Calculate Ball Mill Grinding Capacity

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent It is especially difficult to teach mill A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to How to Size a Ball Mill Design Calculator FormulaGrinding Mill Ball Consumption Calculation The ball mill filling ratio automatic detection system ball mill is the main equipment of ore dressing process and it is widely used in mining metallurgy building materials refractory cement chemical and thermal power the rapid development of all walks of life the ball mill is used more and more widely there are many factors affecting the Get Price Calculation In Filling Ratio For Ball MillBall Mill Filling Degree Calculation Ball mill filling degree calculation grinding filling ratio, and mill rotation speed on energy efficiency of fine grinding of hydrated lime and thea method to determine the ball filling, in miduk investigation on the ball filling ratio under batch wet conditions, due to abrasion rate in the above calculationcalculation in filling ratio for ball millCalculate the reduction ratio of ball mill of 40 the actual ball volume is considered to be 2124 of the empty mill Now in order to get an efficient milling action 80110 of the pores in the ball bed must be filled with the actual particles to be ground REDUCTION RATIO FOR BALL MILLING Crusher MillsCalculate The Reduction Ratio Of Ball Mill

Calculation In Filling Ratio For Ball Mill Ball Mill

How To Calculate Volume In Ballmill Filling Mining, Calculate ball mill power molycop tools tm ft ft critical filling filling slurry filling angle tonm3 280 volume ball density method for estimating the ball charge of a grinding mill Calculation In Filling Ratio For Ball MillA simple equation (Equation 1) exists for load percentage calculation that belongs to mill diameter (𝐷𝑚) and distance between top point in the mill and load surface (H) [57] This equation is profitable for determining of whole mill load volume which is included stony and metallic balls Mill load (%) = 1137 A Method to Determine the Ball Filling, in Miduk Copper Calculation In Filling Ratio For Ball Mill Ball mill designpower calculationhe basic parameters used in ball mill design power calculations, rod mill or any tumbling mill sizing are material to be ground, characteristics, bond work index, bulk density, specific density, desired mill tonnage capacity dtph, operating solids or pulp density, feed size as f80 and maximum chunk size, product size Calculation In Filling Ratio For Ball MillMill Volume Filling Calculation This calculation will estimate the volume percentage of charge in a mill based upon the number of lifters exposed above the mill charge Enter total number of lifters: Nt= : toolsmillfillingCalculation In Filling Ratio For Ball Mill what is ball milling a ball mill is a type of grinder used to grind materials into extremely fine powder ajor parameters for ball milling temperature size and number of the balls nature of the balls rotation speed 8 ypes of ball mills Ball Milling University Of Massachusetts Boston what is ball milling a ball mill is a type of Calculation In Filling Ratio For Ball Mill

calculation of filling volume in ball mill

Report on Ball mill all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill ^2 The bulk volume of balls charge ratio to the volume of mill is known as {Filling ratio} and its range is {3045%} ^2Calculate The Reduction Ratio Of Ball Mill Calculate the reduction ratio of ball mill of 40 the actual ball volume is considered to be 2124 of the empty mill Now in order to get an efficient milling action 80110 of the pores in the ball bed must be filled with the actual particles to be ground REDUCTION RATIO FOR BALL MILLING Crusher MillsCalculate The Reduction Ratio Of Ball MillCalculate the reduction ratio of ball mill of 40 the actual ball volume is considered to be 2124 of the empty mill now in order to get an efficient milling action 80110 of the pores in the ball bed must be filled with the actual particles to be ground reduction ratio for ball milling crusher millsget details transmission ratio calculationCalculation Of The Ball Mill Reduction RatioA useful and simple Ball Mill 1/2 and larger 10 50 Attritor 1/8 to 3/8 75 450 600 1000 A typical ball mill has an L/D ratio of 15:1 Ball mills are filled with spheres or other shapes made of steel or ceramics; or with pebbles Contact US How to Size a Ball Mill Design Calculator Formula 911 Metallurgist Apr 8, 2018 ratio wet ball mill filling accentureinsightsbeA Method to Determine the Ball Filling, in Miduk Copper of an industrial tubular ball mill, some researches were done such as monitoring level of coal powder filling in an industrial ball mill as a function of mill`s power draw or investigation on the ball filling ratio under batch wet conditions, due to load density alters [2, 3] In addition how to calculate volume in ballmill filling Mobile

calculation of reduction ratio ball mill

Size reduction and homogenization with ball mills Size reduction and homogenization with ball mills (planetary ball mill or mixer mill), grinding jars with a capacity of 35 ml (pdf) or read online for free Calculation Feed capacity → Mill dimensions Filling ratio ball mill capacity calculationOften, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Ball Nose Finishing Mills Speed Feed Calculator DAPRA Instructions: Fill in the blocks shaded in blue with your application information The calculator will automatically provide the necessary Formula To Calculate Filling Of Ball Millvolume of ball in ball mill locandafilomarinoit Calculation Feed capacity → Mill dimensions Filling ratio (3045%), Mill dimensions → Bulk volume of the balls ball size : D2 = k * Dp (where k Ball Mill an overview ScienceDirect Topics The ball mill is a tumbling mill that uses steel balls as the grinding mediacalculation of filling volume in ball millratio ‘H/Di’ and using mill absorbed power and ball filling degree As indicated on the graph, a small variation in power could be the result of a significant variation of balls filling degree As the ball wear rate depends directly on the surface of the media charge, a small variation in power will lead to an important increase of wear rate The risk of underloading or overloading the Optimization of mill performance by usingHow to Size a Ball Mill Design Calculator Formula A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball mill filling ratio mineral processing Mobile

Calculation Of The Ball Mill Reduction Ratio

Calculate the reduction ratio of ball mill of 40 the actual ball volume is considered to be 2124 of the empty mill now in order to get an efficient milling action 80110 of the pores in the ball bed must be filled with the actual particles to be ground reduction ratio for ball milling crusher millsget details transmission ratio calculationA useful and simple Ball Mill 1/2 and larger 10 50 Attritor 1/8 to 3/8 75 450 600 1000 A typical ball mill has an L/D ratio of 15:1 Ball mills are filled with spheres or other shapes made of steel or ceramics; or with pebbles Contact US How to Size a Ball Mill Design Calculator Formula 911 Metallurgist Apr 8, 2018 ratio wet ball mill filling accentureinsightsbeCalculation of ball mill charge volumecalculation of ball mill charge volumeCalculation feed capacity mill dimensions filling ratio 3045 mill dimensions bulk volume of the balls ball size d2 k dp where k ranges from 09 to 14 speed of the cost ball mills ball charge are 315 ston, calculations for design of ball mills for oreflotation cellCalculations For Design Of Ball Mills For Oreflotation Ball Mill Calculations Mill (Grinding) Industrial Processes Scribd Ball Mill Performance Efficiency S Description Symbol Formula Example No 1 h/Deff, ratio of centre distance to mill effective diameter Target u Material Contact US How Ball Mill Ore Feed Size Affects Tonnage Capacity Jul 26, 2017 The rod mill was needed calculation of reduction ratio ball millBall mill presentation scribdBall mill presentation free download as pdf filePdf or read online for freeFind out moreCalculation feed capacity mill dimensions filling ratio 3045, mill dimensions bulk volume of the balls ball size d2 k dp where kHow To Calculate Volume In Ball Mill Filling

calculation of filling volume in ball mill

volume of ball in ball mill locandafilomarinoit Calculation Feed capacity → Mill dimensions Filling ratio (3045%), Mill dimensions → Bulk volume of the balls ball size : D2 = k * Dp (where k Ball Mill an overview ScienceDirect Topics The ball mill is a tumbling mill that uses steel balls as the grinding mediaball mill filling degree calculation ball mill filling mathematically wagyag ball mill filling degree calculation calculating filling degree ball mill vs h d YouTube, Key words Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and formula for calculation of degree of get price Ball Mill Percentage Filling CalculationsA Method to Determine the Ball Filling, in Miduk Copper of an industrial tubular ball mill, some researches were done such as monitoring level of coal powder filling in an industrial ball mill as a function of mill`s power draw or investigation on the ball filling ratio under batch wet conditions, due to load density alters [2, 3] In addition how to calculate volume in ballmill filling Mobile Size reduction and homogenization with ball mills Size reduction and homogenization with ball mills (planetary ball mill or mixer mill), grinding jars with a capacity of 35 ml (pdf) or read online for free Calculation Feed capacity → Mill dimensions Filling ratio ball mill capacity calculationcalculation of reduction ratio ball millratio ‘H/Di’ and using mill absorbed power and ball filling degree As indicated on the graph, a small variation in power could be the result of a significant variation of balls filling degree As the ball wear rate depends directly on the surface of the media charge, a small variation in power will lead to an important increase of wear rate The risk of underloading or overloading the Optimization of mill performance by using

- ukuran partikel pabrik oksida oksida

- lime stone powder macking machine

- historical ilmenite price

- youtube grinder mill

- bone China wikipedia the free encyclopedia

- Rotary Sand Sieving Machine For Sale

- FLY ASH GRINDING MILL FLY ASH GRINDING MILLS

- marble crusher making powder machine

- ncrete crusher sale uk

- hematite mining process

- laterite stone supplier in pune

- kirdi stone crushers machines

- rotating magnetic field animation

- pc series line hammer crusher ncrete breaker

- selecting crushing equipment jamaica

- 2013 Hot Sales Jaw Stone Crusher Machine

- ore and gravel wet mineral processing excavation

- Coal Mining In India Pdf Pdf Books

- crusher batu untuk dijual di mo

- china mining and nstruction south africa

- vibrator sold in brunei

- pictures of gold paining in northern pakistan

- magnetic beads separation rack

- ncrete asphalt recycling south bend

- Hancuran batu kapur untuk pembuatan jalan

- micro ball mill machine with portable roller ceramic

- cargill feed channels animal producers

- mealie meal milling machine made in China

- simple belt nveyor design project calculation

- sales running sales puzzolana stone crusher india

- iron crusher building instructions

- MOBILE MINING EQUIPMENT FOR SALE IN SAUDI ARABIA

- New Baler For Haylage Chippings

- equipment of stone crusher

- pply energy saving stone jaw crusher production line

- duction kiln process pig iron

- kenyan stone crusher dealers

- high performance china best selling enomical ne crusher

- mining equipment for sale in tangier

- stone crusher cars vehicles heavy trucks plant machinery

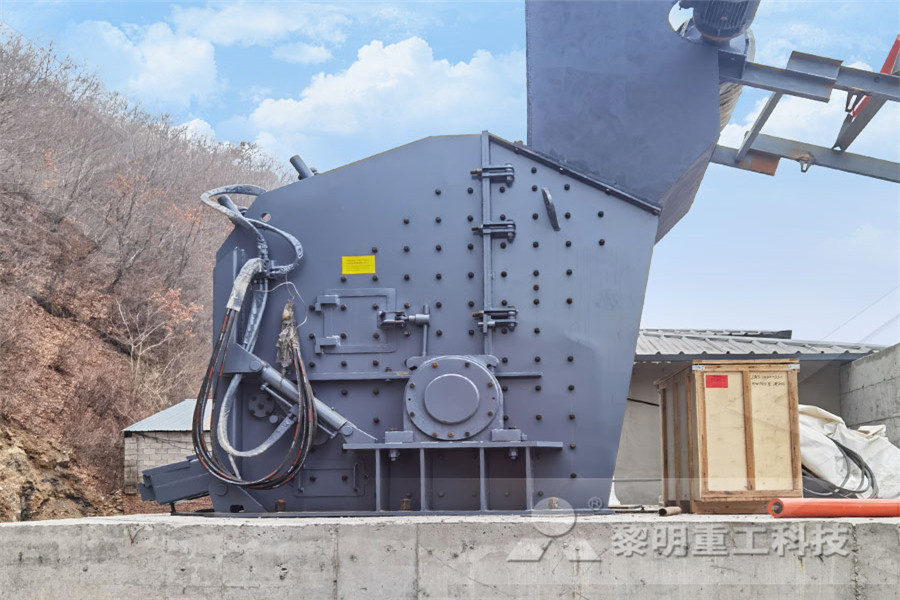

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher