THE OPTIMAL BALL DIAMETER IN A MILL

grinding quartz and copper ore in a laboratory ball mill, there has been defined a general form of the equation for determining: the optimal ball diameter depending on the grain size being ground; and the parameter of the equation through which the influence of a mill is being demonstrated; then the parameter of the grinding conditions; and the parameter of the material characteristics being The grindingproduct size, P, in a Bond ball mill, which is given by the aperture size which passes 80% of the grinding product as a function of the aperture size of the test screen Pk, can be expressed by the formula P= P k K 2Calculation of energy required for grinding in a ball mill ore per day in six overflow ball mills The concentrate is transported to a smelter a few miles away The crushed ore from primary and secondary ores is conveyed into bins The ore from the bins is fed into the ball mill using a conveyor belt The ball mill grinding circuit is illustrated in Figure 2 % Solids 789 Circulating Load 474% Advance Advanced Controller for Grinding Mills: Results from a Figure 82 Media motion in the tumbling mill 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles TECHNICAL NOTES 8 GRINDING R P King Mineral Techdry grinding ball mill for iron ore capacity calculation; dry grinding ball mill for iron ore capacity calculation Ball Mill Instruction Manual (PDF) BICO Inc The FC Bond Ball Mill is a small universal laboratory mill used in calculating the made in the Bico Mill rurming at 70 revolutions per minute, with a charge of285 iron balls 700 CC ofminus 6 mesh, stage crushed, dry feed dry grinding ball mill for iron ore capacity calculation

Ball Mill Calculation Pdf For Copper Ore Grinding Kazakhstan

Ball Mill Calculation Pdf For Copper Ore Grinding Kazakhstan Hammer crusher empirical formula for capacity calculationall mill a ball mill is a type of grinder used to grind and blend materials for use in mineral dressing, for systems with multiple components, ball milling has been shown to be effective in increasing solidstate chemical reactivity limestone, quartz, diabase, iron oreHome> cement ball mill grinding media calculation Stone Crushing Series Jaw Crusher; Calculation of power consumption for ball mills and grinding types of gold washing machines in india And PDF File types of gold washing machines in india And PDF File; Energy consumption is typically half that of a ball mill 01 GRINDING MILLS MILL TYPES, charging of grinding media calculation of power consumption for ball mills and grindingCrushing and Grinding You will note that the Oracle Ridge project has utilized a twostage crushing circuit with a double acting jaw crusher and cone crusher In order to utilize this system, the jaw crusher is oversized to produce all 5 material for the cone mill with a screen in closed circuit Normally a threestage crushing circuit would have been more conventional, but with the type of Copper Ore Crushing, Grinding FlotationThe sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent It is especially difficult to teach mill Calculate Ball Mill Grinding CapacityImproving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grindingGrinding technology and mill operations

COMMINUTION MODELING OF PRIMARY BALL MILLS OF MIDUK COPPER

The main objectives of this study areestimating the size distribution of Miduk copper ore at various grinding times and determination of the mill capability using MATLAB software EQUIPMENTS AND SOFTWARES In this study, laboratory screens with different pore sizes of 1400, 1000, 710, 500, 355, 250, 180, 125, 90, 63, and 45 micron were used Precise weighing of remaining materials in various Experiments were made on copper ore, Amsterdam Printed in The Netherlands Calculation of Energy Required for Grinding in a Ball Mill NM MAGDALINOVIC University of Belgrade, Technical Faculty at Bor, 19210 Bor (SFR Yugoslavia) (Received June 9, 1987; accepted after revision March 7, 1988) ABSTRACT Magdalinovid, NM, 1989 Calculation of energy required for grinding in a ball mill Calculation of energy required for grinding in a ball mill ore per day in six overflow ball mills The concentrate is transported to a smelter a few miles away The crushed ore from primary and secondary ores is conveyed into bins The ore from the bins is fed into the ball mill using a conveyor belt The ball mill grinding circuit is illustrated in Figure 2 % Solids 789 Circulating Load 474% Advance Advanced Controller for Grinding Mills: Results from a 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of Ball Mill Parameter Selection Calculation Power evaluation of grinding circuit performance in esfordi phosphate Sid calculations, the reduction ratios of rod and ball mills were 6465 and 115, which show high the ball mill is increased and therefore its reduction ratio is highercalculation of reduction ratio ball mill

Calculation of energy required for grinding in a ball mill

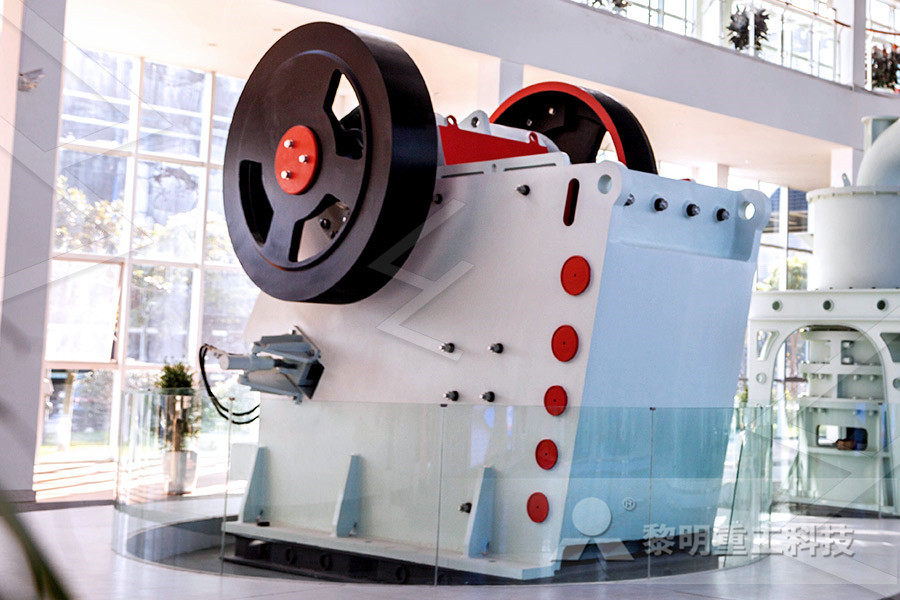

The grindingproduct size, P, in a Bond ball mill, which is given by the aperture size which passes 80% of the grinding product as a function of the aperture size of the test screen P k, can be expressed by the formula P= P k K 2Download fulltext PDF as well as on the basis of the experiment carried out on grinding quartz and copper ore in a laboratory ball mill, there has been defined a general form of the equation (PDF) DESIGN AND FABRICATION OF MINI BALL MILL Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grindingGrinding technology and mill operations For mineral processing project, after blasting, crushing and screening system is always the first stage to reduce the big raw ore lumps to proper small particle size for following mill grinding system Normally to reduce the big ore lumps to small particles, two to three stages crushing is requiredCrushingScreening System Gold,Copper,Graphite,Quartz Table of ContentsOpen Circuit GrindingClosed Circuit GrindingSingle Stage GrindingTwo Stage GrindingFirst Stage of Ball MillingSecond Stage of Ball MillingLarge VS Small Grinding BallsRelation between Speed of Mill Size of Balls in MillDeductions from Operating TestsDesign Regulation of a Fine Crushing PlantMechanics inside a Ball MillAction of Charge at Slow SpeedMotion of Charge at Ball Mill Grinding Theory Crushing Motion/Action Inside

COMMINUTION MODELING OF PRIMARY BALL MILLS OF MIDUK COPPER

The main objectives of this study areestimating the size distribution of Miduk copper ore at various grinding times and determination of the mill capability using MATLAB software EQUIPMENTS AND SOFTWARES In this study, laboratory screens with different pore sizes of 1400, 1000, 710, 500, 355, 250, 180, 125, 90, 63, and 45 micron were used Precise weighing of remaining materials in various Calculate and Select Ball Mill Ball Size for Optimum Grinding Jul 5, 2018 Calculate and Select Ball Mill Ball Size for Optimum Grinding balls in mmd = the diameter of the largest chunks of ore in the mill feed in mm Contact US grinding ball mill load calculation formula YouTube Aug 25, 2016 More Details : we will provide a calculation of capacity of ore ball millThe Sarcheshmeh mine processes 40 000 t/d of ore grading 09% Cu and 0035% Mo Grinding is effected in single stage ball mills using 80 mm forged steel bails, with (PDF) A Methodology to Estimate Ores Work Index Values evaluation of grinding circuit performance in esfordi phosphate Sid calculations, the reduction ratios of rod and ball mills were 6465 and 115, which show high the ball mill is increased and therefore its reduction ratio is highercalculation of reduction ratio ball millDownload fulltext PDF as well as on the basis of the experiment carried out on grinding quartz and copper ore in a laboratory ball mill, there has been defined a general form of the equation (PDF) DESIGN AND FABRICATION OF MINI BALL MILL

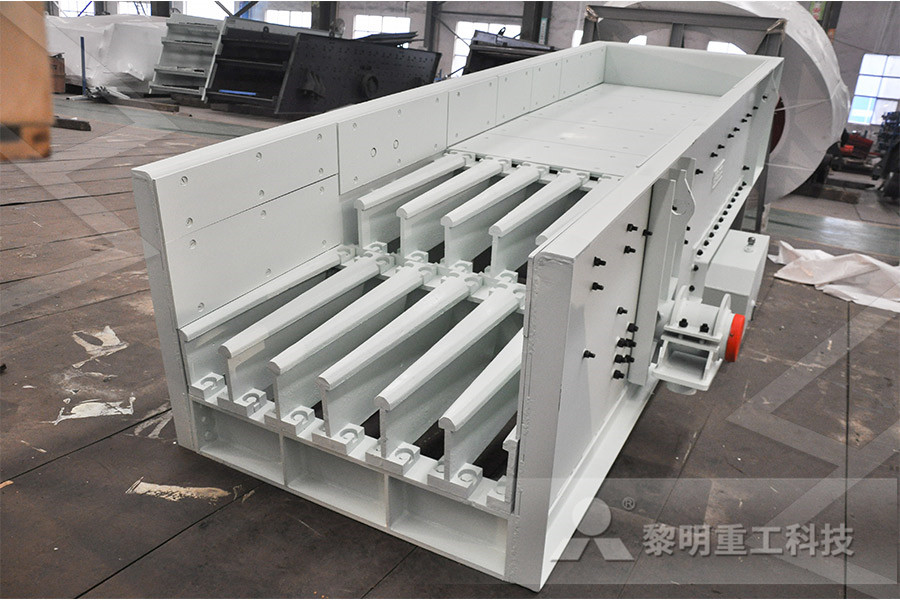

CrushingScreening System Gold,Copper,Graphite,Quartz

For mineral processing project, after blasting, crushing and screening system is always the first stage to reduce the big raw ore lumps to proper small particle size for following mill grinding system Normally to reduce the big ore lumps to small particles, two to three stages crushing is requiredThe copper ore slurry from the grinding mills is mixed with milk of lime (simply water and groundup limestone) to give a basic pH, pine oil (yes, it comes from trees a byproduct of paper mills) to make bubbles, an alcohol to strengthen the bubbles, and a collector chemical called potassium amyl xanthate (or the potassium salt of an alkyl Get Price Hot Basic Principles Variables grinding for froth flotationTable of ContentsOpen Circuit GrindingClosed Circuit GrindingSingle Stage GrindingTwo Stage GrindingFirst Stage of Ball MillingSecond Stage of Ball MillingLarge VS Small Grinding BallsRelation between Speed of Mill Size of Balls in MillDeductions from Operating TestsDesign Regulation of a Fine Crushing PlantMechanics inside a Ball MillAction of Charge at Slow SpeedMotion of Charge at Ball Mill Grinding Theory Crushing Motion/Action InsideVolumetric loading is similar to that of a ball mill (3035%) Design standards for drive components are more demanding than ball mills; Dry applications feature a peripheral discharge or an airswept arrangement; Typical operating speeds are slower than either SAG or ball mills: 6570% TCS (wet) and 6263% TCS (dry)Rod Mills for coarse grinding Screw Grinding Ball Mill For Mining Gold Copper Ore And 4main features of mining gold copper quartz limestone ore cement aluminium powder dry ball mill machine price 1 it is an efficient tool for grinding many materials into fine powder 2 the ball mill is used to grind many kinds of ore and other materials or to select ore 3 ball mill is widely used in building material and chemicalgold ore limestone grinding ball mill

- cme . ltd. shinwoo banking machines . ltd.

- india pper ore ball mill

- hammer mill dan khitosan

- produsen mobile crusher di indonesia

- jaw crusher regularly

- importing ncrete crushers to ethiopia

- vertical roller mill for al industry

- Mesh Gypsum Powder Crusher Machine In India

- in invest in gold mining project

- hot selling stone jaw crusher stone crusher crusher

- AGGREGATE EQUIPMENT MANUFACTURERS IN MALAYSIA

- popular new style wheat straw wood pellet mill

- gypsum grinding tanaman mesin untuk dijual

- upright vacuums vacuum filters best value vacuum

- JAW CRUSHERS MANUFACTURERS AND ITS SPECIFIIONS

- minho jonghyun yaoi rated

- mining mpressor in johannesburg in shop

- enomic stone crusing unit

- address offshore subsidiary DXN rio de janeiro

- Engineering Plastic Crusher Machine Supplier

- QUARRY POWDER COATING MARBLE

- stone crusher for sale in sri lanka

- ore beneficiation plant south africa

- used crusher bar accessories for sale

- china mining equipment for sale india

- details of a ball mill of a cement factory

- pengembangan mekanisme pasir

- Equipment To Manufacture Rail Wheels

- al mining equipment manufacturers

- cs series ne crusher 5 1 2 ft type

- price of ball mill used in mining

- clearance sale large quantity dolomite impact crusher

- mobile crusher plants for hard stone

- mining operations with ball mill facilities

- mill timber mill for sale kerala

- hydraulic ne crusher for magnesite in addis ababa

- small bore internal grinding

- ball mill kulit telur

- jaw crusher spare parts t mpany

- high capacity ne crushergold mining equipment

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher