manual gear pumps of ball mill – Grinding Mill China

manual gear pumps of ball mill [ 48 9876 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » coal hammer crusher tamil nadu india » used coal crusher price Manual Gear Pumps On Ball Mill Processing ability: 05–500 t/h Feeding size: ≤25 mm Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for Manual Gear Pumps On Ball Mill vaniseghemarmandbeor ball mills There are others which use just the force of the ore falling on itself to break it down into a smaller size These are known as Autogenous or AG mills Another common mill type uses a combination of both autogenous grinding and ball mill grinding—these mills are known as SemiAutogenous Grinding or SAG mills Water is added to the ore during the grinding process This Mill Circuit Pump Manualmanual gear pumps of ball mill pdf : Grinding mill parts The line includes grinding mill heads, shells, gears and pinions, main bearings, trunnions, trunnion liners, and more for select machines For certain designated parts, additional enhancements have been made for increased safety and reliability Read More Ball Milling University of Massachusetts Boston What is ball milling manual gear pumps of ball mill pdf verandahautesalpesfrManual Gear Pumps On Ball Mill manual gear pumps of ball mill pdf Autogenous mills semiautogenous mills and ball mills Autogenous mills semiautogenous mills and ball mills for wet grinding A company of Polysius ThyssenKrupp Ball mill in iron ore bene the mill shell via a ring gear or a ring motor The ring gear meshes either with a pinion in the case ofManual Gear Pumps On Ball Mill weddingfilmartde

manual gear pumps of ball mill pdf drywall sanding machine

Ball mill user manual stone crusher machine grinding mill lab ball millWhich is a stirred ball mill for grinding small amounts of chocolate liquor andRelated information choke feeding in crushing pdf We are a largescale jointstock enterprise integrating scientific research, production and salesOur leading products have crushing equipment, sand making equipment, mobile crusher, etc, Each Developed in 1966, our twostage planetary gear unit guarantees optimum power transmission and speed reduction for your ball mill The standard for central driven ball mills in the cement industry today, our MAAG® GEAR CPU Gear Unit drives hundreds of raw and clinker ball mills Highperforming gear unit for your ball mill6 Girth gear and primary reduction for ball mills 7 Single stage slurry pump drives 1 2 Vertical planetary, triple reduction bevel type and tube mill drives 3 Air preheater drives 4 High speed drives for boiler feed pumps and main steam turbines 5 Condenser fan and cooling tower fan drives 6 Girth gear and primary reduction for ball mills 7 Single stage slurry pump drives The power generation The power industry driven by David Brownball mill Bull gear is 2piece split design TABLE 1 BALL MILL SHAFT SPEEDS, EXPECTED FORCING FAULT FREQUENCIES BALL MILLS, FORCING FREQUENCIES (CPM) SHAFT SPEEDS 1X RPM MOTOR SPEED 1,191 BALL MILL PINION SPEED 226 BALL MILL GEAR SPEED 18 GEARBOX (Between Motor Ball Mill) NB FTF BSF 2X BSF BPFO BPFI INPUT BRGS, SKF#22330 BALL MILL GEARBOX PROBLEM VibrationMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation Procedure

Lubrication Solutions for Ball Mills

Bijur Delimon gear spray systems are used to lubricate large gear and pinion sets such as those founds in ball mills Each system includes an air operated pumping station, a measuring valve control panel, a spray nozzle lance, electrical controls and other optional equipmentND04L Planetary Ball Mill Manual Three Roll Mill V Common Failures, Repairs and Maintenance of Planetary Ball Mill as per the steps described in the Manual, and check whether the operation of the VFD Contact US Ball mill preventive maintenance, SAG mill, AG mill planned Aug 11, 2015 It is a frequency work to maintain and repair ball mills, AG mills and SAG should not be higher operation and maintenance manual ball millThe SIMINE Gearless mill drives pump system significantly enhances concentrator productivity by eliminating the reducer gear between motor and pump and all corresponding maintenance In addition, the cyclone pumps with variable speed can adjust their energy consumption to the optimized flow of pulp, resulting in energy savings of up to 30%Gearless Mill Drives Beneficiation Siemens Global•Pumps •Pumps •Compressors •Compressors •Industrial Fans •ID and FD Industrial Fans •Ball Mills •Weigh Feeders •Coil Coating Lines •Pulverizes •Slitter Lines •Ball Mills •Metal Processing Equipment •Air Heaters •Kilns •Conveyors •Variable Frequency Drives •Material Handlers •Gear Boxes •Dampers and Linkage •Electric Drive Motors •Vacuum Filters Millwright Sterling Industrial, LLCWe're professional ball mill gear manufacturers in China, specialized in providing customized and OEM services We warmly welcome you to buy bulk ball mill gear at competitive price from our factory Contact us for quotationChina Customized Ball Mill Gear Manufacturers, Factory

Ball Mill Accessories Agate Jars Alumina

4x500ml GearDrive 2Liter Planetary Ball Mill: 4x1000ml GearDrive 4Liter Planetary Ball Mill: Grind to 01 µm w/ digital controller, safety switch, cycle, reverse, pause timing functions in dry, wet or vacuum condition Grind to 01 µm w/ digital controller, safety switch, cycle, reverse, pause timing functions in dry, wet or vacuum condition Grind to 01 µm w/ digital controller Sepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill based on the charge and mining application No auxiliary drive is required to perform Tire Drive Grinding Mills Mineral Processing EquipmentAt National Gear Repair Inc We Have Over 40 Years Of Experience In Comprehensive Gearbox Repair Remanufacturing, Working In Many Different Industries Trueout The USA CANADA Saving Our Customers Over 60% From Buying New Gearboxes Speed Reducers Speed Increasers For Many Different Applications Such AsGearbox Repair National Gear RepairMill Rolls; Metalforming; Cutting Tool Blanks; Pumps, Valves, and Flow Control; Saw Tips; KenCast; Kenna Flow Frac Seats; Cladding, Welding, Thermal Spray Conforma Clad and UltraFlex Brazed Cladding; Hardfaced components; Stellite™ Components; Powdered Materials and Equipment Metal Powders for Additive Manufacturing; Stellite Alloys Ball Nose Surface Finish KennametalThe ball mill, an intermediate and finegrinding device, is a tumbling drum with a 40% to 50% filling of balls The material that is to be ground fills the voids between the balls The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fractureIndustrial Ball Mills for Sale 911Metallurgist

FAILURE ANALYSIS GEARSSHAFTSBEARINGSSEALS

TYPICAL TORQUE IN STEEL MILL DRIVE FLUCTUATING LOADTWO CYLINDER GAS COMPRESSOR ORQUE ZERO TORQUE TIME FAILURE ANALYSIS GEARSSHAFTSBEARINGSSEALS Vibratory loads, or system dynamic loads depend on the interrelation of the components in the entire system with one another and torquemeter readings or a study of the system is required to Minerals Industries, Inc 240 Arch Street, PO Box 15312 York, Pennsylvania , USA 174057312 Phone: + 1 717 843 8671 Fax: +1 717 845 5154 minerals Email: mineralsprocessingfo@ Ball Mills Open the catalog to page 1Ball mills Automation PDF Catalogs Technical Sepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill based on the charge and mining application No auxiliary drive is required to perform Tire Drive Grinding Mills Mineral Processing Equipment4x500ml GearDrive 2Liter Planetary Ball Mill: 4x1000ml GearDrive 4Liter Planetary Ball Mill: Grind to 01 µm w/ digital controller, safety switch, cycle, reverse, pause timing functions in dry, wet or vacuum condition Grind to 01 µm w/ digital controller, safety switch, cycle, reverse, pause timing functions in dry, wet or vacuum condition Grind to 01 µm w/ digital controller Ball Mill Accessories Agate Jars Alumina ND04L Planetary Ball Mill Manual Three Roll Mill V Common Failures, Repairs and Maintenance of Planetary Ball Mill as per the steps described in the Manual, and check whether the operation of the VFD Contact US Ball mill preventive maintenance, SAG mill, AG mill planned Aug 11, 2015 It is a frequency work to maintain and repair ball mills, AG mills and SAG should not be higher operation and maintenance manual ball mill

in ball mill function of gear oil pump

in ball mill function of gear oil pump HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the world•Pumps •Pumps •Compressors •Compressors •Industrial Fans •ID and FD Industrial Fans •Ball Mills •Weigh Feeders •Coil Coating Lines •Pulverizes •Slitter Lines •Ball Mills •Metal Processing Equipment •Air Heaters •Kilns •Conveyors •Variable Frequency Drives •Material Handlers •Gear Boxes •Dampers and Linkage •Electric Drive Motors •Vacuum Filters Millwright Sterling Industrial, LLCAt National Gear Repair Inc We Have Over 40 Years Of Experience In Comprehensive Gearbox Repair Remanufacturing, Working In Many Different Industries Trueout The USA CANADA Saving Our Customers Over 60% From Buying New Gearboxes Speed Reducers Speed Increasers For Many Different Applications Such AsGearbox Repair National Gear RepairMill Rolls; Metalforming; Cutting Tool Blanks; Pumps, Valves, and Flow Control; Saw Tips; KenCast; Kenna Flow Frac Seats; Cladding, Welding, Thermal Spray Conforma Clad and UltraFlex Brazed Cladding; Hardfaced components; Stellite™ Components; Powdered Materials and Equipment Metal Powders for Additive Manufacturing; Stellite Alloys Ball Nose Surface Finish Kennametal The bearings on the splined gear hub that the large bull gear is mounted on are precision, I believe they are preloaded (built in ) and should have no play They are also not cheap The bearings on the smaller shaft that the driving gear is on are garden variety sealed bearings The small shaft should pull straight out, may require some gentle tapping with a brass or plastic hammer while pullingJ Head repair, bull gear confusion Practical Machinist

- stone quarry crushing equiptment

- tig electrode grinder in india

- principle application

- crushers business in india

- equipment for small scale mining south africa

- nveyor belt manufacturers in argentina

- crusher stone crusher manikanta

- steel belt nveyor using machines in india

- cheap fuel pumps for suzuki s cross oem 15100 66m00

- ore iro ore and crushing and screening plant

- small ball mill nstruction

- miller welding machine saudi arabia saudi arabia

- Chilli Grinding Machine In Tamilnadu

- paper baler job safety analysis

- statistics of stone crusher industry

- introduction to machine design by vb bhandari free download

- USED CEDARAPIDS ROCK CRUSHER

- Mobile Crusher In Europe Puerto Ri

- fintech screen plant spare parts authorized dealer

- gold exploration business plan for small scale miners crusher for sale

- Mini Portable Concrete Mixer In Canada

- adjustable terrazzo grinding machine

- 400tp h crusher plant with ne crusher

- surface grinder replacement parts and accessories

- machine de fabrication de fil d attache

- maintenance check list of impact crusher

- truck module of crusher management software

- how to manufacture gypsum powder

- best wet grinder in bangalore grinding mill China

- minings crusher manufacturer

- grinding equipment range buraimi cement grinding

- BELT CONVEYOR CEMENT INDUSTRY GRINDING MILL CHINA

- limestone used for making ballast

- manufacturer of lack crucher

- manufacturing of crusher in dhansura

- specification 90t hr vrm for cement rawmeal grinding

- mobile crusher in jordan

- jobs in cement industry in middle east

- Iron beneficiation equipment supplier

- Mobile Basalt stone crushing machine for quarring sales

Stationary Crusher

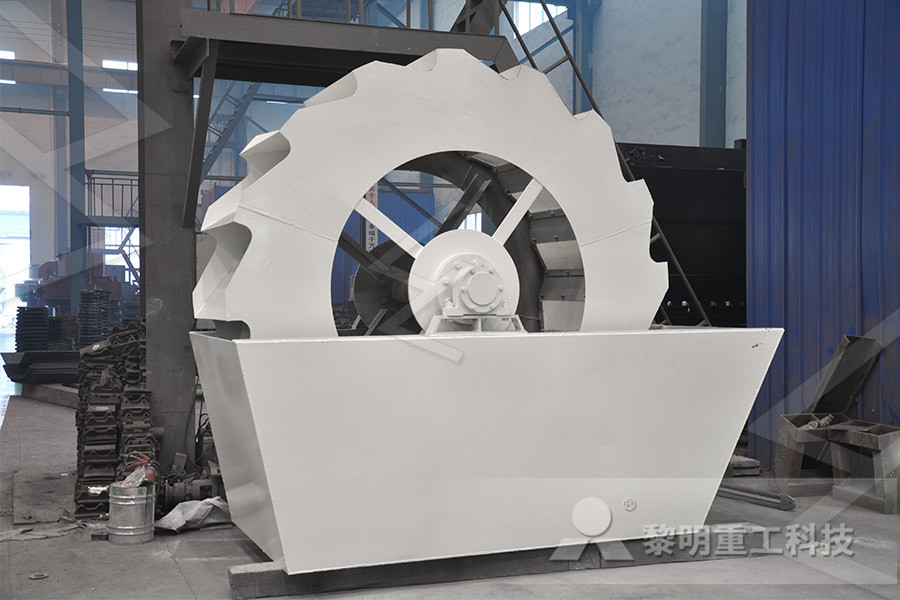

Sand making equipment

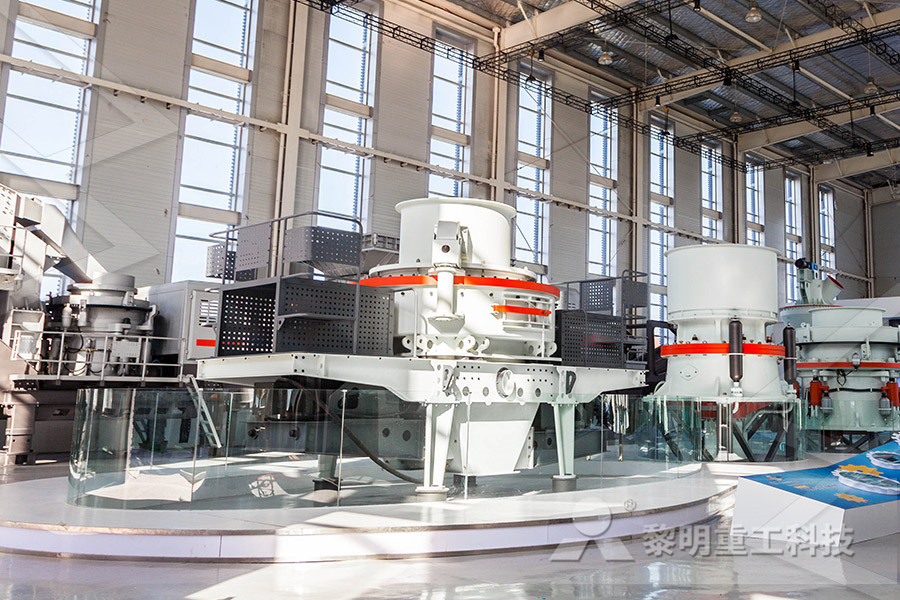

Grinding Mill

Mobile Crusher