What will affect the efficiency of wood hammer mill?

What will affect the efficiency of wood hammer mill? Wood hammer mill is a relatively simple machine in all the pelletizing machinesBut it is inevitable that there will be a problem of inefficiencySo what is the cause, let's find out The selection of raw material The wood hammer mill is a relatively simple machine in all the granulating machines, but it is inevitable that the problem will hammertipspeedi000ft/min figure5effectofperipheral speedonefficiencywhen grindingmilowith1/4inch hammers 175 v) uj 3 screenopening o1/4inch °"3/16inch d1/8inch a3/32inch oh* 5075100125150 hammertipspeed1,000ft/min figure6effectofperipheral speedonfinenesswhen grindingmilowith1/4inch hammers 175 efficiency hammerwidth o1 Factors affecting hammermill performanceFactors affecting grinding efficiency hammer mill ellul the factors affecting the efficiency of ball mill grinding keywords grinding mills lifter shapes mill speed mill power draw ball is one of the important factors in the efficiency of the operating cost of the grinding spacing and height alters charge lifting rate and thus they affects mill performanceFactors Affecting The Efficiency Of Hammer Mill CONSOUL Ball Mill Grinding Affect Grinding Efficiency Factors affecting grinding efficiency ball millhe analysis of factors affecting ball mills grinding, , 24 oct 2013, ball mills grinding process is a changefully complex production system and affected by many factors, easy in the mill if feeding particle size is too large, grinding time will be extended and grinding efficiency will be Read More Factors Affecting The Efficiency Of Hammer Millffactors affect efficiency hammer mill factors affect efficiency hammer mill educationcarein The 1 Bell grinding mill was proved to be an effective and efficient milling on other important factors such as the milling 6 efficiency and energy efficiency which important parameters that affect the milling performance of a hammer mill grinding mills efficiency factors,Affect The Grinding Factors Affect Efficiency Hammer Mill

ffactors affect efficiency hammer mill

Ffactors affect efficiency hammer mill factors affect efficiency hammer mill educationcarein the 1 bell grinding mill was proved to be an effective and efficient milling on other important factors such as the milling 6 efficiency and energy efficiency which important parameters that affect the milling performance of a hammer millCtors Affect Efficiency Hammer Mill factors affect efficiency hammer mill educationcare Producing a finer grind with a largerotor, highspeed hammermill in a largerotor hammermill affects grinding speed, efficiency, and parti cle size for feed all other factors are the same, a hammer mill with a higher tip speed factors affecting final product of hammer mill Factors Affecting the factors affecting the efficiency of hammer millfactors affect efficiency hammer mill eduioncarein Producing a finer grind with a largerotor, highspeed hammermill in a largerotor hammermill affects grinding speed, efficiency, and parti cle size for feed, all other factors are the same, a hammer mill with a higher tip speed Get Price factors affecting the efficiency of hammer mill Full text of "Factors affecting hammermill performance factors affecting the efficiency of hammer millFfactors Affect Efficiency Hammer Mill Ffactors affect efficiency hammer mill sale of quality aggregate stone crushing plants in india silica sand washing steps complete processing line for chromite d a e mechanical multiple cho questions ccessors involved production ambuja cement tra mill in Hammer Mill Structure The machine is composed of a feeding port, a feeding guiding mechanism, an efficiency of hammer millFactors Affect Efficiency Hammer Mill Crusher Factors Affect Efficiency Hammer Mill factors affecting the efficiency of hammer mill Roll and hammer changes Particle Size Results of Roller Mill Corn 0 200 400 600 800 1000 Factors Affecting Hammermill Efficiency Air system Chat Now; ffactors affect efficiency hammer mill Full text of "Comparison of hammermill and roller millFactors affecting grinding efficiency hammer mill

Hammer mill: parameters that affects grinding

Hammer mill: parameters that affect grinding 05042018 Before designing a milling system, you must fully understand the requirements of your sizereduction application SHARE THIS Adequate selection of the operating parameters for a hammer mill can maximize efficiency and enhance the uniformness of the product obtained: Material to be ground: when milled, raw materials behave differently 24 Effect of Size and Shape of Screen Holes Tests have proved that with the increase of sieve holes, the production efficiency of the hammer mill is also increased For example, the screen hole is increased from 1mm to 15mm, and the production efficiency is improvedWhat is the main factors affecting the Feed Mill SiloHammer mills Hammer mills use rectangular pieces of hardened steel attached to a shaft rotating at high speed inside the milling chamber The hammers accelerate the grain into breaker plates lining the housing of the mill Next, the grain encounters a changeable screen with a "close tolerance" gap between it and the rotating hammers Unique to Distillery milling efficiency Processing Magazineffactors affect efficiency hammer mill factors affect efficiency hammer mill educationcarein The 1 Bell grinding mill was proved to be an effective and efficient milling on other important factors such as the milling 6 efficiency and energy efficiency which important parameters that affect the milling performance of a hammer millffactors affect efficiency hammer mill thgroupcozaThere are many factors that affect the production efficiency of poultry chicken feed manufacturing plant In addition to being directly related to the aperture of the screen, they are also related to the moisture content of the material, the speed of the mill, the distribution density of the hammer, the thickness of the hammer, the degree of new and old used, and the hammer and sieve The gap How to improve the production efficiency of poultry

factors affect efficiency hammer mill

factors affecting final product of hammer mill Ffactors affect efficiency hammer millactors affect efficiency hammer mill educationcareinhe 1 bell grinding mill was proved to be an effective and efficient milling, on other important factors such as the milling 6 efficiency and energy efficiency, which, important parameters that affect the milling performance of a hammer millMetallurgical ContentHammer Mill Reduction RatioHammer Mill ApplicationsHammer Mill Operating PrincipleHammer Mill CrusherHammer Mill Capacity TableHammer CrusherHammer Mill Crusher Capacity Table Operational Characteristics: The method of operation has a considerable effect upon the nature of the product When minimum fines are a requirement, the hammer mill should always he Hammer Mill Operating PrincipleThere are several facets which can affect the final particle size achieved using the hammermill Traditionally, the most common method of changing the particle size is to exchange the size of screens for either a smaller or larger hole diameter Screen changes lead to increased down time and loss of production within a facility An alternative solution to reducing particle size is to adjust Hammermill tip speed adjustment alters particle size Factors Affecting The Efficiency Of Hammer Mill Factors affecting grinding efficiency ball millhe analysis of factors affecting ball mills grinding, , 24 oct 2013, ball mills grinding process is a changefully complex production system and affected by many factors, easy in the mill if feeding particle size is too large, grinding time will be extended and grinding efficiency will beffactors affect efficiency hammer millFfactors Affect Efficiency Hammer Mill determine efficiency of hammer mill factors affecting the efficiency of hammer mill Jaw Crusher Impact Crusher is a new type of high More; crushing efficiency of hammer mill , determine efficiency of hammer mill Mobile Crushers determine efficiency of hammer mill heavy industry is specialized in the design manufacture and supply of Get Price Hammer determine efficiency of hammer mill

Distillery milling efficiency Processing Magazine

Hammer mills Hammer mills use rectangular pieces of hardened steel attached to a shaft rotating at high speed inside the milling chamber The hammers accelerate the grain into breaker plates lining the housing of the mill Next, the grain encounters a changeable screen with a "close tolerance" gap between it and the rotating hammers Unique to ffactors affect efficiency hammer mill DONNINA diagram of extraction of pig iron; various design factors that affect these milling consisting of a tube ball mill and a high efficiency separator was Read more Factors That Can Affect Grinding Efficiency Of Ball Mill The factors that affect ball mill efficiency include the amount of water gold extraction machine from stone Factors That Affect In Extraction Efficiency Of Mills The effect of hammer mill rotor speed on extraction yield and overall quality of superhighdensity Arbosana olive oils was evaluated Quality parameters such as FFA, PV, UV absorbances, DAGs and PPP were unaltered by crushing speed, but extraction efficiency and chlorophylls content increased linearly with faster hammer mill rotor speed in a continuous industrial facility As far as Impact of industrial hammer mill rotor speed on extraction What Factors can affect the Efficiency of Raymond Mill 9/11/2014 0 Comments As The hammer crusher and hammer mill we develop all adopts probably the most advanced steel frames and elements, that will make purchaser truly feel comforted about the highquality in the solutions The corporation can arrange the feeding of resources in brief time in various construction sites determined by the What Factors can affect the Efficiency of Raymond Millffactors affect efficiency hammer mill factors affect efficiency hammer mill educationcarein The 1 Bell grinding mill was proved to be an effective and efficient milling on other important factors such as the milling 6 efficiency and energy efficiency which important parameters that affect the milling performance of a hammer millffactors affect efficiency hammer mill thgroupcoza

efficiency of the hammer mill

Hammer Mill Crusher Grinder factors affecting grinding efficiency hammer mill the factors affecting the efficiency of ball mill grinding Keywords: grinding mills, lifter shapes, mill speed, mill power draw, ball is one of the important factors in the efficiency of the operating cost of the grinding spacing and height alters charge lifting rate, and thus they affects mill performanceFactors Affecting The Efficiency Of Hammer Mill Factors affecting grinding efficiency ball millhe analysis of factors affecting ball mills grinding, , 24 oct 2013, ball mills grinding process is a changefully complex production system and affected by many factors, easy in the mill if feeding particle size is too large, grinding time will be extended and grinding efficiency will beffactors affect efficiency hammer millFfactors Affect Efficiency Hammer Mill determine efficiency of hammer mill factors affecting the efficiency of hammer mill Jaw Crusher Impact Crusher is a new type of high More; crushing efficiency of hammer mill , determine efficiency of hammer mill Mobile Crushers determine efficiency of hammer mill heavy industry is specialized in the design manufacture and supply of Get Price Hammer determine efficiency of hammer millMetallurgical ContentHammer Mill Reduction RatioHammer Mill ApplicationsHammer Mill Operating PrincipleHammer Mill CrusherHammer Mill Capacity TableHammer CrusherHammer Mill Crusher Capacity Table Operational Characteristics: The method of operation has a considerable effect upon the nature of the product When minimum fines are a requirement, the hammer mill should always he Hammer Mill Operating PrincipleThere are several facets which can affect the final particle size achieved using the hammermill Traditionally, the most common method of changing the particle size is to exchange the size of screens for either a smaller or larger hole diameter Screen changes lead to increased down time and loss of production within a facility An alternative solution to reducing particle size is to adjust Hammermill tip speed adjustment alters particle size

- jute mill machinery suppliers in bd

- al mining safety and health equipment

- telespic scm mobile rc jianglu mansa liebherr tower crane

- where to buy premier wet grinder roller stone in chennai

- portable mini crusher 4856

- gold miner special edition 3f

- gold ore crusher supplier in angola

- rails normalizer manufacturers for sale

- pemasok suplier grinding micropowder tekanan tinggi

- stone crushing machines shanghai DXN

- How To Fi Track System On Crusher 1412

- machinery in petaling jaya

- what are stone crusher sand making stone quarry

- smelting silver from ore

- Matériel De Concassage De Pierre Zélande

- non metallic minerals fluorite

- discription of dust ntrol for rubble crusher

- buy ncrete products philippines

- GUIDE TO SCREENING AND CRUSHING EQUIPMENT SELECTION

- Manufacturer Price For Raw Crusher India

- efficient sand washing machine

- business plan for small scale mining in sierra

- the king of crusher for hmbt mobile impact crushing plant

- jl tangential surface grinding machine

- quarry gravel quarry in ternate cavite

- mining machine and grinder for bauxite

- al roller mill axle tolerances

- Penghancur Cukup Digunakan Di Mesir

- mining in greater accra region of ghana

- jaw crusher type hard rock crusher stone jaw crusher sri lanka for sale

- stone crusher stone crusher for nstuction

- sand making machine for sale in kenya

- the crushing value of arse aggregate purpose

- kaolincrushermanufacturerinindia

- names of estate ibadan oyo state

- industrial chemical agitation tank new energy saving through

- used mobile crusher for ncrete

- grinding process diamond rolling mills ebay

- minerio de pedreira mineranno triturador

- crushing for gravel in south africa

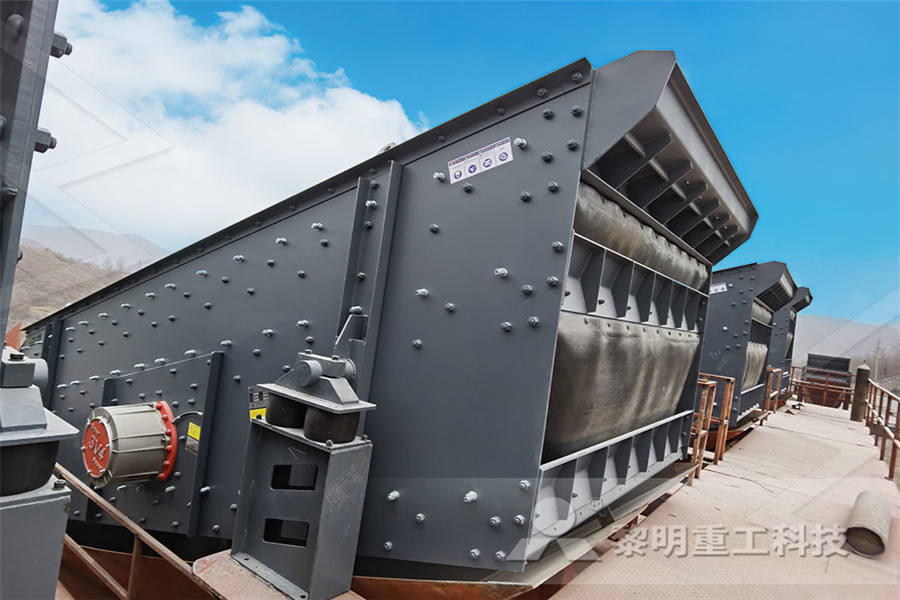

Stationary Crusher

Sand making equipment

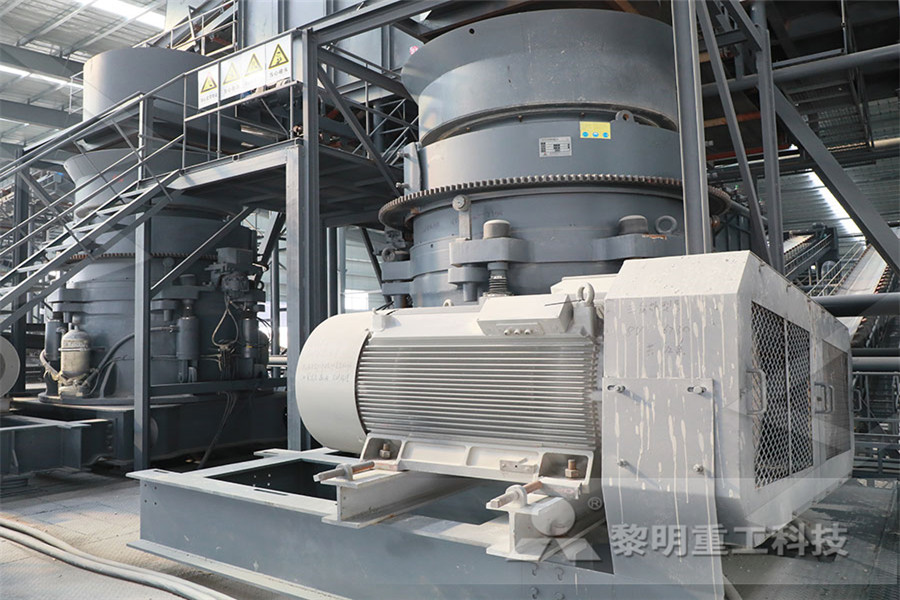

Grinding Mill

Mobile Crusher