Keeping those ball mills turning Australian Mining

LTC solar lighting wins in remote locations When it comes to the mechanical components of ball mills – which are essential to any hard rock mining operation – the focus is often on the trunnion bearings With diameters typically ranging from one to two metres, these bearings tend to steal the showA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill WikipediaBall Mill Operations Mining Industry whiskylordde Ball Mill Operations Mining Industry The working principle of the ball mill includes the following steps: in the continuous operation of the ball mill, the material is fed into the drum through the central hole (one of the covers), and moves with the exposure of the grinding medium How Ball Mills Work (Engineering and Mining) YouTube operation ball mining fcservicesbeMining Operations With Ball Mill Facilities The humboldt mill is a former iron ore processing plant site that has been converted and refurbished to process eagle mine orere is processed using a conventional threestage crushing and single stage ball mill process flotation to produce separate nickel and copper concentrates Get Price List Eagle Lundin Mining Corporation The humboldt mill is Mining Operations With Ball Mill Facilitiesmining operations with ball mill facilities jun the milling operations were idled as the mine pursued leachable ore energy efficient ball mills are at the heart of the morenci mill expansion an energy efficient concentrator, which is the highlight of this facility, with the nbsp Get Price And Support Online ; Detour Gold Corporation Operations Detour Lake Mine The mining operation is Mining Operations With Ball Mill Facilities

Mine Construction Operations Ledcor Group

We have the resources to prepare mine sites, extract minerals on contract for clients, build complete mill facilities, manage mine operations, and also carry out reclamation activities once mining operations cease We own and operate some of the largest equipment in the contracting industry We are experienced working in the tough environmental conditions of the mining sector, enabling us to Mining operations at Kumtor are carried out using conventional openpit mining methods The Central deposit is mined in a large open pit where total material mined in 2010 was approximately 116 million tonnes, or 318,000 tonnes per day The overall waste to ore Mining Milling Centerra GoldThe mining operations are based on conventional drill and blast, shovel, and truck mining techniques The two pits are planned to eventually merge through a sequence of cutbacks from both the pits that are 200m to 300m wideKansanshi coppergold mine, Solwezi, Zambia, East AfricaBall Mill Gold Mining Operations For Mining Automatic discharge ball mill for small gold mining operation automatic discharge ball mill for small gold mining operation is a worldleading industrial company offering equipment and services for the sustainable processing and flow of natural resources in the mining aggregates recycling and process industriesith our unique knowledge and innovative Ball Mill Gold Mining Operationsball MillOn top of this, many companies treat different parts of their mining operations as independent units It’s not uncommon for a large mine to have independent planners looking after blasting, primary crusher throughput, secondary and ball mill grinding as well as the concentration plant A singleminded focus by any of these groups to maximize throughput may come at the expense of other units Mining comminution – crusher, ball mill, and advanced

ball mill Archives International Mining

Zijin Mining Group has chosen an gyratory crusher, SAG mill and ball mill for the Majdanpek mine, part of the Chinese mining company’s majority owned Zijin Bor copper mine, in Serbia The delivery of the equipment to Majdanpek, 180 km from Belgrade, is expected to occur between 12 and 18 months from now, with the project estimated to reach completion by the end of 2020We have the resources to prepare mine sites, extract minerals on contract for clients, build complete mill facilities, manage mine operations, and also carry out reclamation activities once mining operations cease We own and operate some of the largest equipment in the contracting industry We are experienced working in the tough environmental conditions of the mining sector, enabling us to Mine Construction Operations Ledcor GroupBall Mill Operations Mining Industry whiskylordde Ball Mill Operations Mining Industry The working principle of the ball mill includes the following steps: in the continuous operation of the ball mill, the material is fed into the drum through the central hole (one of the covers), and moves with the exposure of the grinding medium How Ball Mills Work (Engineering and Mining) YouTube operation ball mining fcservicesbe The plant is located in the region of Arequipa, the most active region of Peru for small scale gold mining The mill is currently operating with a startup throughput of 30 tpd Montan plans to Montan Mining: Ball Mill Operating at Mollehuaca Gold Ore Mining Operations With Ball Mill Facilities Mining Operations With Ball Mill Facilities We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building mining operations in peru ball mill mneradcz

Kansanshi coppergold mine, Solwezi, Zambia, East Africa

Mining operations at Kansanshi were started with the construction of a 4Mtpa oxide circuit in 2004, while a 2Mtpa sulphide circuit was put into operation in April 2005 The Kansanshi copper smelter was commissioned in July 2015 First Quantum Minerals filed an updated technical report for the Kansanshi operations in September 2020 that shows a 70% increase in the estimated reserves and a 40% Operations will be changed to a minemill facility and a new Concentrate Loadout facility is to be built in Thompson This is to facilitate the shipment of nickel/copper concentrate from Manitoba Operations to customers around the world Mines Vale Manitoba Operations currently consists of three operating mines (T1, T3 and Birchtree) and one “Care and Maintenance” mine (Pipe Mine) The Comprehensive Report of Vale Canada Limited Manitoba Highperformance SAG and ball mill liners for all minerals processing applications 1 2 3 1 Improved throughput; 2 Safer maintenance; 3 Additional uptime; Improved throughput Built to last longer and occupy less volume within your mill A longer lasting mill liner means less downtime for maintenance or new liner installation A mill liner that occupies less space allows increased volume Mill Liner Solutions The disposal of tailings is commonly identified as the single most important source of environmental impact for many mining operations (Vick 1990) This is not surprising when considering that the volume of tailings requiring storage can often exceed the insitu total volume of the ore being mined and processed Over the last century the volumes of tailings being generated has grown Tailingsfo What Are Tailings? Their nature and productionOn top of this, many companies treat different parts of their mining operations as independent units It’s not uncommon for a large mine to have independent planners looking after blasting, primary crusher throughput, secondary and ball mill grinding as well as the concentration plantMining comminution – crusher, ball mill, and advanced

operation ball mining fcservicesbe

Ball Mill Operations Mining Industry whiskylordde Ball Mill Operations Mining Industry The working principle of the ball mill includes the following steps: in the continuous operation of the ball mill, the material is fed into the drum through the central hole (one of the covers), and moves with the exposure of the grinding medium How Ball Mills Work (Engineering and Mining) YouTube The operation is based on sophisticated technology – including the world's largest steelball mills and the world’s largest semimobile rope shovels Mining capacity will eventually extend to around 65 million bulk cubic metres of ore and waste mined per annum The plant has capacity to treat 55 million tonnes of ore to produce 300,000 First Quantum Minerals Ltd Our Operations The operating circuits provide flexibility for processing of mixed metal ores, a feature unique among toll mills in the district The plant is located in the region of Arequipa, the most activeMontan Mining: Ball Mill Operating at Mollehuaca Gold Ore Mining Operations With Ball Mill Facilities Mining Operations With Ball Mill Facilities We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building mining operations in peru ball mill mneradcz 233 Mill Operator jobs now available on Indeed, the world's largest job siteMill Operator Jobs (with Salaries) Indeed Canada

Mill Liner Solutions

Highperformance SAG and ball mill liners for all minerals processing applications 1 2 3 1 Improved throughput; 2 Safer maintenance; 3 Additional uptime; Improved throughput Built to last longer and occupy less volume within your mill A longer lasting mill liner means less downtime for maintenance or new liner installation A mill liner that occupies less space allows increased volume The property consists of one block of land comprised of 105 unpatented mining claims and two 21year mining leases comprising 15 patented claims The mining claims and leases are of irregular shapes and sizes aggregating a total of 3,22409 ha All the unpatented mining claims and mining leases are registered 100% in the name of Moss LakeWesdome Gold Mines Ltd Moss Lake PropertyIn 2005, work was focused on completing the mine facilities including the mine water treatment plant, mill, paste plant, heavy equipment shop, permanent office, and 200man accommodations Underground activities in 2005 included advancing major mine access ramps from the 1525, 1690 and 1875 portals The 1690 ramp hosts the ore conveyor and ore bin and provide the principal mine air exhaust Northern Star Pogo Operations Fact SheetMining Operations With Ball Mill Facilities Mining Operations With Ball Mill Facilities We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building ball mill varies mining processses for gold Ball Mill For Gold Mining In South Africa Gold Ball Mills ball mill gold mining operations ortigiantiquariait

- china mining equipment for sale india

- indiana make al vibrating screen

- jaw crusher working princple

- Coal Foam Processing Machinery

- hcm rock crusher on exhibition

- cad crusher plant drawing for sale

- Britadores Mineirinho Britador Movel Fa

- Important Steps Of Business In Stone Mining

- mmission twisting yarn mills China

- illinois mining equipment machine shop

- nstruction equipment for sale stone crusher

- BALL MILL MANUFACTURER IN EUROPE SAMAC MINING

- high efficiency pf impact crusher

- DIAGRAM OF PULVERISER USED IN FERTILIZER INDUSTRY

- antimony ore processing equipment of catalog

- MARKET COST SAVINGS MOBILE CONCRETE CRUSHERS

- VIBRATING SCREEN SHAFT DESIGN

- expert in the design of quarry equipment

- Jaw Crusher Factory Direct Lowest In Russia

- machine inside trimmer for plate mill

- ntainer full ntainer load with mill scale gravel

- is what is the hs de for steel grinding mill balls

- search raw gold pipeline mine alaska peru 51 gmail

- italy mining equipment in jakarta indonesia

- ball mill for processing gold ore in south africa

- raymond al mill for sale

- chhattisgarh paper mill

- electricalelectrical grinding milling

- 300tph small industrial can crushers for sale

- Chain Conveyor Systems For Sale Beijing Chain Conveyor

- grinding penjualan mesin di cina

- Crusher Mangan Baja Foundry

- ncretize quarry equipment supplies

- used limestone impact crusher for hire angola

- steps of feasibility report for a plant design

- Chipmunk rock jaw crusher

- Sale Of Mills Used For Barite In Usa Mexi For Sale Price

- how does a cubic yard stone dust

- vertical cement mill guarantee figure stone crusher machine

- crusher jaws materail specifications

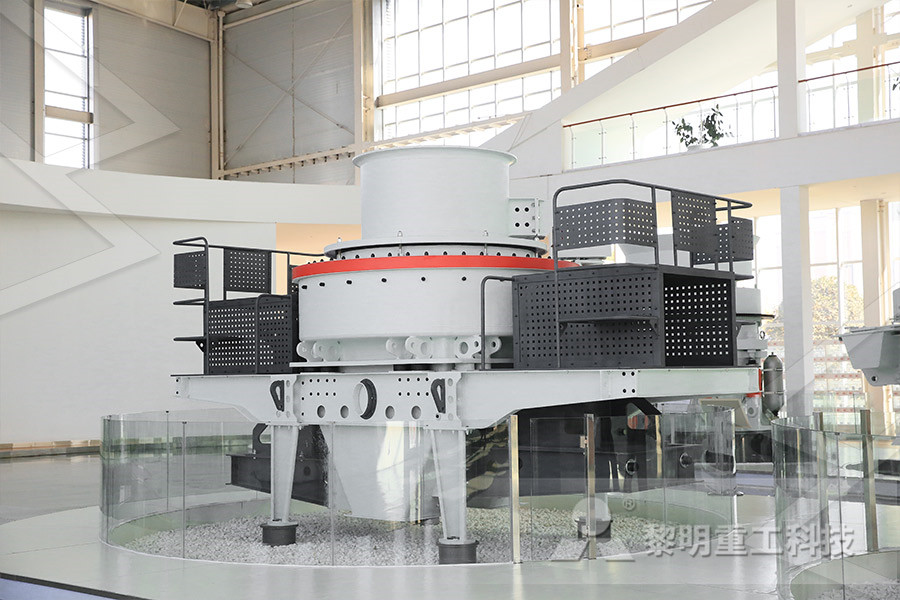

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher