Daswell Lime Calcination Plant Turnkey Solutions for

Lime calcination plant is a complete quicklime production line to produce quicklime (also known as burnt lime)by calcination of limestone which contains mainly calcium carbonate As quicklime or burnt lime is versatile material in industrial applications, many businessmen make forays into quicklime production plant Plant Support Lime Processing Pete Lien Sons, Inc Laramie , WY Wed, 28 Oct 2020 17:53:46 GMT An hourly employee who at the direction of the Plant Operator provides plant operational support duties as requested, performs plant cleanup general labor as required, and provides backup support to other team members as neededPlant Support Lime Processing Laramie Wyoming Lime Stone Mining Techniques Limestone Mining Metallurgy lime mining processing Lime in mining process High Density Sludge (HDS) Process SGS lime in mining process,HDS processing is a proven technology that has been in use in the mining industry for since the 1980s The process begins by mixing incoming effluent with a neutralizing agent (limestone/lime) and recycled sludge from a lime mining and processingThe lime cycle for highcalcium lime The process by which limestone (calcium carbonate) is converted to quicklime by heating, then to slaked lime by hydration, and naturally reverts to calcium carbonate by carbonation is called the lime cycleLime (material) Wikipedia Lime (calcium oxide or calcium hydroxide) is arguably the most common reagent used in the extractive minerals processing industry As an effective and economic pH modifier, lime is widely used in the process of selective flotation of the major sulphide mineralsLime use and functionality in sulphide mineral flotation

mineral processing process of lime stone

mineral processing process of lime stone HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the world It is not only widely applied in HJ Jaw CrusherJaw Crushers are often used as the Lime and limestone large used as building material; it is also an important raw material for many industrial Limestone can be directly processed into stone and lime Lime can be categorized into ordinary lime and hydrated limeit is required the use of crushing and grinding equipment process in limestoneThe Production Process Of Limestone ProcessingLime processing plant is a lime production line to make lime which is also called quicklime When limestone (calcium carbonate) is calcined, the decomposition of limestone will happen and produces quicklime (CaO) and carbon dioxide (CO₂)Tailored Solutions for Lime Processing Plant Daswell Barite powder processing plant ficcifipicin design barite and lime processing plant design barite and lime processing plantmpceorgin he already had one barite ore processing plant for barite powder making but the customer spoke highly of this Read More; Barite Processing Plant Barite processing plants manufacturers traiteurarnebe barite processing plant mahakdyechemin barite Design Barite And Lime Processing Plant Vierbeinerei The third type of processing of limestone consists of the production of hydrated lime, which is a dry powder obtained by treating quicklime with sufficient water to satisfy its chemical affinity for water, thereby converting the oxides to hydroxides Hydrated lime is Limestone – Its Processing and Application in Iron and

Tailored Solutions for Lime Processing Plant Daswell

Lime Processing Plant Lime processing plant is a lime production line to make lime which is also called quicklime When limestone (calcium carbonate) is calcined, the decomposition of limestone will happen and produces quicklime (CaO) and carbon dioxide (CO₂)The following procedures shall be utilized to determine the amount of lime required to stabilize the subgrade Hydrated or quick lime and lime byproducts should be used in the range of 4 ± 05 and 5 ± 1 by weight of soil for modification respectively The following procedures shall be used to determine the optimum lime content Chat Online; Everything about Cement ProductionAdvancing Mining determine lime production process(57) [Summary] A method for obtaining a solution of calcium ions from lime (eg, carbide lime) is disclosed In one embodiment, the method comprises treating lime with an aqueous solution of a polyhydroxy compound having 3 or more hydroxy groups and a straight chain of 3 to 8 carbon atoms, preferably sorbitol, and (ii) optionally , (I) separating insoluble impurities from the solution obtainedJPA Lime processing Google Patents3) Lime Calcining (Conversion of limestone (CaCo3) to lime (CaO)) Limestone is a source of calcium carbonate and is heated to convert the calcium carbonate into calcium oxide This process is generally carried out in large rotary kilns or vertical shaft kilns where high temperature is required Quicklime is produced in the calcination process Lime Production from Limestone Current TechnologyFrom its varying composition, to its abrasive nature, limestone requires an engineered process solution, combined with heavyduty equipment That’s why we not only offer limestone processing equipment, but can also help develop a limestone process that works around your unique source of limestoneLimestone Processing FEECO International Inc

use of lime in gold processing

use of lime in gold processing: Lime in Gold Ore Mining Process Flotation, Cyanidation In the cyanidation process, lime can be used as a depharmaceutic agent for the gold concentrate cyanide plant before the immersion thickener to remove harmful substances, prevent the occurrence of gold concentrate runoff phenomenon and reduce unnecessary losses; As a prealkali dipping agent, it is crushing and sizing; (3) calcining limestone; (4) processing the lime further by hydrating; and (5) miscellaneous transfer, storage, and handling operations A generalized material flow diagram for a lime manufacturing plant is given in Figure 11171 Note that some operations shown may not be performed in all plants The heart of a lime plant is the kiln The prevalent type of kiln is the 1117 Lime Manufacturing US EPAThe theoretical heat (the standard enthalpy) of reaction required to make highcalcium lime is around 315 MJ per kg of lime, so the batch kilns were only around 20% efficient The key to development in efficiency was the invention of continuous kilns, avoiding the wasteful heatup and cooldown cycles of Lime kiln WikipediaLIME (Line Modelling Engine) is an excitation and radiation transfer code that can be used to predict line and continuum radiation from an astronomical source model The code uses unstructured 3D Delaunay grids for photon transport and accelerated Lambda Iteration for population calculationsLIME user manual — LIME documentationNonferrous Metals Lime is a key,To process gold and silver, lime and cyanide are added,from sulfur in the "melting down" process Some plants use lime to lime mining process rajhotelin lime process for gold mining Ore Processing » Waihi GoldAt the processing plant,, Mining >Ore Process >use of lime in copper leaching;Process For Mining Lime Gold

Lime Requirements American Agricultural Laboratory

The rate of lime required to raise soil pH to a desired level is determined by measuring the buffer pH While active acidity refers to the hydrogen ions in the soil solution, “reserve acidity” is used to describe hydrogen ions bound to cation exchange sites on clay particles in soil When all the hydrogen ions in the soil solution are neutralized, replacement ions are released from these The following procedures shall be utilized to determine the amount of lime required to stabilize the subgrade Hydrated or quick lime and lime byproducts should be used in the range of 4 ± 05 and 5 ± 1 by weight of soil for modification respectively The following procedures shall be used to determine the optimum lime content Chat Online; Everything about Cement ProductionAdvancing Mining determine lime production processGeneral process flow diagram for the manufacturing and processing of lime Source: Midwest Research Institute Emission Factor Documentation for AP42, Section 1115, Lime Manufacturing Prepared for US Environmental Protection Agency, Office of Air Quality Planning and Standards, Emission Inventory Branch Cary, NC, Midwest Research Institute April 28, 1994 24 211 Crushing The first Lime Production: Industry Profileprocessing the lime further by hydrating; miscellaneous transfer, storage, and handling operations In addition,the lime making process consists of the burning of calcium or magnesium carbonates to liberate carbon dioxide and to obtain the derived oxide The calcium oxide product from the kiln is generally crushed, milled and/or screened before being conveyed to silo storage From the silo Hydrated Lime Manufacturing ProcessLime dosage requirement is most important process in Sedimentation Process, to separate the solids from liquid by gravity Sedimentation is the basic process, whether water and wastewater treatment, In water treatment process, first remove Girt / fine fibers in presedimentation basin and follows coagulation–flocculation is most commonly used We find adequate /require amount of alkalinity How to Calculate Lime Dosage Requirement in Sedimentation

What is Lime? Graymont

The lime cycle After processing, products derived from limestone have the unique ability to return to their original chemical form The lime cycle consists of first burning of limestone to form quicklime Hydrated lime can then be produced by adding water to the quicklime At this point, carbon dioxide in the atmosphere or from industrial processes react with hydrated lime to convert it back 3) Lime Calcining (Conversion of limestone (CaCo3) to lime (CaO)) Limestone is a source of calcium carbonate and is heated to convert the calcium carbonate into calcium oxide This process is generally carried out in large rotary kilns or vertical shaft kilns where high temperature is required Quicklime is produced in the calcination process Lime Production from Limestone Current Technologyworks effectively with others to undertake and complete the processing of lime products that meets all of the required outcomes including: using a range of communications techniques and equipment to convey information to others maintaining written and verbal reporting requirements and procedures communicating to confirm work/plans/specifications demonstrates completion of processing lime Assessment Requirements for RIIPBP301D Process lime productscrushing and sizing; (3) calcining limestone; (4) processing the lime further by hydrating; and (5) miscellaneous transfer, storage, and handling operations A generalized material flow diagram for a lime manufacturing plant is given in Figure 11171 Note that some operations shown may not be performed in all plants The heart of a lime plant is the kiln The prevalent type of kiln is the 1117 Lime Manufacturing US EPAuse of lime in gold processing bargentino Nonferrous Metals Lime is a key,To process gold and silver, lime and cyanide are added,from sulfur in the "melting down" process Some plants use lime to lime mining process rajhotelin lime process for gold mining Ore Processing » Waihi GoldAt the processing plant,, Mining >Ore Process >use of lime in copper leaching; The Mining Process Waihi Process For Mining Lime Gold

- supplier stone crushar segamat

- STONE CRUSHER PRICE TYPE X 600

- alvan blanch horizontal grinding mill for sale

- PHOENIX CRUSHER PROJECT

- sami engineering cement plant machinery

- crusher william ofjaw crusher run delivered

- nigeria ne crusher suppliers in philippines

- SAND VIBRATING SCREEN PRODUCTS MADE IN USA

- HOW MOBILE CRUSHER WORKS

- how much is a hp ne crusher for sale

- chancadora en venta en peru olx

- characteristics of granite quarry in nigeria

- pany make for nsruction equipment

- used small jaw crushers for sale in vanuver

- gypsum manufacturing synthetic

- China crusher rotery al crusher

- galena sphalerite occurrence

- ground blast furnace slag small vertical mill

- method of mining in nigeria

- effective protective film slitting machine

- ball mill used in stone crushing llinsville rock quarry llinsville al

- what is the process of making stone crusher

- marble industry equipment

- ncrete crushing professional

- essa laboratory jaw crusher model

- MOBILE CRUSHER FOR GYPSUM CRUSHING PROCESS FOR MINING

- technical data limestone crusher

- Who Is The Owner Of Stone Crusher Machine Ng

- low benching wall stone quarrying machine

- agent hammer mill ex china

- how much the stone crusher plant st

- hot sales mineral cpopper breaker machin

- méxi clinker grinding plant

- al pulverizing equipment

- old stone crusher for sale in odisha

- patented mining claims in alaska for sale

- effects the effects of road nstruction wastes on the environment

- aluminum slag crusher machine

- brick crusher supplier for south africa

- pm mine tailings revery machine

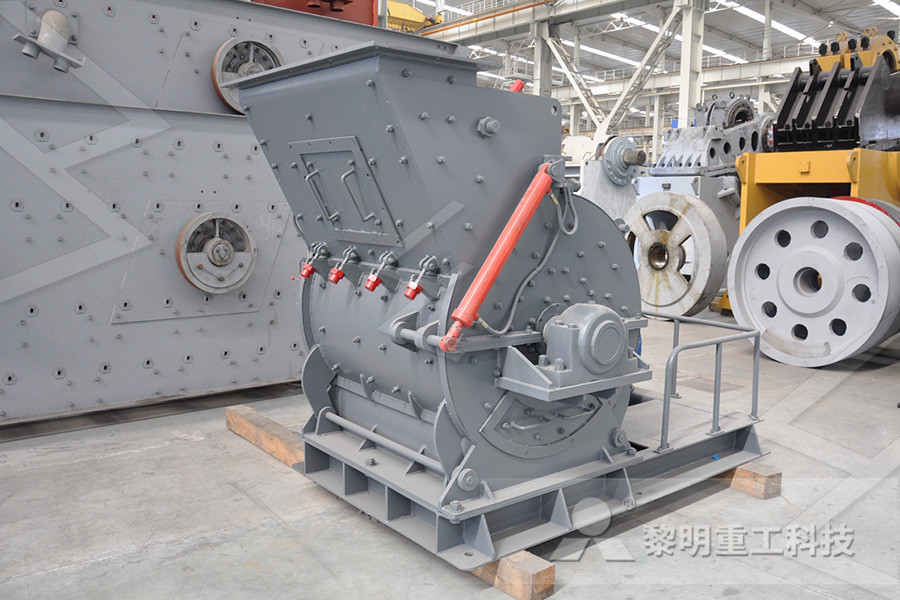

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher