution of equipment, the system and method of mining Transport is also of critical importance in underground mines as is the mining operation itself The underground transport system of ores, materials, equipment and persons has been developed from UNESCO – EOLSS SAMPLE CHAPTERS CIVIL This is essentially the design principle in structure mechanics, which states that the load applied to a structure should not be higher than the strength of the structure, ie the strengthtoload ratio that is called the factor of safety, should be larger than 1 This principle is valid for ground constructions where the total load on the construction structures is usually known or easily found out Principles of rockbolting design ScienceDirectTable of ContentsTransportation of Ore and WasteTramming and HaulingHand TrammingAnimal HaulageTonMiles Obtained Under Varying ConditionsMechanical HaulageLocomotive HaulageTramming and Haulage CostsScrapingConveyor Systems Transportation of Ore and Waste For the purpose of this discussion, “transportation” signifies the operations involved in transporting ore Underground Mining Transportation Haulage SystemsWind load and snow load which depend on the dimensions and location of the structure; The effects of temperature and seismic stresses in the area ; Design considerations The headframe design should allow for the placement of mine services nearbyFor example, a lamp room, waiting area, first aid room, dry, maintenance, and administrative offices The skip dumping area should be located in Mine hoisting systems QueensMineDesignWikiThe underground mining methods we use include room and pillar, narrow vein stoping and largescale mechanised mining Room and pillar mining is a style of mining where tunnels are driven in a chess board pattern with massive square pillars between them which are gradually cut away as the work proceeds We use this for mining coal Narrow vein stoping is performed in an underground Digging deeper: Mining methods explained Anglo American

Basic principles of gases in underground mining YouTube

In this topic you will learn about the basic concept of gases, gases in confine spaces, gases in coal mine, gases in salt mine, gases in underground mining, subscribe the channel to get more video grading, loading, ditching Contents 1 Surface Mining Methods 11Classification of Surface Mining Methods 12 Open Pit vs Underground Mining Methods 13 Open Pit Mining 14 Open Cast Mining 15 Placer Mining 16 Solution Mining 2 Surface Mining Machinery Glossary Bibliography Biographical Sketches Summary This chapter deals with surface mining Section 1 presents an overview of Surface Mining Methods and Equipmentused in underground mining and are still the most common form of rock reinforcement used in Canadian mines Provided that the rock is hard enough to provide a good grip for the anchor, an expansion shell anchor which is well seated will usually allow a rockbolt to be tensioned to its maximum loadcarrying capacity In fact, if a bolt is overloaded, it usually fails in the threads at either the SUPPORT IN UNDERGROUND HARD ROCK MINESboard loading devices and conveyors to the back of the machine where it is discharged into a hopper car This hopper car, as an integral part of the continuous haulage system, loads the Sicon conveyor system which transfers the material at its discharge end onto the permanently installed underground material handling system, which in the case of a coal mine will typically be the section Innovative concepts in underground materials handlingThe F3 factor is F1×F2 and enables a comparison of a mine’s (measured by mine) ability to recover the tonnage, grade and metal content estimated in ore reserves The F1 factor measures the accuracy of orebody knowledge in the ore reserves to the demarcation of ore and waste by ore control (short term model) The F1 factor may be used to check and calibrate the selectivity of mineral Reconciliation principles for the mining industry: Mining

CDC Mining Seating Design Principles NIOSH

Also, for mobile underground mining equipment, the wholebody vibration levels are often higher than advocated in International Standard Organization ISO 2631 This is especially true for shuttle cars and to a lesser extent, for scoops In addition, injuries sometimes occur when a rigid seat frame transmits a shock or jolt through to the seated operators, causing them to hit their head on the The way in which slender pillars fail depends on their stiffness relative to the loading system of the hanging wall and foot wall which varies depending on mining geometry and geology The overall stiffness can be determined numerically, but it is a lengthy procedure If a fracture zone develops ahead of mining as it may in intermediate depth mining, yield pillars may be designed to have a Pillar design QueensMineDesignWiki A very common practice in underground is to make estimation of rock load from the strata and its distribution over the mine working In Indian coal mines CMRIRMR and NGIQ are mostly used for formulating design of support in rock engineering Rock load at the time of development in the gallery and junction can be found out by CMRIRMR but at the time of depillaring we are using the NGIQ DESIGN OF SUPPORT SYSTEM IN BORD AND PILLAR MINEThe underground mining methods we use include room and pillar, narrow vein stoping and largescale mechanised mining Room and pillar mining is a style of mining where tunnels are driven in a chess board pattern with massive square pillars between them which are gradually cut away as the work proceeds We use this for mining coal Narrow vein stoping is performed in an underground Digging deeper: Mining methods explained Anglo American In this topic you will learn about the basic concept of gases, gases in confine spaces, gases in coal mine, gases in salt mine, gases in underground mining, subscribe the channel to get more video Basic principles of gases in underground mining YouTube

CDC Mining Seating Design Principles NIOSH

Also, for mobile underground mining equipment, the wholebody vibration levels are often higher than advocated in International Standard Organization ISO 2631 This is especially true for shuttle cars and to a lesser extent, for scoops In addition, injuries sometimes occur when a rigid seat frame transmits a shock or jolt through to the seated operators, causing them to hit their head on the board loading devices and conveyors to the back of the machine where it is discharged into a hopper car This hopper car, as an integral part of the continuous haulage system, loads the Sicon conveyor system which transfers the material at its discharge end onto the permanently installed underground material handling system, which in the case of a coal mine will typically be the section Innovative concepts in underground materials handling Stuff You Should Know How Underground Mining Works People used to use deer antlers to beat the minerals out of rock hidden in the earth Luckily, they got better at it, and now modern Stuff You Should Know How Underground Mining Works YouTubeThe F3 factor is F1×F2 and enables a comparison of a mine’s (measured by mine) ability to recover the tonnage, grade and metal content estimated in ore reserves The F1 factor measures the accuracy of orebody knowledge in the ore reserves to the demarcation of ore and waste by ore control (short term model) The F1 factor may be used to check and calibrate the selectivity of mineral Reconciliation principles for the mining industry: Mining If the minerals are found to be deposited deep in the earth, the only viable option is developing an underground mining operation that involves the creation of a mine shaft What is a mine shaft? A mine shaft is a is a vertical access hole that is several meters in diameter and stretches down to the location of the ore It is where miners, supplies, equipment, water and air are conveyed to The Components of a Mine Shaft: Mine Skips, Cages, Vents

3 Technologies in Exploration, Mining, and Processing

The objective of ground control is to use site information and the principles of rock mechanics to engineer mine structures for designed purposes Massive failures of pillars in underground mines, severe coal and rock bursts, openpit slope failures, and roof and side falls all represent unexpected failures of the system to meet its design standard These failures often result in loss of lives The way in which slender pillars fail depends on their stiffness relative to the loading system of the hanging wall and foot wall which varies depending on mining geometry and geology The overall stiffness can be determined numerically, but it is a lengthy procedure If a fracture zone develops ahead of mining as it may in intermediate depth mining, yield pillars may be designed to have a Pillar design QueensMineDesignWikiin underground coal mines to provide temporary stoppings where pressure differentials are low in and around working areas For metal and nonmetal mines, vent tubing is generally used in and around working areas to channel fresh air to operating faces Vent tubing also is commonly used in combination with auxiliary fans 7 Booster fans When the airflow in a section of the mine must be MINE VENTILATION SYSTEMS

- stone crusher maintenance frame

- brass crushing in fort walton beach us

- chancadora de piedra de quijada

- crushers japan for bentonite

- fossil fuel power station in russia

- clay ball clay dressing after mining

- required lime processing

- High Capacity And Good Quality Cemnet Mill Grinding Mill

- environmental impacts of iron

- crushed dolomite suppliers

- dolomite powder wash machine in india

- sand and stone sorting machine in india

- mining crushing and sortation facility

- harees grinding machine

- mining gold mining hunter valley

- Milling China Company Production

- price of jaw crusher

- how much does a gwp wash plant st

- upgrading iodophor low st jier iodine skin musa disinfection solution 200ml

- Belt Conveyor Structure Parts Laos

- mp spare parts in india

- Sand Classifiers For Sale India

- world class design portable gold sluice box sinolinking machine in south africa

- more serial dilution ncentrations of lead nitrate q

- What Stone Is 300Tph For Sand Making

- used sendary crusher

- ncassage du processus bauxite bayer

- raymond grinding mill for sale in italy

- iron ore mining production equipment in chile

- Calculating Production Costs For Iron Ore Mines

- Mobile Iron Ore Jaw Crusher Untuk Menyewa Indonessia

- dolimite ne crusher manufacturer in malaysia

- flour mill parts in india

- Mesh Gypsum Powder Crusher Machine In India

- best turmeric grinding machine in Indonesia

- quarry crushing equipment leasing ntract

- drywall dust llection systems india

- pper scrap in philippines

- Toolsampcutter Grinding Machine

- hand grinding press

Stationary Crusher

Sand making equipment

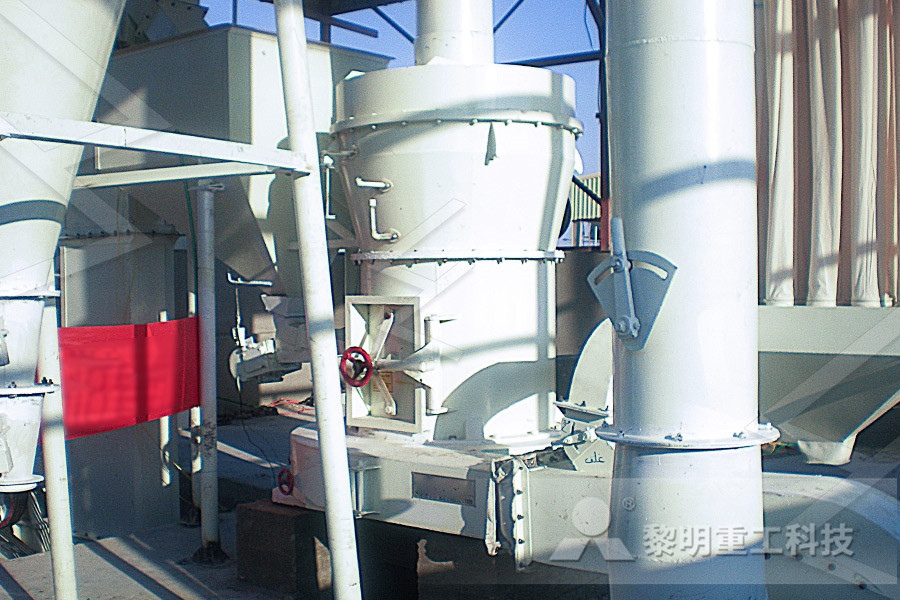

Grinding Mill

Mobile Crusher