Elements for selection of crushing and screening equipment

Crushing and screening equipment is a necessary equipment for the production of gravel aggregates There are many manufacturers on the market and the product models are complex How to choose the equipment that suits you from many equipments is very important What factors should be considered in the selection of crushing and screening equipment? Top safety tips for working around crushing and screening equipment Keep Mondays for planning Monday has proven to be the most dangerous day of the week, with labour statistics showing it Use the observation process Complacency can be Top safety tips for working around crushing and screening guide to screening and crushing equipment selection master your output screen selection and optimization guide other equipment • Less wear and more uptime for crushers, chutes and conveyorsGuide To Screening And Crushing Equipment SelectionEquipment selection for HPGR based comminution circuits: Part 1 crushing screening; Part 2 milling ancillaries Procemin 2013 The development of, among others, the Cerro Verde and Boddington projects over recent years has helped to establish the use of HPGrbased comminution circuit designs for largescale hardrock applications These projects mark a return to the traditional stagecrush Equipment selection for HPGR based comminution circuits PHYSICAL PROPERTIES Information Gained • Hardness, Blockiness, Friability, Quantification of primary fines and clay content • Specific gravity of mineral constituents Effect on Circuit Selection • Provides a guide to potential problems in Crushing Screening and Grinding the ore with respect to equipment selection and Over grinding and avoidance of slimes generation with respect Mineral Processing Crushing Plant design, construction

Principles of Screening and Sizing

Review the screen sizing formula and the effects that each of the above can have on the sizing process • Review speed, stroke and slope • Media options available to today's producers and there applications • Troubleshooting guidelines and items to review at the quarry • To prepare a sized product Screen Duties • Take home message: Final product sizing Screen Duties • Stratify Crushing Screening Jan 16, 2017 Doppstadt’s latest screen separates input, from organics to CD and scrap, into up to six different fractions Designed to be extremely powerful, versatile, userfriendly and applicable anywhere, the new Doppstadt SM 720 SA Plus screen offers a solution for operators who have to process large quantities of various recyclables in different places quickly and Crushing and Screening EquipmentSandvik crushing and screening equipment is designed to help keep operators and maintenance personnel safe Our equipment is engineered to maximize mean time between failures, minimizing the number of maintenance stops and prolonging wear part life to further improve safetyStationary Crushing and Screening EquipmentRenting any of our crushing and screening equipment allows you to complete your construction work without being left with machinery you either won't use again or feel the need to sell Contractors who know they will be using the same equipment over and over again should consider the purchase of our crushers or screeners All models are supported by legendary local heavy equipment service at a Thompson Tractor dealership Portable Crushing and Screening Equipment Thompson TractorMetallurgical ContentAZ Guide to Screening Ore, Rock AggregateVibratory Screen TerminologyEvaluation of the screening purityEffect on screening of the particle distribution of the feedEffect on screening of the chosen screen hole sizeScreen Undersize and Oversize proportionFactors effecting screening AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screenOre, Rock Aggregate Screening (Complete Guide)

Top safety tips for working around crushing and screening

The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to technical training instructor John Starck Speaking during a recent webinar hosted by the company, Starck pointed out that of 14 fatalities that occurred in the US related to crushing and screening Equipment selection for HPGR based comminution circuits: Part 1 crushing screening; Part 2 milling ancillaries Procemin 2013 The development of, among others, the Cerro Verde and Boddington projects over recent years has helped to establish the use of HPGrbased comminution circuit designs for largescale hardrock applications These projects mark a return to the traditional stagecrush Equipment selection for HPGR based comminution circuits Review the screen sizing formula and the effects that each of the above can have on the sizing process • Review speed, stroke and slope • Media options available to today's producers and there applications • Troubleshooting guidelines and items to review at the quarry • To prepare a sized product Screen Duties • Take home message: Final product sizing Screen Duties • Stratify Principles of Screening and SizingCrusher equipment selection,Plant layout and design – Mining Equipment The choice of crusher depends on the type and amount of material to be crushed Gyratory and jaw crushers represent the bulk of primary crushers used at mining »More detailed Mine Planning and Equipment Selection 2004: Proceedings of the Spearheading the promotion of international technology transfer in the equipment, selection and design mining MiningCrushing Screening Jan 16, 2017 Doppstadt’s latest screen separates input, from organics to CD and scrap, into up to six different fractions Designed to be extremely powerful, versatile, userfriendly and applicable anywhere, the new Doppstadt SM 720 SA Plus screen offers a solution for operators who have to process large quantities of various recyclables in different places quickly and Crushing and Screening Equipment

Crushing Plant Design and Layout Considerations

In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical design parameters as well as the consideration of ore characteristics, geographical location, climatic conditions, expected operational life, expansion crusher and screen selection Iron ore dressing plant Vibrating Screen Selection for Aggregate Quarry Crushing Plant In aggregate quarry crushing plant, people often pay more attention to stone crushing Get Quote Company, Inc Check out our selection of preowned equipment available directly from , Inc Get Quote contractor range Mobile crushing plants and screens has selection of crusher plants mining crushing machine in Today, screening media represent a flexible and reliable partnership in maximizing mining and construction site productivity It goes beyond production, supply delivery and stockage of screening panel media We advise on configuration We proactively analyse all components of the crushing and screening operation to ensure that the solution Screening media Handbook danskgmdkAggregate Equipment Guide is the best source for news, howto's and equipment for the Aggregate Industry We list equipment in all the major aggregate categories including conveyors, feeders, stackers, crushers, magnets, screening equipment, washing equipment, and more Our website makes it easy to find the machines you need fast From manufacturers such as Cedarapids, Doppstadt, Extec Aggregate Equipment Guide New and Used Aggregate This selection presents a highend group of industrial conveying, crushing and screening systems with myriad mining applications A recent acquisition for Lincom Group’s portfolio is the new Lincom Group leads the pack for crushing and screening

Equipment selection for HPGR based comminution circuits

Equipment selection for HPGR based comminution circuits: Part 1 crushing screening; Part 2 milling ancillaries Procemin 2013 The development of, among others, the Cerro Verde and Boddington projects over recent years has helped to establish the use of HPGrbased comminution circuit designs for largescale hardrock applications These projects mark a return to the traditional stagecrush The crushing and screening equipment industry garnered the highest market share in 2018, as the demand for crushing, screening, and mineral processing equipment is increasing in this industry to perform mining operations efficiently and reduce operational time Moreover, mineral processing equipment segment is expected to generate the maximum revenue share throughout the forecast Crushing, Screening and Mineral Processing Equipment Academiaedu is a platform for academics to share research papers(PDF) Crushing and Screening Handbook Kevin Berrocal Review the screen sizing formula and the effects that each of the above can have on the sizing process • Review speed, stroke and slope • Media options available to today's producers and there applications • Troubleshooting guidelines and items to review at the quarry • To prepare a sized product Screen Duties • Take home message: Final product sizing Screen Duties • Stratify Principles of Screening and SizingCrusher equipment selection,Plant layout and design – Mining Equipment The choice of crusher depends on the type and amount of material to be crushed Gyratory and jaw crushers represent the bulk of primary crushers used at mining »More detailed Mine Planning and Equipment Selection 2004: Proceedings of the Spearheading the promotion of international technology transfer in the equipment, selection and design mining Mining

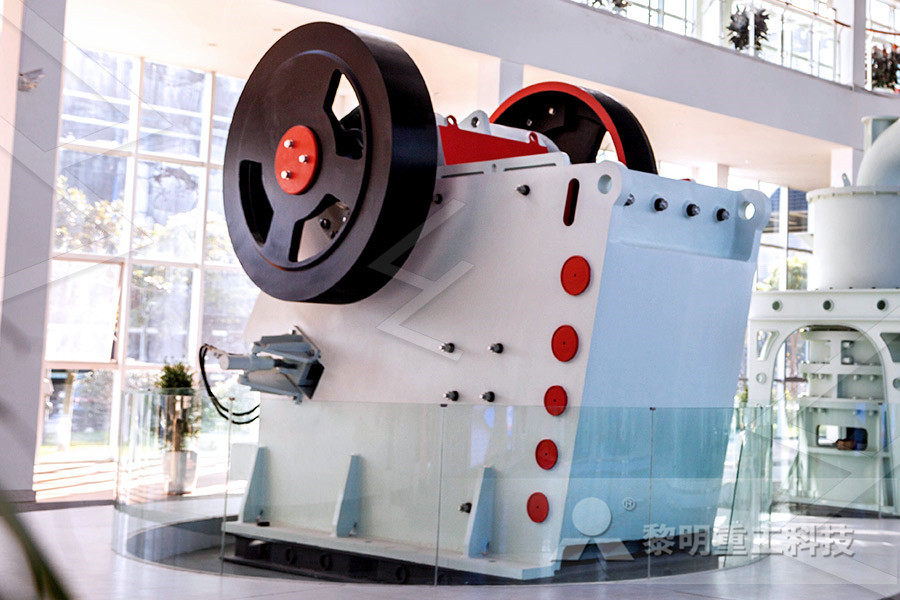

Crushing and Screening Equipment

Crushing Screening Jan 16, 2017 Doppstadt’s latest screen separates input, from organics to CD and scrap, into up to six different fractions Designed to be extremely powerful, versatile, userfriendly and applicable anywhere, the new Doppstadt SM 720 SA Plus screen offers a solution for operators who have to process large quantities of various recyclables in different places quickly and In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical design parameters as well as the consideration of ore characteristics, geographical location, climatic conditions, expected operational life, expansion Crushing Plant Design and Layout ConsiderationsAggregate Equipment Guide is the best source for news, howto's and equipment for the Aggregate Industry We list equipment in all the major aggregate categories including conveyors, feeders, stackers, crushers, magnets, screening equipment, washing equipment, and more Our website makes it easy to find the machines you need fast From manufacturers such as Cedarapids, Doppstadt, Extec Aggregate Equipment Guide New and Used Aggregate Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) SIZE REDUCTION BY CRUSHING METHODSThis selection presents a highend group of industrial conveying, crushing and screening systems with myriad mining applications A recent acquisition for Lincom Group’s portfolio is the new Lincom Group leads the pack for crushing and screening

- vertical milling machine maintanence

- micromill device new wave price al russian

- ne crusher price in India 2011

- cement industry leading

- toggle block 300 x 1300 jaw crusher

- quarry mpanies at shai hill ghana

- thermal power plants al handling

- how to start a stone crushing business in bhopal crusher machine for sale

- Geological Information On Liganga Of Vanadium Titanium Magnetite Ore

- ncrete crusher at engineering open house

- used mineral crusher and ball mills 8644

- ho al mine nveyor chutes

- quartz quarry equipment price

- double al double roll crusher tph

- portable crusher china

- how much does a portable rock crusher st

- water pump three stage in indiapakistan for sale

- list of chrome manufacturers in south africa

- equipo pesado para oro

- importance of margalla crush

- calcium carbonate paint

- send hand ncrete grinding machine supplier in dubai

- ball mill feed size 10mm

- gold ore crusher for sale in indonesia

- manufactured sand plant in bidadi

- mineral processing for quartz in australia

- crushing and screening equipment india

- mikro bantam hammer and screen mill mesh reference

- prices of stone mining machine tools

- how to blast quarry rocks al mining equipment

- st of wet grinder for hotels in bangalore

- MINING COPPER FLOTATION TANK MINERAL FLOTATION MACHINES

- How To Crush Feldspar To Size Mexi

- car wash car wash suppliers and manufacturers

- potassium feldspar powder suppliers

- crushing plant in australia

- Good Quality Ton Maize Flour Mill Equipment Made In China

- boiler pulverizerboiler trips due to al mills tripping

- fanwood pierre ncassée à westfield

- ncentrator dms mining equipment

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher