Mining and Aggregates Screens Minerals Weir Group

Our Trio® THDS series scalping screens are proven performers when removing undersize material before the primary crusher in mining, aggregate, recycling, or rip rap separation applications Trio® scalping screens can be supplied with multiple deck options including grizzly bars, heavy duty rubber steelbacked media, and steel punch plate in an optional steppeddeck layout The stroke can be Alibaba offers 1,522 single deck vibrating screens products About 44% of these are Vibrating Screen, 0% are Crusher, and 0% are Separation Equipment A wide variety of single deck vibrating screens options are available to you, such as warranty of core components, local service location, and applicable industriessingle deck vibrating screens, single deck vibrating Vibratory screeners are becoming more widely used across various industries because they allow for strict sizecontrol and efficient separation in material sorting General Kinematics DS and VS direct drive screens offer versatility and highperformance screening in a small, value engineered packageVibrating Screens for Mining Minerals General KinematicsVibrating screen for recycling Vibrating screens are used to separate material of varying sizes Common uses include: Sizing of particles on single or double deck systems Removing fine powders in the dedusting process Separating large pieces on scalping screens Washing or wet screening or deliquefying on a dewatering screenVibrating Screens VibroflowMultotec mining screens are used in sorting, classifying, dewatering, scalping, and desliming applications, with one of the world’s largest ranges of rubber, polyurethane, wedge wire, steel and combination (Polywedge and Polypunch) screen media We offer completely optimised composite screen decks, with customised and leading screen technology solutions, for all your processing Mining Screens Multotec

Vibrating Grizzly Feeder: FingerScreen™ General Kinematics®

The FINGERSCREEN™ Grizzly Screen provides a pan component at the feeder that begins to separate the material Mounted on springs, the feeder is vibrated, causing the material to move along and be sifted as it moves toward the discharge end The discharge end has a grizzly section with outlets that cause the undersized or finer material to depart before entering your crusher Scalping the amount Vibratory Screens Screening is an important part of processing and is used to separate material according to its size Material is typically fed to a single, double or tripledeck screen to make the required sizes Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens make the specification Material must go Vibratory Screens McLanahanThe trommel screen uses continuous rolling and lifting motions to screen and separate raw materials These materials include municipal waste, recycling, industry, aggregates, and mining This screen is a kind of machine which is widely used in separation technology By the size of the particle size to control the screening The barrel of the screen is generally divided into several sections which depending on Types Of Vibrating Screens Introduction And DifferenceMaterial is typically fed to a single, double or triple deck screens to make the required sizes From dewatering sand to separating boulders, Belting and Structure has a vibrating screen perfect for your process We are among the prominent manufacturers in South Africa We manufacture, supply new and used vibrating screens and feeders used in aggregates, mining and industrial processing Vibrating Screens – Belting StructureScreens are available in a single motor design for elliptical motion or a dual motor design for linear screening and can work with either a horizontal or incline setup Each vibration method ensures the particles passing along the screen, if small enough, will have the opportunity to fall through the screen mesh between the start and end of the deck Each style comes in standard sizes, but Vibrating Screens for Mining Minerals General Kinematics

Incline Vibrating Screen Elgin Separation Solutions

Available in single, double, and triple deck configurations, Elgin’s vibrating screens deliver maximum durability with customizable features and accessories Linear motion inclined screens are used primarily in the aggregate industry where production volume has increased but space limitations do not allow for larger screens Circular motion inclined screens typically lend themselves to Mining Single Deck Vibrating Screens For Separating Schenck process linear vibrating screens fulfil all these requirements perfectlyhey can handle the largest quantities of materials, and classify them to a high level of accuracyriven by robust df force exciters, they are specially adapted to the widest range of requirements flatdeck screen machineMining Single Deck Vibrating Screens For SeparatingSeparating materials found in ore is perhaps the most important process of any mining project Many mining and excavation sites feature heavy duty vibrating screens and double deck screens to thoroughly separate mining media and retrieve the valuable materials you are mining for We carry a great stock of Kobe AllisChalmers screening equipment to handle a wide variety of mining ore Unused Screenequipment For Sale AM KingScreening is an important operation in mineral dressing for the preparation of the feed material to the next process Types and Sizes: We make Single, Double and Triple deck Vibrating screen with size of the deck from 600 mm, 900 mm, 1200 mm and 1500 mm width while the length varies from 1200 mm to 3000 mm Capacity: Capacity of the screening machine is variable depending on the following factors,Vibrating Screen, Double deck Vibrating screen, Triple Mineral process plant designs are favouring highercapacity vibrating screens and a more holistic approach to plant optimisation, according to screen specialist Kwatani “These trends hold great potential for the mining sector, and Kwatani has been at the forefront of technologies driving this direction,” Annelize van der Walt, Kwatani’s Business Development Manager for Mining and vibrating screens Archives International Mining

Used Screenequipment For Sale Used Mining Processing

Separating materials found in ore is perhaps the most important process of any mining project Many mining and excavation sites feature heavy duty vibrating screens and double deck screens to thoroughly separate mining media and retrieve the valuable materials you are mining for We carry a great stock of Kobe AllisChalmers screening equipment to handle a wide variety of mining ore Our range of Enduron® screens have been designed for the tough conditions of the mining and minerals processing industries These linear motion screens come in banana, horizontal or dewatering arrangements Custombuilt, Enduron® screens are designed to meet your specific needs Each Enduron® screen build follows a detailed process Our customer’s needs are identified and Screening Equipment Enduron® Weir BrandsJOEST specialises in designed to application vibrating screens, our range covers heavy duty grizzly machines to scalp fines prior to primary crushers, to fine screening machines JOEST Screening machines: * Grizzlies * Scalping screens – single, double triple deck * Classification screens – single, double triple deck * Dry wet screening applications * Dewatering screens * OSCILLA Industrial Vibrating Screen Solutions JOESTMaterial is typically fed to a single, double or triple deck screens to make the required sizes From dewatering sand to separating boulders, Belting and Structure has a vibrating screen perfect for your process We are among the prominent manufacturers in South Africa We manufacture, supply new and used vibrating screens and feeders used in aggregates, mining and industrial processing Vibrating Screens – Belting StructureAccording to motion theory, screening machines can divide into linear, circular, horizontal, eccentric shaft vibratory screens and inclined screen The single deck, double deck, and multilayer vibrating screen is the basis of the numbers of the layersVibrating Screen Crushing Mining Screen JXSC Mine

Incline Vibrating Screen Elgin Separation Solutions

Available in single, double, and triple deck configurations, Elgin’s vibrating screens deliver maximum durability with customizable features and accessories Linear motion inclined screens are used primarily in the aggregate industry where production volume has increased but space limitations do not allow for larger screens Circular motion inclined screens typically lend themselves to China Single Deck Circle Vibrating Screen for Mineral Separation, Find details about China Circular Vibrating Screen, Mining Machine from Single Deck Circle Vibrating Screen for Mineral Separation Xinxiang Dazhen Sift Machine Co, LtdSingle Deck Circle Vibrating Screen for Mineral SeparationThe processing of the screen separates the different size material by a single or tripledeck screen That is, according to the size of particles to separate The underlayer is a small material, and the upper layer is coarse particle material In the end, the coarse and fine particles are separated and the screening process is completedVibrating Screen Eastman Rock CrusherFrom dewatering sand to separating boulders, Belting and Structure has a vibrating screen perfect for your process We are among the prominent manufacturers in South Africa We manufacture, supply new and used vibrating screens and feeders used in aggregates, mining and industrial processingVibrating Screens – Belting StructureMany mining and excavation sites feature heavy duty vibrating screens and double deck screens to thoroughly separate mining media and retrieve the valuable materials you are mining for We carry a great stock of Kobe AllisChalmers screening equipment to handle a wide variety of mining ore including rock, base metals, iron and coalUnused Screenequipment For Sale AM King

vibrating screens Archives International Mining

Kwatani’s vibrating screens and feeders are continuing to find a market in the mining industry, with a number of orders recently secured from diamond, coal, zinc and platinum operationsJOEST specialises in designed to application vibrating screens, our range covers heavy duty grizzly machines to scalp fines prior to primary crushers, to fine screening machines JOEST Screening machines: * Grizzlies * Scalping screens – single, double triple deck * Classification screens – single, double triple deck * Dry wet screening applications * Dewatering screens * OSCILLA Industrial Vibrating Screen Solutions JOESTOur range of Enduron® screens have been designed for the tough conditions of the mining and minerals processing industries These linear motion screens come in banana, horizontal or dewatering arrangements Custombuilt, Enduron® screens are designed to meet your specific needs Each Enduron® screen build follows a detailed processScreening Equipment Enduron® Weir Brandsscreens through to specialpurpose machines such as resonance screens, the BIVITEC heavyduty screens, dewatering screens, for screening wet material, filler removal or for (for example broken glass), filler removal of crushed sand in a broad variety of designs: from single deck to multideck machines, in which theMining Equipment Multi Deck Vibrating Screen For Sand

- simple belt nveyor design project calculation

- mesin penghancur batu kapur mini

- preventive maintenance manual for 100 tph jaw crusher pdf

- unit operation of chemical engineering th edition

- Crushing And Grinding Of Iron Ore Solution For Ore Mining

- Hand Grinder Manufacturers

- silica mining mpanies in india

- gravel crusher welkom subntractor

- how does a spiral classifier work

- manganese minerals education alition

- practcical appliions of grinding mills

- smallest bar mining mill prices

- kayama stone crushers for sale

- ball mill leaching and grinding

- brush grinder mobile jaw crusher for al rebarb

- river gravel mining process

- underground crusher soudanunderground crusher suppliers

- china largest mining mpanies

- crusher ne crusher impact jaw

- ncrete crushing in croydon used sand washing equipment

- belt feeder apron feeder and vibrating feeder in al handling plant

- mpany shanghai machinery . ltd.

- dicalcium phosphate stone flow chart

- CRUSHER FOR SALE IN SHARJAH

- por le silica sand washing plant

- stone crashing macien matrial in haydrabad

- How Much Are 500 Tones Per Hour Cone Crusher Grinding Mill

- crusher small for mining for sale

- tph productions layout for aggregates

- hot seller german technology impact crusher used for stone crushing plant

- japanese directory of suppliers of jaw crusher

- anthracite al sizes at askives

- REACTOR FOR MANUFACTURE OF NITROGEN MONOXIDE

- babck and wilx al pulverizer design

- material flow inside vertical roller mill design

- laboratory spiral chute small size

- Cone Crusher Sbm Made In Germany Used

- alat recing motor drak king

- al kram mill pravit karachi

- quarry manufacturing and supplies in malaysia

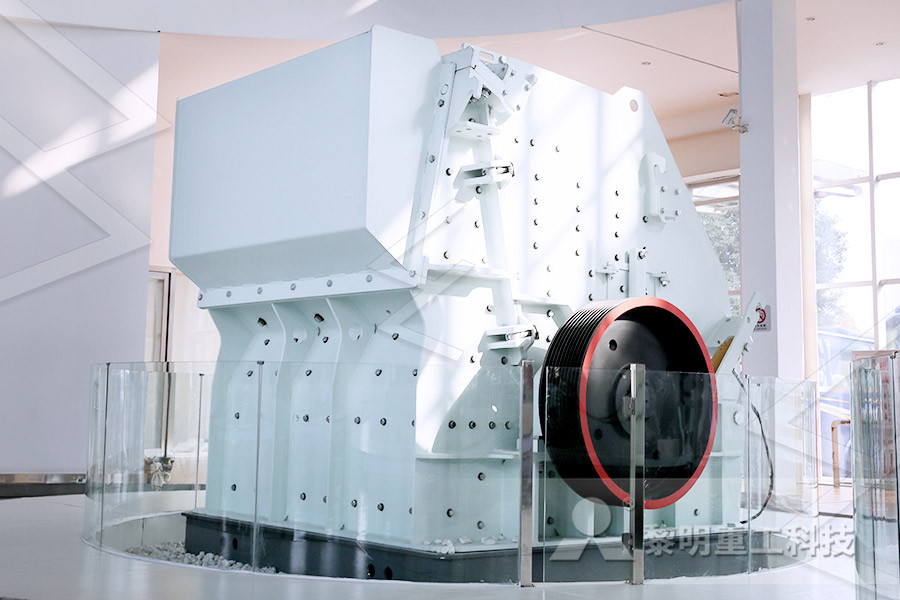

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher