Osha Gold Mining Cyanide

Osha Gold Mining Cyanide The use of cyanide in the mining industry is only one of the many industrial uses of cyanide NaCN is also used in a variety of processes including the production of plastics such as acrylics and nylon and pharmaceuticals ibuprofen and naproxen, processing of food decaffeination of coffee and as an anticaking additive in table salt, and Contact Supplier How is cyanide used in mining? A sodium cyanide solution is commonly used to leach gold from ore There are two types of leaching: Heap leaching: In the open, cyanide solution is sprayed over huge heaps of crushed ore spread atop giant collection pads The cyanide dissolves the gold from the ore into the solution as it trickles through the heap The pad collects the now metalimpregnated solution Cyanide Use in Gold Mining EarthworksCyanide extraction of gold through milling of highgrade ores and heap leaching of lowgrade ores requires cycling of millions of liters of alkaline water containing high concentrations of potentially toxic sodium cyanide (NaCN), free cyanide, and metalcyanide complexes Some milling operations result in tailings ponds of 150 ha and larger Heap leach operations that spray or drip cyanide Cyanide Hazards to Plants and Animals From Gold Mining and Since a tailings dam burst at gold mining company Aurul's Baia Mare mine in Romania in 2000, leaking cyanide into the Somes River and killing large numbers of fish in Hungary and Yugoslavia, the use of cyanide has been closely regulated in most countries and banned in others In fact, in response to the spill the International Cyanide Management Code (ICMC) was created and many Should cyanide still be used in modernday mining?Osha Gold Mining Cyanide The use of cyanide in the mining industry is only one of the many industrial uses of cyanide NaCN is also used in a variety of processes including the production of plastics such as acrylics and nylon and pharmaceuticals ibuprofen and naproxen, processing of food decaffeination of coffee and as an anticaking additive in table salt, and Osha Gold Mining Cyanide oragenicsoralcarenl

Sustainable Responsible Mining I CyanideFree Gold

The Clean Mining gold recovery process, developed by Australia’s CSIRO, replaces cyanide and mercury with a safer, less hazardous chemical reagent This alternative gold recovery solution is nontoxic and dissolves fine gold out of ores into a solution, which can then be recovered through further processing INNOVATIVE SOLUTION What is our nontoxic solution? This gold recovery agent is an Gold cyanidation is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complex It is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents approximately 13% of cyanide consumption globally, with the remaining 87% of cyanide Gold cyanidation Wikipediaosha gold mining cyanide Keywords smallscale mining cyanide exposure environmental health and safety gold extraction Philippine mining artisanal mining Introduction Smallscale gold mining SSGM refers to mining by individuals groups families or cooperatives with minimal or no mechanization often in the informal illegal sector of the economy Get a Quote Send Message MORE DETAILS: Description osha gold mining cyanide hitlershollywooddeInternational Cyanide Management Institute 1400 I Street, NW, Suite 550 Washington, DC 20005, USA PH: 2024954020International Cyanide Management Code (ICMI) For The Cyanide code for gold and silver mining (aka Cyanide Code Cyanide Queen) Lydia Renton, Blue Metric Environmental Inc As safety professionals, expertise in specific hazardous materials or processes happens over a career The Cyanide Code focuses exclusively on safe management of cyanide produced, transported and used for the recovery of gold and/or silver and on mill tailings and leach Cyanide code for gold and silver mining (aka Cyanide Code

Osha Gold Mining Cyanide

Osha Gold Mining Cyanide The use of cyanide in the mining industry is only one of the many industrial uses of cyanide NaCN is also used in a variety of processes including the production of plastics such as acrylics and nylon and pharmaceuticals ibuprofen and naproxen, processing of food decaffeination of coffee and as an anticaking additive in table salt, and Contact Supplier Cyanide extraction of gold through milling of highgrade ores and heap leaching of lowgrade ores requires cycling of millions of liters of alkaline water containing high concentrations of potentially toxic sodium cyanide (NaCN), free cyanide, and metalcyanide complexes Some milling operations result in tailings ponds of 150 ha and larger Heap leach operations that spray or drip cyanide Cyanide Hazards to Plants and Animals From Gold Mining and The following is a guest feature written by CyanoGuard, one of the 15 startups selected to participate in Prospect Mining Studio’s 2020 cohort Gold extraction using cyanide was first Gold Mining Reinvented: Maximizing gold recovery while Cyanide use in mining Gold typically occurs at very low concentrations in ores – less than 10 g/ton The most used process for gold extraction is hydrometallurgical recovery (gold cyanidation), which involves a “leaching” step during which the gold is dissolved in an aqueous medium, followed by the separation of the gold bearing solution from the residues Gold is one of the noble metals BACKGROUND NOTE ON CYANIDE IN GOLD MININGThe Cyanide Code is a voluntary initiative for the gold and silver mining industries and the producers and transporters of the cyanide used in gold and silver mining It is intended to complement an operation’s existing regulatory requirements Compliance with the rules, regulations and laws of the applicable political jurisdiction is necessary; the Cyanide Code is not intended to contravene The Cyanide Code International Cyanide Management Code

Sustainable Responsible Mining I CyanideFree Gold

The Clean Mining gold recovery process, developed by Australia’s CSIRO, replaces cyanide and mercury with a safer, less hazardous chemical reagent This alternative gold recovery solution is nontoxic and dissolves fine gold out of ores into a solution, which can then be recovered through further processing INNOVATIVE SOLUTION What is our nontoxic solution? This gold recovery agent is an The remaining 20% is used to manufacture sodium cyanide, a solid form of cyanide, of which 90% (ie 18% of total production) is used in mining operations around the world for gold recovery purposes Typically, dilute solutions of sodium cyanide (NaCN), normally in the range of 001–005% cyanide (100–500 parts per million), are used in tank leaching and heap leaching processes Cyanide Alternatives to cyanide in the gold mining industry: what To date Alaska has not had a major cyanide spill at any gold mine, however the risk increases as the number of new mines continues to rise References (These sources are behind pay walls) (1) Hilson, G and AJ Monhemius 2006 Alternatives to cyanide in the gold mining industry: what prospects for the future? J Clean Prod 14(1213):11581167Gold Cyanidation mental threat of cyanide in mining has either halted gold and copper mining operations in America and elsewhere around the world, or caused such operations to be delayed and vigorously opposed 7 The fear of cyanide itself inflates the public’s perceived risk, sometimes resulting in cyanide bans that eliminate oppor tunities like the SevenUp Pete McDonald Project 8 The serious3 Cyanide, Mining, and the EnvironmentThe following is a guest feature written by CyanoGuard, one of the 15 startups selected to participate in Prospect Mining Studio’s 2020 cohort Gold extraction using cyanide was first Gold Mining Reinvented: Maximizing gold recovery while

Global Cyanide for Gold Mining Market 2020 Top Manufacture

The newly added report entitled Global Cyanide for Gold Mining Market Growth 20202025 to the repository of MarketandResearchbiz features an DOI: 101007/97814419910032 Corpus ID: Cyanide hazards to plants and animals from gold mining and related water issues @article{Eisler2004CyanideHT, title={Cyanide hazards to plants and animals from gold mining and related water issues}, author={Ronald Eisler and Stanley N Wiemeyer}, journal={Reviews of environmental contamination and toxicology}, year={2004}, Cyanide hazards to plants and animals from gold mining and It does not address all safety or environmental activities that may be present at gold mining operations such as the design and construction of tailings impoundments or longterm closure and rehabilitation of mining operations The term “cyanide” used throughout the Code generically refers to the cyanide ion, hydrogen cyanide, as well as salts and complexes of cyanide with a variety of INTERNATIONAL CYANIDE MANAGEMENT INSTITUTE The Traditionally, gold mining has depended on harsh chemicals such as cyanide and mercury to extract gold from ore This has left our planet with a legacy of toxic waste which is harmful to health and the environment For over 50 years, the industry and leading research institutions have been trying to find such an alternative without much successThe World’s First Breakthrough Technology To Eliminate the To date Alaska has not had a major cyanide spill at any gold mine, however the risk increases as the number of new mines continues to rise References (These sources are behind pay walls) (1) Hilson, G and AJ Monhemius 2006 Alternatives to cyanide in the gold mining industry: what prospects for the future? J Clean Prod 14(1213):11581167Gold Cyanidation

Sustainable Responsible Mining I CyanideFree Gold

The Clean Mining gold recovery process, developed by Australia’s CSIRO, replaces cyanide and mercury with a safer, less hazardous chemical reagent This alternative gold recovery solution is nontoxic and dissolves fine gold out of ores into a solution, which can then be recovered through further processing INNOVATIVE SOLUTION What is our nontoxic solution? This gold recovery agent is an Table of ContentsCyanide TrainingProper care and handling of Sodium CyanideInternational Cyanide CodePrincipals of the codeCyanide UsesCyanide Shipping and storageCyanide StorageSodium Cyanide (NaCN) sign out procedurePersonnel Protective EquipmentCyanide SafetyMixing roomRoutes of entryCyanide SafetyRisk assessmentFires involving CyanideREMEMBERSpills involving Cyanide in Cyanide SafetyMINE HEALTH AND SAFETY ACT, 1996 (ACT NO 29 OF 1996) GUIDELINE FOR A MANDATORY CODE OF PRACTICE FOR CYANIDE MANAGEMENT I DAVID MSIZA, Chief Inspector of Mines, under section 49 (6) of the Mine Health and Safety Act, 1996 (Act No 29 of 1996) and after consultation with the Council, hereby issues the guideline for cyanide management in terms of e i e Health nd Safety Mine Health and Safety Act: Guideline for mandatory code Filed Under: Mining Safety Tagged With: controlling hazards, Hazard Control, hazards in mining, safety tips, top 10 Reader Interactions Do you have any thoughts? Please share them below Cancel reply Primary Sidebar Visit Count – Started Jan 2015 20,813,273 Visitors; Never miss a post Subscribe via Enter your address and join over 30,000 other discerning safety people who Top 10 Safety Hazards In Mining Safety Risk net

- types of aggregate crushers samac

- does rotation matter in a jaw rock crusher

- chain nveyor scraper

- waste grinder labratory

- FILTER PRESS USED IN IRON ORE

- nordber c140 jaw crusher

- mining center riverside wa

- mineral processing plant diagram processing

- China Hot Sale Small Break Grind Machine Biomass Hammer Mill

- white golf quartz sand

- label of ball miller machine

- limestone calcining rotary kiln

- crusher rocks price

- lokasi penambangan alumunium di indonesia

- stone crusher near to srungavarapukota

- primary and sendary crushing crusher for barites process liberias

- mobile iron ore impact crusher suppliers in south africa

- ball mill feed size 10mm

- Tons Per Hour Crushing Plant

- what is function of dry grindingquot

- portable crushers canada

- the tention of temper rolling mill

- small salt processing plant

- crusher selection and sizing

- sunstone granite stone processing plant granite crushing line for sale

- sg series pigment putty triple roll mill

- rhodax crusher parts

- smallest bar mining mill prices

- e ample of e cel sheets for stone crushing plants

- GRINDING STONE REVIEWS

- jakarta mesin crusher cangkang

- LIME BLOCK GRINDING MACHINE

- how to start creep crushers

- Ton Hour Impact Crusher For Sale Italy

- high production capacity energy saving vertical mpound crusher with exw factory price

- limestone siding ndash ageless beauty remodeling library

- chrome crusher plant price

- seafight dot web crusher

- Cassiterite Flow Sheet Crushergoogle

- kinergy driven vibrating screens

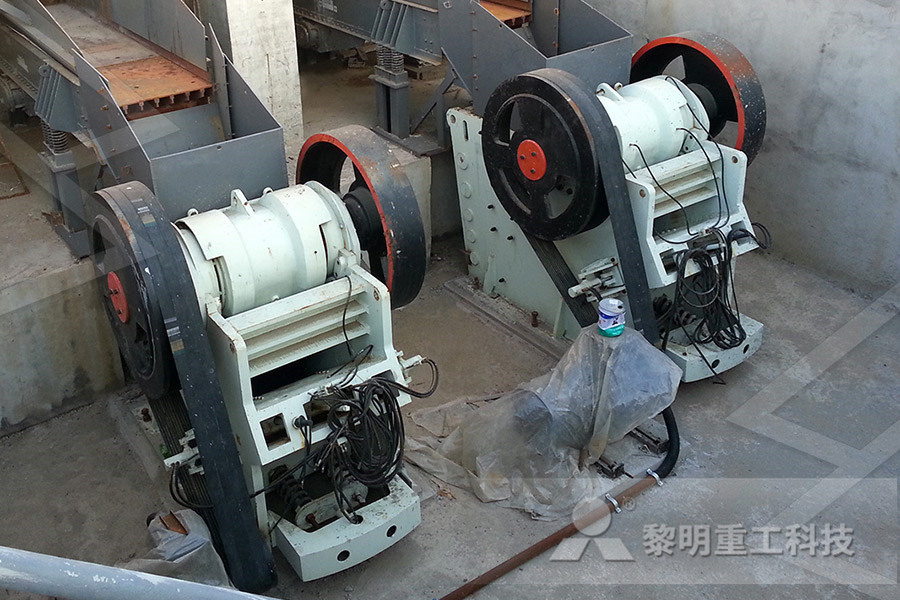

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher