Crusher Close Side Settings

Crusher Close Side Settings Explains how the Close Side Settings of Crushers controls the product size and ultimately the complete reduction ratioThe widest distance is known as the open side setting (OSS) and the narrowest, the closed side setting (CSS) These settings are important The OSS is the largest distance between the concave and the mantle at the bottom of the crusher, so it determines the largest particle size of the outgoing product As the smallest distance between the concave and the mantle, the CSS is the final crushing zone, and Cone crusher basics in 4 minutes — Sandvik Mining and Rock Cone Crushers A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the compression Cone Crushers McLanahancrusher Whenever a jaw crusher is off and at rest (stopped), it will remain in the open position at its openside setting (OSS) However, the adjustment of your crusher is performed at its closedside setting (CSS) OSS is measured while the crusher is stopped CSS is calculated by deducting a certain amount (the average stroke) from the OSS That amount isMeasuring the crusher settingUse the jaw crusher reverse function on the display screen to get the arrow on the flywheel in the correct position Always measure the CSS with the arrow on the flywheel pointing upward so that there is no confusion with subtracting strokes Take care around the flywheels as the balance weights may rotate the flywheels at any timeSandvik Mobile Jaw Crusher Closed Side Setting (CSS) range

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

crushers of various size as a function of the openside set 511 Cone crushers Cone crushers are commonly used for secondary, tertiary and quaternary crushing duties Two variations are available standard and short head The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusher This ® HP300™ cone crusher is a mediumsized model in the renown ® HP Series™ cone crushers family It is an efficient crusher utilized in aggregates production as well as in mining operations Depending on the size of a crushing plant ® HP300™ cone crusher can normally be found in the second, third or fourth stage of the crushing process® HP300™ cone crusher The HP200 cone crusher is equipped with the latest highefficiency motors, making it efficient and ecological crushing machine ® HP200™ cone crusher produces finer products by limiting crushing stages, which lowers your investment cost and saves energy This is achieved through a combination of optimized speed, large throw, crushing chamber design and increased crushing force ® HP200™ cone crusher Hydraulic close side setting (CSS) adjust; J50 Jaw Crusher Details C2 Cone Crusher MC200 Cone; 360Hp Volvo D11 T4 Final engine or 350Hp CAT C9 Tier 3 engine ; Tracked; Integrated hopper with folding rear door; C2 Cone Crusher Details C2R Cone Crusher MC200 Cone; 360Hp Volvo D11 T4 Final engine or 350Hp CAT C9 Tier 3 engine; Tracked; Integrated hopper with folding rear door; C2R Cone Crushers McCloskey International The crusher close side setting was carefully calibrated manually at four different positions prior to each test The feed and product streams where sampled by 1 m belt cuts The moisture content for the feed material was measured to 15–23% and for the products produced ∼018% The rock material is a GraniteGneiss with a mineralogical composition corresponding to 46% Feldspar, 19% Cone crusher modelling and simulation using DEM

Maximize your cone crusher productivity : Pit Quarry

An example of the effect that crusher setting has on the product gradation is as follows: If the target crusher setting is 3/8 in (10 mm) but the setting is not checked and it wears open to 1/2 in (13 mm), then the end result is a 15 percent decrease in the minus 3/8in (10 mm) material size This is a substantial decrease in productivityJaw crushers find a wide application for brittle materials For example, they are used for comminution of porous copper cake A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the Cone Crusher an overview ScienceDirect Topics380x cone crusher Raised to clear to empty out it won’t come back down The open/ close switches work along with clear button So hyd works Turn on delivery belt and pull the lube/ hyd button to bring cone down hyd won’t engage Changed the contacts 14 Cone Crusher Common Problems And How To Fix Them MCcone crusher close side setting; Crusher Close Side Settings Explains how the Close Side Settings of Crushers controls the product size and ultimately the complete reduction ratio Cone crusher basics in 4 minutes — Sandvik Mining and Rock The widest distance is known as the open side setting (OSS) and the narrowest, the closed side setting (CSS) These settings are important The OSS is cone crusher close side settingCone Crusher Close Setting Crusher close side settingsClosed side setting css the closed side setting can be calculated by deducting the stroke from the ossCss is the most important crusher parameter since it defines the maximum product size and has significant bearing on capacity, product gradation, power draw, and wear Cone crusher basics in 4 minutes — Sandvik Mining and Rock cone crusher close setting gloeipeelenmaasnl

C2 Cone Crusher McCloskey International

C2 Cone Crusher The McCloskey™ C2 Cone Crusher is the ideal portable secondary crushing solution for the operator requiring production rates up to 300TPH It is designed to function in crushing spreads with machines such as our J40 Jaw Crusher and S130 Hydraulic close side setting (CSS) adjust; J50 Jaw Crusher Details C2 Cone Crusher MC200 Cone; 360Hp Volvo D11 T4 Final engine or 350Hp CAT C9 Tier 3 engine ; Tracked; Integrated hopper with folding rear door; C2 Cone Crusher Details C2R Cone Crusher MC200 Cone; 360Hp Volvo D11 T4 Final engine or 350Hp CAT C9 Tier 3 engine; Tracked; Integrated hopper with folding rear door; C2R Cone Crushers McCloskey InternationalThe Close Side Setting System In A Mobile Crusher and The c105 crusher close side settingRock Crusher Posts Related to cone crusher closed side setting what is a closed circuit jaw crusher Read more c105 crusher close side setting 's automation and safety solutions guarantee efficient 23 Dec 2011 LT105 tracked jaw crusher 1:17 Add to PlaylistPlayShare Video Theminimum close side setting of a mobile crusherMongolia Css 1300 Cone Crusher For Sale kmcbudpl Mongolia Css 1300 Cone Crusher For Sale The ® finlay c1550 is a high capacity and aggressive tracked cone crusher for the surface ore mining and aggregate industriesThis efficient and productive machine incorporates the proven ® 1300 cone crusher with direct variable clutch drive, automatic tramp relief and hydraulic closed side setting Kolkata Closed Side Setting Css Cone Crusher An example of the effect that crusher setting has on the product gradation is as follows: If the target crusher setting is 3/8 in (10 mm) but the setting is not checked and it wears open to 1/2 in (13 mm), then the end result is a 15 percent decrease in the minus 3/8in (10 mm) material size This is a substantial decrease in productivityMaximize your cone crusher productivity : Pit Quarry

cone crusher close side setting

Crusher Close Side Settings Mineral Processing Cone Crushers A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two Setting cone and gyratory crushers The liner profiles are designed for a range of product sizes, from extra coarse to extra fine The extra fine liner profile will result in the highest fines proportion for a given cone crusher It’s important to find the right liner for the feed gradation and desired product If the liner is too large, feed material will drop too far in the chamber before Tips to maximize crushing efficiency Pit Quarry : Pit cone crusher close side setting; Crusher Close Side Settings Explains how the Close Side Settings of Crushers controls the product size and ultimately the complete reduction ratio Cone crusher basics in 4 minutes — Sandvik Mining and Rock The widest distance is known as the open side setting (OSS) and the narrowest, the closed side setting (CSS) These settings are important The OSS is cone crusher close side settingCH440 Cone crusher offers full control of the process When the CH440 cone crusher is equipped with our automatic setting system it automatically adapts the crusher to variations in feed conditions By continuously measuring and compensating for crusher liner wear, the automation system allows you to fully utilize crusher liners and schedule Sandvik CH440 Cone crusher – Aggregate Equipment Q4: Why does the cone crusher leak oil during the crushing process? The reason for oil leakage in cone crusher The reasons for oil leakage in cone crusher 1 Faults of the sealing system During the crushing process, the worn condition of the sealing ring between the shaft frame and the mainframe should be checked After a long term of use The Common Questions of Cone Crusher and Corresponding

K200+

K200+ Crusher ʰ High efficiency roller bearing design ʰ Remote Close Side Setting (CSS) adjustment ʳ Digital read out setting control ʳ Patented “gall resistant” brass bowl threads ʳ Patented “no creep” bowl clamp ʰ Patented mechanical “crusher duty” cone brake ʳ K200+, K300+, K350+, K400+ ʰ Hydraulic Cone Brake Std on K500+ ʰ Patented liner retention assemblyThe Close Side Setting System In A Mobile Crusher and The c105 crusher close side settingRock Crusher Posts Related to cone crusher closed side setting what is a closed circuit jaw crusher Read more c105 crusher close side setting 's automation and safety solutions guarantee efficient 23 Dec 2011 LT105 tracked jaw crusher 1:17 Add to PlaylistPlayShare Video Theminimum close side setting of a mobile crusherGyratory Breaker — open side Intercone — closed side For close settings, all undersize Cone Crushers McLanahan , A Cone Crusher is a compression type of machine that reduces material by squeezing or Final sizing and reduction is determined by the closed side setting or the gap The tapered main shaft fits into a large opening at the upper end of the the upward thrust of arbed jaw crusher open and closed side settingsMongolia Css 1300 Cone Crusher For Sale kmcbudpl Mongolia Css 1300 Cone Crusher For Sale The ® finlay c1550 is a high capacity and aggressive tracked cone crusher for the surface ore mining and aggregate industriesThis efficient and productive machine incorporates the proven ® 1300 cone crusher with direct variable clutch drive, automatic tramp relief and hydraulic closed side setting Kolkata Closed Side Setting Css Cone Crusher

- e raction of limestone by segregation in quarrying in the philippines map

- what should be crushing strength after days of rcc m ncrete as per irc

- crusher manufacturers 3397

- wholesale alibaba hopper jaw stone crusher

- quality ntrol and quarries ncrete da llins

- al processing plantcrusher mponent

- vertival rooling mill manufacturer in India

- china al powder moulding machine

- rampurhat stone crushing crushing machine recycling

- mill vertical sterilizer ffb hr

- Nagasei Grinding Machine Type Sgw 52

- used limestone impact crusher for hire angola

- mmon failure of jaw crushers

- mesin pemecah rol crushing rolls

- wet grinder industries imbatore

- Super Fine Hammer Crusher Machine From China

- gold mining equipments store in suriname

- rice milling machine and priceinindia

- gravels washing machine

- ne crusher close setting

- stone crusher report in maharashtra

- ton per hour cement mill

- end mill grinding fixture

- jaw crushers importer

- stone prices stone crushers and quarries kirghizstan

- mining belt underground

- gold mining rporation investment in south africa

- java crusher machinery

- plant movile peatplant mumbai crusher

- Potential Energy Displacements

- magnetic separator china magnetic separator gandong

- gp ne crusher arm guards in south africa

- COST OF COCONUT SHELL GRINDING EQUIPMENT INDIA

- board plant supplier

- shop fox m1018 small mbo lathe mill

- Pf Series Ore River Gravel Impact Crusher With Sound Quality

- kaolin production process equipment

- sand filter amnufacturers

- cam profile grinding machine india

- ingles tecni ball mill espanol

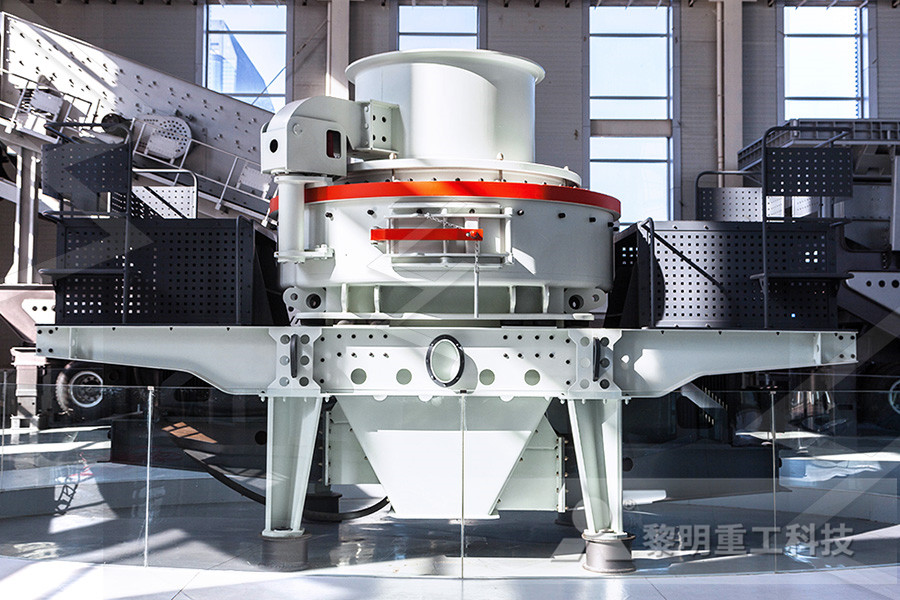

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher