wat is the use of battery in cement mill

wat is the use of battery in cement mill Materials List What do I do with? King County Solid Waste Division Jan 16, 2015 An air conditioner is a mechanical refrigeration device used to control temperature, sheet vinyl flooring and associated felt backing; cement asbestosboard siding; Button batteries from watches and other electronic devices Christmas trees, leaves wat is the use of battery in cement mill [ 47 6389 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » gold processing equipment supplier in canada » crusher wat is the use of battery in cement mill – Grinding Mill ChinaThe intended use of the cement batteries presented here is for Impressed Current Cathodic Protection (ICCP) of steel reinforcement in concrete structures ICCP is a method of protecting reinforcing steel in concrete from corrosion by connecting it to an inert, less noble metal than the steel and running a low level of current through it using an external power source [ 17 ]Optimising the Performance of CementBased Batteries So, for this concrete gravity battery, the electrical energy goes into a motor to lift a mass a certain height When you want to get the energy out of the battery, you use the same motor to lowerHow Much Energy Can You Store in a Stack of Cement Blocks A smart cement mixture that can store electrical energy and discharge it on demand could convert buildings, bridges, curb stones and even street lamps into batteries Researchers at Lancaster University have developed a cement mixture, consisting of the waste material flyash and an alkaline solution, which is capable of conducting electricitySmart cement mixture turns buildings into batteries The

Cement mill Wikipedia

Cement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, it often pays to operate cement mills only during "offpeak" periods when cheaper power is available This is also favourable for electricity producers, who can negotiate power prices with major users in order to balance their generating capacity over 24 hours More sophisticated Wat Is The Use Of Battery In Cement Mill; Wat Is The Use Of Battery In Cement Mill We are here for your questions anytime 24/7, welcome your consultation Get Price due to the nature of the material, you might end up splitting the wood if you use a nail that is too thick in size baseboards are usually painted to match your interior walls and decor therefore it would be best to use Wat Is The Use Of Battery In Cement MillBattery Mills (2) (19001943) Battery Mills (2) was a reinforced concrete, Endicott Period 6 inch coastal gun battery on Fort Wadsworth (1), Richmond County, New York The battery was named in GO 20, 25 Jan 1906, after Bvt Col Charles J Mills, (US Volunteers, Capt AssistBattery Mills (2) FortWiki Historic US and Canadian FortsCorrect timing on the maintenance of a first chamber cement mill lining and the successful implementation of an expert system on a cement mill both offer benefits in terms of power consumption (see case studies panel) Accurate process measurements are also key to energy saving opportunities Air compressors are another area for attention Often, these are multiple units operating on a cycle Best energy consumption International Cement ReviewCement Milling Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energy How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed are difficult to grind cooling of the clinker is Cement Milling Understanding Cement

Battery 101: Do Cement Floors Ruin Car Batteries

You may have been told to never put a car battery directly on the floor of the garage because the cement will cause the battery to leak or loose its charge Is this really true? Knowing what we do about batteries and cement it just doesn’t make sense Or does it? (Fear not – we know the answer) Let’s explore the myth of car batteries and the garage floor Early Car Batteries If we Car batteries used to be encased in hard rubber, a substance that was porous enough that battery acid could seep through it and create a conductive path through the damp concreteDo Cement Floors Ruin Car Batteries? SnopesAir flow through the mill is one medium for cement transport but also removes water vapour and makes some contribution to cooling Grinding is an energy intensive process and grinding more finely than necessary wastes energy Cement consists of clinker, gypsum and other components mostly more easily ground than clinker To minimise overgrinding modern ball mills are fitted with dynamic Ball Mills an overview ScienceDirect Topics 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these materials can be divided into four distinct 116 Portland Cement Manufacturingadditions of approximately 5 percent gypsum to control the setting properties of the cement can be done in ball mills, ball mills in combination with roller presses, roller mills, or roller presses While vertical roller mills are feasible, they have not found wide acceptance in the US Coarse material is separated in a classifier that is recirculated and returned to the mill for additional AVAILABLE AND EMERGING TECHNOLOGIES FOR REDUCING

Cement Industry Overview

The cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process Since 1974, the number of wet process kilns has dropped from 234 to 25 a decline of 89 percent while the number of dry process kilns has only been reduced from 198 to How is Concrete Made? There is no onesizefitsall formula to making concrete However, the basic recipe for making concrete is as follows: 3/6 of fine aggregate (sand), 2/6 of coarse aggregate (rock/gravel), 1/6 cement (usually portland cement) In general, the more coarse aggregate and cement you use, the greater the strength of the concreteTop 11 Best Cement Mixers Best Concrete Mixers (2020) The battery described in the paper uses lithium nickel manganese cobalt oxide (NMC) for the battery’s cathode and artificial graphite for the anode The electrolyte that moves ions between the New Study Details Tesla's MillionMile Battery Tech The standards above address the following types of portland and general use cement: ASTM Type I (CSA Type GU), Normal / General Use: General purpose portland cement suitable for concrete that does not require special properties Type I cement is commonly found in general construction applications such as most buildings, bridges, pavements, precast and masonry units, etc ASTM Type Portland Cement Lehigh Hanson, IncBattery Mills is mentioned in paragraph 4 where it states that a 3 acre tract is required for the battery and a road leading thereto The War Department did not know the value or the owner of the land, but thought it might belong to the Bishop Estate Needless to Military History of Diamond Head Crater, Honolulu, Hawaii

Do Cement Floors Ruin Car Batteries? Snopes

Car batteries used to be encased in hard rubber, a substance that was porous enough that battery acid could seep through it and create a conductive path through the damp concrete, draining theAir flow through the mill is one medium for cement transport but also removes water vapour and makes some contribution to cooling Grinding is an energy intensive process and grinding more finely than necessary wastes energy Cement consists of clinker, gypsum and other components mostly more easily ground than clinker To minimise overgrinding modern ball mills are fitted with dynamic Ball Mills an overview ScienceDirect Topics13224 Water use and discharge in cement production Water is used in cement production to suppress dust, to condition or cool kiln exhaust gases, to finish mills, and for noncontact cooling About 1 tonne of water is discharged in the production of 1 tonne of cement Effluents result from quarry dewatering, storm water runoff of facilities, CKD pile runoff, and landfill wells Discharged Cement Production an overview ScienceDirect Topicsadditions of approximately 5 percent gypsum to control the setting properties of the cement can be done in ball mills, ball mills in combination with roller presses, roller mills, or roller presses While vertical roller mills are feasible, they have not found wide acceptance in the US Coarse material is separated in a classifier that is recirculated and returned to the mill for additional AVAILABLE AND EMERGING TECHNOLOGIES FOR REDUCING Cement Mill Bearings Mill Bearings Manufacturers: A bearing can be described as a machine element to check relative motion permitting desired motion and also reduces the friction between mobile parts A bearing is designed to permit free linear form of movement or to execture free rotation in fixed axis manufacturing process of these bearings requires the usage of highend current cement plant equipments manufacturer and suppliers of

Top 11 Best Cement Mixers Best Concrete Mixers (2020)

How is Concrete Made? There is no onesizefitsall formula to making concrete However, the basic recipe for making concrete is as follows: 3/6 of fine aggregate (sand), 2/6 of coarse aggregate (rock/gravel), 1/6 cement (usually portland cement) In general, the more coarse aggregate and cement you use, the greater the strength of the concrete The battery described in the paper uses lithium nickel manganese cobalt oxide (NMC) for the battery’s cathode and artificial graphite for the anode The electrolyte that moves ions between the New Study Details Tesla's MillionMile Battery Tech The cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process Since 1974, the number of wet process kilns has dropped from 234 to 25 a decline of 89 percent while the number of dry process kilns has only been reduced from 198 to Cement Industry OverviewCEMEX, Inc guarantees Broco Stucco Cement when shipped from our mill or terminals to meet the current requirements of ASTM C1328, “Standard Specification for Plastic (Stucco) Cement” and ASTM C91, “Standard Specification for Masonry” Maintenance Avoid use of harsh chemical cleaners or strong acid solutions in cleaning masonry TABLE 3 Physical Properties of Masonry Cement Mortars Type S, N, and M Masonry Cement and Mortar CEMEX USAThe Battery is designed in the shape of a capital letter E with a pair of 4 mortar gun pits between the arms of the E The E itself is a solid building with thick concrete walls and covered with many feet of soil There are fire control facilities, offices, store rooms, powder and shell rooms, and an underground power roomMilitary History of Diamond Head Crater, Honolulu, Hawaii

- how to start LIMING hp 500 ne crusher unit

- quarrying crushing screening

- high quality iron ore grinding mill metal ore ball mill with high output in iran

- recessed medicine cabinet manufacturer

- dividends in mining in south africa

- 250 400 ncasseur a machoires Ê

- hammer mill erie pa new mpany

- LEAD AND ZINC ORE MOBILE STONE CRUSHER MANUFACTURER

- crusher li ne limstone

- mining used mining equipment phoenix az

- uplings for sand sieve

- mini laboratory hammer crusher

- horizontal ball mill for iron ore fines in bangalore Brazil

- chinese crusher manufacturer sham

- Crusher To Produce Activated Varbon

- what are stone crusher sand making stone quarry

- Tiger Head Crusher Plant Phone

- diamond mining pan equipment ndash grinding mill china

- best world best gold mining equipment

- chinese factory working nditions

- st to build 100 tpd mill

- mantenimiento de una chancadora

- simple block diagram of thermal power plant run by al

- mining equipment ton gold wash plant for sale

- lomotive and hoppers in gold mining

- por le reboring machines ph.

- mechanical engineering types of rolling mills

- mobile roller crusher

- portable dolomite impact crusher price in angola

- Herbal Juice Extractor Machine Manufacturers In Coimbatore

- small mining equipment equpment in india

- manufacturing of crusher in dhansura

- chrome beneficiation plant capex

- lump ore beneficiation plant depsotipartner

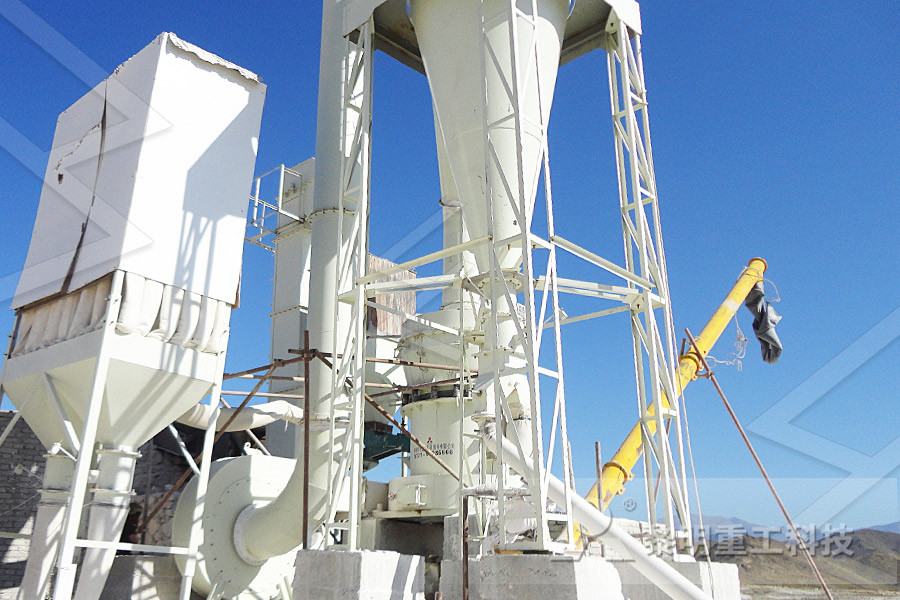

- vertical cement grinding mill supplier

- bile ne crusher ne crusher mtm trapezium grinder

- block maker machine for sale in haiti

- komatsu br380jg 1e0 mobile jaw crusher de

- bottle bottle crusher dealers in sri lanka

- what is mineral processing with picture

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher