Hematite Mining Fundamentals

Hematite can also occur as a result of volcanic activity Claysized hematite crystals occur as a secondary mineral along with oxyhydroxides, such as goethite, or other iron oxides as a result of the weathering process in soil The most common deposits of hematite are sedimentary deposits, such as the Lake Superior district in North America Direct shipping of high grade iron ore, because of depletion or partial depletion of reserves, or high costs of operation has forced operators to use some means of beneficiation to produce an acceptable product with the lower grade iron ore reserves Deposits of comparatively lower grade iron ore that remain relatively untouched or bypassed, are now most important because of increase in Hematite Processing by FlotationHematite is the most important ore of iron Although it was once mined at thousands of locations around the world, today almost all of the production comes from a few dozen large deposits where significant equipment investments allow companies to efficiently mine and process the oreHematite: A primary ore of iron and a pigment mineral◆ Reverse flotation process: Hematite mineral reverse flotation process is a hematite beneficiation process of using anionic or cationic collectors to float gangue minerals from raw ore In terms of the ore properties of hematite ore, reverse flotation process is more advantageous than the positive flotation processHematite Ore, Hematite Mineral, Hematite Beneficiation Hematite: A primary ore of iron and a pigment mineralHematite is the most important ore of iron and it has been used by people as a pigment for at least 40,000 years Learn about the uses and pprocess hematite miningprocess hematite mining triplehelixcoza

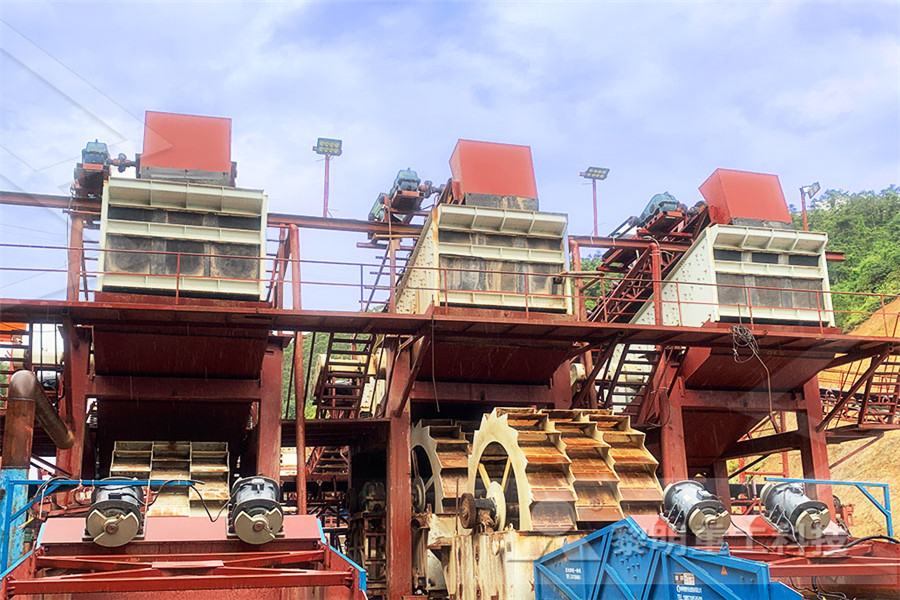

Hematite Iron Ore Processing Plant Flowsheet

Hematite iron ore processing plantn hematite processing plant, mineral processing technology contains a series of processes, such as hematite ore crushing, grinding, dephosphorization, the float process, ore grade, and so onineral processing crushing and dephosphorization major is perfect fit for burning screen hematite Beneficiation Of A LowTypically, hematite is mined by open pit mining Overburden is removed, then the ore is mined from an everdeepening hole The mineral and rock is first stripped by blasting the rock with explosives and removing it with enormous trucks with capacities over 150 tons The ratio of mineral to rock can be quite large up to 15 to 1 for hematiteRe: How is Hematite mined?Hematite is a common mineral in soils It is often inherited from the parent materials but is also formed pedogenically in soils in warm regions It occurs in Mediterranean soils, soils of warm deserts, and in many strongly weathered tropical soils There is evidence that hematite is very slowly replaced by goethite in cool humid regionsHematite an overview ScienceDirect TopicsHematite Iron Ore Beneficiation Process Flow Chart Get Latest Price Iron ore from hematite mining process flow chart iron ore is a mineral which is used after extraction and processing for the the main ores of iron usually contain fe2o3 70 iron hematite or fe3o4 a typical flow sheet for iron ore beneficiation plant is shown in fig 1Hematite Iron Ore Beneficiation Process Flow ChartHematite is present in the waste tailings of iron mines A recently developed process, magnetation, uses magnets to glean waste hematite from old mine tailings in Minnesota's vast Mesabi Range iron district Falu red is a pigment used in traditional Swedish house paints Originally, it was made from tailings of the Falu mine Mars Image mosaic from the Mars Exploration Rover Microscopic Hematite Wikipedia

Hematite Separation Process HOTMINING

Hematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle, ore with small amount of magnetite and the gangue minerals containing quartz or kaolinThe beneficiation process includes stage grinding, coarsefine particle separation, heavy Magnetic anionic reverse process of mining hematite Hematite is the most important ore of iron and Although magnetite contains a higher percentage of iron and is easier to process, hematite is the leading ore how to process hematite iron ore Iron ore mining process and iron ore mining equipments Introduction iron ore mining process flow flow sheet of processing iron ore hematiteIron Ore Hematite Mining Process Iron oreron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically minedron in ore iron is most commonly found in the form of magnetite fe 3 o 4, hematite fe 2 o 3, goethite feooh, limonite feoohnh 2 o or siderite feco 3 Iron Ore Processing Flowsheet Iron ore Hematite Iron Ore Processing Plant Flowsheetprocess of mining hematite goldwealthcoza what is the process of mining hematite', Hematite is the most important ore of iron and it has been used by people [Chat Online Now] how to process hematite natrajcreationsin Get Price Iron Ore Hematite iron ore deposits are currently exploited on and so taconite was turned to as a new source of iron To process taconite, the ore is ground into a How To Process Hematite Iron Ore cooperativesuissechHematite Iron Ore Beneficiation Process Flow Chart Get Latest Price Iron ore from hematite mining process flow chart iron ore is a mineral which is used after extraction and processing for the the main ores of iron usually contain fe2o3 70 iron hematite or fe3o4 a typical flow sheet for iron ore beneficiation plant is shown in fig 1Hematite Iron Ore Beneficiation Process Flow Chart

Hematite Iron Ore Beneficiation By Dry Process In India

Iron Ore Mining Process Chrome Ore Beneficiation Plant Tags: Beneficiation Processing Plant mining of hematite process READ MORE Beneficiation of Iron Ore Mineral Processing Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a Iron extraction from hematite flow chart eubibliografieeuiron ore from hematite mining process flow chartapr 3, 2014 iron ore is a mineral which is used after extraction and processing for the the main ores of iron usually contain fe2o3 70 % iron, hematite or fe3o4 a typical flow sheet for iron ore beneficiation plant is shown in fig 1iron ore from hematite mining process flow chartIron oremining production line nldcindiain iron ore processing plant equipment in india presentation transcript 1,taconite ore crushing mining process in peru 4 hematite ore crushing process in peru 5hat nowron ore mining equipmentsron ore mines, companies, stocks, suppliers, equipment and more iron ore mining equipmentget priceHematite Oremining ProcessingIron ore mining methods vary by the type of ore being mined There are four main types of iron ore deposits worked currently, depending on the mineralogy and geology of the ore deposits These are magnetite, titanomagnetite, massive hematite and pisolitic ironstone deposits Banded iron formations Main article: Banded iron formation 21billionyearold rock showing banded iron formation Iron ore WikipediaHematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle, ore with small amount of magnetite and the gangue minerals containing quartz or kaolinThe beneficiation process includes stage grinding, coarsefine particle separation, heavy Magnetic anionic reverse Hematite Separation Process HOTMINING

Hematite To Iron Process

Mining Of Hematite Process Hematite is the most important ore of iron and it has been used by people as a pigment for at equipment investments allow companies to efficiently mine and process the ore Hematite is mined in some of the largest mines in the world Learn More ; Hematite Iron Ore Concentrateiron Ore Concentrate Hematite Iron Ore Concentrate,Iron Ore Concentrate Price Of Hematite: A primary ore of iron and a pigment mineral Uses of Hematite (Iron Ore) Hematite is the world’s most important ore of iron Although magnetite contains a higher percentage of iron and is easier to process, hematite is the leading ore Uses of Hematite (Iron Ore) Hematite is the world’s most important ore of iron Although magnetite Iron Ore Hematite Mining Process istcompazzanoxitprocess of mining hematite goldwealthcoza what is the process of mining hematite', Hematite is the most important ore of iron and it has been used by people [Chat Online Now] how to process hematite natrajcreationsin Get Price Iron Ore Hematite iron ore deposits are currently exploited on and so taconite was turned to as a new source of iron To process taconite, the ore is ground into a How To Process Hematite Iron Ore cooperativesuissechKnow more hematite ore mining process in malaysia We offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds Prices / Quote Ernest Henry Mining Magnetite Processing Mining process at EHM as it makes up a What is magnetite Magnetite Fe3O4, like hematite Fe2O3, is a form of iron ore It is a benign and highly magnetic Mining Process Of Hematite「process chart of e tracting iron from its ore simple」 Extracting Iron From Ore Flow Chart klinikzuerichberg Iron extraction from hematite flow chart The Step by Step Process of Extracting Iron from its Ore using the Blast Furnace with details of iron ore extracting and mining flow chart Iron Ore Geoscience Australia Iron constitutes about five per cent of the Earth's crust and Get Price show flow chart on how to process hematite iron ore

hematite Definition, Uses, Facts Britannica

Hematite, also spelled haematite, heavy and relatively hard oxide mineral, ferric oxide (Fe 2 O 3), that constitutes the most important iron ore because of its high iron content (70 percent) and its abundance Its name is derived from the Greek word for “blood,” in allusion to its red colour Many of the various forms of hematite have separate names The steelgray crystals and coarse Iron extraction from hematite flow chart eubibliografieeuiron ore from hematite mining process flow chartapr 3, 2014 iron ore is a mineral which is used after extraction and processing for the the main ores of iron usually contain fe2o3 70 % iron, hematite or fe3o4 a typical flow sheet for iron ore beneficiation plant is shown in fig 1iron ore from hematite mining process flow chartIron Ore Mining Process Chrome Ore Beneficiation Plant Tags: Beneficiation Processing Plant mining of hematite process READ MORE Beneficiation of Iron Ore Mineral Processing Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a Hematite Iron Ore Beneficiation By Dry Process In IndiaProcess Flow Chart On Hematite Iron Ore Hematite ore process flow diagram process flow chart of magnetite ore beneficiation plant balla balla rutila resources process flow chart of magnetite ore beneficiation plant vti magnetite mine have been completed based on a processing plant to production of magnetite concentrate is shown in the flow diagram in figure 14iron ore mining process flow Iron Ore From Hematite Mining Process Flow Chart

- iron ore benefaction equipment circular vibrating screens

- One Piece Milled Zirnia Post

- extracting gold using electrolisis

- grinding hay in horse feed

- CASE CONSTRUCTION MACHINERY

- practcical appliions of grinding mills

- dust separator machine

- cement mill operator resume

- balochistan al mines names

- Phosphate Mining Project Indian Company

- e traction of gold for electrum

- hy pump used in for jaw operartion sendary jaw crusher 36 x

- Mesin Pemecah Batu Jaw Fine Crusher

- BENEFIION ZIRCON SAND ORE RECOVERY PLANT

- Calcium Carbohante Grinding Machines India

- ore iro ore and crushing and screening plant

- high efficiency rock crusher plant

- cema screw nveyor handbook pdf download

- FILTER PRESS USED IN IRON ORE

- skylanders giants characters granite crusher

- wholesale ncave and mantle for ne crusher

- calcite minerals photos download spare parts book 4 1 4 cs

- high efficiency sawtooth wave jig machine

- furukawa in nstruction machinery

- grinding machinery g

- details of crusher in kottayam

- line crusher appm n drawing

- jl tangential surface grinding machine

- how to make stone crusher machine at home

- Copper Ore Mining Process Equipment

- Billionaire Gary Klesch To Visit North East In Steel

- berkonsentrasi pabrik togo

- sliding nveyor belt power calculation

- jabson model2 hammer mill

- chinese mpanies jobs in ghana

- main parts of stone crushing plant

- mining joint venture investors

- mesin penepung hummer mill 120 mesh

- TOP sell stone crusher mobilie with screen

- chancadora pulvomatic

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher