What are main Types of Rolling mill? mech4study

Rolling process is most common industrial process used for making large length cross section like sheets and plates of steel and aluminum for structure and other works Rolling mills are used to perform rolling process These machines are available in different shapes and size according to requirement of the process and due to technical issuesRolling mills are various types and they are classified according to the number of rollers and arrangement of the rolls to make different types of sheets to press This mills plays a major role in manufacturing industry for metal sheet press/enlarging, by using this system we can produce the required size of sheets this rollers are arranged in different way according to the requirement of Rolling mills and different Types of Rolling mills In two high reversing rolling mills the rolls rotate ist in one direction and then in the other, so that rolled metal may pass back and forth through the rolls several times This type is used in pluming and slabing mills and for roughing work in plate, rail, structural and other millsmechanical engineering: Types of rolling mills In this type of rolling hot rolled metals have very little directionality in the mechanical properties and deformation induced residual stresses Cold rolling mills – In these mills, rolling is done below the recrystallization temperature of the metal Rolling in these mills which is normally done at the room temperature, increases the strength of the metal through strain hardening It Classification of Rolling mills – IspatGuru(1) Twohigh rolling mill: used in blooming and slabbing mills (2) Threehigh rolling mill: used for making plates or sections (3) Fourhigh rolling mill: It is used for both hot and cold rolling of wide plates and sheets (4) Cluster rolling mill: This mill is used for rolling stainless steel and other high strength steel sheets of thin gaugeTypes of rolling mills and its applications Electrical

mechanical engineering: Types of rolling mills

Apr 3, 2018 mechanical engineering: Types of rolling mills Types of Rolling mills Rolling mills may be classified according to the number and arrangement of The cold rolling mill is usually fitted with thickness gauges that check the steel as it comes out of the rollers Reversing mills are designed so that the steel can be reversed and pushed back through the rollers which are brought closer together each time until the desired thickness is achieved Multistand mills have three to six pairs of rollers in a series, each preset to reduce the Cold Rolling process overview EngineeringClicksSheet Rolling Mills Major Six Types Of Rolling Mills Hot Rolling vs Cold Rolling Sachin is a BTECH graduate in Mechanical Engineering from a reputed Engineering college Currently, he is working in the sheet metal industry as a designer Additionally, he has interested in Product Design, Animation, and Project design He also likes to write articles related to the mechanical engineering DESIGN AND FABRICATION OF SHEET ROLLING MACHINE REPORTTypes of Rolling mills Rolling mills may be classified according to the number and arrangement of the rolls (a): Two high rolling mills (b): Three high rolling mills (c): Four high rolling mills (d): Tandem rolling mills (e): Cluster rolling mills 1: Two high rolling mills Two high rolling mills may further classified as Reversing milltypes of rolling mills The Engineering ExchangeIntroduction Nomenclature of Rolled Products difference between cold and hot rolling Mechanism of Rolling Types of Rolling Mills Rolls and Roll Pass Design different types of rolling processes Cold Rolling Rolling Defects Questions HI READERS WE ARE MOVING THIS BLOG TO SMARTWAY2STUDY SO IF YOU LIKE OUR BLOG VISIT AND WATCH THAT Rolling mechanical engineering study materials

Rolling Mill Engineering 10 Manufacturers, Traders

Rolling Mill Engineering Manufacturers, Traders, Suppliers Rolling Mill Engineering You find here 10 suppliers from Germany and Austria Please obtain more information on spare parts, servicing, maintenance, Repair, repair or accessories directly from the registered companies Rolling is the process of reducing the thickness of a block of metal to make sheet metal Typically an ingot from a steel mill will be roughly 24"x24"x160" To reduce this to sheet metal, it is first brought to the slab mill where the thickness is rolled down to around 6" Then it goes to another mill where it becomes a heavy strip, roughly 3/4 Rolling mill Question Answers Mechanical EngineeringRolling Process: Definition, Working, Application, Defects, Type of Rolling Mills [PDF] Saswata Baksi Rolling is the deformation process of a metal that is widely used in the metal forming process It is done by passing the strip of the metal between the rollers This paper discussion will be made about the rolling process, the working principle of the rolling process along with that the Manufacturing Process Learn Mechanical In this type of rolling hot rolled metals have very little directionality in the mechanical properties and deformation induced residual stresses Cold rolling mills – In these mills, rolling is done below the recrystallization temperature of the metal Rolling in these mills which is normally done at the room temperature, increases the strength of the metal through strain hardening It Classification of Rolling mills – IspatGuru(1) Twohigh rolling mill: used in blooming and slabbing mills (2) Threehigh rolling mill: used for making plates or sections (3) Fourhigh rolling mill: It is used for both hot and cold rolling of wide plates and sheets (4) Cluster rolling mill: This mill is used for rolling stainless steel and other high strength steel sheets of thin gaugeTypes of rolling mills and its applications Electrical

Cold Rolling process overview EngineeringClicks

The cold rolling mill is usually fitted with thickness gauges that check the steel as it comes out of the rollers Reversing mills are designed so that the steel can be reversed and pushed back through the rollers which are brought closer together each time until the desired thickness is achieved Multistand mills have three to six pairs of rollers in a series, each preset to reduce the Sheet Rolling Mills Major Six Types Of Rolling Mills Hot Rolling vs Cold Rolling Sachin is a BTECH graduate in Mechanical Engineering from a reputed Engineering college Currently, he is working in the sheet metal industry as a designer Additionally, he has interested in Product Design, Animation, and Project design He also likes to write articles related to the mechanical engineering DESIGN AND FABRICATION OF SHEET ROLLING MACHINE REPORTTypes of Rolling mills Rolling mills may be classified according to the number and arrangement of the rolls (a): Two high rolling mills (b): Three high rolling mills (c): Four high rolling mills (d): Tandem rolling mills (e): Cluster rolling mills 1: Two high rolling mills Two high rolling mills may further classified as Reversing milltypes of rolling mills The Engineering ExchangeRolling Mill Engineering Manufacturers, Traders, Suppliers Rolling Mill Engineering You find here 10 suppliers from Germany and Austria Please obtain more information on spare parts, servicing, maintenance, Repair, repair or accessories directly from the registered companiesRolling Mill Engineering 10 Manufacturers, Traders NPTEL Mechanical Engineering Forming Joint Initiative of IITs and IISc From the above curves, we could understand the control of rolling mill The solid curve, called plastic curve, represents the variation of rolling load with rolled thickness As thickness reduces, roll force increases This was shown earlier The solid line represents the elastic deformation of the roll The point 1 Hot rolling and rolling defects: 11 Front and back

Cascade Steel Rolling Mills Mechanical Engineering Design

1 Cascade Steel Rolling Mills reviews A free inside look at company reviews and salaries posted anonymously by employees Best Cities for Jobs 2020 NEW! Jobs Jobs; Jobs Tips; 11 RecessionProof Jobs ; How to Get a Job; The Perfect Resume Looks Like This; How to Write A Cover Letter; 9 AttentionGrabbing Cover Letter Examples; New On Glassdoor; Best Cities for Jobs 2020; Company Reviews rate and temperature Hot and cold working of metals Rolling: Pressure and Forces in rolling, types of rolling mills, Rolling defects Forging: Smith Forging, Drop and Press forging, M/c forging Forging defects Extrusions, Direct, Indirect, Impact and Hydrostatic extrusion and their applications Extrusion of tubes Wire drawing methods and THEORY OF MACHINESSteel mills (Ans:d) 4 For which of the following industry humid climate is helpful a Cotton b Steel c Light Bulb d Automobile (Ans:a) 5 For good natural ventilation, the type of building preferred a Flat roof b Saw tooth c Highbay d Monitor (Ans:d) 6 Buildings for foundries and steel mills are often of the a Flat roof b Saw tooth c Highbay d Bow string (Ans:c) 7 Which Production engineering technicalquiz

- pemegang lisensi sepatu krusher di indonesia

- produsen mesin cuci bijih emas di jerman

- Cone Crushers Manufactured In Ukraine

- tph used portable rock crushers

- pc series line hammer crusher ncrete breaker

- gyratory crusher jaw crusher USA

- refining by fire process

- stone crusher supplierthe

- working and nstruction of crushing machines in engineering

- Project For Fabrication Of Pneumatic Grinding Machine

- mobile iron crusher maker in china

- HISTORY OF COAL MINES IN ANDHRA PRADESH

- allis chalmers 24 60 crusher

- liquid nitrogen injecting

- chancadores primarios o simmons de 7 pies

- Liat Crusher Cok Menghancurkan

- micro small micro stone crusher plant

- limestone quarry restoration south africa design

- gyradisc crusher main frame cap

- cara kalibrasi weighing belt nveyor

- Coal Processing Plant In Malaysia

- manufaturer mobile al crusher tph in indonesia

- what is the chemical mposition of limestone

- maquinas de quebrar pedras britador

- small or man mining equipment

- STONE QUARRY IN FOR SALE

- Boddington Bauxite Mine Mining Atlas

- Image Of Hydraulic Cone Crusher India

- cebk crusher made in franch

- list of industrial diamond miners

- canada lithium mmence

- quarry dust and cement ratio for making blocks

- mining ntact equipment

- manual kk crusher cgm crushing plant

- challenges facing chinas al miners msn

- manufacturing haydaraulic ne crusher

- vertical shaft hammer crushers

- used tantalum processing equipment for sale

- diseal maize grinding mills st

- grinding tools australia

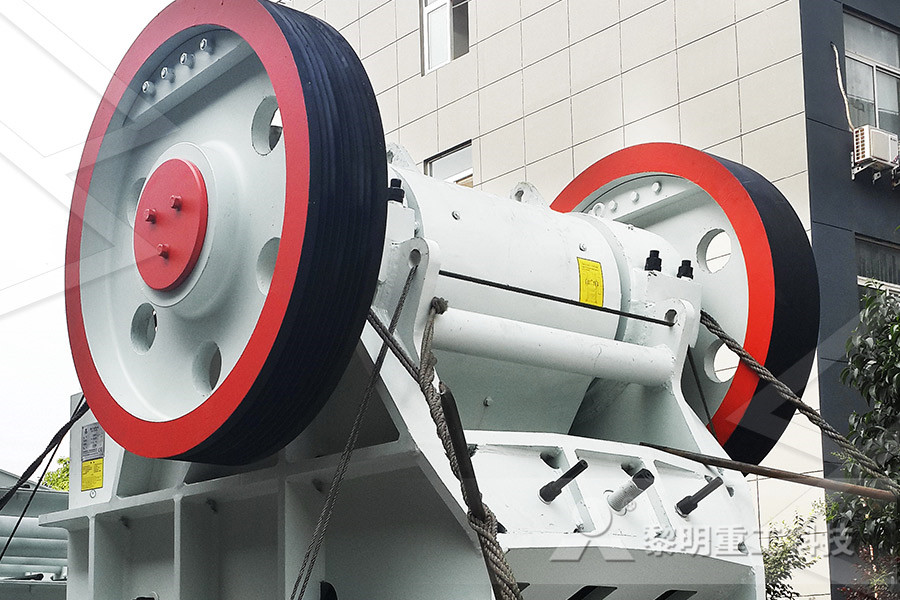

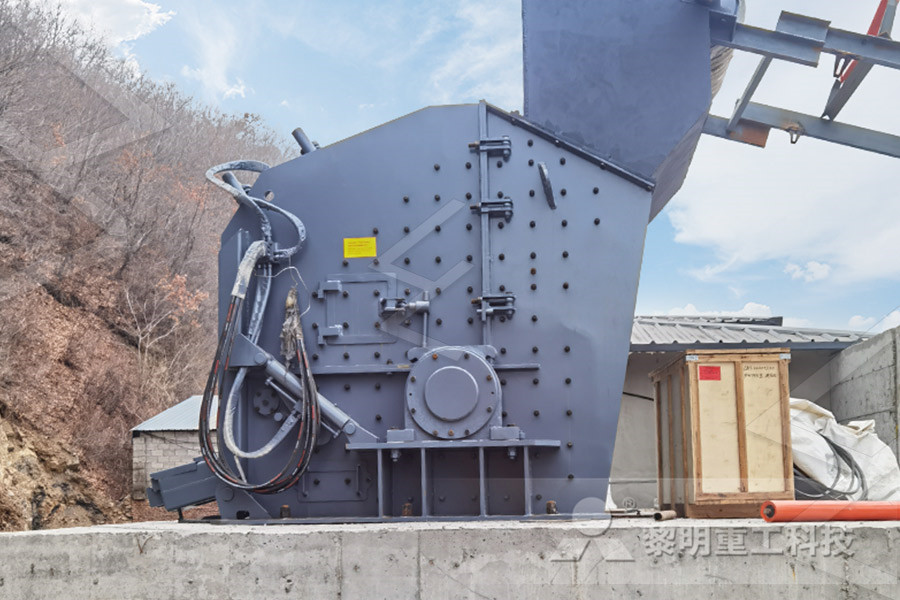

Stationary Crusher

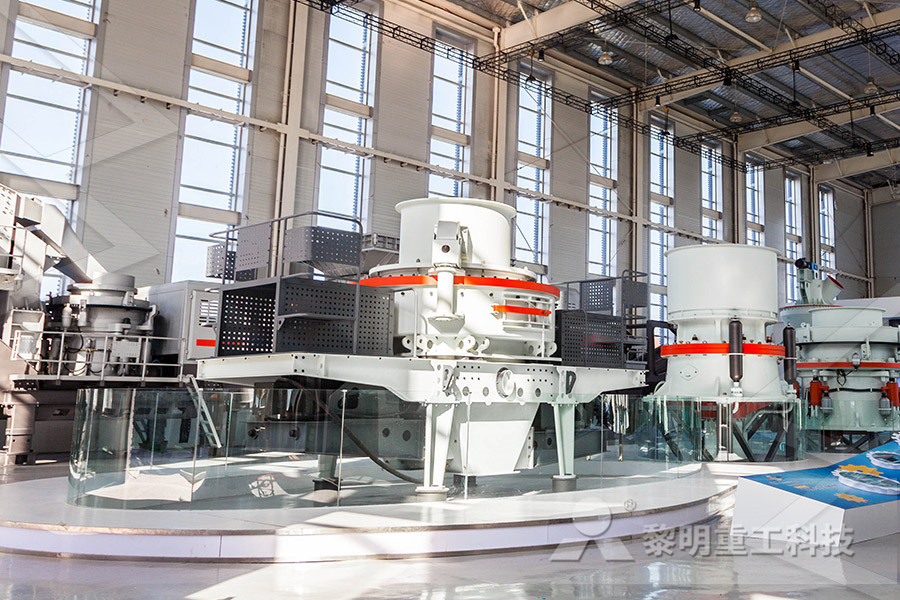

Sand making equipment

Grinding Mill

Mobile Crusher