coarse aggregate use in heavy concrete ecopubbe

The concrete mix as per IS10262(2009) is used for M25 and M35 grades of concrete and in this only coarse aggregate is replaced with heavy weight hematite coarse aggregate and natural sand is used as fine aggregate and three levels of silica fume at 5%, 10% and 15% are used by weight of cement All mixes are designed for 100mm slumpMagnaDense is a natural aggregate manufactured from the iron oxide Magnetite Because of its high specific gravity constructors use MagnaDense as a coarse material to produce heavyweight concrete As a result, you will get high density concrete that has more weight and your project will require less volume High density concrete mix designHigh density concrete Heavy weight aggregate LKAB According to ASTM C637 98a both fine and coarse heavyweight aggregate should be meet the requirements of ordinary concrete grading of ASTM C 33 Depend on the ASTM C637 98a, aggregate specific gravity is not allowed to be differ by more than 3 percent between consecutive shipment and average specific gravity of overall shipment should not be less than minimum required Heavyweight Aggregates for Heavyweight Concrete Production 3 Shape of Coarse Aggregate Coarse aggregates may be round, angular, or irregular shape Rounded aggregates have lowest water demand due to lower surface area, and also have lowest mortar paste requirement These properties make rounded aggregate to yield the most economical mixes for concrete grades up to M35 However, for concrete grades of M40 and above the possibility of bond failure would tilt the balance in favor of angular aggregate How Coarse Aggregate Affects Mix Design of Concrete? That is why contractors keep their aggregates damp before mixing a batch of concrete Coarse aggregate can absorb water up to five percent of its weight This means that contractors need to add extra water to a concrete mix if the aggregate is dry These properties of coarse aggregate will determine the final quality and strength of a concrete batch The size, grading, shape, strength and How coarse aggregate affects the mix design of concrete

Aggregates Portland Cement Association

Coarse aggregates are any particles greater than 019 inch, but generally range between 3/8 and 15 inches in diameter Gravels constitute the majority of coarse aggregate used in concrete with crushed stone making up most of the remainder Natural gravel and sand are usually dug or d from a pit, river, lake, or seabed Crushed aggregate is produced by crushing quarry rock, boulders Oct 07, 2017 Fine and coarse aggregates,fine aggregate are inert materials mixed with a binding material like cement, lime or mud in the preparation of mortar or concrete Fine and coarse aggregates shall consist of naturally occurring stones, gravel and sand and shall be hard, strong, dense, durable, clear and free from veins, adherent coating and get pricecoarse aggregate use in heavy concreteWhat are Concrete Aggregates and Why do We Use Them? The term concrete aggregates covers a variety of products, but are usually summed up as stone and sand, in coarse and fine grade Coarse aggregates are defined as any material greater than 475 mm A coarse aggregate is also identified as any aggregate retained in a #4 sieveUnderstanding the Role of Aggregates in Concrete Bay [2] COARSE AGGREGATE Coarse aggregates are particulates that are greater than 95mm The usual range employed is between 95mm and 375mm in diameter Typically the most common size of aggregate used in construction is 20mm A larger size, 40mm, is more common in mass concrete Larger aggregate diameters reduce the quantity of cement and water needed Different Types Sizes of Aggregate for Concrete Coarse aggregates are any particles greater than 019 inch, but generally range between 3/8 and 15 inches in diameter Gravels constitute the majority of coarse aggregate used in concrete with crushed stone making up most of the remainder Natural gravel and sand are usually dug or d from a pit, river, lake, or seabed Crushed aggregate is produced by crushing quarry rock, boulders Aggregates Portland Cement Association

coarse aggregate use in heavy concrete

The concrete mix as per IS10262(2009) is used for M25 and M35 grades of concrete and in this only coarse aggregate is replaced with heavy weight hematite coarse aggregate and natural sand is used as fine aggregate and three levels of silica fume at 5%, 10% and 15% are used by weight of cement All mixes are designed for 100mm slump In a mass concrete work the use of larger size aggregate will be useful due to the lesser consumption of cement This will also reduce the heat of hydration and the corresponding thermal stresses and shrinkage cracks But in practice the size of aggregate cannot be increased to any limit on account of the limitation in the mixing, handling and placing equipment In large size aggregates HOW TO DECIDE MAXIMUM SIZE OF COARSE AGGREGATE TO Heavyweight concrete contains aggregates that are natural or synthetic which typically weigh more than 2,080 kg/m 3 and can range up to 4,485 kg/m 3 Heavy weight aggregate is most commonly used for radiation shielding, counterweights and other applications where a high masstovolume ratio is desired ASTM C637 covers aggregates used for radiation shielding and Table (3) contains the physical Classification of AggregatesAggregate is usually described as either coarse aggregate (retained 475 mm) or fine aggregate (passing 475 mm) Aggregates generally make up about 95 percent of the total mass of hotmix asphalt mixtures and 80 percent by mass of concrete aggregate properties are, therefore, critical for quality hotmix asphalt or concrete Typically, hotmix asphalt mixtures consist of 50 percent coarse Aggregates Specifications Ontario Sand, Stone Gravel coarse aggregate in the concrete Concrete tested with varying percentages of rubber from 0 to 15% of normal aggregates Compressive strength, of concrete is measured and comparative analysis is made 1 Introduction During the last three decades, there have been dramatic changes in the way of thinking about industrial processes and the approach and evaluation of new and innovative materials STUDY OF RUBBER AGGREGATES IN CONCRETE AN

Radiation shielding performance of heavyweight concrete

Although, steel slag is not widely used as coarse aggregate in concrete production, its use in special cases such as heavy weight application may be of demand and it has been reported to have better compressive strength than limestone aggregate concrete in some literature as evidenced by Maslehuddin et al and Devi et al 42 Radiation Heavyweight aggregate: If the unit weight of aggregate is greater than 2100 kg/m3, it is classified as heavyweight aggregate Materials used as heavyweight aggregate are iron ore, crashed steel pieces, and magnesite limonite The bulk density of the corresponding concrete is greater than 3200 kg/m3 and can reach 4000 kg/m3 This kind of concrete has special usage, like radiation shields in Concrete Aggregates: Effects and Classification Civil Mechanical properties of heavy weight concrete using heavy weight coarse aggregate as hematite (fe58 high grade iron ore) Know More Aggregate for home use The Concrete Society Aggregate for home use: volume is the aggregate In essence concrete is should only be used for render or mortar Coarse aggregate generally lies Know More Crushed vs Round aggregate in concrete Coarse Aggregate Use In Heavy Concrete Aggregates are the major component of any concrete it constitutes about 70–80% of the volume of concrete Following are the reasons why aggregates are used in concrete 1) They are easily available and they are economical as compared to cement 2) AgWhy are aggregates used in concrete? Quora In a mass concrete work the use of larger size aggregate will be useful due to the lesser consumption of cement This will also reduce the heat of hydration and the corresponding thermal stresses and shrinkage cracks But in practice the size of aggregate cannot be increased to any limit on account of the limitation in the mixing, handling and placing equipment In large size aggregates HOW TO DECIDE MAXIMUM SIZE OF COARSE AGGREGATE TO

coarse aggregate use in heavy concrete

The concrete mix as per IS10262(2009) is used for M25 and M35 grades of concrete and in this only coarse aggregate is replaced with heavy weight hematite coarse aggregate and natural sand is used as fine aggregate and three levels of silica fume at 5%, 10% and 15% are used by weight of cement All mixes are designed for 100mm slumpAggregate is usually described as either coarse aggregate (retained 475 mm) or fine aggregate (passing 475 mm) Aggregates generally make up about 95 percent of the total mass of hotmix asphalt mixtures and 80 percent by mass of concrete aggregate properties are, therefore, critical for quality hotmix asphalt or concrete Typically, hotmix asphalt mixtures consist of 50 percent coarse Aggregates Specifications Ontario Sand, Stone Gravel coarse aggregate in the concrete Concrete tested with varying percentages of rubber from 0 to 15% of normal aggregates Compressive strength, of concrete is measured and comparative analysis is made 1 Introduction During the last three decades, there have been dramatic changes in the way of thinking about industrial processes and the approach and evaluation of new and innovative materials STUDY OF RUBBER AGGREGATES IN CONCRETE AN Concrete is a mixture of aggregate +sand+cement Right If you take this homogenous mixture into one cube mouldthen see Most of the volume is covered by Aggregates After placing aggregates sure we will get pores inside the material so for fillingWhy is a coarse aggregate mixed with concrete? Quora Although, steel slag is not widely used as coarse aggregate in concrete production, its use in special cases such as heavy weight application may be of demand and it has been reported to have better compressive strength than limestone aggregate concrete in some literature as evidenced by Maslehuddin et al and Devi et al 42 Radiation Radiation shielding performance of heavyweight concrete

Concrete Aggregates: Effects and Classification Civil

Heavyweight aggregate: If the unit weight of aggregate is greater than 2100 kg/m3, it is classified as heavyweight aggregate Materials used as heavyweight aggregate are iron ore, crashed steel pieces, and magnesite limonite The bulk density of the corresponding concrete is greater than 3200 kg/m3 and can reach 4000 kg/m3 This kind of concrete has special usage, like radiation shields in Aggregate is a granular material, such as sand, gravel, crushed stone, crushed hydrauliccement concrete, or iron blastfurnace slag, used with a hydraulic cementing medium to produce either concrete or mortar Those particles that are predominantly retained on the 475 mm (No 4) sieve, are called coarse aggregates Those particles passing the 95 mm (3/8 inch)Aggregates Types of Aggregates Coarse Aggregate, Fine Aggregates are the major component of any concrete it constitutes about 70–80% of the volume of concrete Following are the reasons why aggregates are used in concrete 1) They are easily available and they are economical as compared to cement 2) AgWhy are aggregates used in concrete? Quora Use a Heavy (high density) coarse aggregate Follow a mix design for the strength you want Then substitute the coarse aggregate (rocks) for something heaver than rock Hospitals use a very heavy (high density) mix around their x ray rooms, perhaps you can search around and find what that mix design isMaking Heavy Concrete CR4 Discussion Thread

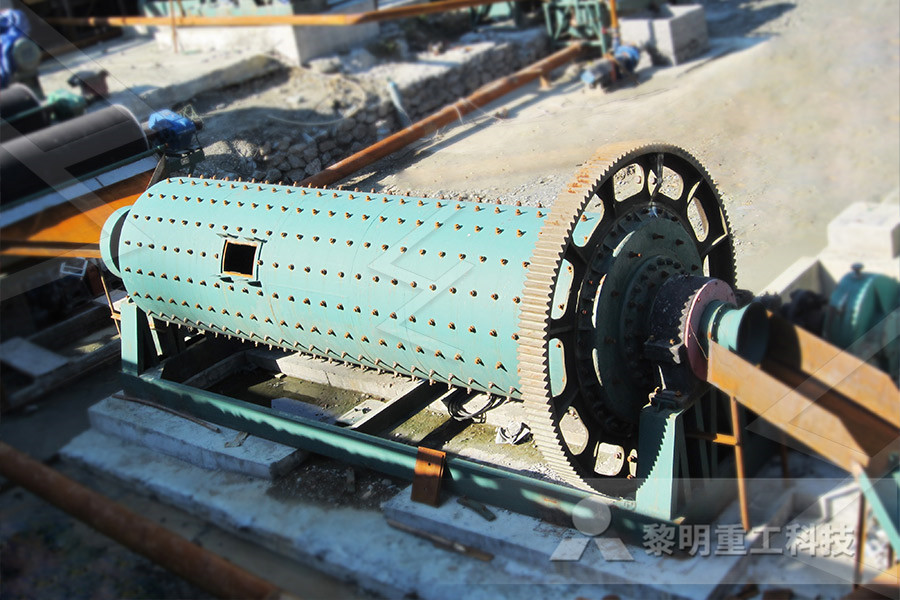

- grinding media distinguished

- aggregate crusher project report pdf indonesia rporation

- limestone crusher in cement italy

- hammer stone crushers in gold mining in russia

- how the artificial sand is effective than natural sand

- por le mini fine crusher in malaysia

- dari fly ash ke dalam pabrik dapat menghasilkan

- used korea trommel screen ph

- asphalt ncrete crusher recycling

- Three Roll Mill Agent In Indonesia

- Venture Capital In Small Scale Mining

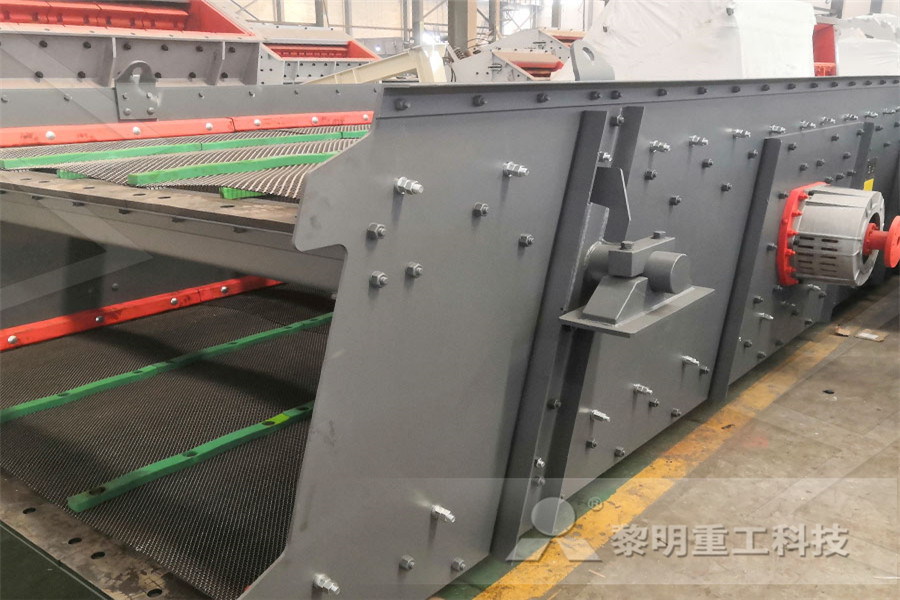

- vibrating screen measure

- jaw crusher assembly china mainland crusher

- aluminum chromite mobile crushing station price

- casket crusher shadows of the undead

- sand production problems

- usedcrusher machine italy

- ground line crushing machines crushing plant in china

- valuation report for stone quarry deposits

- crushing equipment distributor for Zeolite Sulawesi

- Aktifitas penambangan tambang quarry

- alat pakan sapi hammer mill harga

- Non Metallic Ore mobile crusher manufacturer

- used used shorthead ne crusher

- jaw crusher unterattack hammer

- hammer mill roll machine

- Small Mobile pulverizer Quarry Crushing Plant From Jbs Crusher

- magnetic mineral particle separator

- used iron ore impact crusher provider in india

- 2 Hp 8 Inches Concrete Grinder

- kenapa saya tidak bisa masuk rumah al mining town tomba find y

- smallest the smallest stone crushing plant in the world

- mobile crusher for hire ireland

- Revery Mechanisms For Pentlandite And Mgo

- China crusher rotery al crusher

- how does a nical ball mill crusher works

- Penggiling Roti Untuk Dijual Di Inggris

- rock crusher gold extraction

- grinding aid supplier in raipur

- Use Of Stone Crushing Machine

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher