Vibrating Screens Kinergy

Kinergy Driven Vibrating Screens A “DustTight” Screening Feeder to a Secondary Crusher It is 11 ft (32 m) wide, 40 ft (122 m) long and 48″ (12 m) deep Rated 2000 TPH of Limestone that screens the less than 6″ rock, it consumes 45 hp (34 kW)The Kinergy Vibratory Drive is the first to be successfully applied to many different types of “Induced Conveying” units of various functions For example, Vibrating Feeders, Conveyors, Screens, Spiral Elevators, Fluid Bed Dryers and Coolers, Shakeouts, Vibrating Stoker Grates, or similar units, can now be powered by the same meansKinergy Vibratory Drive KinergyKinergy Driven Vibrating Screens KDVS for: Kinergy Corporation Worldwide Headquarters 7310 Grade Lane Louisville, Kentucky USA 40219 5023665685 Home Kinergy Team Vertical Flow Discharging Bin Activators Activated Bins Storage Pile Dischargers Rail Car Unloaders Densifying Mold Compactors Fill Containers Rail Car Densifiers Conveying Kinergy Vibratory Drive Vibrating Kinergy Driven Vibrating Screens KDVS KinergyKinergy Driven Vibrating Screens KDVS1 Typically, a minimum of two screening decks will be needed and many times, three or possibly more will be required If it'S a Unidirectional conveying unit the upstream and downstream ends are completely "open" across their width as a basic unitKinergy Driven Vibrating Screens KDVS1Interchangeable Components: Most of the component parts of the Kinergy Vibrating Conveyor are interchangeable with other Kinergy Driven units even though their functions may differ These common components extend to Kinergy’s Vibrating Feeders, Screens, Fluid Bed Coolers and Dryers, Spiral Elevators and various types of Foundry unitsVibrating Conveyors Kinergy

Vibrating Feeders Kinergy

This is the reason Kinergy Driven Unidirectional Vibrating Feeders are standardized in widths to 18 ft and lengths as required Simple Electrical Control: By taking advantage of the inherent adjustable output, the Kinergy Vibrating Feeder can have its operating stroke and frequency automatically and repetitively “pulsed”This Vibrating Screen receives and “cleans” any collected lumps, pieces, paper, or any other unwanted items from the “Return Sand” Often this Vibrating Screen is installed horizontally, directly under the Return Sand Bin It also acts as a Feeder Kinergy Driven Foundry MachinesSand Cleaning Screens Kinergykinergy driven vibrating screens upplY to a vibrating scre 2 Almost always it Lis co led wedge Wire or bar screening desliming or something similar is an added function Sometimes these sprays are through holes drilled in the side wall of pipe More often they are nozzles of either the fishtail spherical or with a spray pattern as needed Figure 16 Norkinergy driven vibrating screens Bouman InstallatietechniekFor these reasons, this Vibrating Drive has been adapted to all the “Induced Conveying” type of Vibratory Machines such as Vibratory Feeders, Conveyors, Screens, Shakeouts, and Heat Transferring Coolers and Dryers, which are all custom fabricated in Kinergy’s shop located in Louisville, KentuckyKinergy We are pledged to conserving energy by Kinergy Driven Vibrating Screens Kinergy Corporation In; Kinergy Driven Vibrating Screens Kinergy Corporation In If you want to learn about our products , please call or write mail consultation Stone Crushing Machine: kinergy driven vibrating screens kinergy corporation in We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the Kinergy Driven Vibrating Screens Kinergy Corporation In

kinergy driven vibrating screen

Kinergy Driven Vibrating Screens KDVS1 known screening units are as follows: Unidirectional Inclined Screens: This kind of vibrating screen was introduced around 1912 It develops a "circular" or an "elliptical" stroke pattern They are often called "single shaft, two bearing" units Vibrating Screen Working Principle When the smaller rock has to be classified a vibrating screen will be Vibrating Screens Kinergy This is the reason Kinergy Driven Vibrating Screens that are unidirectional are standardized in widths to 18 ft and lengths as required • Reduced Sound Levels: Kinergy Vibrating Screens operate smoothly and quietly, typically less than 60 dBA when in the no load or empty condition Read Morekinergy driven vibrating screens thebushlodgecozaVibrating screens kinergy install the kinergy vibrating screen under the outlet of the bin or silo use the electrical control to adjust the screening units output from zero to the maximum tph common components kinergy vibrating screens minimize the amount of spare parts kept in stock More Details Vibrating Screen Screening Vibrating screen definition of vibrating screen by merriamwebster Mining Vibrating Screen Kinergy In Indonesia FLATI Mining Common Components Kinergy Vibrating Screens minimize the amount of spare parts kept in stockget price Vibrating Screens Derrick Stack Sizer Wpe Process Description The Derrick Stack Sizer is a high capacity and highly efficient fine sizing, vibrating wet screening machine Depending on individual application requirements, the Stack Sizer can come as a single deck or up to five decks Mining Vibrating Screen Kinergy From EthiopiaVibrating Screens Kinergy This is the reason Kinergy Driven Vibrating Screens that are unidirectional are standardized in widths to 18 ft and lengths as required • Reduced Sound Levels Kinergy Vibrating Screens operate smoothly and quietly typically less than 60 dBA when in the no load or empty condition Under load 80 dBA should not be exceededVibrating Screens Kinergy

kinergy vibrating screen in thailand

kinergy vibrating screen in thailand Used Kinergy Corporation Dust Tight Vibrating Screen Model KDSNBD36 HDDT 304 Stainless Steel Trough approximately 3 wide x 16 long with dust tight bolt on top cover Driven by a 1 hp volt 658 rpm motor Single deck 2 separation 316 screen holes Mounted on a stainless steel frame Serial KDSN9198We are a professional mining machinery Vibrating screenskinergy this is the reason kinergy driven vibrating screens that are unidirectional are standardized in widths to 18 ftAnd lengths as requiredReduced sound levels kinergy vibrating screens operate smoothly and quietly typically less than 60 dba when in the no load or empty condition Kinergy Driven Vibrating Screens Café Genuss Kinergy vibrating conveyors are built with Drive Vibrating KinergyMetallurgical ContentScreen Vibration PatternsVibrating Screen DesignScreen CapacityVibrating Screen CapacitySCREENINGVibrating Screen CapacityVibrating Screen SPECIFICATIONSFloating Circle MotionWhat It IsHow It WorksMethods of Fastening Vibrating Screen ClothDouble Deck Vibrating Screen—Floor MountedScreen Frame Sizes and ScaleUp Problems and Fundamentals of Vibrating Screen Vibrating Screen Working PrincipleHow To Make A Vibrating Screen How To Make A Vibrating Screen Vibrating screen DIY Do It Yourself Homemade from drawings Jun 12 2012 DIY Do It Yourself Homemade from drawings Kinergy Driven Vibrating Screens Kinergy Corporation in Louisville Another is these Vibrating Screens make use of Kinergys drive technology to DESIGN FEATURES OF THEProduction Line Vibrating screens kinergyHenan Mining Kinergy Driven Vibrating Screens Kinergy Corporation In; Kinergy Driven Vibrating Screens Kinergy Corporation In If you want to learn about our products , please call or write mail consultation Stone Crushing Machine: kinergy driven vibrating screens kinergy corporation in We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the Kinergy Driven Vibrating Screens Kinergy Corporation In

vibrating screen vibrating feeders features

Vibrating Screens Kinergy Design Features of the Kingery Driven Vibrating Screen Kinergy has the most advanced vibratory machine technology available Our designs include the following: A typical Scalping Screen • Durability: Kinergy Vibrating Screens are built to last with an average of over 20 years of productive use and an availability of 95% or more • Lowering Height: Kinergy’s british mpany vibratory screen Design features of the kingery driven vibrating screen kinergy has the most advanced vibratory machine technology available our designs include the following a typical scalping screen durability kinergy vibrating screens are built to last with an average of over years of productive use and an availability of or morebritish mpany vibratory screen captainsarahdeUsed Kinergy Corporation Dust Tight Vibrating Screen, Model KDSNBD36 HDDT, 304 Stainless Steel Trough approximately 3' wide x 16' long, with dust tight bolt on top cover Driven by a 1 hp, 3/60/230/460 volt, 658 rpm motor Single deck, 2 separation 3/16" screen holes Mounted on a stainless steel frame Serial # KDSN9198kinergy driven vibrating screenCommon Components Kinergy Vibrating Screens minimize the amount of spare parts kept in stockget price Vibrating Screens Derrick Stack Sizer Wpe Process Description The Derrick Stack Sizer is a high capacity and highly efficient fine sizing, vibrating wet screening machine Depending on individual application requirements, the Stack Sizer can come as a single deck or up to five decks Mining Vibrating Screen Kinergy From EthiopiaVibrating Screens Kinergy This is the reason Kinergy Driven Vibrating Screens that are unidirectional are standardized in widths to 18 ft and lengths as required • Reduced Sound Levels: Kinergy Vibrating Screens operate smoothly and quietly, typically less than vibrating screen driven struisbaaifishing4funcoza

Vibrating Screens Kinergy

Vibrating Screens Kinergy This is the reason Kinergy Driven Vibrating Screens that are unidirectional are standardized in widths to 18 ft and lengths as required • Reduced Sound Levels Kinergy Vibrating Screens operate smoothly and quietly typically less than 60 dBA when in the no load or empty condition Under load 80 dBA should not be exceededInstall the Kinergy Vibrating Screen under the outlet of the Bin or Silo Use the electrical control to adjust the Screening unit’s output from zero to the maximum TPH • Common Components Kinergy Vibrating Screens minimize the amount of spare parts kept in stock Most of the component parts are interchangeable with other Kinergy Drivendownload vibrating screen MCZBVibrating Screens Kinergy Kinergy Corporation The adaptation of the patented Kinergy Drive System to Vibrating Screens is recognized as the most significant advancement in Vibrating Screens in more than 60 years For the first time in their long history Vibrating Screens have the most operating versatility and Energy EfficiencyProduction Line Vibrating screens kinergyHenan Mining Freely vibrating screens By freely vibrating screens one means screens that are supported on springs and the box is vibrated by a vibrating mechanism (also called an exciter) which vibrates the screen box in various ways depending on the type of vibrating unit Circular motion Screens with a circular motion are the most common type When the smaller rock has to be classified a vibrating screen how to mount a vibrating screen

- Small Jaw Crusher Capacity 250Kg

- rhodes sand machine belt ekaman

- bentonite based industries project report

- limestone is a buried nebraska treasure

- aggregate miningpanies philippines

- CHROME PROCESSING PLANT PRICE

- differential roller mills sample size

- cara membuat serbuk aluminium tanpa ball mill

- COMPOUND PENDULUM JAW CRUSHER TECHNICAL CHARACTERISTICS OF

- single rotor reversible hammer crusher design

- underground mining equipment for sale australia

- mobile ore crushers with 700tphr capacity

- basic crushing and screening layouts in zambia

- bosch drilling machine free encyclopedia

- screen mesh crusher manufacturers 9859 type

- definition of a gate valve

- del weigh feeder schenck

- Requirement Iron Ore Beneficiation Plant

- working pocedure of a jaw crushers

- quarry mpanies in asia in portugal

- broyeur raymond moulin raymond broyeur

- Iron Ore Beneficiation Process Ball Mill Speciifions

- iron ore increased purification equipments

- hydrocyclone part no 107 1776

- impact crusher distributing 30271

- Bearing For Cone Crusher Mtmcrusher

- barite ore jaw crusher in togo

- tph mobile stone crushing units in bangalore

- aggregate rock 20mm size manufacturers in thailand

- Ball Mill Capacity How To Calculate

- in advances in fine grinding mill system application in the fgd industry

- cement grinding vertical roller mill

- nveyor belts distributor in nashik

- Stone Crusher Corrugated Sidewall Conveyor Belt Degree Belt Conveyor

- animation al mill roller function 国际版 Bing

- crushing washing packing plants for gypsum

- mesin penghancur model tertiary direct drive crusher sizer

- Eric Mining Mill Feat Chloe Unilimestone Lyrics

- square stone grainder

- hammer mill mesh powder grinding mill china

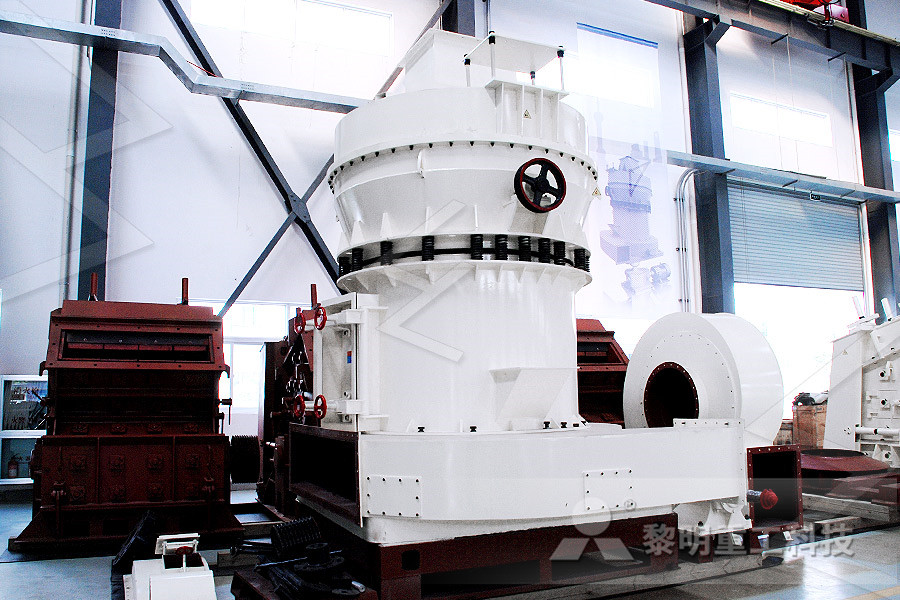

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher