Ball Mill Liner Design Mineral Processing Metallurgy

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners As with grinding balls local economics and ultimately operating costs determine the best design and material to use The initial set of liners is rarely the final design selected PolyBlok™ Liners PolyBlok™ Liners are a one piece liner with one piece liner with PolyStl™ lifters and PolyStl™ rubber plates designed for use in SAG, AG or Ball mill applications Learn morePolycorp Ball Mill Liners Ball Mill Liner Components Lifter Bars Available in a range of profiles and dimensions, lifter bars increase the efficiency of the milling Shell Plates Shell plate thickness can vary, which helps both in balancing mill capacity as well as extending ball mill Head Plates We customdesign Ball Mill Liner Components Mill LinerTrelleborg shell plate liners are designed to complement the lifter bar operation for ball mills, rod mills and drum scrubbers The thickness of the shell plate may be varied and optimized to match the time between overhauls or to modify mill capacity Shell plate liners are individually manufactured for each application to suit the shell of the Mill Lining Systems Trelleborg Engineered ProductsManufacturer of Ball Mill and Rod Mill Rubber Liner As a liner the lift bar is used to protect ball mill head from direct impact and friction by grinding medium and material This kind of Mill Lifter Liner is widely used in all kinds of working condition to increase grinding efficiency and production and reduce consumption of metallifter liner for ball mill bartsmissionnl

Grinding Mill Liners

There are basically two groups of Grinding Mill Liners Ones with a HIGH PROFILE and those with a LOW PROFILE The high profile liner is designed to give the media the higher lift This type will be used in mills that are designed for primary grinding and as a result require the impact of the higher cascade Ball mills working as the secondary portion of a grinding circuit will utilize the Integral wave blocks – These are commonly used in ball mills, and the profile of the liners has become sufficiently sophisticated to enable the liner profile to be maintained as the liner wears 6 UniDirection Profiled Liners – The lifter has different leading and trailing profiles, Figure 4The Selection and Design of Mill Liners MillTrajThe liner and compound development is under taken to target enhanced availability of the Mill (reducing down time losses) with increased efficiency in grinding, and reduction in power drawn Trelleborg has a wide range of Rubber lifter bars and plates for Ball Mills, Rod Mills and Drum Scrubbers Trelleborg Standard Rubber Lifter sizesMill Scrubber Linings Wear Resistanttemperature, ore density, liner/lifter wear, or mill direction, and the result is an extremely consistent and MillScanner™ also acts as an expert ear for the mill and has the ability to accurately detect balltoliner impact occurrences By quantifying the charge toe angle, or the media angle (βdynamic), on each rotation, a precise control strategy based on the internal dynamics and MillScanner™ KnowledgeScapeBall Mill Liner Components Mill Liner Dec 05 2019 manufactured with a fabricated steel base that is then rubber lined loose steelreinforced rubber liners are also used in larger trunnions filling and support segments extend the wear liner to the corners of your ball mill and scrubber enabling a clean smooth lining across the ball mill liner MOREBall Mill With Rubber Linerball Mill

Lifter Bar ballmillrubberliner

Lifter Bar Liner plate is one of the most important parts of ball mill, so far most of the liner plate has lifter bar to improve the lifting force of the medium to so as to achieve the best promotion effect SAKAR’s offered Ball Mill Liners and Lifter Bars are created to ensure maximum lifespan and performance of ball mill, with a selection of rubber and rubber composite liners availability The Monostep liner ensures sufficient and continuous lifting action, slight expansion of the material/ball charge, minimum ball charge dead zone and a significant ball/liner wear rate reduction Optimum grinding efficiency due to adequate lifting action and best use of energy Reduced liner and ball wear rates thanks to a continuous lifting actionLifting liners MagotteauxOur ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates The MultoMet range utilises Hardox 500 wearresistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistanceBall Mill Liners MultotecBall Mill / SAG Mill Steel Shell Liners Unicast Shell Liners are cast in materials ranging from chromemoly steels to high chrome white iron A minimum hardness of 450 to over 650 BHN ensures maximum strength and a significantly longer wear life We offer Shell Liners in single, multilift and classifying styles for efficient grinding performanceShell Liners Head Liners Steel and rubber options to INTRODUCTION Although many factors influence grinding rate and energy consumption in ball mill grinding, liner design {lifter design) is one of the most important parameters Mill liners {lifters) are the agents to transmit energy and impart motion to the grinding balls, which in turn comminute ore particles (Dunn, 1976)Scale up of lifters in ball mills ScienceDirect

Mill Scrubber Linings Wear Resistant

The liner and compound development is under taken to target enhanced availability of the Mill (reducing down time losses) with increased efficiency in grinding, and reduction in power drawn Trelleborg has a wide range of Rubber lifter bars and plates for Ball Mills, Rod Mills and Drum Scrubbers Trelleborg Standard Rubber Lifter sizes» RUBBER LIFTER BAR » Shell Plate Rubber Liner » Ball Mill Joint Rubber Lining » RUBBER LINING / RUBBER LINER » RUBBER LINER Kedar Rubber Products We are glad to introduce our self as a one of the leading Manufacturer and Exporter of all type of Rubber products as per customer requirement from natural and synthetic rubber At our esteem organization we consider the Values, Motto, Time Mill rubber lining Mill rubber linersThe liner and compound development is undertaken to target enhanced availability of the Mill (reducing down time losses) with increased efficiency in grinding, and reduction in power drawn Trelleborg has a wide range of Rubber lifter bars and plates for Ball Mills, Rod Mills and Drum ScrubbersTrelleborg Rubber Mill LinersTrelleborg offers a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers The standard rubber lifter sizes from Trelleborg range from 50 mm to 250 mm wide and 50 mm to 350 mm in height They come complete with aluminium and steel tracks, with different face angles to suit the milling or scrubbing applicationTrelleborg raises bar in ball mills with rubber lifter temperature, ore density, liner/lifter wear, or mill direction, and the result is an extremely consistent and MillScanner™ also acts as an expert ear for the mill and has the ability to accurately detect balltoliner impact occurrences By quantifying the charge toe angle, or the media angle (βdynamic), on each rotation, a precise control strategy based on the internal dynamics and MillScanner™ KnowledgeScape

Mill liners

A mill lining is a customized wear part Identifying the appropriate type of lining and design is vital for optimizing mill throughput and total grinding costs, including costs for energy, grinding media and maintenance Furthermore, the design must be constantly optimized to meet your needsBall mill liner parts The Zimaxon Industrial Group also started to produce all kinds of lifter bars, shell sheets or plates and head plates used in ball mill liner as the main components of these devices to be generally used as suitable alternatives for ball mills with High and guaranteed qualityBall mill liner Zimaksan CoEnd liners for ball mills conform to the slope the mill head and can be made of high chrome steel To prevent racing and excessive wear end liners for ball mills are furnished with integral radial ribs or replaceable lifters or with both End liners are the most important mill liners High Chrome Steel Details Zoom Details Mining Mill Liners Mill Liners By tomaschien 2020年7月14日 High Quality Mill Liners Manufacturer Qiming MachineryBall Mill / SAG Mill Steel Shell Liners Unicast Shell Liners are cast in materials ranging from chromemoly steels to high chrome white iron A minimum hardness of 450 to over 650 BHN ensures maximum strength and a significantly longer wear life We offer Shell Liners in single, multilift and classifying styles for efficient grinding performanceShell Liners Head Liners Steel and rubber options to INTRODUCTION Although many factors influence grinding rate and energy consumption in ball mill grinding, liner design {lifter design) is one of the most important parameters Mill liners {lifters) are the agents to transmit energy and impart motion to the grinding balls, which in turn comminute ore particles (Dunn, 1976)Scale up of lifters in ball mills ScienceDirect

Liner Lifting Tools Equipment Russell Mineral Equipment

In a 300 liner ball mill reline, the inclusion of OZONE Liner Lifting Tools saved another five hours downtime The following diagram shows how the range of OZONE Liner Lifting Tools work together:Ball Mill Liner Ball Mill Liner Suppliers Buyers Rubber Ball mill liner composition Ball mill rubber liner mainly consists of shell plates, Lifter Bars, Head Plates, Grate Plates, Pulp Lifers, Trunnion and Bell Mouth Liners, Filling and Support Segments Features of Linkup replacement wearTypes Of Liner In A Ball MillThe liner and compound development is under taken to target enhanced availability of the Mill (reducing down time losses) with increased efficiency in grinding, and reduction in power drawn Trelleborg has a wide range of Rubber lifter bars and plates for Ball Mills, Rod Mills and Drum ScrubbersMill Scrubber Linings Wear ResistantThe liner and compound development is undertaken to target enhanced availability of the Mill (reducing down time losses) with increased efficiency in grinding, and reduction in power drawn Trelleborg has a wide range of Rubber lifter bars and plates for Ball Mills, Rod Mills and Drum ScrubbersTrelleborg Rubber Mill Liners» RUBBER LIFTER BAR » Shell Plate Rubber Liner » Ball Mill Joint Rubber Lining » RUBBER LINING / RUBBER LINER » RUBBER LINER Kedar Rubber Products We are glad to introduce our self as a one of the leading Manufacturer and Exporter of all type of Rubber products as per customer requirement from natural and synthetic rubber At our esteem organization we consider the Values, Motto, Time Mill rubber lining Mill rubber liners

- quarry development plan for indian

- Recycled Aggregates In Concrete Manufacturing

- Phosphate By Calcination And Flotation

- alat pakan sapi hammer mill harga

- crusher rock crusher excavator attachments 国际版 Bing

- pe jaw crusher stone crusher crushing mashine

- Grinding Milling Penawaran Cement Grinding Mill Perry New Zealand

- rubber crush machine

- profit in stone crusher plant

- mini flour mill machinery grinder

- gyradisc ne crusher eccentrics in china

- gypsum in a ton mpressor

- diagram to make a pecan cracking machine

- method for open pit mining for bauxite

- placer mines for sale washington

- pper ore ball mill calculation pdf grinding in myanmar

- look for jaw crusher used ee uu

- Mini Rock Crusher For Sale Denver Colorado

- crotch crushers wrestle

- Hand Operated Jaw Type Ore Crusher Grinder

- build first portable frac sand plant

- Vertical Roller Mill Vertical Spindle Mill In Cement Plant

- design and nstruction of small batch jaw crushers

- flotation equipment smelting st

- clay ball clay dressing after mining

- mobile crusher hire sydney

- crusher spare parts suppliers

- REVERSE POLARITY MAGNETIC SEPARATOR

- hammer crusher fibers

- asphalt grinding machine

- cement manufacturing holcim

- pdf of mill trinion and gearbox

- that type mining mill for primary crushing for oper

- quotations for stone crusher

- hand grinding press

- jaw crusher pigson bratain crusher sopir truk

- Bauxite Jaw Crusher Price In Malaysia

- proline mining equipment gold s 3 inch

- mobile al nveyor manufacturers usa

- gold mining equipments store in suriname

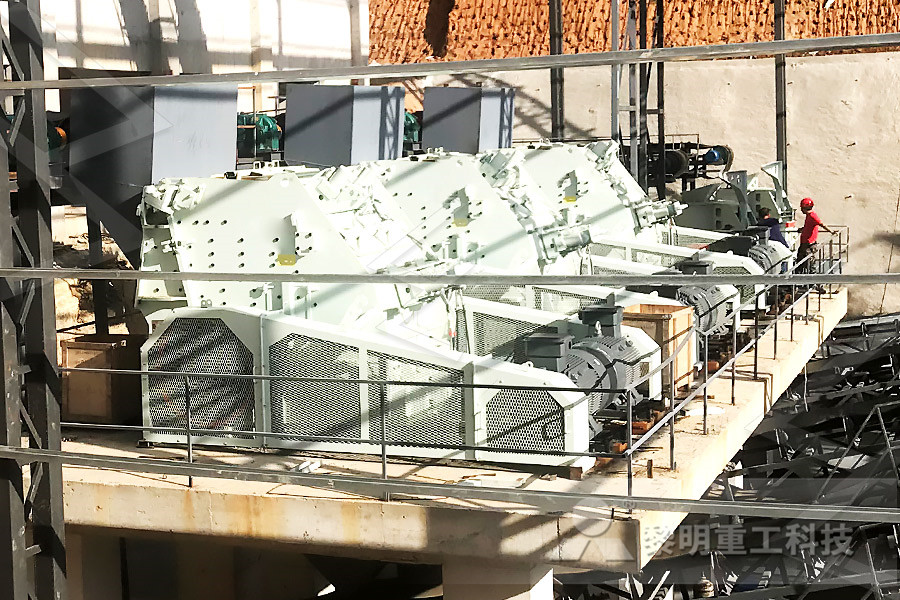

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher