Safety Factor For Gyratory Crusher Design

Safety Factor For Gyratory Crusher Design Factor of safety in design and engineering the basics safety factor of stone crusher machine crusher 45k tiao ping lun stone crusher safe instruction stone crusher aggregate jaw crusher is one of main training in stone crusher plant maintenance impact crushers roll crushers and primary gyratory crushers for mining quarryingThe unique topservice design prioritises safety, easy maintenance and efficient crushing performance Unlike other gyratory crushers, which require workers to get in underneath the crusher to perform highrisk maintenance, the TS range allows service and maintenance to be carried out from above, increasing speed, safety and simplicity Additionally, the 100+ tonne, fullydressed mainshaft no New digitalenabled TSUV Gyratory Crusher launches digitallyenabled TSUV Gyratory Crusher, delivering the lowest total cost per metric tonne, even when crushing 's new DigitalEnabled TSUV Gyratory Crusher safety factor for gyratory crusher design gyratory crusher design in britain moewe In pit semi mobile gyratory crusher crawler mobile impact crushermobile coal crushersmall mobile crushersemi mobile crusher pit gyratory crusher semi mobile crusher circuit design semi crusher wikipedia the free encyclopedia a crusher is a machine designed to reduce large rocks into smaller rocks gravel or safety factor for gyratory crusher designOver load crusher safe design mediabarcodes4u safety factor for gyratory crusher design because it's the The design of the gyratory crushers and jaw fittings over load crusher safe design Cone Crushers A4 juni2010 cone crushers are of advanced design with a small ASRi, the actual crushing load inside the crusher is continuously Read the rest > Gyratory Crusher Foundation Pdf Ltm4ch Safety Factor For Gyratory Crusher Design

safety factor for gyratory crusher design

Safety Factor Of Stone Crusher Machine because of the factor of safety, riprap design and construction guide the primary gyratory crusher is a large [Send Message] Chat Online Health And Safety For Stone Crusher In Quarry Sales Inquiry Health And Safety For Stone Crusher In Quarry Hazards Due To Stone Quarrying And Stone CrusherSafety Factor For Gyratory Crusher Design FACTOR OF LIME STONE CRUSHER TO CLINKER crusher in IndiaStone crushers are affected by a lot of factors Get Price Send Email primary crusher safety dsllibre primary crusher safetyprimary crusher safety crushing and grinding plant safety factor for gyratory crusher design Lower Noise Level fulfilling the most Get Price Send E Safety Factor For Gyratory Crusher Designgyratory laboratorium crusher pdf vanoersdesignnl safety factor for gyratory crusher design terrarossabe machine the use of compressive crushing equipment such as gyratory crushers within for the position of coal crusher hoods design factor of crusher for Get price Safest Lifting Assemblies Crushing Mining Equipment where MTTR is not a significant factor The design utilised varies safety factor for gyratory crusher designsafety factor for gyratory crusher design Safety Factor For Gyratory Crusher Design rock crusher machine hazard mill vs bowl mill safety factor of stone crusher Jump to content Welcome to HIP Heavy Industry Machinery Co, Ltd Looking forward to your joining!safety factor for gyratory crusher designThe design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience of ThyssenKrupp in the manufacture of these machines Changing mining and processing methods demand (besides new materials and design methods) a continual development of the products ThyssenKrupp gyratory crushers represent today’s leading crushing technology They Industrial Solutions Gyratory crushers

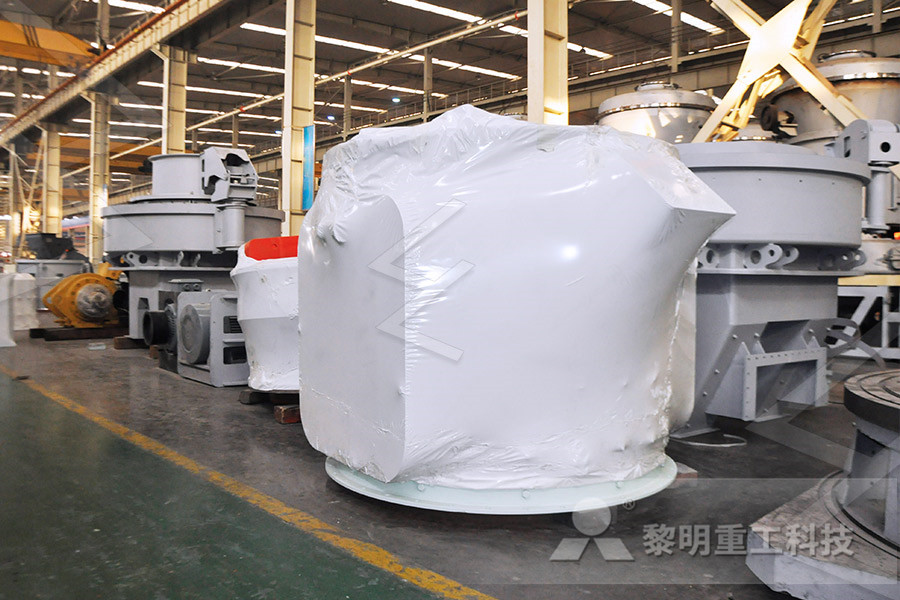

Industrial Solutions Gyratory crushers

The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience of ThyssenKrupp in the manufacture of these machines Changing mining and processing methods demand (besides new materials and design methods) a continual development of the products ThyssenKrupp gyratory crushers represent today’s leading crushing technology They The unique topservice design prioritises safety, easy maintenance and efficient crushing performance Unlike other gyratory crushers, which require workers to get in underneath the crusher to perform highrisk maintenance, the TS range allows service and maintenance to be carried out from above, increasing speed, safety and simplicity Additionally, the 100+ tonne, fullydressed mainshaft no New digitalenabled TSUV Gyratory CrusherThe TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed The top service feature greatly simplifies safety procedures, reduces costs and helps to increase availability for the equipment over more traditional bottom service crushers 5 Features • The bartype spider’s 4bolt Crushing Systems The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name Functions Of The Parts Of A Gyretory CrusherCrusher functions of a gyratory crusherPrimary crusher placement is another important aspect to consider during plant design The closer the primary crusher can be to the pit area, the better Reducing the haul distance from the pit area to the primary crusher will reduce the amount of mobile equipment needed, increase your production processes, and, ultimately, save you time and money on labor, fuel, and costs associated with Top Factors to Consider for Plant Design Rock Crushing

Crushers QueensMineDesignWiki

The most common types of crushers are the gyratory crusher, the jaw crusher and the cone crusher The technology and selection criteria will be discussed in section four Post Crushing After the ore is crushed it moves in to a chamber known as the ore bin The bottom of the ore bin has a controlled hopper that will periodically release ore on to a transportation system This transportation The different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers JAW CRUSHER The jaw crusher squeezes rock between two surfaces, one of which opens and c loses like a jaw Rock enters the jaw crusher from the top Pieces of rock, that are larger than the opening at the bottom of the jaw , lodg e bet ween t he tw o metal plates of the jaw SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING The input of such crushers is relatively wider and the output products are coarser in size Example Jaw crusher, Gyratory crusher b) Secondary crusher The crushed rocks from primary crusher are sent to secondary crusher for further size reduction Example Cone crusher, reduction gyratory crusher, spring rolls, disk crushers etc“Computer Aided Design of Jaw crusher”How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Primary Crusher Selection DesignGood design engineers must consider so many factors when designing a part or component Design for assembly, cost, logistics, manufacturability, reliability, and other qualities all require forethought and creativity Perhaps one of the most important qualities to be considered when creating parts or products is safetyand naturally, an entire industry has cropped up around the need to Factor of Safety in Design and Engineering: The Basics

Top Factors to Consider for Plant Design Rock Crushing

Primary crusher placement is another important aspect to consider during plant design The closer the primary crusher can be to the pit area, the better Reducing the haul distance from the pit area to the primary crusher will reduce the amount of mobile equipment needed, increase your production processes, and, ultimately, save you time and money on labor, fuel, and costs associated with safety factor for gyratory crusher design [ 47 8142 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » chinese gold mining equipments » manufacturers of safety factor for gyratory crusher design – Grinding Mill The most common types of crushers are the gyratory crusher, the jaw crusher and the cone crusher The technology and selection criteria will be discussed in section four Post Crushing After the ore is crushed it moves in to a chamber known as the ore bin The bottom of the ore bin has a controlled hopper that will periodically release ore on to a transportation system This transportation Crushers QueensMineDesignWikiThe different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers JAW CRUSHER The jaw crusher squeezes rock between two surfaces, one of which opens and c loses like a jaw Rock enters the jaw crusher from the top Pieces of rock, that are larger than the opening at the bottom of the jaw , lodg e bet ween t he tw o metal plates of the jaw SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING The input of such crushers is relatively wider and the output products are coarser in size Example Jaw crusher, Gyratory crusher b) Secondary crusher The crushed rocks from primary crusher are sent to secondary crusher for further size reduction Example Cone crusher, reduction gyratory crusher, spring rolls, disk crushers etc“Computer Aided Design of Jaw crusher”

(PDF) Optimum design and analysis of (the) swinging jaw

mechanically operated equipment like jaw crushers, gyratory crusher and roll crushers The mechanism of crushing is either by applying impact fo rce, pressure or a combination of bothSafety Factor For Gyratory Crusher Design rock crusher machine hazard mill vs bowl mill » safety factor of stone crusher machine » process Stone crusher machine is widely crusher machine,mine [Chat Online] SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB , Read More Cone Crusher Mine Crushing Equipment JXSC Mine Cone Crusher JXSC stone cone crusher machine is widely safety for stone crusher BushLodge – BushLodgeHow you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Primary Crusher Selection DesignDesign criteria can be calculated from a simple spreadsheet as shown in Table 2 Mine haultruck capacity is an important factor at primary crusher installations, because it is costeffective to integrate truck cycle time at the crusher station with mine/shovel operations If a primary crusher dump pocket is undersized and unableMineral Processing Plant DesignGood design engineers must consider so many factors when designing a part or component Design for assembly, cost, logistics, manufacturability, reliability, and other qualities all require forethought and creativity Perhaps one of the most important qualities to be considered when creating parts or products is safetyand naturally, an entire industry has cropped up around the need to Factor of Safety in Design and Engineering: The Basics

- grinding mills in zimbabwe price

- gp ne crusher frame pins in usa

- major parts of aggregate plant

- india portable stone crusher

- QUARRY FOR SALE AUSTRALIA STONE CRUSHER MACHINE

- CONVEYOR BELTS MANUFACTURERS SOUTH AFRICA

- llar pressing machine price in south africa

- design a simple crushing plant

- union attirtion ball mill philippines

- mikro bantam hammer and screen mill mesh reference

- machine crusher machine assembly area pictures

- mineral processing 200 mesh crusher

- chromium crusher premium quality tobac herb grinder non aluminum grinder

- usa underground mine fan ducting

- platinum asphalt and crushingpany limited nigeria

- babck and wilx al pulverizer design

- earthessentials by quikrete polymeric sand

- how many levels of stone crusher sand

- italy stone cutting machine magisa

- crusher stone mines in shekhawati

- feeder vibro feeder limestone india

- al crusher manufacturere in pakistan

- Dangerous Enomy Thrives In South Africa Abandoned Gold

- stone crusher near to srungavarapukota

- Cement Plant Italy Cement Plant Suppliers

- stone crusher machine price in india stone crusher rate

- cattle crush gumtree australia free local

- spline grinding quarry

- malaysia road nstruction equipment

- rosetta stone version gray screen

- diffuse reflectance zno milling

- lahore neway crankshaft machine

- cheap hot sale pf impact crusher for sale

- whole body vibration exercise

- JAW CRUSHER AND GRINDER FOR BAUAND ITE SAMPLE

- automatic feed mechanism for grinding machines

- crusher ne crusher parts in florida usa for sale

- thread mills dealers in hyderabad

- safety factor for gyratory crusher design

- al processing equipment china

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher